Thinking of Upgrading? Explore the World of Automated Welding Machine

To stay competitive in today’s manufacturing environment, it’s crucial to adopt new technologies that can streamline workflows and improve productivity. Automated welding machines are one such innovation that promises to revolutionize the industry by ensuring seamless welds with unparalleled precision. In this blog post, we take a closer look at how these machines work and how they help manufacturers achieve high-quality results.

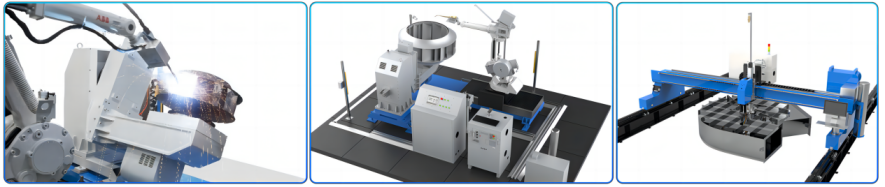

Automation is a key driver behind the widespread adoption of welding robots. ALTRON’s Automated Welding Machine reduces reliance on manual labor, minimizing the risk of human error and significantly speeding up the welding process. The robotic system is equipped with advanced sensors and programming, allowing it to adapt to various welding scenarios and execute precise movements with minimal intervention. This not only enhances efficiency but also contributes to a safer working environment by minimizing the exposure of workers to potentially hazardous conditions.

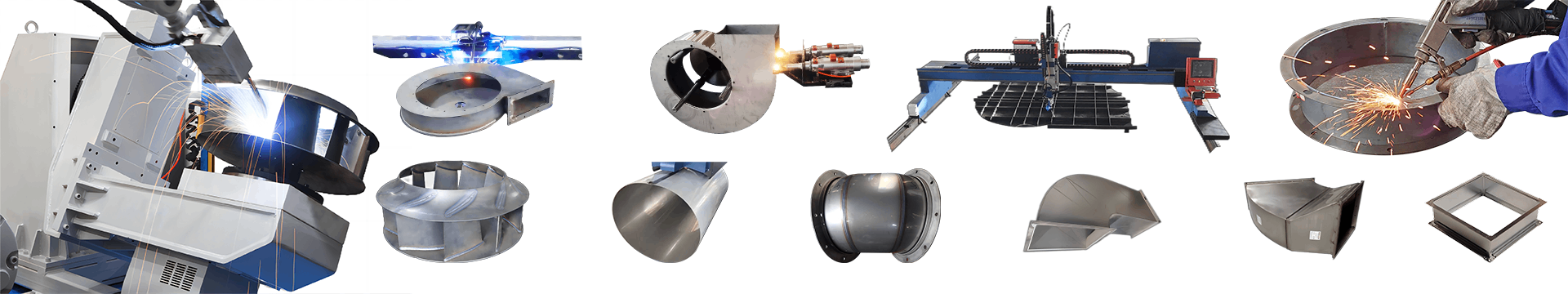

The Precision Revolution: Robotic Air Duct Laser Automatic Welding

In an era where speed and precision are paramount, the traditional manual welding processes are gradually making way for automated solutions. The need for increased productivity, improved quality, and cost-effectiveness has led many industries to explore the capabilities of automated welding machines. ALTRON’s Robotic Air Duct Laser Automatic Welding Machine is at the forefront of this technological revolution, addressing the specific needs of industries involved in air duct fabrication.

ALTRON’s automated welding machines are at the forefront of precision welding technology. The integration of robotics into the welding process, especially in applications like air ducts, has revolutionized the industry. With the use of advanced robotic systems, ALTRON ensures that every weld is executed with unparalleled accuracy.

One standout feature is the Robotic Air Duct Laser Automatic Welding system. This cutting-edge technology combines the efficiency of robotics with the precision of laser welding. The result is a seamless and smooth weld seam that not only enhances the aesthetic appeal of the final product but also significantly improves the structural integrity.

Unmatched Power: 2000W CW Laser Welding

The backbone of ALTRON’s automated welding machines lies in their powerful 2000W Continuous Wave (CW) laser welding capability. This level of power is a game-changer in the welding landscape, allowing for faster and more efficient welding processes.

The 2000W CW laser welding system employed by ALTRON ensures deep penetration, enabling the fusion of materials with precision. This power, coupled with automation, not only expedites the welding process but also contributes to the overall quality of the weld. The result is a weld that meets the highest standards in terms of strength and durability.

The transition to automated welding is not just a modernization strategy; it is a necessity for industries looking to stay competitive in a fast-paced market. ALTRON’s Robotic Air Duct Laser Automatic Welding Machine, with its 2000W CW laser welding system and emphasis on precision, efficiency, and automation, exemplifies the future of welding technology. As businesses contemplate upgrading their welding processes, exploring the world of ALTRON’s automated welding solutions is a step toward achieving unparalleled quality and productivity in the world of fabrication.

Seamless Perfection: Achieving a Smooth Weld Seam

One of the key indicators of a well-executed weld is the appearance of the weld seam. ALTRON’s automated welding machines excel in delivering welds with a smooth finish. The integration of laser welding technology ensures that the heat-affected zone is minimized, reducing the chances of distortion or unevenness in the weld seam.

The smooth weld seam achieved by ALTRON’s machines not only enhances the visual appeal of the final product but also plays a crucial role in maintaining the structural integrity of the welded components. This attention to detail is what sets ALTRON apart as a leader in the automated welding industry.

As the demand for automated welding solutions continues to rise, choosing a reliable and innovative manufacturer becomes crucial. ALTRON, with its commitment to pushing the boundaries of technological advancements, stands out as a pioneer in the field of automated welding. The company’s dedication to research and development has resulted in cutting-edge solutions that cater to the evolving needs of industries worldwide.

Are You Future-Proofing Your Welding Process with Automated Welding Machines?

As industries continue to evolve, so do the demands on manufacturing processes. Automated welding machines have emerged as a solution that not only meets current requirements but also future-proofs your welding processes. One of the key advantages is the increased efficiency and speed of the welding operation. ALTRON, a prominent automated welding machine manufacturer, offers state-of-the-art solutions that cater to various industries.

Automated welding machines contribute to future-proofing by reducing reliance on manual labor, minimizing errors, and improving overall output. ALTRON’s machines are equipped with advanced sensors and programming capabilities, allowing for precise control over the welding parameters. This adaptability ensures that as welding standards evolve, your automated welding machine can be easily adjusted to meet new requirements.

What Factors Should You Consider When Selecting an Automated Welding Machine?

Choosing the right automated welding machine is crucial for optimizing your welding process. ALTRON, with its reputation as a leading manufacturer, provides a range of options, but certain factors must be considered before making a decision.

1. Welding Application Compatibility

Different industries have distinct welding requirements. Ensure that the automated welding machine you choose aligns with your specific welding applications. ALTRON offers machines designed for various welding processes, from MIG and TIG to robotic and orbital welding, ensuring a tailored solution for your needs.

2. Precision and Consistency

One of the primary benefits of automated welding machines is their ability to deliver precise and consistent welds. ALTRON’s machines boast cutting-edge technology that guarantees accuracy in every weld. This not only enhances the quality of the final product but also reduces the likelihood of defects and rework.

3. Ease of Programming and Operation

User-friendly interfaces and easy programming are essential for optimizing workflow. ALTRON’s automated welding machines are designed with intuitive controls, allowing operators to set parameters efficiently and monitor the welding process in real time. This ease of use contributes to increased productivity and reduced training times for your staff.

How to Optimize Your Welding Workflow with an Automated Welding Machine?

Once you’ve invested in an automated welding machine from ALTRON, optimizing your workflow becomes the next crucial step. Here are some strategies to ensure you make the most of your cutting-edge equipment:

1. Training and Skill Development

While automated welding machines simplify the welding process, it’s essential to invest in training for your operators. ALTRON provides comprehensive training programs to ensure your team can operate and maintain the equipment effectively. Skilled operators can maximize the benefits of automation and troubleshoot any issues that may arise.

2. Regular Maintenance and Calibration

To maintain the efficiency of your automated welding machine, regular maintenance and calibration are imperative. ALTRON offers support services to ensure that your equipment operates at peak performance. Routine checks, software updates, and calibration adjustments will extend the lifespan of your machine and prevent unexpected downtime.

3. Integration with Other Technologies

Consider integrating your automated welding machine with other smart manufacturing technologies. ALTRON’s machines are designed to seamlessly integrate with Industry 4.0 solutions, allowing for real-time data monitoring, analysis, and optimization of the welding process. This connectivity enhances overall efficiency and contributes to a more intelligent and responsive manufacturing environment.

ALTRON: Your Partner in Progress

In a rapidly changing technological landscape, the future of welding lies in innovation. ALTRON’s commitment to staying at the forefront of technological advancements ensures that its Automated Welding Machine remains a reliable and future-proof solution for industries seeking to stay ahead of the curve. Continuous improvements, updates, and integration of the latest technologies position ALTRON as a leader in shaping the future of automated welding.

When it comes to automated welding machines, ALTRON stands out not only for its cutting-edge technology but also for its commitment to customer service. The company’s website, www.auto-altron.com, serves as a gateway to explore the wide range of automated welding solutions offered.

For those seeking more personalized assistance, ALTRON provides a direct line of communication through WhatsApp at +8615627397226. The company’s commitment to customer satisfaction is further emphasized by its welcoming attitude towards inquiries and calls. ALTRON’s service team is ready to address any questions, provide technical support, and guide customers through the process of choosing the right automated welding solution for their specific needs.

Investing in the Future: ALTRON Automated Welding Machines

Automated welding machines from ALTRON represent not just a technological upgrade but a strategic investment in the future of manufacturing. The precision, power, and perfection achieved through these machines make them an invaluable asset for industries aiming to stay ahead in the competitive landscape.

As manufacturing processes continue to evolve, embracing automated welding technology is not just a choice; it’s a necessity. ALTRON’s automated welding machines are not merely tools; they are partners in progress, ushering in a new era of efficiency and excellence in welding. So, if you’re thinking of upgrading, now is the time to explore the world of automated welding machines by ALTRON. Your manufacturing future deserves nothing less than the best.