Guide to Axial Fan: Production and Quality Enhancement

Axial fans are essential components in a wide array of industrial and commercial applications, known for their efficiency in moving air through a system. This blog delves into the intricacies of producing axial fans, the advanced machinery involved, and how modern technology can improve their quality. Let’s explore the fascinating world of axial fans and how ALTRON, a leading solution provider, streamlines their production.

What are Axial Fans?

Definition and Functionality

Axial fans are devices designed to move air or gas parallel to the fan’s axis of rotation. Unlike centrifugal fans that push air perpendicular to the axis, axial fans pull air directly through the blades. This makes them ideal for applications requiring high airflow at low pressure, such as ventilation, cooling, and air conditioning systems.

Applications of Axial Fans

Axial fans are ubiquitous in both industrial and commercial settings. They are used in HVAC systems, industrial exhausts, cooling electronic equipment, and even in wind tunnels. Their design allows for high efficiency and performance, making them indispensable in environments where air movement is crucial.

Advantages of Axial Fans

The primary advantages of axial fans include their simplicity, cost-effectiveness, and ability to handle large volumes of air. They are relatively easy to install and maintain, and their straightforward design makes them adaptable to various settings. Axial fans also operate quietly, making them suitable for environments where noise reduction is a priority.

How to Produce Axial Fans?

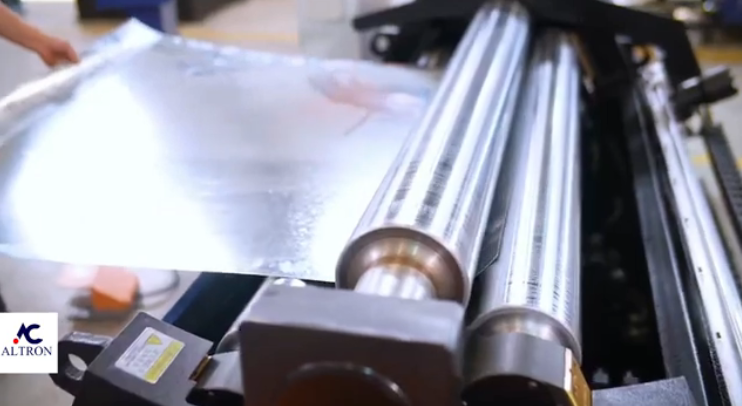

Axial Flow Fan Rolling

The production of axial fans begins with the rolling process, which involves shaping materials into the cylindrical form required for the fan’s housing. This is achieved using advanced CNC rolling machines.

CNC Rolling Machine Key Features

Four-Roller Configuration: The machine features a four-roller setup, ensuring balanced and simultaneous rounding of materials. This configuration provides excellent uniformity and consistency in the rounding process.

Versatile Application: The CNC rolling machine can handle a wide range of materials, including metals, plastics, and composites, accommodating various thicknesses and shapes to meet diverse production requirements.

Precision Control: Equipped with a digital control system, the machine allows precise adjustments in speed, pressure, and roller alignment, ensuring accurate rounding results.

Efficient and Time-Saving: High-speed operation and efficient roller movement significantly reduce production time and increase productivity.

User-Friendly Interface: The machine’s intuitive controls and clear display simplify operation and minimize the learning curve for operators.

Axial Fan Seam Welding

After rolling, the cylindrical components need to be welded to form a complete axial fan housing. This process utilizes a specialized lifting straight seam welding machine.

Lifting Straight Seam Welding Machine Features

Versatile and Efficient: Designed for welding straight seams in various metal components, the machine ensures high-quality welds with exceptional performance.

Adjustable Welding Height: The lifting mechanism allows easy adjustment of the welding height, accommodating different workpiece sizes and requirements.

Precision and Stability: The machine executes the welding process with precision and stability, resulting in uniform and reliable welds.

User-Friendly Control System: Operators can easily adjust welding speed, voltage, and current to achieve optimal weld quality for different materials and thicknesses.

Robust and Durable Structure: The machine is built to withstand heavy workloads and provide long-lasting performance, incorporating safety features like automatic overload protection and emergency stop functions.

Axial Fan Flanging & Punching

The final step in producing axial fan housings involves flanging and punching, performed by a CNC flanging machine like the ACFB-1605.

CNC Flanging Machine ACFB-1605 Key Features

CNC Control System: The advanced CNC control system ensures precise control over the flanging process, with an easy-to-use interface for programming and adjusting parameters.

Versatile Flanging Capabilities: The machine can handle straight flanging, curved flanging, and multi-angle flanging, suitable for various materials like steel, aluminum, and stainless steel.

High Precision and Stability: Engineered for outstanding precision, the ACFB-1605 maintains tight tolerances, ensuring consistent and uniform flange dimensions.

Efficient Production: Optimized design and advanced control system maximize production efficiency, offering fast cycle times and high-speed flanging capabilities.

Safety Features: Integrated safety measures, including emergency stop buttons, safety guards, and interlocks, ensure a secure working environment.

How to Improve the Quality of Axial Fans with CNC Flanging Machines?

Automated Production Line for Axial Flow Fans

The integration of automated production lines can significantly enhance the quality and efficiency of axial fan production. ALTRON offers cutting-edge solutions for this purpose.

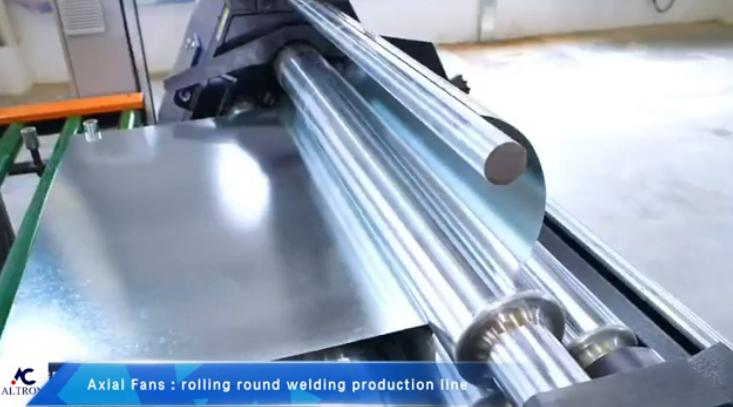

Rounding & Welding Auto Production Line for Industrial Exhaust Fan Cylinder Pipe

Rounding Process: Advanced rounding mechanisms precisely shape the cylinder pipe, ensuring accurate and uniform results.

Welding Capability: State-of-the-art welding technology seamlessly joins the edges of the rounded pipes, creating strong and durable welds.

Automation and Efficiency: Fully automated operation minimizes manual labor, reduces production time, and increases overall efficiency.

Customization Options: The production line can be tailored to meet specific requirements, accommodating various pipe diameters, lengths, and materials.

Quality Control and Monitoring: Equipped with sensors and monitoring systems, the production line ensures precise control over the rounding and welding processes, maintaining superior quality.

Air Duct Automatic Rolling Production Line

Streamlined Manufacturing Process: Designed to produce air ducts for various applications, this automated production line ensures unmatched efficiency, precision, and reliability.

Applications:

HVAC Systems: Efficient production of air ducts for heating, ventilation, and air conditioning systems.

Industrial Ventilation: Ideal for manufacturing air ducts used in industrial ventilation systems.

Commercial Buildings: Suitable for air ducts in commercial buildings, such as offices, shopping malls, and hotels.

Residential Ventilation: Can manufacture air ducts for residential systems, including kitchen exhausts, bathroom fans, and whole-house ventilation.

Specialized Applications: Meets the specific requirements of cleanrooms, laboratories, hospitals, and data centers.

Which Solution is the Simplest and Most Efficient to Produce Axial Fans?

For those looking for the simplest and most efficient solution to produce axial fans, ALTRON’s comprehensive automated production lines stand out. These systems integrate advanced CNC machines and automated processes, ensuring high precision, efficiency, and consistency. By minimizing manual labor and incorporating state-of-the-art technology, ALTRON’s solutions streamline the production workflow, enhance quality control, and significantly boost productivity.

Who Provides Automated Machine Solutions for Axial Fans?

ALTRON: A Pioneer in Industrial Fan Automation

ALTRON AUTO is recognized as a trailblazer in the realm of industrial fan automation production line solutions. Established with a focus on research and development, ALTRON combines innovation with sustainable development to deliver cutting-edge machinery. Their facilities are strategically located in Jiangsu, Wuxi, and Guangdong Province, while the sales company operates out of Guangzhou, covering an area of over 12,000 square meters.

Comprehensive Solutions and Expertise

ALTRON’s team comprises core technicians and engineers dedicated to providing comprehensive customized solutions for metal forming. Their expertise spans metal spinning, stamping, stretching, cold forming, polishing, and automatic welding. This broad range of capabilities ensures that they can meet the diverse needs of axial fan production with high precision and efficiency.

Innovation-Driven Approach

At the heart of ALTRON’s success is its commitment to innovation. The company’s strong R&D, production, and sales teams continuously push the boundaries of technological advancement. This innovation-centric approach has led to leapfrog development, establishing a unique innovation culture that sets ALTRON apart from its competitors.

When to Buy Automated Machines to Produce Axial Fans?

Scaling Up Production

Investing in automated machines is crucial when scaling up production. Manual processes may suffice for small-scale operations, but as demand increases, automation becomes necessary to maintain consistency and meet deadlines. Automated machines enhance production speed, reduce labor costs, and ensure uniformity in the final products, making them indispensable for large-scale manufacturers.

Enhancing Product Quality

Quality is a critical factor in axial fan production. Automated machines provide precise control over manufacturing parameters, resulting in high-quality, reliable products. If a company aims to enhance the quality of its axial fans to meet stringent industry standards or specific customer requirements, transitioning to automated solutions is a strategic move.

Reducing Operational Costs

While the initial investment in automated machinery can be significant, the long-term benefits include reduced operational costs. Automation minimizes manual labor, decreases the likelihood of errors, and improves overall efficiency. Companies experiencing rising labor costs or frequent production errors should consider automated solutions to streamline operations and improve profitability.

Why Do You Need ALTRON’s Automated Machines and Solutions for Axial Fans?

Technological Innovation

ALTRON’s automated machines are at the forefront of technological innovation. Their CNC rolling machines, lifting straight seam welding machines, and CNC flanging machines are designed to deliver exceptional performance and precision. These machines incorporate advanced features like digital control systems, user-friendly interfaces, and robust safety measures, ensuring optimal results and operator safety.

Comprehensive Customer Support

ALTRON’s commitment to customer satisfaction is evident in its comprehensive support services. From the initial consultation to after-sales support, ALTRON provides turnkey projects tailored to each customer’s specific needs. Their technical team assists with installation, training, and maintenance, ensuring that clients get the most out of their investment.

Sustainable Development

ALTRON places a strong emphasis on sustainable development. Their production processes and machines are designed to minimize environmental impact, aligning with global sustainability goals. Companies looking to adopt greener manufacturing practices will find ALTRON’s solutions conducive to their sustainability objectives.

Contact Information

For more information on ALTRON’s automated machines and solutions for axial fans, visit their contact page at ALTRON Contact: https://www.auto-altron.com/contact.

Conclusion

In conclusion, the production of axial fans involves several critical steps, each requiring precision and efficiency. Advanced CNC machines, automated production lines, and ALTRON’s innovative solutions ensure the highest quality and performance of axial fans, meeting the demands of various industrial and commercial applications.