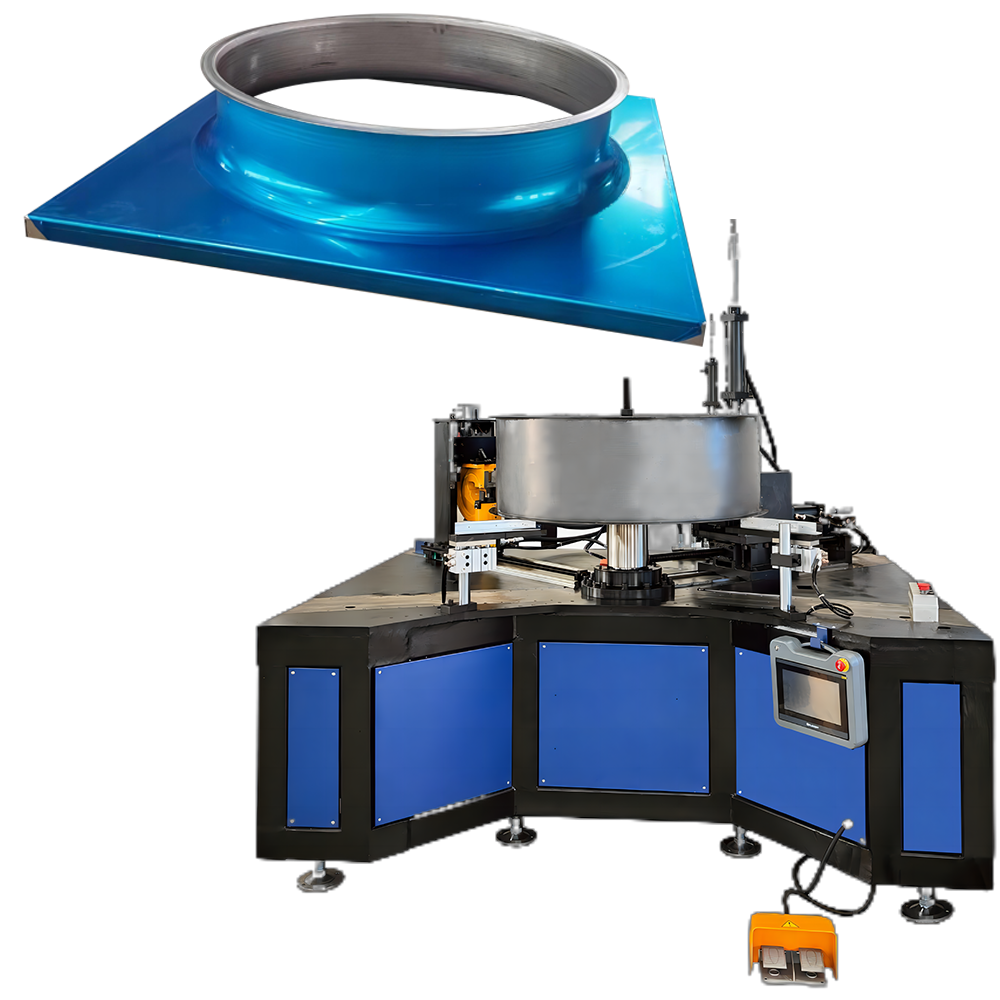

Square Plate Internal Spinning and Flanging Machines

Application of square plate internal spinning machine

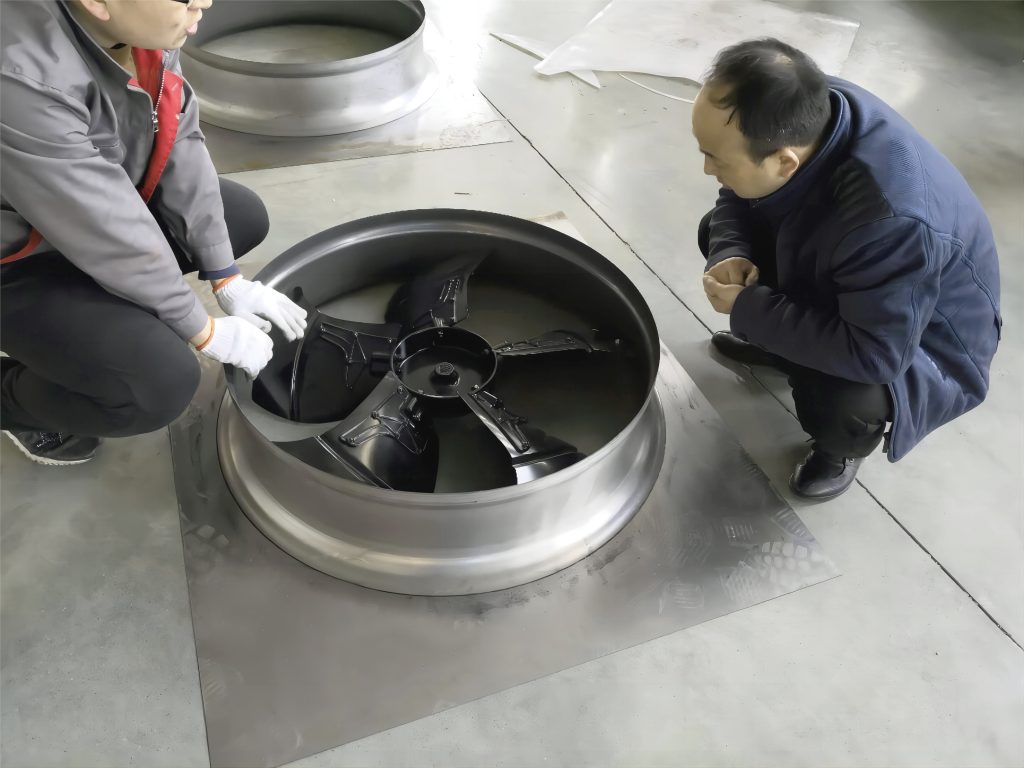

Square plate internal spinning machines and square plate flanging machines are used in square plate accessories such as the air outlet of the outdoor unit of refrigeration equipment and the protective cover of air conditioning fans.

internal spinning machines:

The square plate internal spinning machine is mainly used to fix the square plate. The hydraulic platform fixes the square plate on the internal spinning machine. The CNC program controls the spinning trajectory of the internal spinning mechanism. The high-speed spinning and x-axis of the internal spinning wheel Axis, Z-axis movement, spinning it into a specific shape;

This process replaces the large-size hydraulic drawing mold and the complex multi-process stamping process, and the cycle and R&D funds are greatly reduced, which is about 15% of the development cost of hydraulic drawing.

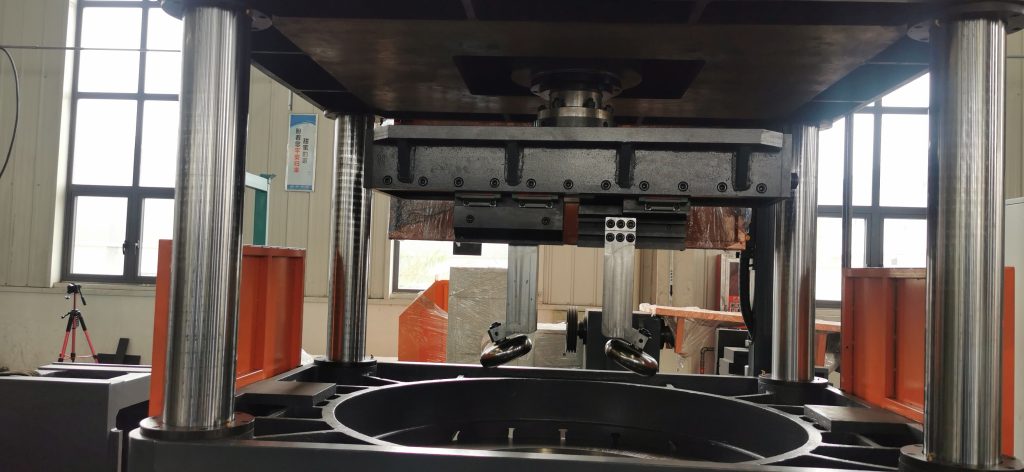

Square plate flanging machines:

The square plate machine mainly uses a square plate internal spinning machine to complete single-hole spinning. The air outlet needs to be fixed with a protective net or connected to other air duct parts, so a flange edge and installation holes are needed.

We have specially developed two machines for flanging this type of product.

Practical application equipment and scenarios of square plate air outlets

Air conditioning fan outlet, refrigeration equipment outdoor unit air outlet, airport outdoor refrigeration equipment, large industrial air conditioning equipment host, etc.

Introduction to the cooperative processing of square plate internal spinning and flanging machines:

In the realm of metalworking, precision and efficiency reign supreme, and the application of cutting-edge technology is pivotal in achieving these goals. Two crucial machines that have significantly impacted the manufacturing landscape are the Square Plate Internal Spinning Machine and the Square Plate Flanging Machine.

These specialized tools have revolutionized metal shaping processes, offering unmatched precision and versatility in producing a wide array of components.

The Square Plate Internal Spinning Machine is a marvel of engineering that has found its niche in shaping and forming various metal components with unparalleled accuracy. It operates on the principle of rotational force applied to a square plate, enabling the transformation of flat metal sheets into intricate, three-dimensional shapes.

This process involves the controlled movement of the plate, which, when combined with specialized tooling, crafts the metal into precise and complex geometries. This technology finds extensive use in manufacturing industries that require intricate and customized metal components, such as aerospace, automotive, and even architectural sectors.

The Square Plate Internal Spinning Machine offers unparalleled flexibility in shaping materials like aluminum, steel, and alloys, catering to diverse industry needs. One of the key advantages of this machine lies in its ability to produce components with minimal material waste. The precise manipulation of the metal sheet ensures that the final product retains its structural integrity while minimizing excess material, thereby reducing production costs and material usage—an environmentally conscious approach embraced by modern manufacturing.

Complementing the Internal Spinning Machine is its counterpart, the Square Plate Flanging Machine. While the spinning machine focuses on shaping, the flanging machine specializes in creating precise flanges on metal components.

Flanges, integral in joining and connecting different parts, demand accuracy and consistency, which the Square Plate Flanging Machine delivers effortlessly. This machine operates by using specialized dies and tools to shape the edges of metal plates, forming flanges of varying sizes and specifications. Its versatility allows for the creation of flanges with different angles, ensuring compatibility with diverse assembly requirements across industries.

The Square Plate Flanging Machine finds its application in a myriad of industries, from manufacturing heavy machinery to fabricating components for pipelines and even in shipbuilding. Its ability to produce uniform and robust flanges enhances the structural integrity of various assemblies, ensuring reliability and safety in critical applications. When these two machines collaborate in a manufacturing setting, their synergy unlocks a realm of possibilities.

Integrated workflows leveraging both the Internal Spinning and Flanging Machines enable the production of highly complex components with impeccable precision. The combination allows for the creation of intricate shapes with perfectly flanged edges, meeting the exacting standards of modern engineering. The technological advancements incorporated into these machines contribute significantly to streamlining manufacturing processes. They reduce lead times, minimize manual intervention, and enhance the overall quality of the final product. The precision and repeatability achieved through these machines not only improve efficiency but also elevate the standard of manufactured components in various industries.

Moreover, the integration of automation features in these machines further amplifies their efficiency. Automated control systems ensure consistent operation, reducing human error and optimizing production throughput. This level of automation not only improves efficiency but also provides a safer working environment by minimizing human intervention in high-risk operations. In conclusion, the Square Plate Internal Spinning Machine and Square Plate Flanging Machine stand as epitomes of technological innovation in metalworking. Their precision, versatility, and efficiency have redefined the manufacturing landscape, enabling the production of intricate components with unmatched accuracy.

As industries continue to evolve, these machines remain integral in shaping the future of manufacturing, ushering in an era of unparalleled precision and efficiency in metal component production.