ALTRON's automated welding solutions are mainly provided to factories of industrial fan manufacturers

As the industrial landscape evolves, precision and efficiency become paramount in manufacturing processes. ALTRON, a frontrunner in automated welding solutions, plays a pivotal role in optimizing production for industrial fan manufacturers.

Practical applications of industrial fans:

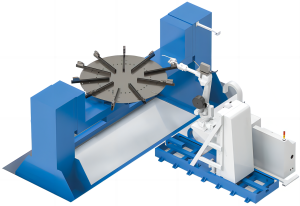

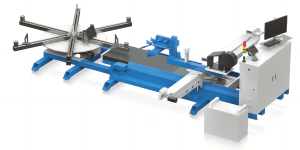

Welding-industrial fan impeller

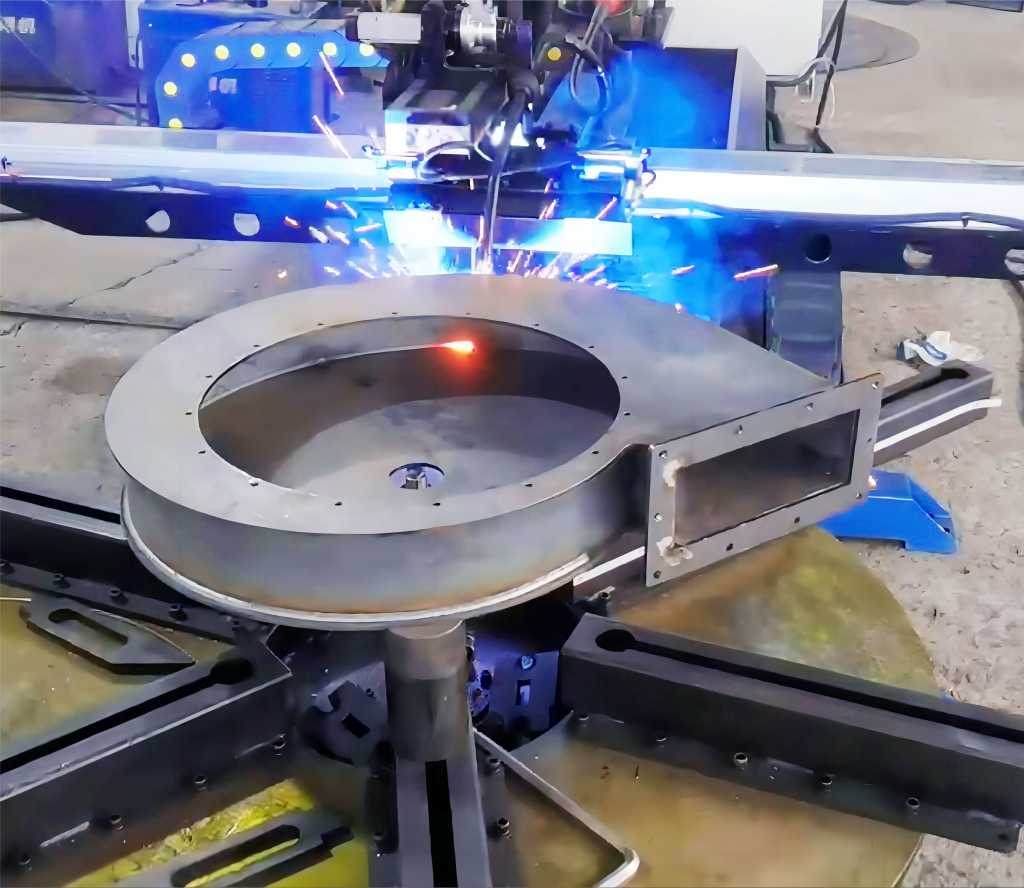

Welding – detail of industrial fan impeller application in real factory:

Parameters Of Vision Guided Fan Impeller Welding Machine

| Item | HYL03-0.1T | HYL01-0.5T | HYL02-1T | HYL04-2T | HFT01 | HFT02 |

| Machine Dimension (L*W*H) |

2000*2000*1800mm | 3500*2200*2000mm | 3700*2500*2100mm | 3700*2700*2100mm | 6000*7000*3000mm | 6000*7000*3000mm |

| Machine Mass | 1500 KGS | 3500 KGS | 5000 KGS | 6000 KGS | 9200 KGS | 10800 KGS |

| Dia. Of Impeller | 300-600 mm | 400-1260 mm | 400-1600 mm | 400-2000 mm | ≤3.8 M | ≤3.8 M |

| Height. Of Impeller | ≤600 mm | ≤1000 mm | ≤1000 mm | ≤1000 mm | ≤2.4 M | ≤2.4 M |

| Load (With Tooling) | 100 KGS | 500 KGS | 1000 KGS | 2000 KGS | 5000 KGS | 8000 KGS |

| Power Supply | Equipment: AC220V; Welding M/C: AC380V |

Equipment: AC220V; Welding M/C: AC380V |

AC380V | AC380V | AC380V | AC380V |

|

|

|

|

||||

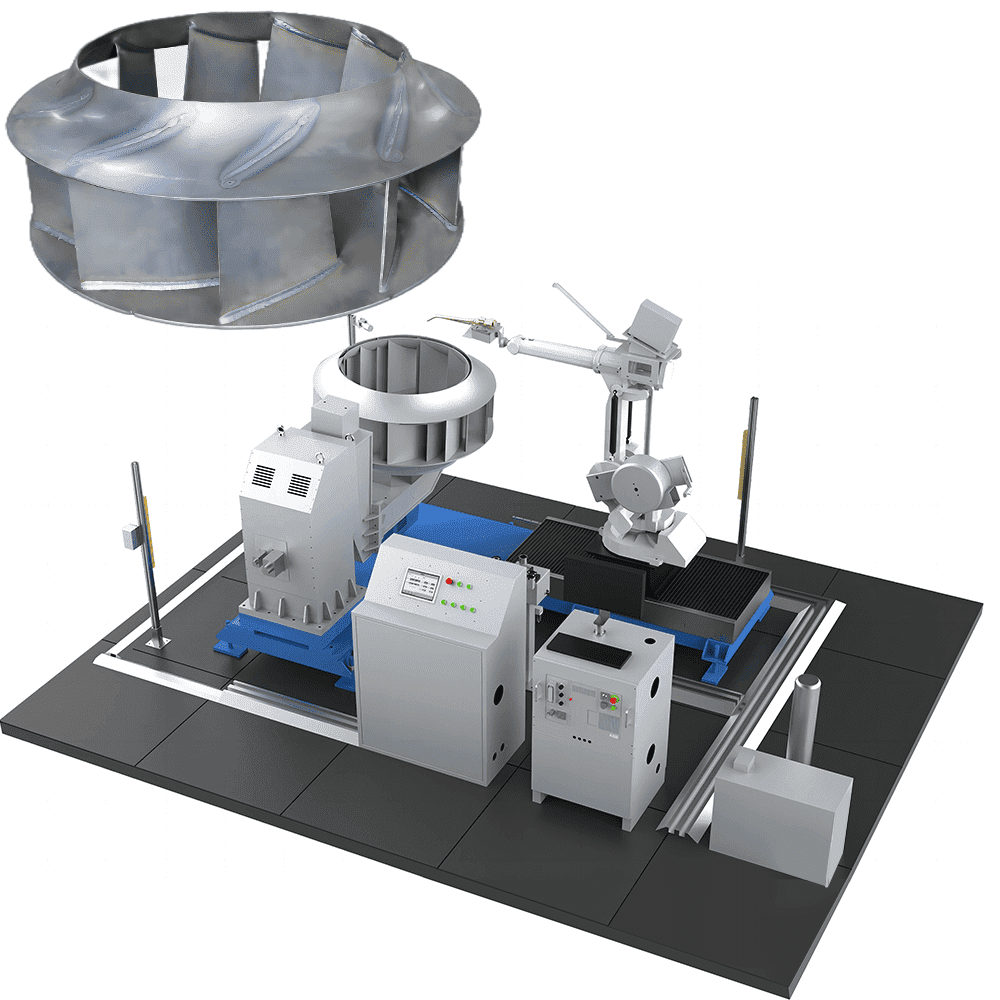

Welding-industrial fan volute

Welding – detail of industrial fan volute application in real factory:

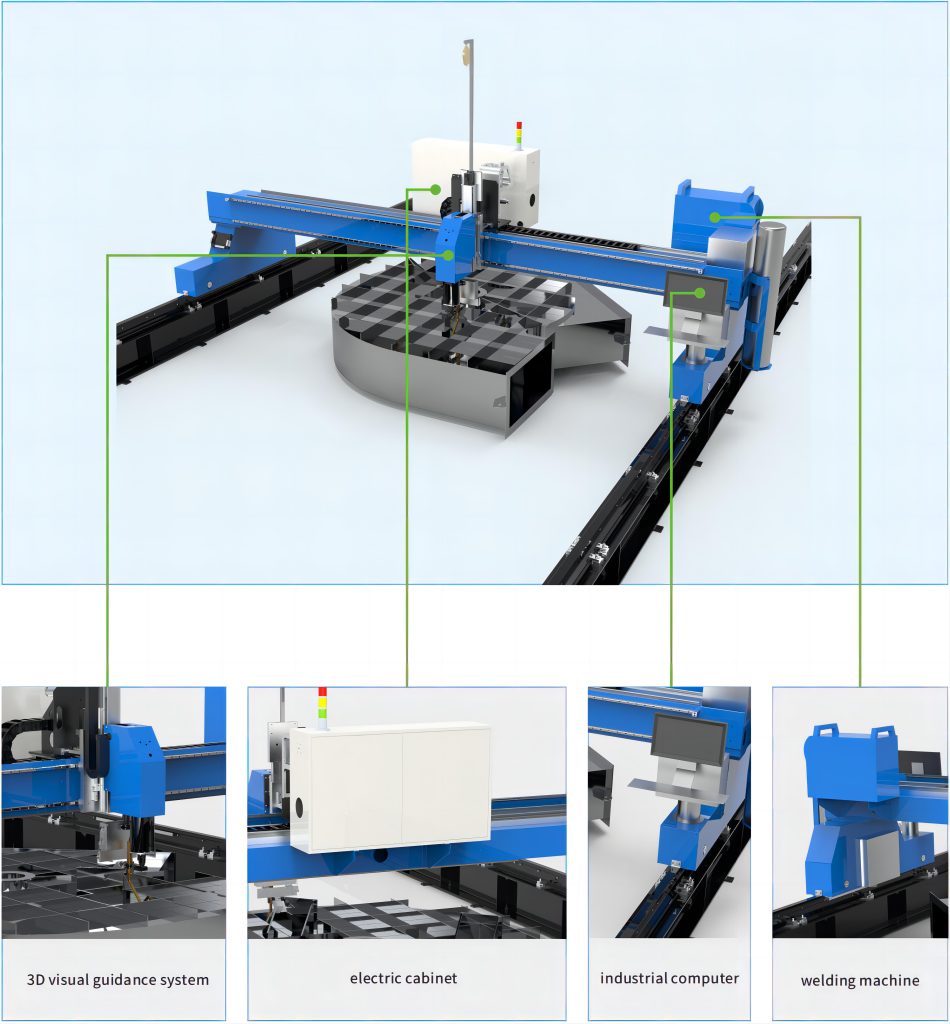

Fully Automatic Welding Equipment For Fan Volute

| Item | HWK11V2 | HWK10V2.5 |

| Machine Dimension (L*W*H) |

5600*3100*1700mm | 6500*3600*1700mm |

| Machine Mass | 1.6 T | 2.3 T |

| Radius Of Volute | 100-1500 mm | 800-2000 mm |

| Load | 1 T | 2 T |

| Power Supply | Equipment: AC220V; Welding M/C: AC380V |

Equipment: AC220V; Welding M/C: AC380V |

| Power Motor (not include welder) |

7 KW | 9 KW |

|

|

|

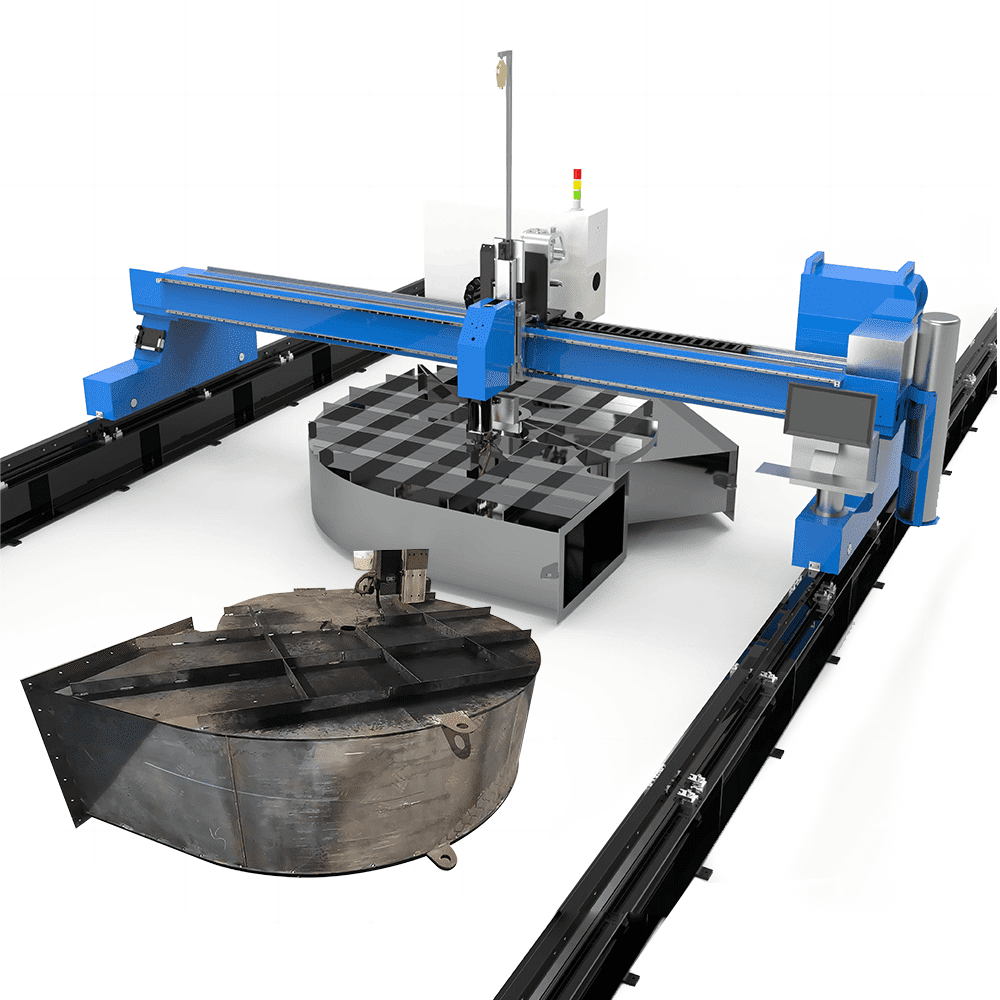

Welding-industrial fan Volute case reinforcement

Gantry Stiffener Automatic Welding Equipment

| Item | HJQJ01 / HJQJ02 |

| Length | Full length of track 10-20 meters, out of range support customization |

| Width | Total width of equipment 4M / 5M / 6M / 7M |

| Height | 3.2 Meters |

| Machine Mass | 5 T (not include track) |

| Applicable Product Size | Product length < total rail length – 2 meters; Product width < machine width – 1.2 meters |

| Power Supply | Equipment: AC380V; Welding M/C: AC380V |

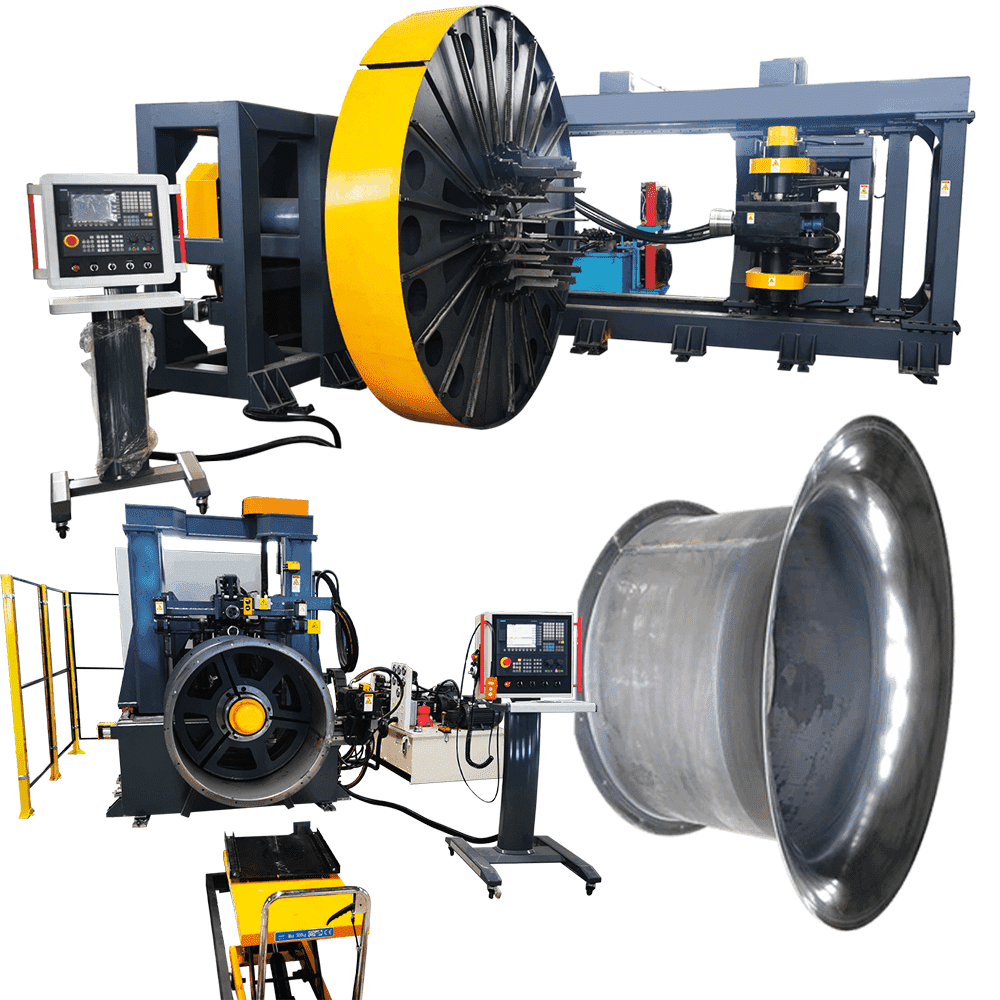

Axial flow fan duct roll forming, welding and flanging (production line)

ALTRON ends automatic welding applications in various industries and advantages of industrial fans

Industrial fans serve as indispensable components across various sectors, from HVAC systems to manufacturing plants. The demand for these fans necessitates streamlined and flawless production, where welding holds a crucial position in ensuring structural integrity and performance.

ALTRON steps in with its cutting-edge automated welding solutions tailored explicitly for the intricate needs of industrial fan manufacturing.

Automated welding, a cornerstone of modern manufacturing, offers a multitude of advantages over traditional welding methods. ALTRON’s solutions leverage advanced robotics and state-of-the-art technologies, minimizing human error and maximizing precision in the welding process.

By integrating these systems into factories dedicated to industrial fan production, ALTRON significantly enhances efficiency while maintaining uncompromised quality standards.

The core of ALTRON’s automated welding lies in its adaptability and precision. These solutions are meticulously engineered to accommodate various fan designs, sizes, and materials commonly used in the industry.

Whether it’s the welding of fan blades, housings, or support structures, ALTRON’s technology seamlessly adapts to diverse production requirements, ensuring consistent and high-quality welds throughout the manufacturing process.

Furthermore, ALTRON’s automated welding systems offer a level of consistency unattainable through manual welding techniques. The precision-driven nature of robotics ensures uniformity in weld quality, minimizing defects and enhancing the overall reliability of industrial fans.

This level of reliability is crucial, especially in applications where performance and safety are non-negotiable factors.

Beyond consistency and precision, ALTRON’s solutions significantly contribute to the speed of production. The automation of welding processes streamlines manufacturing timelines, allowing industrial fan factories to meet market demands promptly.

The accelerated production rate does not compromise quality, thanks to the stringent quality control measures integrated into ALTRON’s systems.

One of the key aspects that sets ALTRON apart is its commitment to innovation and continuous improvement. The company invests significantly in research and development, constantly refining its automated welding technologies.

This dedication ensures that industrial fan manufacturers benefit from cutting-edge solutions that align with the latest advancements in the welding industry.

Moreover, ALTRON’s commitment extends to providing comprehensive support and training to the factories implementing its automated welding solutions.

The company’s team of experts offers in-depth training programs, ensuring that factory personnel are proficient in operating and maintaining the systems. This support minimizes downtime, optimizes efficiency, and maximizes the return on investment for industrial fan manufacturers.

The impact of ALTRON’s automated welding solutions transcends mere operational enhancements. By enabling factories to produce high-quality industrial fans efficiently, ALTRON contributes to the broader industrial landscape.

Reliable and top-performing industrial fans, manufactured with precision and speed, further bolster various sectors, ranging from aerospace to manufacturing and agriculture.

In conclusion, ALTRON stands as a frontrunner in providing automated welding solutions tailored explicitly for industrial fan manufacturers.

Through precision, adaptability, speed, and unwavering commitment to innovation, ALTRON revolutionizes the manufacturing process, elevating the quality and efficiency of industrial fan production to new heights.

As industries continue to evolve, ALTRON remains at the forefront, empowering manufacturers to meet and exceed market demands while upholding unparalleled quality standards.