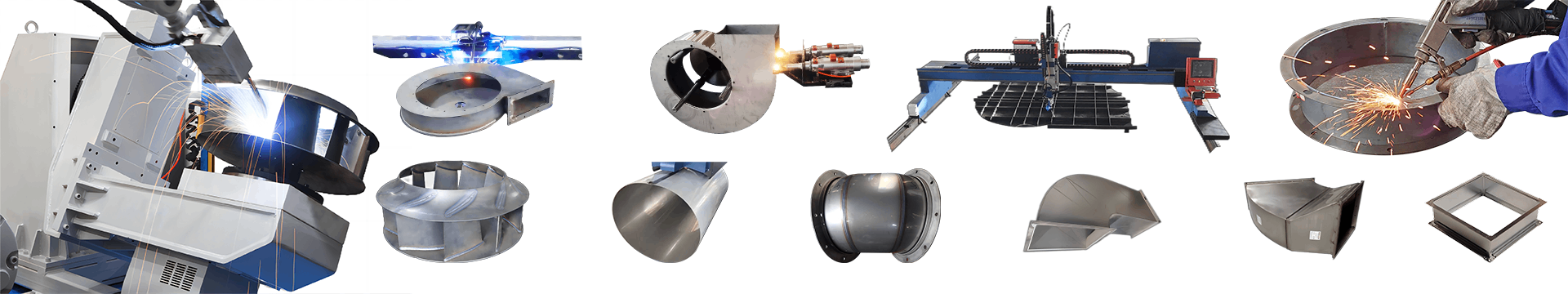

Advancing AI Robot Welding Solutions For Centrifugal Fans

AI robot welding solutions offered by suppliers like ALTRON are revolutionizing centrifugal fan manufacturing by enhancing quality control, ensuring safety compliance, and driving efficiency. As technology continues to evolve, the industry can expect further improvements in productivity, quality, and innovation, cementing AI robot welding as a cornerstone of modern manufacturing processes.

Introduction to Centrifugal Fans and Welding Challenges

1.1 Importance of Centrifugal Fans

Centrifugal fans play a crucial role in various industries, including HVAC, automotive, aerospace, and manufacturing. They are essential for applications such as ventilation, air conditioning, combustion, and material handling.

1.2 Welding Challenges

Manufacturing centrifugal fans involve intricate welding processes due to the complex shapes and materials involved. Common challenges include achieving consistent weld quality, minimizing defects, and maintaining productivity while ensuring structural integrity.

The Role of AI in Industrial Robotics

2.1 Introduction to AI

Artificial Intelligence (AI) involves the development of systems capable of performing tasks that typically require human intelligence. In industrial robotics, AI is utilized to enhance automation processes, improve decision-making, and optimize efficiency.

2.2 Applications in Industrial Robotics

AI-driven robotics revolutionize manufacturing by enabling predictive maintenance, adaptive control, and real-time monitoring. These advancements enhance precision, flexibility, and safety in various production processes.

Understanding Robot Welding in Centrifugal Fan Manufacturing

3.1 Significance of Robot Welding

Robot welding offers numerous advantages in centrifugal fan manufacturing, including increased productivity, consistency, and precision. Robots can perform complex welding tasks with higher efficiency and repeatability compared to manual labor.

3.2 Specific Welding Techniques

In the manufacturing of centrifugal fans, various welding techniques are employed, such as MIG (Metal Inert Gas) welding, TIG (Tungsten Inert Gas) welding, and laser welding. Each technique has its advantages depending on factors like material type, thickness, and desired weld quality.

3.3 ALTRON’s AI Robot Welding Solutions

ALTRON provides cutting-edge AI-driven robot welding solutions tailored for centrifugal fan manufacturing. Their systems utilize advanced algorithms to optimize welding parameters, adjust in real time to changing conditions, and ensure consistent weld quality.

Benefits of Implementing AI Robot Welding Solutions

4.1 Improved Productivity

By automating welding processes with AI-driven robots, manufacturers can significantly increase production output and reduce cycle times. AI algorithms optimize welding paths and parameters, minimizing idle time and maximizing efficiency.

4.2 Enhanced Consistency

AI-enabled robots ensure consistent weld quality across production batches, reducing variability and defects. By maintaining precise control over welding parameters, manufacturers can achieve uniformity in weld strength and appearance.

4.3 Cost-Effectiveness

While the initial investment in AI robot welding solutions may be substantial, the long-term cost savings are significant. Reduced scrap, rework, and labor costs, coupled with increased productivity, result in a substantial return on investment over time.

Enhancing Quality Control with AI in Welding

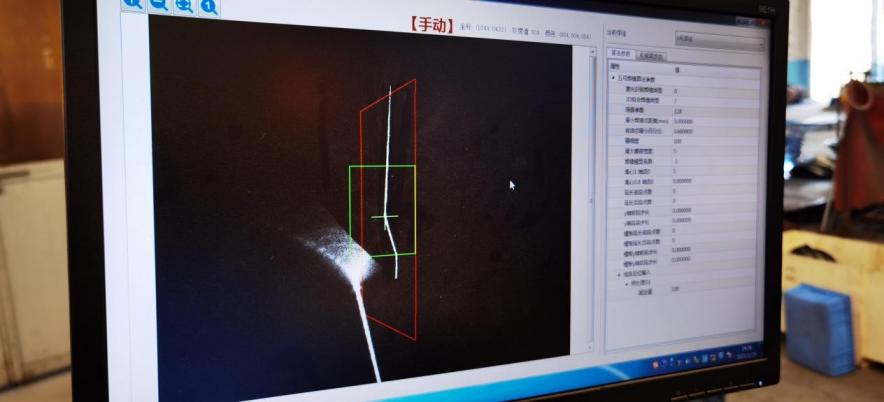

5.1 Real-time Monitoring

AI technology plays a crucial role in enabling real-time monitoring and quality control during welding processes. By utilizing sensors and sophisticated algorithms, AI systems continuously analyze parameters such as voltage, current, and travel speed, detecting anomalies and deviations from desired welding conditions.

5.2 Reduction of Defects

The implementation of AI robot welding solutions leads to a significant reduction in defects and enhances product quality. AI algorithms can identify potential issues early in the welding process, allowing for prompt adjustments to minimize defects such as porosity, undercutting, and lack of fusion. This proactive approach ensures that each weld meets the required standards and specifications.

Safety Measures and Regulations in AI Robot Welding

6.1 Importance of Adhering to Safety Regulations

Adhering to safety regulations and guidelines is paramount in implementing AI robot welding solutions. Safety protocols must be established to protect workers from hazards associated with robotic welding, including electrical shocks, arc flash, and fumes. Compliance with industry standards such as ISO 10218 and ANSI/RIA R15.06 ensures the safe operation of robotic welding systems.

6.2 Safety Protocols and Risk Mitigation Strategies

Robotic welding cells should be equipped with safety features such as fencing, interlocks, and light curtains to prevent unauthorized access and ensure operator safety. Additionally, risk assessments should be conducted to identify potential hazards and implement appropriate mitigation measures, such as emergency stop buttons and protective equipment.

Market Status

7.1 Growing Demand

The market for centrifugal fans is witnessing steady growth driven by increasing industrialization, infrastructure development, and HVAC system installations across various sectors. As demand for centrifugal fans rises, manufacturers face the challenge of meeting production targets while maintaining high standards of quality and efficiency.

7.2 Evolving Needs

Manufacturers of centrifugal fans are under pressure to deliver products that meet stringent performance requirements, regulatory standards, and customer expectations. There is a growing need for advanced welding solutions that can optimize production processes, reduce defects, and enhance product quality.

Challenges in Centrifugal Fan Manufacturing

8.1 Complex Welding Processes

Centrifugal fan manufacturing involves intricate welding processes due to the complex shapes, sizes, and materials of fan components. Achieving consistent weld quality across various materials such as steel, aluminum, and stainless steel presents a significant challenge for manufacturers.

8.2 Quality Control

Ensuring weld quality is critical in centrifugal fan manufacturing to prevent defects such as porosity, undercutting, and lack of fusion. Manual inspection methods are time-consuming and prone to human error, making it challenging to maintain consistent quality standards.

AI Robot Welding Solutions

9.1 ALTRON’s Innovative Approach

ALTRON offers cutting-edge AI robot welding solutions designed to address the unique challenges faced by manufacturers of centrifugal fans. Their advanced technology combines artificial intelligence, robotics, and real-time monitoring to optimize welding processes and enhance productivity.

9.2 Precision and Efficiency

AI-driven robotic welding systems from ALTRON offer unmatched precision and efficiency in welding centrifugal fan components. By utilizing AI algorithms to optimize welding parameters and paths, these solutions ensure consistent weld quality while minimizing cycle times and material waste.

9.3 Real-time Monitoring and Quality Control

ALTRON’s AI robot welding solutions feature real-time monitoring capabilities that enable continuous quality control throughout the welding process. Sensors and cameras detect deviations from desired welding conditions, allowing for prompt adjustments to minimize defects and ensure product integrity.

9.4 Customization and Flexibility

ALTRON understands that every manufacturing operation is unique, which is why they offer customizable AI robot welding solutions tailored to meet the specific needs of centrifugal fan manufacturers. Whether it’s welding different materials, accommodating varying production volumes, or addressing specific welding challenges, ALTRON can provide a solution that fits your requirements.

Future Trends and Outlook in AI Robot Welding for Centrifugal Fans

10.1 Predictions for the Future

The future of AI-driven robot welding technology in centrifugal fan manufacturing is promising, with continued advancements expected in areas such as machine learning, collaborative robotics, and digital twinning. These advancements will further enhance productivity, quality, and safety in welding processes, driving continued adoption across industries.

10.2 Emerging Trends and Research Areas

Emerging trends in AI robot welding for centrifugal fans include the integration of augmented reality (AR) for remote monitoring and troubleshooting, the development of predictive maintenance algorithms, and the use of additive manufacturing techniques for complex geometries. Additionally, research into human-robot collaboration and autonomous welding systems will shape the future landscape of welding automation.

Customizing Your AI Robot Welding Solutions for Centrifugal Fans

11.1 Understanding Your Needs: Initial Consultation

The first step in customizing AI robot welding solutions for centrifugal fans is to conduct an initial consultation with ALTRON. During this phase, their team of experts will work closely with you to understand your specific requirements, production goals, and challenges.

11.2 Assessment of Requirements

ALTRON will assess factors such as fan design, material specifications, production volume, and desired weld quality. This comprehensive analysis ensures that the AI robot welding solution is tailored to meet your exact needs and specifications.

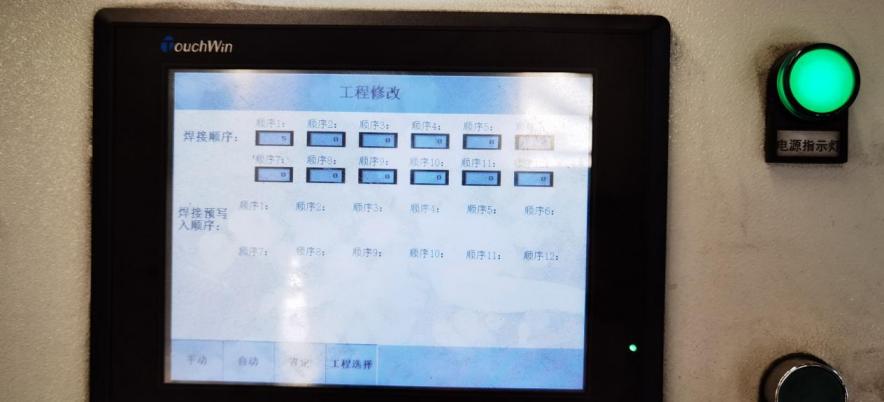

11.3 Designing the Solution: Customized Solution Design

Based on the assessment of requirements, ALTRON will design a customized AI robot welding solution for centrifugal fan manufacturing. This solution may include robotic arms, welding equipment, sensors, and AI algorithms tailored to optimize welding processes.

11.4 Integration with Existing Systems

ALTRON ensures seamless integration of the AI robot welding solution with your existing production systems and workflows. Their team will collaborate with your engineers and technicians to minimize downtime and disruptions during implementation.

Implementation and Testing

12.1 Installation and Commissioning

Once the solution is designed, ALTRON’s engineers will oversee the installation and commissioning process. They will calibrate the robotic arms, configure welding parameters, and conduct comprehensive testing to ensure optimal performance.

12.2 Training and Support

ALTRON provides training for your operators and maintenance staff to ensure they are proficient in operating and maintaining the AI robot welding solution. Additionally, their technical support team is available to provide ongoing assistance and troubleshooting as needed.

Why Choose AI Robot Welding Solutions for Centrifugal Fans from ALTRON

13.1 Expertise and Experience

ALTRON has extensive expertise and experience in providing AI robot welding solutions for various industries, including centrifugal fan manufacturing. Their team of engineers and technicians is highly skilled in designing, implementing, and supporting robotic welding systems.

13.2 Cutting-edge Technology

ALTRON utilizes cutting-edge technology, including advanced AI algorithms, robotic automation, and real-time monitoring systems, to deliver superior welding solutions. Their innovative approach ensures optimal performance, productivity, and quality in centrifugal fan manufacturing.

13.3 Customization and Flexibility

ALTRON understands that every manufacturing operation is unique, which is why they offer customizable solutions tailored to meet your specific requirements. Whether you need to weld different materials, accommodate varying production volumes, or address specific welding challenges, ALTRON can provide a solution that fits your needs.

13.4 Commitment to Quality and Support

ALTRON is committed to delivering high-quality products and services to their customers. From initial consultation to ongoing support, they prioritize customer satisfaction and strive to exceed expectations in every aspect of their business.

Conclusion

The integration of AI-driven robot welding solutions revolutionizes centrifugal fan manufacturing, addressing common welding challenges while enhancing productivity, consistency, and cost-effectiveness. ALTRON’s advanced technologies empower manufacturers to stay ahead in a competitive market by delivering superior quality products efficiently and reliably.

In the era of Industry 4.0, embracing AI and robotics is not just a choice but a necessity for companies striving for innovation and excellence in manufacturing. As the demand for high-performance centrifugal fans continues to grow, leveraging AI robot welding solutions becomes increasingly vital for meeting the industry’s evolving needs.