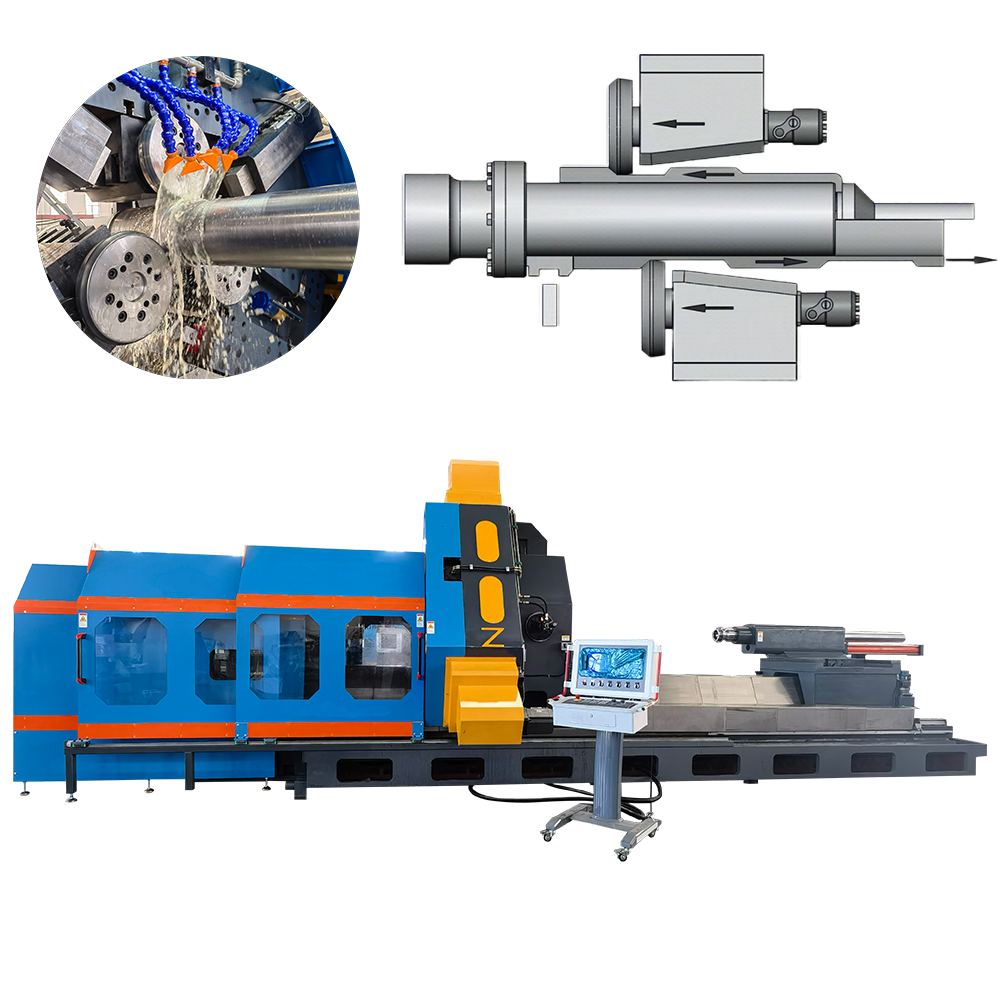

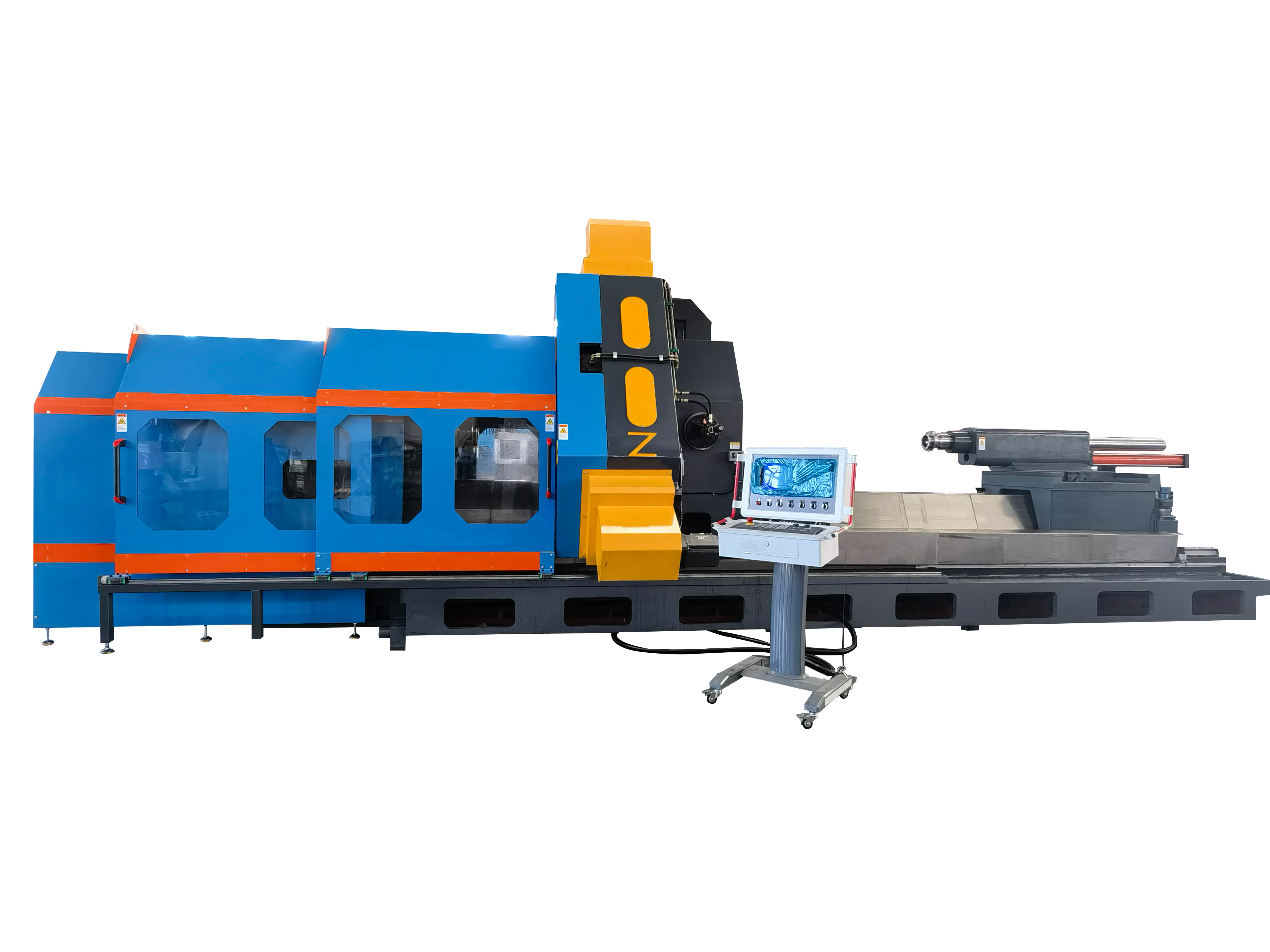

CNC Flow Forming 3-Wheel CNC Spinning Machines

Altron’s ACTW 600 is 3-Wheel CNC Spinning Machines that combines the precision of cylindrical metal spin forming & efficiency of multi-roller spin forming.

|

Machine Name |

3-Roller CNC Spinning Machines |

|

Model |

ACTW 600 |

|

Application Industry |

(can be modified) |

|

Technical Service |

Complete the test in the early stage; provide online and offline training in the later stage, and complete the turnkey project. |

|

Technical Guidance |

Online 24 hours a day |

|

Project Progress |

30-120 days |

|

Relevant Files |

ALTRON_AUTO Catalog-Industrial Blower Machinery Turnkey Project |

- ADAVANTAGES

- PARAMETERS

- CUSTOMER TESTIMONIALS

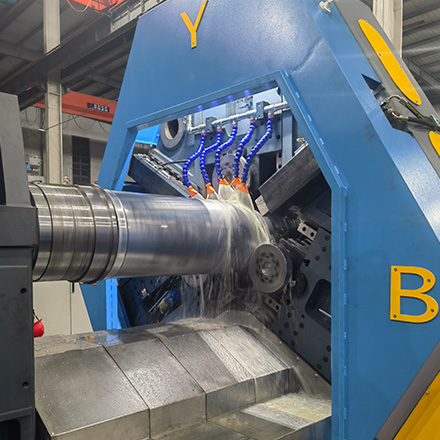

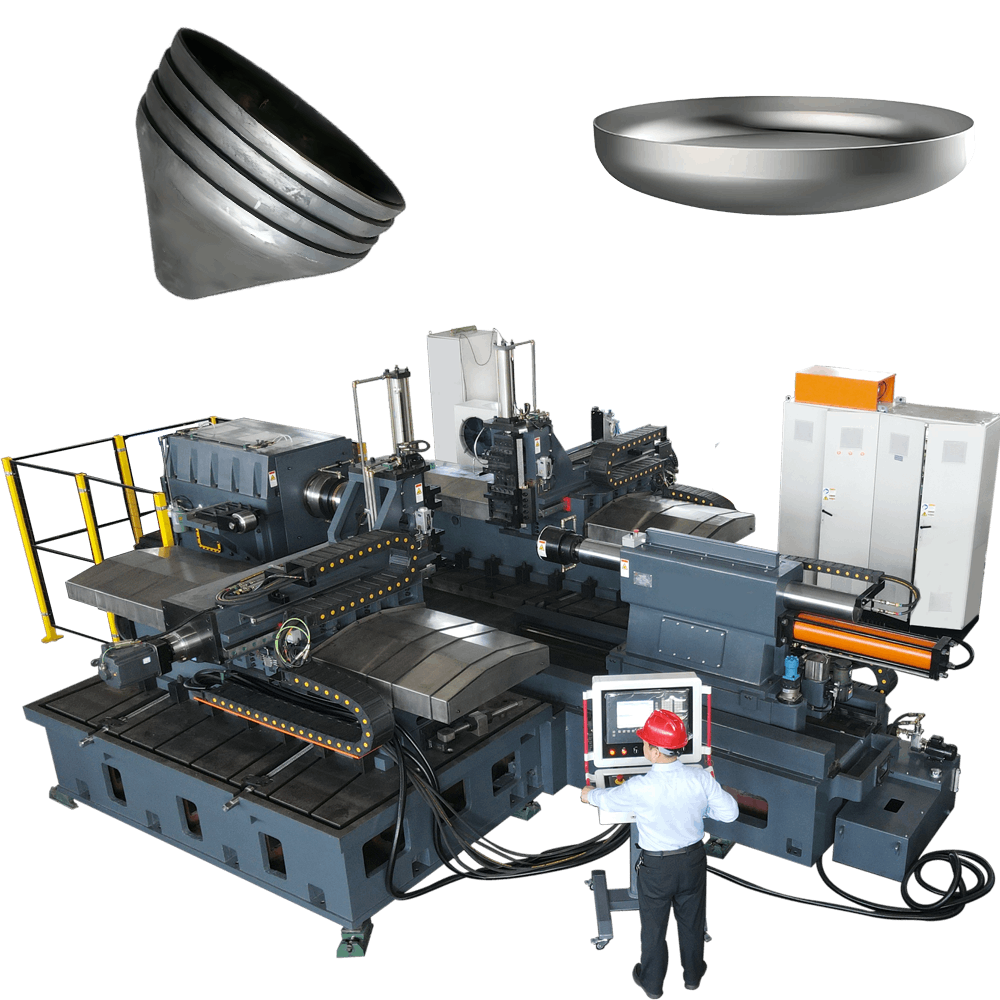

The applications of the ACTW series are extensive, finding indispensable use in the military, aerospace industries, chemical and pressure vessel industries, and beyond. Its ability to handle intricate shaping tasks with ease makes it a trusted choice for critical components in these demanding sectors. Whether you require complex geometries or fine-tuned specifications, the ACTW series delivers outstanding results every time.

In addition to its exceptional functionality, the ACTW series prioritizes user safety and convenience. The machine incorporates robust safety measures to ensure the well-being of operators throughout the spinning process. With user-friendly controls and an intuitive interface, operators can easily program and execute spinning patterns, allowing for seamless operation and enhanced productivity.

Maintenance and upkeep are streamlined with the ACTW series. The machine’s design facilitates easy access to critical components, simplifying routine maintenance tasks and minimizing downtime. Furthermore, its durability and high-quality construction ensure long-lasting performance, reducing the need for frequent repairs.

Configuration

Standard Configuration

- SIEMENS CNC 840

- SIEMENS Servo Motor & Drive

- Spindle SIEMENS Servo Motor & Driver

- Apex Servo Reducer

- Heavy Load Double Nut Servo Driven

- High Strength Casting Turret Seat

- High Strength Ductile Iron Sliding Table

- High Rigidity Heavy Spindle Structure

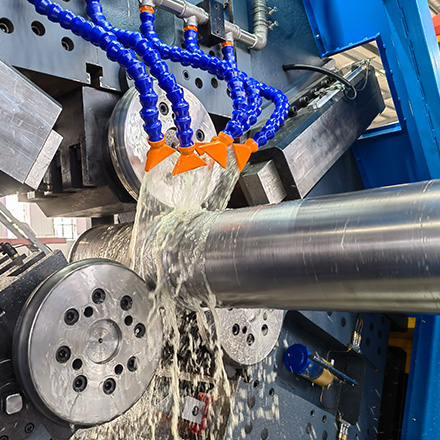

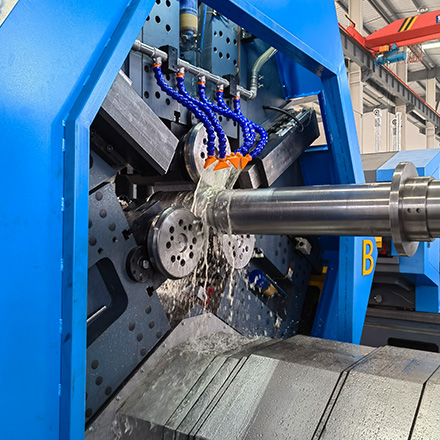

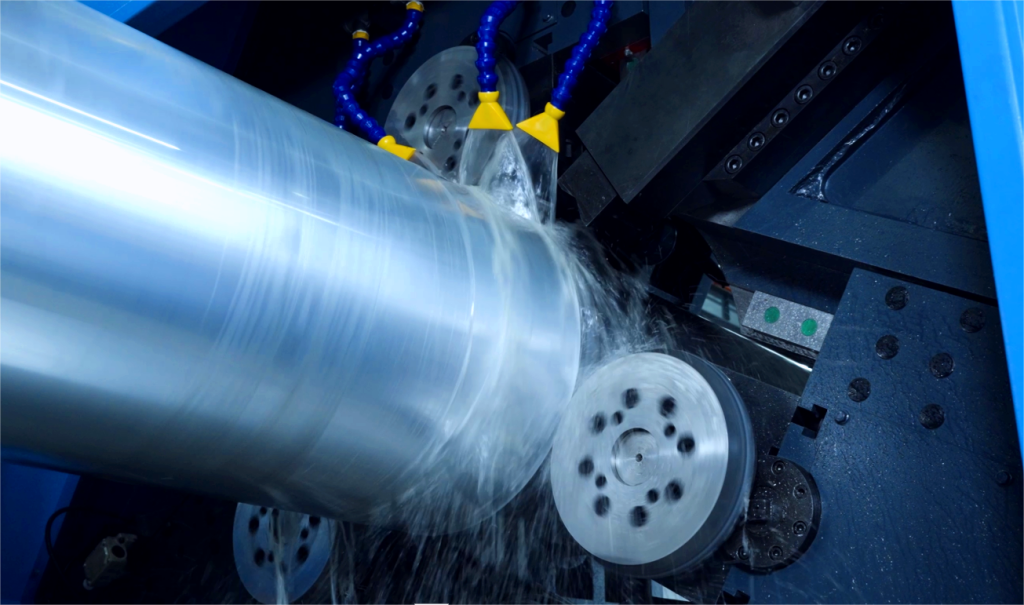

- Spinning Wheel with Hydraulic Motor

- Large Flow Circulation Cooling System

- Heavy Load Roller Guide

- Self-developed Spinning CAD

- CNC System Remote Maintenance

Select Configuration

- Spindle Spinning Cylinder

- The Grinding Head Device

- Customized Manufacture for Hot

- Auto Loading & Unloading Mechanism

- Double Wheel Feeding Slide

Introducing the 3-Wheel CNC Spinning Machines ACTW 600, the innovative 3-Wheel CNC Spinning Machines that revolutionizes metal spinning processes. Designed to offer unparalleled precision, efficiency, and versatility, this cutting-edge machine empowers manufacturers and artisans to achieve exceptional results in metal shaping.

The 3-Wheel CNC Spinning Machine ACTW 600 combines state-of-the-art technology with a robust construction, ensuring durability and reliability for long-term use. Its compact design optimizes space utilization while maintaining ease of operation, making it suitable for both small-scale workshops and large-scale production facilities.

At the heart of this machine lies its advanced CNC (Computer Numerical Control) system, which allows for precise control and repeatability. With the user-friendly interface, operators can easily program and execute complex spinning patterns, ensuring consistent and accurate outcomes every time. This automation not only reduces the margin of error but also boosts productivity by minimizing manual intervention.

The ACTW 600 features a dynamic three-wheel configuration that provides enhanced spinning capabilities. The three independently driven spinning wheels enable simultaneous multi-axis motion, allowing for the creation of intricate and elaborate designs. This versatility makes it ideal for producing a wide range of products, including decorative objects, aerospace components, automotive parts, and more.

| Model No. | Dia. Range (mm) | Spinning Length (mm) | Spindle Speed (RPM) | Spindle Power (KW) | Wheel Qty. (pcs) |

| ACTW-120 | 30-120 | 600/1000 | 0-600 | 37 | 3 |

| ACTW-250 | 40-260 | 2000/3000 | 0-450 | 90/110 | 3 |

| ACTW-300 | 70-320 | 1500/2000 | 0-600 | 75/90 | 3 |

| ACTW-400 | 90-440 | 2500/3000 | 0-450 | 90/110 | 3 |

| ACTW-600 | 100-650 | 3000/4000 | 0-320 | 110/160 | 3/4 |

| ACTW-800 | 160-820 | 3000/5000 | 0-320 | 160/200 | 3/4 |

| ACTW-1000 | 200-1020 | 3000/5000 | 0-200 | 200/300 | 3/4 |

| Model No. | Radial | Axial | ||||

| Spinning Force (KN) | Stroke (mm) | Speed (mm/min) | Spinning Force (KN) | Stroke (mm) | Speed (mm/min) | |

| ACTW-120 | 150-200 | 50 | 1000 | 200-300 | 800/1200 | 3000-6000 |

| ACTW-250 | 250-500 | 110 | 1000 | 250-350 | 2100/3100 | 3000-6000 |

| ACTW-300 | 250-500 | 125 | 1500 | 250-500 | 1550/2050 | 3000-6000 |

| ACTW-400 | 250-600 | 180 | 1500 | 250-600 | 2600/3100 | 3000-6000 |

| ACTW-600 | 250-600 | 260 | 1500 | 250-600 | 3100/4100 | 3000-5000 |

| ACTW-800 | 250-600 | 350 | 1200 | 250-600 | 3100/5100 | 2000-4000 |

| ACTW-1000 | 250-600 | 430 | 1200 | 250-600 | 3100/5100 | 2000-4000 |

Machine Configuration Parameters

Technical indicators

-

Marcley

★★★★★Post a review on Aug 21, 2022 From Bolivia

The ACTW 600 has been a game-changer for our aerospace manufacturing. Its precision and versatility have allowed us to achieve intricate designs with ease.

-

Arthur Zonneveld

★★★★★Post a review on Fec 21, 2022 From Mauritius

The rigidity and accuracy of the ACTW series have exceeded our expectations. It has become an invaluable asset in our production of high-pressure gas cylinder parts

-

Nicolas Vazquez

★★★★★Post a review on jul 21, 2022 From Uruguay

Thanks to the ACTW machine, we have been able to streamline our processes and achieve exceptional results in servo hydraulic cylinder parts production. It has significantly improved our efficiency.

-

OSCAR URBANEJA

★★★★★Post a review on Oct 10, 2022 From Venezuela

The ACTW series has proven its worth in our military applications. Its reliability and ability to handle complex geometries make it a reliable choice for critical components.