ALTRON’s Automated Welders: One-Stop Service & Welding Process Optimization

In the realm of industrial manufacturing, the pursuit of efficiency, precision, and safety has led to the rise of automation. ALTRON, a leading manufacturer in the field, has taken automation to new heights with its state-of-the-art automated welders. These innovative machines have transformed the welding landscape by combining advanced technology with unparalleled craftsmanship. This blog delves into the world of automated welders, exploring their benefits, applications, and how ALTRON is shaping the future of welding.

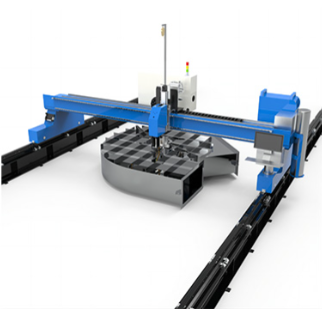

Streamlining Welding with Gantry Stiffener Auto Welding Machines

Among the advancements in automated welding technology, the Gantry Stiffener Auto Welding Machine stands tall as a testament to innovation. Engineered by the manufacturer ALTRON, this machine embodies efficiency and accuracy. By understanding the intricacies of its operation and optimizing its welding parameters, manufacturers can unlock its full potential.

Achieving Optimal Welding Results Through Parameter Optimization

To harness the capabilities of the Gantry Stiffener Auto Welding Machine to their fullest extent, manufacturers must focus on optimizing welding parameters. This entails a systematic approach to adjust settings such as welding speed, current, voltage, and shielding gas flow rate. Through iterative testing and analysis, these parameters can be fine-tuned to achieve the perfect balance between weld quality and efficiency.

The Evolution of Welding Automation

Automated Welding: A Technological Leap Forward

Traditional welding methods, while effective, often require a skilled human welder to perform repetitive and precise tasks. ALTRON’s automated welders have redefined this process by seamlessly integrating robotics, computerized controls, and cutting-edge sensors. This combination ensures a level of accuracy and consistency that human hands alone can rarely achieve. The result is increased productivity, reduced error rates, and enhanced workplace safety.

Precision Perfected: ALTRON’s Innovation

At the heart of ALTRON’s automated welders lies a dedication to precision. These machines are equipped with sophisticated sensors and cameras that allow them to analyze the workpiece in real time, making instant adjustments to welding parameters. Whether it’s a complex joint or a simple seam, ALTRON’s automated welders ensure uniformity and accuracy, even in the most challenging welding applications.

A Clear Focus: Camera Parameters in Welding Automation

Central to the effectiveness of any automated welding system is its ability to perceive and analyze the welding environment. This is where camera parameters play a pivotal role. The Gantry Stiffener Auto Welding Machine boasts impressive camera specifications:

- Maximum Scanning Speed (FPS):With a scanning speed of 13.5 frames per second, the machine captures real-time data of the welding process. This rapid data acquisition enables precise monitoring and control.

- Data Resolution (Megapixel):A resolution of 0.2 megapixels ensures that even the minutest details of the welding area are captured with clarity. This high resolution contributes to accurate analysis and informed decision-making.

- Central Object Distance: The camera’s focal point is set at 420 mm. This choice of distance strikes a balance between capturing a broad view of the welding area and focusing on specific details.

- Standard Field of View (XY):The camera covers an area of 220×160 mm, providing a comprehensive view of the welding scene. This wide field of view aids in assessing the overall weld quality.

- Standard Depth of Field (Z): The depth of field spans ±60 mm, allowing the camera to focus on welds located at different heights. This capability is essential for maintaining consistent quality across various joint configurations.

- Data Interface:The machine’s USB3.0 interface facilitates efficient data transfer, enabling seamless communication between the camera and other system components.

- Power Management:Operating at 24V and 5A, the camera system is designed to deliver optimal performance while maintaining energy efficiency.

Benefits of Automated Welders

Enhanced Efficiency and Consistency

Automated welders by ALTRON drastically improve efficiency by minimizing the time required for setup, welding, and post-weld processes. Unlike human welders, these machines can operate 24/7 without fatigue, leading to consistent and uninterrupted production cycles. The reduction in variability contributes to higher product quality and fewer rework instances, translating to cost savings and improved customer satisfaction.

Workplace Safety and Operator Well-being

Welding, by nature, involves exposure to high temperatures, fumes, and hazardous materials. ALTRON’s automated welders mitigate these risks by allowing operators to monitor the process from a safe distance. This reduces the chances of injuries and health complications, improving the overall well-being of the workforce. Skilled welders can also be redeployed to more intellectually demanding tasks, adding value to the manufacturing process.

Applications of ALTRON’s Automated Welders

Automotive Manufacturing

In the automotive industry, where precision and consistency are paramount, ALTRON’s automated welders have found a significant role. These machines excel in welding car bodies, chassis components, and intricate subassemblies. The ability to maintain tight tolerances ensures that vehicles are structurally sound, enhancing safety and performance.

Heavy Machinery Fabrication

The fabrication of heavy machinery demands robust and reliable welding solutions. ALTRON’s automated welders rise to the occasion by flawlessly joining massive metal components with unparalleled accuracy. This not only contributes to the structural integrity of the machinery but also extends its operational lifespan.

ALTRON: Pioneering the Future of Welding Automation

Continuous Innovation

ALTRON’s commitment to innovation is evident in its relentless pursuit of excellence. Their research and development efforts are dedicated to pushing the boundaries of welding automation, resulting in cutting-edge features and capabilities that set new industry standards.

Custom Solutions for Diverse Needs

Recognizing that every manufacturing environment is unique, ALTRON offers a range of automated welders tailored to various applications. From small-scale operations to large-scale industrial settings, ALTRON’s solutions adapt to the specific requirements of each customer, ensuring optimal results and maximum efficiency.

Conclusion

In the modern manufacturing landscape, ALTRON’s automated welders stand as a testament to the marriage of technology and craftsmanship. With precision, efficiency, and safety at the forefront, these machines are revolutionizing the welding process across industries. By embracing ALTRON’s automated welders, manufacturers are embracing a future where welding is not just a process, but a refined art guided by automation’s steady hand.