Transforming Industries with Aluminium Spinning Machines

Aluminium spinning machines have emerged as pivotal tools in various industries, revolutionizing the way aluminium products are manufactured. From crafting intricate designs to producing durable components, these machines have become indispensable in modern manufacturing processes. Let’s delve into the industry status, needs, and solutions concerning aluminium spinning machines, aluminium alloy spinning, aluminium roof fan spinning, and downblast roof fans.

Aluminium Spinning Machine: Crafting Precision with Innovation

1. Industry Status

Aluminium spinning machines have witnessed a surge in demand across industries due to their ability to shape aluminium sheets into precise and complex forms. With advancements in technology, these machines have become more efficient, allowing manufacturers to meet the growing demands for customised aluminium products.

2. Needs

Manufacturers require aluminium spinning machines that offer versatility, accuracy, and speed to streamline production processes and cater to diverse customer requirements. Additionally, there is a growing need for machines equipped with user-friendly interfaces and automation features to enhance productivity and reduce labor costs.

3. Solutions

ALTRON, a leading aluminium spinning machine manufacturer, addresses these needs by offering cutting-edge solutions tailored to meet the demands of modern manufacturing. Their machines boast advanced control systems, precise spinning capabilities, and modular designs, allowing for seamless integration into existing production lines.

Aluminium Alloy Spinning: Elevating Product Performance

1. Industry Status

The aluminium alloy spinning industry is experiencing significant growth, driven by the rising demand for lightweight and durable components across various sectors such as automotive, aerospace, and electronics. Manufacturers are increasingly turning to aluminium alloys for their superior strength-to-weight ratio and corrosion resistance.

2. Needs

In this dynamic market, manufacturers require aluminium spinning machines capable of handling a wide range of aluminium alloys with precision and efficiency. Additionally, there is a growing demand for solutions that enable seamless transition between different alloy compositions to meet varying customer specifications.

3. Solutions

ALTRON’s aluminium alloy spinning machines are designed to meet the diverse needs of alloy spinning applications. Equipped with advanced tooling options and adaptive control systems, these machines offer unparalleled precision and versatility, allowing manufacturers to produce high-quality alloy components with ease.

Aluminium Roof Fan Spinning: Enhancing Ventilation Solutions

1. Industry Status

Aluminium roof fan spinning plays a crucial role in the ventilation industry, where lightweight and corrosion-resistant components are essential for ensuring efficient airflow and longevity of ventilation systems. As demand for energy-efficient solutions grows, manufacturers are turning to aluminium roof fans for their durability and sustainability.

2. Needs

Manufacturers in the ventilation industry require aluminium spinning smachines capable of producing robust and aerodynamic fan components that can withstand harsh environmental conditions. Moreover, there is a need for solutions that enable efficient mass production without compromising on quality or performance.

3. Solutions

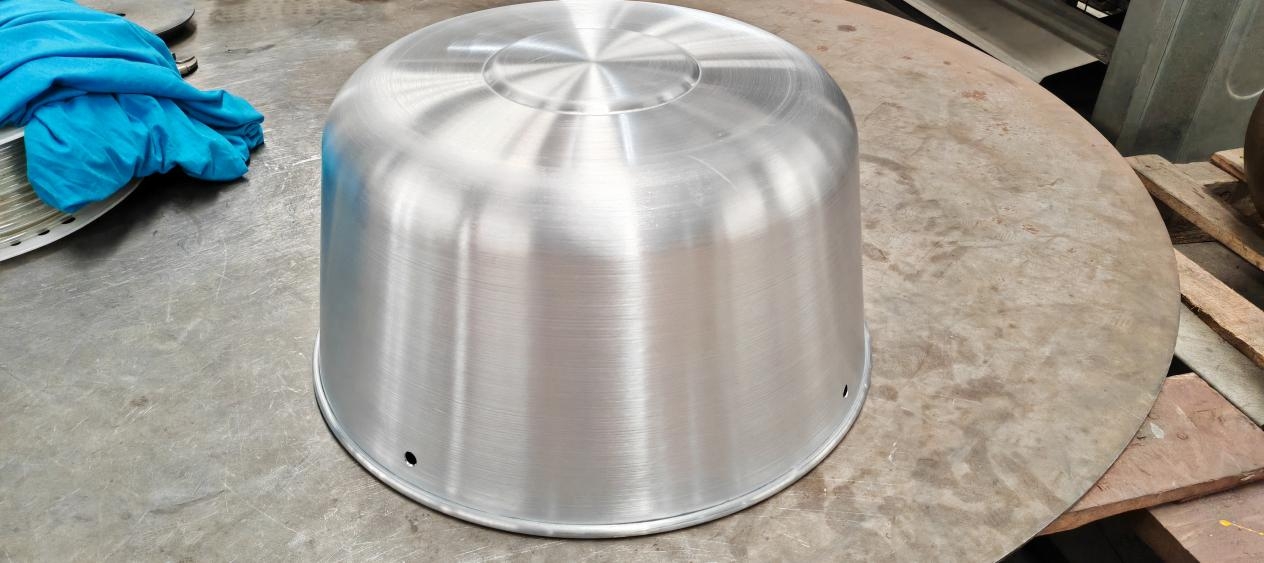

ALTRON addresses these needs with their specialised aluminium roof fan aluminium spinning machine, engineered to deliver superior performance and reliability. These machines feature advanced forming techniques and tooling options tailored specifically for producing high-efficiency fan blades and housings, ensuring optimal airflow and durability.

Downblast Roof Fans: Meeting Industrial Ventilation Demands

1. Industry Status

Downblast roof fans are integral to industrial ventilation systems, expelling hot air and pollutants from enclosed spaces to maintain a safe and comfortable working environment. As industries strive for better air quality and regulatory compliance, the demand for efficient and durable downblast roof fans continues to rise.

2. Needs

Manufacturers of downblast roof fans require aluminium spinning machines capable of producing robust fan assemblies that can withstand the rigors of industrial environments while delivering high-performance ventilation. Additionally, there is a need for solutions that offer quick turnaround times and cost-effective production methods.

3. Solutions

ALTRON’s downblast roof fan spinning machines are designed to meet the demanding requirements of industrial ventilation applications. Featuring robust construction and advanced forming capabilities, these machines enable manufacturers to produce high-efficiency fan assemblies with exceptional durability and performance, ensuring optimal air quality and safety in industrial settings.

Industry Roof Blowers: Enhancing Ventilation Solutions

1. Industry Status

Industry roof blowers play a critical role in maintaining optimal air quality and ventilation in industrial settings. These blowers are essential for expelling pollutants, fumes, and excess heat from enclosed spaces, ensuring a safe and comfortable working environment. The industry is witnessing a steady growth in demand for efficient and reliable roof blowers to meet the stringent ventilation requirements of various sectors.

2. Needs

Manufacturers of industry roof blowers require advanced solutions that offer high-performance ventilation while minimizing energy consumption and operating costs. There is a growing demand for roof blowers equipped with durable components, corrosion-resistant materials, and efficient motor systems to withstand harsh environmental conditions and prolonged use in industrial settings.

3. Solutions

ALTRON addresses these needs by offering state-of-the-art aluminium spinning machines specifically designed for producing industry roof blowers. These machines boast advanced forming capabilities, precise control systems, and robust construction, allowing manufacturers to produce high-quality blower components with exceptional durability and performance. Additionally, ALTRON provides comprehensive support services and customization options to meet the unique requirements of each customer.

Aluminium Spinning Machine: Driving Innovation in Manufacturing

1. Industry Status

The aluminium spinning machine industry is experiencing significant growth, driven by the increasing demand for aluminium products across various sectors such as automotive, aerospace, and consumer electronics. These machines have become indispensable for shaping aluminium sheets into precise and complex forms, offering manufacturers unparalleled flexibility and efficiency in production processes.

2. Needs

Manufacturers require aluminium spinning machines that offer versatility, accuracy, and speed to meet the growing demands for customised aluminium products. There is also a need for solutions that integrate seamlessly into existing production lines, enhance productivity, and reduce labor costs. Additionally, manufacturers seek advanced automation features and user-friendly interfaces to streamline operations and ensure consistent product quality.

3. Solutions

ALTRON, a leading manufacturer of aluminium spinning machines, provides innovative solutions tailored to meet the diverse needs of modern manufacturing. Their machines feature cutting-edge technology, including advanced control systems, adaptive tooling options, and modular designs, enabling manufacturers to produce a wide range of aluminium components with precision and efficiency. ALTRON’s commitment to continuous research and development ensures that their machines remain at the forefront of industry innovation.

Roof Fan Spinning Cases: Optimizing Airflow Efficiency

1. Industry Status

Roof fan spinning cases are essential components of ventilation systems, facilitating the efficient movement of air in commercial and industrial buildings. These cases play a crucial role in optimizing airflow efficiency, ensuring proper ventilation, and maintaining a comfortable indoor environment. As industries focus on energy efficiency and environmental sustainability, the demand for high-quality roof fan spinning cases continues to grow.

2. Needs

Manufacturers of roof fan spinning cases require aluminium spinning machines capable of producing robust and aerodynamic components that can withstand harsh environmental conditions and deliver optimal airflow performance. There is also a need for solutions that offer quick turnaround times, cost-effective production methods, and flexibility to accommodate various design specifications.

3. Solutions

ALTRON offers specialized aluminium spinning machines designed specifically for producing roof fan spinning cases with exceptional precision and durability. These machines feature advanced forming techniques, customizable tooling options, and automated production processes, allowing manufacturers to produce high-quality spinning cases efficiently and cost-effectively. With ALTRON’s cutting-edge solutions, manufacturers can meet the evolving demands of the ventilation industry and deliver superior airflow solutions to their customers.

Upblast Roof Fans: Meeting Industrial Ventilation Demands

1. Industry Status

Upblast roof fans are essential components of industrial ventilation systems, expelling hot air, smoke, and pollutants from enclosed spaces to maintain a safe and healthy working environment. As industries prioritize workplace safety and regulatory compliance, the demand for reliable and efficient upblast roof fans continues to rise.

2. Needs

Manufacturers of upblast roof fans require aluminium spinning machines capable of producing robust fan assemblies that can withstand the rigors of industrial environments while delivering high-performance ventilation. There is also a need for solutions that offer quick turnaround times, cost-effective production methods, and flexibility to accommodate various fan sizes and configurations.

3. Solutions

ALTRON’s upblast roof fan spinning machines are engineered to meet the demanding requirements of industrial ventilation applications. These machines feature rugged construction, advanced forming capabilities, and adaptive control systems, enabling manufacturers to produce high-quality fan assemblies with exceptional durability and performance. With ALTRON’s comprehensive support services and commitment to innovation, manufacturers can confidently meet the ventilation needs of industrial facilities while staying ahead of industry trends and regulations.

Unveiling the ALTRON Series: Setting a New Standard in Aluminium Spinning

1. Standard Configuration

The ALTRON series comes equipped with a comprehensive standard configuration that ensures optimal performance and reliability. Key components include the SIEMENS CNC 828D control system, SIEMENS servo motor and drive, asynchronous servo spindle motor, APEX servo reducer, high-strength ductile iron sliding table, blanks center assembly, back roller assembly, CNC tool turret, hydraulic station and air cooling system, air unload assembly, self-developed spinning system, and control system remote maintenance.

2. Select Configuration

For manufacturers seeking additional capabilities and customization options, ALTRON offers a select configuration that includes features such as spindle spinning cylinder, trimming tool assembly, air conditioner for hydraulic station, hot spinning parts under 700°C, and a teach-in and playback system. These optional features enhance the versatility and functionality of the ALTRON series, allowing manufacturers to meet the unique requirements of their spinning processes with ease.

3. Advantages of ALTRON Series: Unparalleled Precision and Convenience

The ALTRON series single wheel spinning machine offers several distinct advantages that set it apart from the competition. Its thoughtfully designed structure is optimized for the spinning process, providing technicians with exceptional convenience when accessing the operation space. This design feature not only enhances productivity but also ensures safety and ease of maintenance, resulting in a seamless spinning experience for manufacturers.

Conclusion

In conclusion, aluminium spinning machines have become indispensable tools across various industries, driving innovation and efficiency in manufacturing processes. With ALTRON’s cutting-edge solutions, manufacturers can meet the evolving demands of the market and deliver high-quality aluminium products that exceed customer expectations.