Advancements in Industrial Fan Manufacturing: The Role of Altron’s Automatic Welding Machines

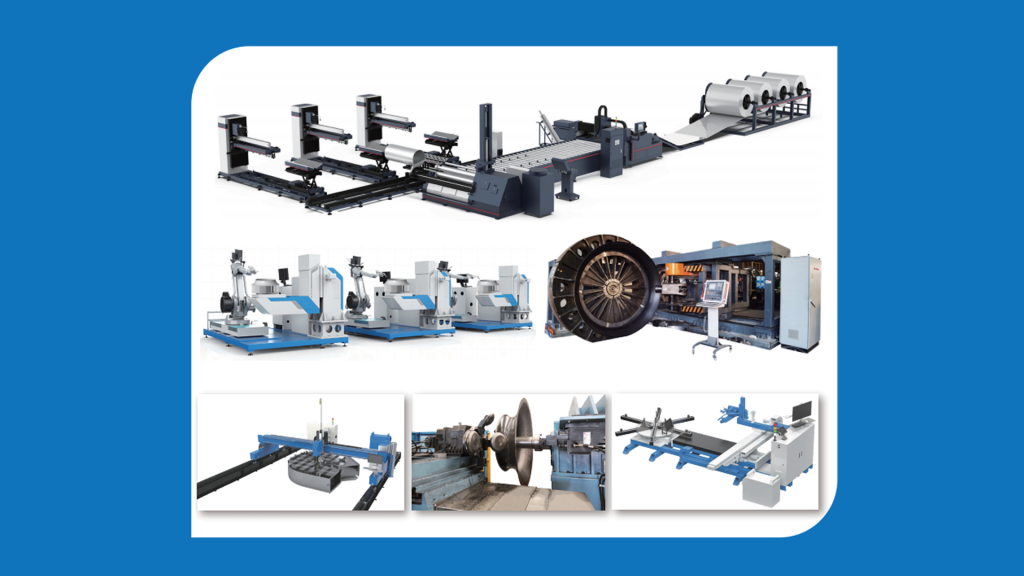

One of the technological marvels that is making waves in the industrial fan industry is the automatic welding machine. Altron is a major player in this field, taking the lead in developing and producing automated welding solutions for industrial fans in China, focusing on robotic welding of impellers for centrifugal fan casings. This blog provides an in-depth look at the technical complexities of Altron automated welding machines, specifically the welding line, impeller welding, industrial centrifugal fan housing welding and the welding of stiffeners for high-pressure large industrial centrifugal fans.

In the dynamic landscape of industrial manufacturing, the use of cutting-edge technology is crucial to achieve efficient, precise and high-quality production. Altron has always been customer-centric, using an engineer’s perspective to help customers solve pre-sales and after-sales problems.

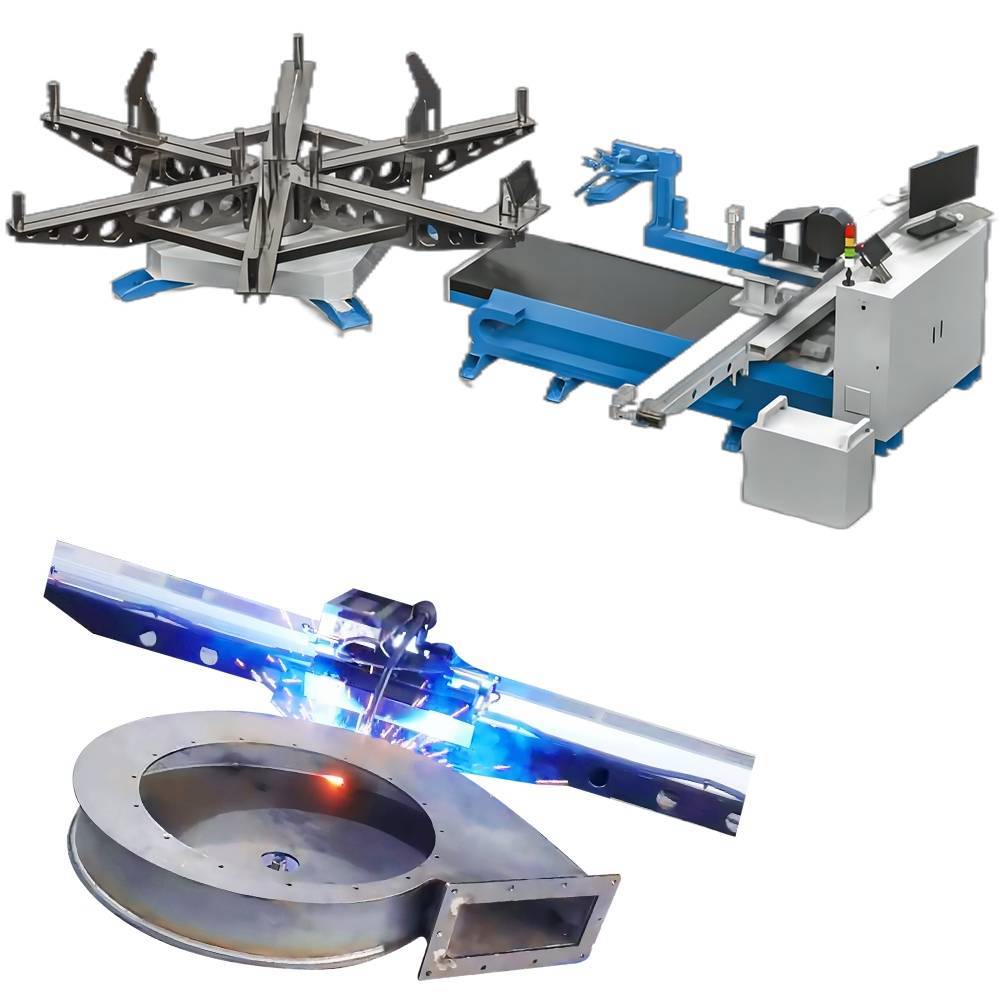

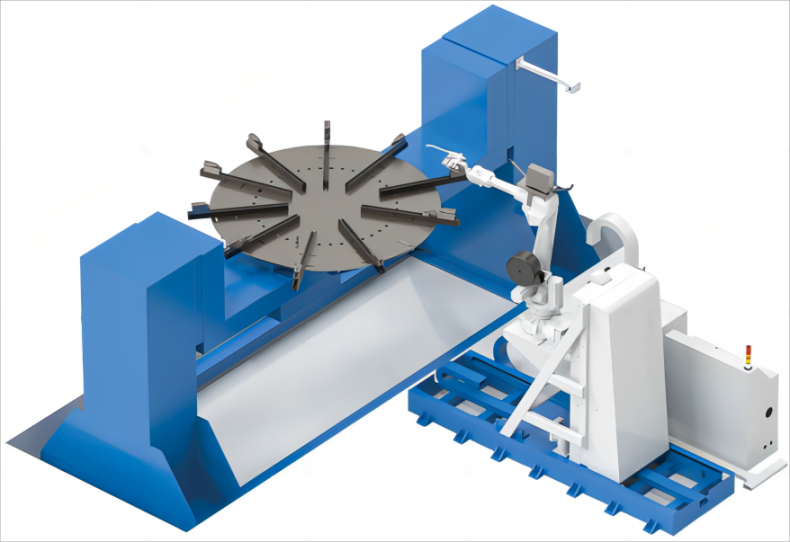

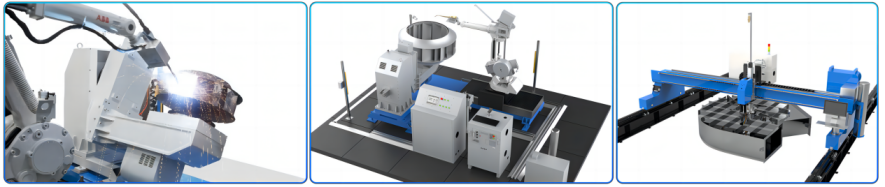

1. Centrifugal Fan Impeller Automatic Welding Machine

1.1 Vision-Guided Computing Logic

At the heart of Altron’s impeller robot welding system lies the sophisticated vision-guided computing logic. This innovative approach utilizes advanced computer vision algorithms to guide the welding process with unparalleled precision. The system employs cameras and sensors to create a real-time visual map of the impeller, allowing the welding machine to adapt to any irregularities in the workpiece.

1.2 Adaptive Welding Techniques

Altron’s impeller welding system employs adaptive welding techniques that dynamically adjust the welding parameters based on real-time feedback from the vision-guided system. This ensures uniform penetration and weld bead quality across the entire impeller surface. The adaptive nature of the system also allows for seamless integration with different impeller designs and materials.

1.3 Enhanced Productivity and Consistency

By automating the impeller welding process, Altron significantly enhances productivity and consistency in industrial fan manufacturing. The precision offered by the vision-guided computing logic results in welds that meet or exceed industry standards, reducing the need for post-weld inspections and rework.

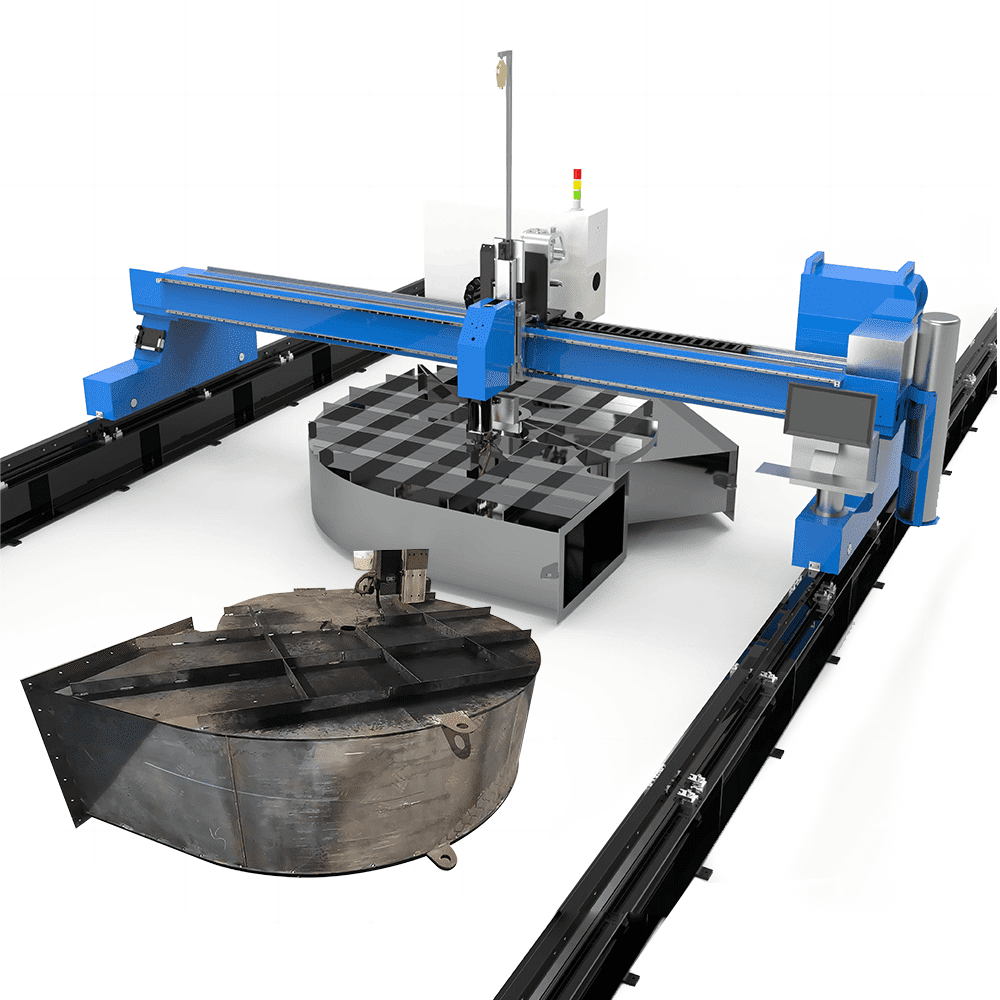

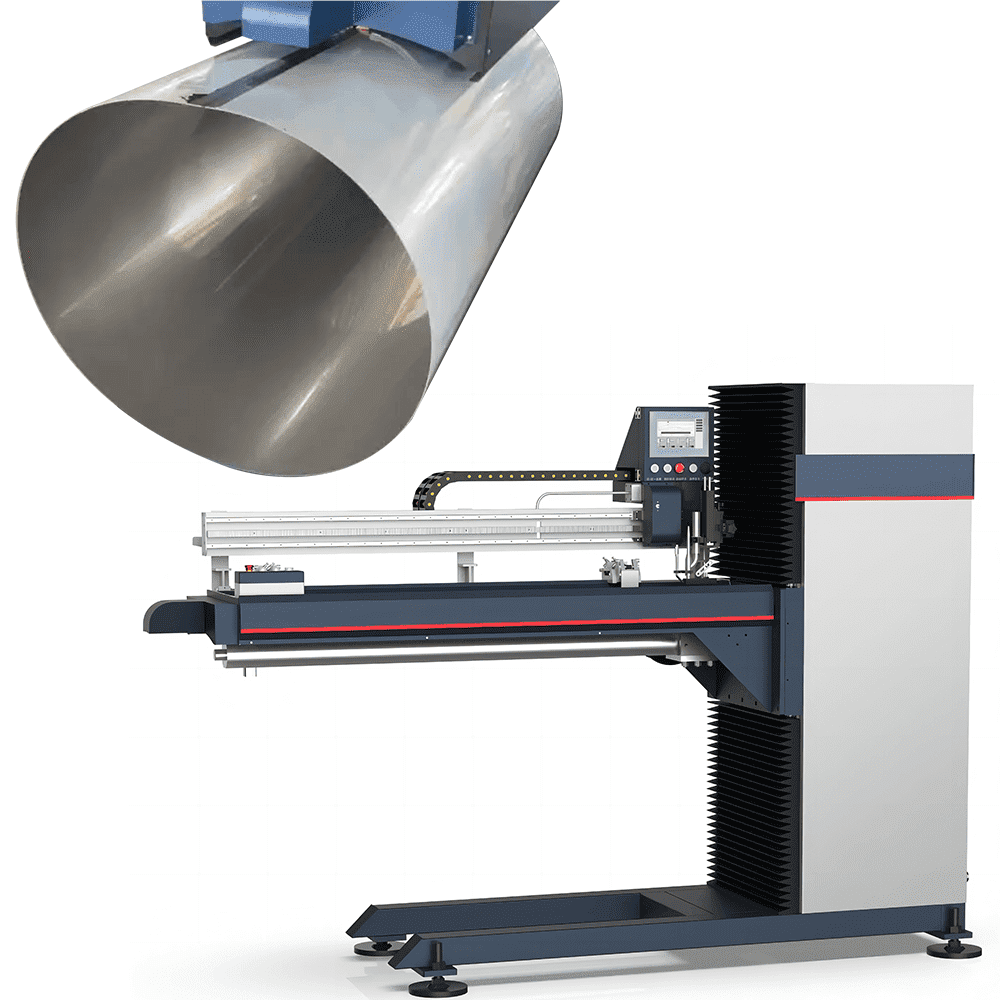

2. Industrial Centrifugal Fan Shell Automatic Welding Machine

Altron’s expertise extends beyond impeller welding to the fabrication of industrial centrifugal fan shells. The gantry welding equipment developed by Altron for this purpose integrates seamlessly with the vision-guided computing logic, providing a comprehensive solution for shell welding in the industrial fan industry.

2.1 Gantry Welding System

The gantry welding system from Altron is designed for efficiency and versatility. It utilizes a gantry structure that enables precise movement and control over the welding torch. This system is particularly effective in handling large and complex centrifugal fan shell components.

2.2 Vision-Guided Precision

Similar to the impeller welding system, the gantry welding equipment employs vision-guided computing logic to achieve precision in the welding process. This is crucial for ensuring uniform weld quality across the intricate geometries of industrial centrifugal fan shells.

2.3 Scalability and Customization

Altron’s gantry welding system is scalable to accommodate a wide range of centrifugal fan shell sizes and configurations. The flexibility of the system allows manufacturers to customize welding parameters for specific fan models, ensuring that each product meets the exacting standards of the industry.

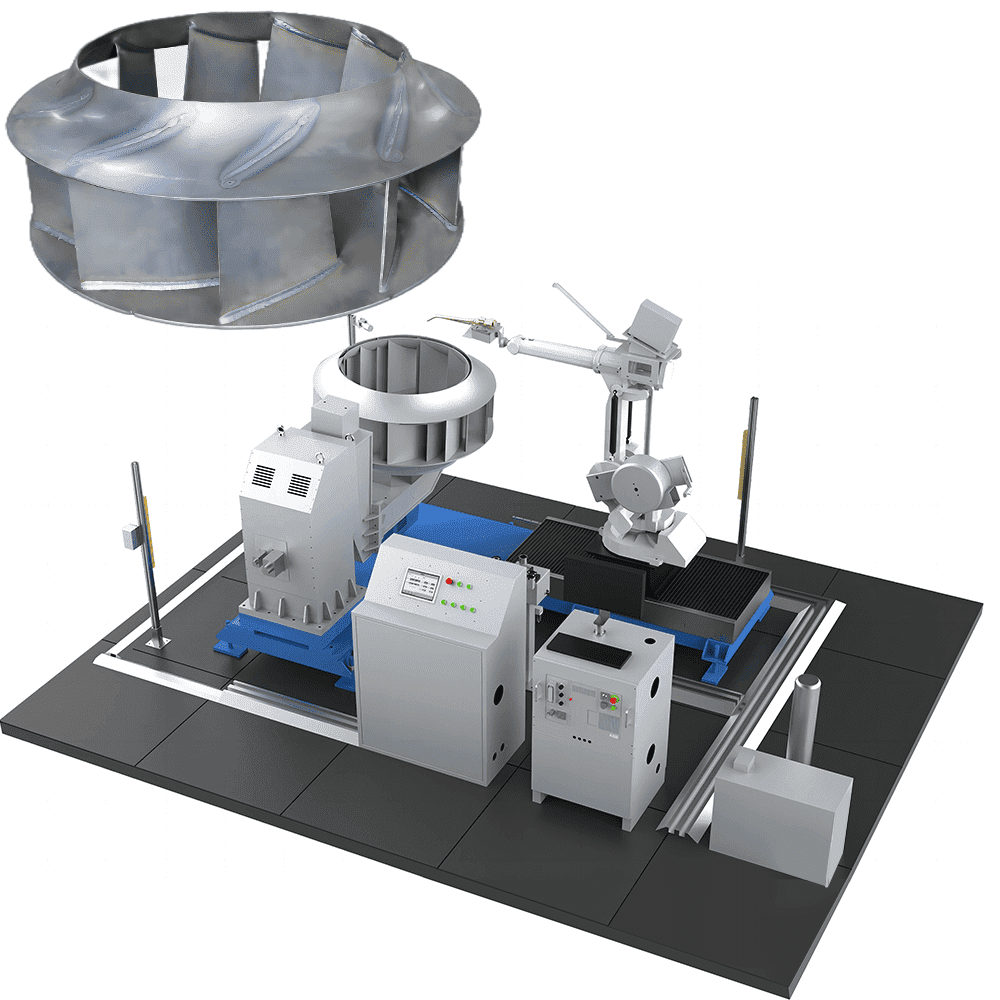

3. High-Voltage Large Industrial Centrifugal Fan Stiffener Welding

The welding of high-voltage large industrial centrifugal fan stiffeners poses unique challenges due to the size and structural requirements of these components. Altron, however, rises to the occasion with specialized welding solutions that cater to the specific demands of stiffener welding in high-voltage industrial fans.

3.1 Structural Integrity

Ensuring the structural integrity of large industrial fan stiffeners is paramount for the safety and performance of the final product. Altron’s welding machines incorporate advanced welding techniques that guarantee robust and reliable welds, even in high-voltage environments.

3.2 Integration of Safety Measures

The automated welding systems developed by Altron prioritize safety in the welding process. Safety measures are integrated into the equipment to mitigate risks associated with high-voltage welding, providing a secure environment for both the equipment and the operators.

3.3 Precision Welding for Enhanced Performance

Precision in stiffener welding is critical for the overall performance of high-voltage industrial centrifugal fans. Altron’s welding machines excel in achieving the required precision, contributing to the longevity and efficiency of the final product.

Automatic Welding Machine For Industrial Fan Conclusion

In the competitive landscape of industrial fan manufacturing, the integration of automated welding machines has become a game-changer. Altron’s commitment to advancing technology in this field is evident in the development of impeller robot welding systems, gantry welding equipment, and specialized solutions for high-voltage large industrial centrifugal fan stiffeners. As the industry continues to evolve, the role of automatic welding machines will undoubtedly remain pivotal in shaping the future of industrial fan production. By embracing these cutting-edge technologies, manufacturers can not only enhance productivity and efficiency but also deliver products that meet the highest standards of quality and safety.