Custom Axial Fan Flanging? Look ALTRON’s Solutions

Axial fan flanging is a crucial component in ensuring the optimal performance and efficiency of industrial fans. ALTRON, a leading manufacturer in the industry, has been addressing the needs of axial fan flanging with its innovative solutions. This blog will explore the significance of axial fan flanging, as well as its challenges and how ALTRON’s solutions are revolutionizing the industry.

Understanding Axial Fan Flanging

Axial fans are widely used in various industrial applications to control temperature, improve air circulation, and ensure a comfortable environment. The performance of these fans depends significantly on the precision of their components, including the fan blades and flanges. Axial fan flanging refers to the process of joining the blades and the flange of the fan with exceptional precision, ensuring efficient airflow and minimal vibration.

The Status of Axial Fan Flanging Industry

The axial fan flanging industry is critical for several sectors, including HVAC, manufacturing, and agriculture. As demand for energy-efficient solutions and enhanced air quality continues to rise, the industry is under constant pressure to meet these evolving needs. The current status of axial fan flanging is characterized by the following:

- Increased Demand:With the growing emphasis on sustainability and energy efficiency, there is a rising demand for high-performance axial fans. Manufacturers need to ensure that the fan components are precisely fabricated and assembled to meet these requirements.

- Complex Fan Designs:Modern axial fan designs have become more intricate, with optimized blade shapes and aerodynamics. Flanging these advanced designs necessitates more sophisticated equipment and processes.

- Quality Control: Maintaining quality control in the production of axial fans is paramount. Any variation in the flanging process can lead to inefficiencies and increased operating costs.

Challenges in Axial Fan Flanging

Despite the growing demand and importance of axial fan flanging, the industry faces several challenges that need to be addressed:

- Precision and Consistency:Achieving precise and consistent flanging results is a complex task that relies heavily on skilled labor and the right equipment. Even minor deviations can lead to reduced fan performance.

- Operational Efficiency:Traditional flanging methods may not be efficient in terms of time and labor. As a result, manufacturers are always on the lookout for streamlined processes.

- Customization:The need for customized axial fans to fit unique applications further complicates the production process. Manufacturers must adapt to these specialized requirements while maintaining quality.

Trends in the Axial Fan Flanging Industry

To meet the evolving needs of various industries, the axial fan flanging sector is experiencing significant trends:

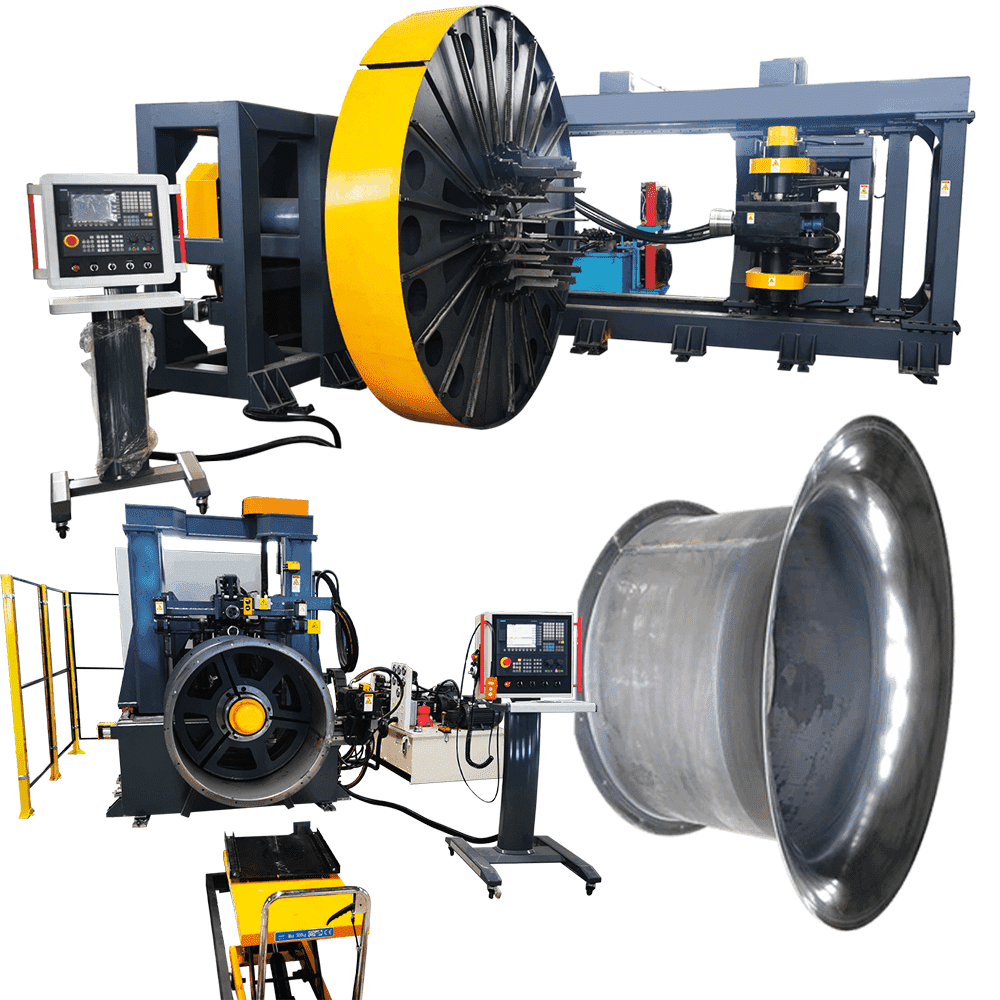

- Automation: The industry is shifting towards automated flanging solutions. These systems provide consistent results and improve operational efficiency by reducing the reliance on manual labor.

- Digitalization:Digital technologies are being integrated into the flanging process to monitor and control fan quality in real time. This enables manufacturers to make immediate adjustments and minimize defects.

- Energy Efficiency:Axial fans are at the forefront of energy-efficient solutions, and flanging technology is adapting to support these advancements by ensuring precise, efficient fan assembly.

Design Considerations for Optimal Axial Fan Flanging

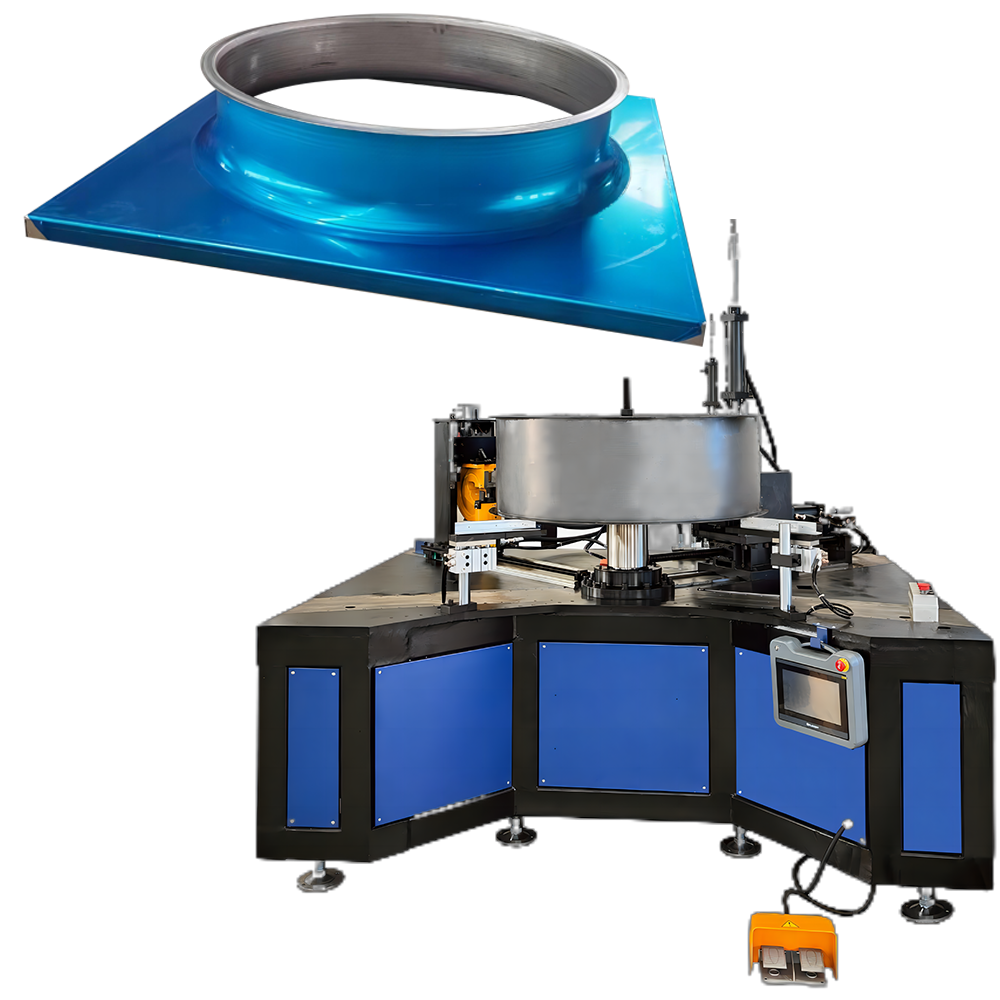

The design of axial fan flanges is not a one-size-fits-all endeavor. The choice of flange design depends on the specific application, fan size, and performance requirements. ALTRON, as a specialist in axial fan flanging machinery, understands the importance of tailoring flanges to meet these criteria. The key design considerations include:

- Flange Shape: The shape of the flange can significantly impact airflow and efficiency. Round flanges are common, but square and rectangular flanges may be used in specific applications. ALTRON’s flanging machines can create flanges of various shapes to accommodate diverse needs.

- Flange Size:The size of the flange should match the fan’s size and capacity. ALTRON’s machines offer precise control over flange dimensions, ensuring a perfect fit for each fan.

- Material Selection:Flange materials must be compatible with the fan and the environment it operates. Common materials include galvanized steel, aluminum, and stainless steel. ALTRON provides solutions for flanging a wide range of materials, ensuring durability and corrosion resistance.

- Flange Thickness:The thickness of the flange affects its strength and stability. ALTRON’s flanging machines allow for consistent and precise flange thickness, meeting the required specifications.

- Flange Seam Type:The type of seam in the flange is essential for sealing and preventing air leaks. ALTRON’s machines can create different seam types, such as Pittsburgh or Snap Lock, to meet the specific needs of the fan.

- Precision and Tolerances:Achieving precise measurements and tolerances is crucial for the optimal operation of axial fans. ALTRON’s machinery is designed to ensure high precision and accuracy in flange production.

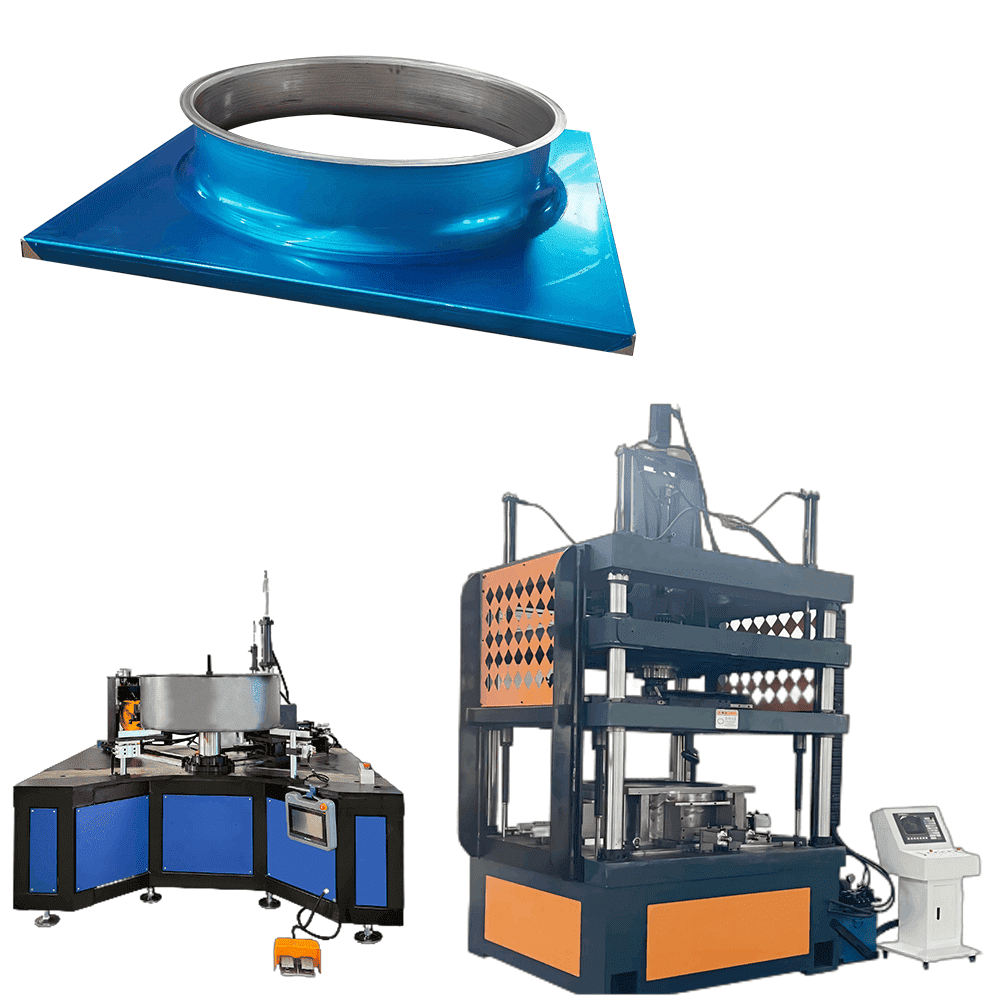

ALTRON’s Solutions for Axial Fan Flanging

ALTRON, a leading axial fan flanging machine manufacturer, has recognized the industry’s status, needs, challenges, and trends, and is committed to addressing them through innovative solutions. ALTRON’s Solutions encompass cutting-edge technology and advanced features to revolutionize the fan flanging process:

- Precision and Consistency:ALTRON’s automated flanging machines provide unmatched precision and consistency, ensuring that every fan meets the required standards. This eliminates the risk of human error and leads to improved fan performance.

- Operational Efficiency: ALTRON’s solutions are designed to optimize production processes. These machines reduce the need for manual labor, resulting in cost savings and faster production cycles.

- Customization:ALTRON offers flexible solutions that can adapt to different fan designs and sizes. This ensures that the unique needs of various industries and applications are met without compromising quality.

- Digital Integration:ALTRON’s machines come with digital controls and monitoring systems, allowing real-time quality assessment and immediate adjustments, which further enhance the quality of axial fan flanging.

- Energy Efficiency: ALTRON is dedicated to supporting the trend of energy efficiency by providing equipment that enables the precise assembly of energy-efficient axial fans.

ALTRON’s commitment to innovation and industry expertise makes it a trusted partner for companies looking to enhance their axial fan manufacturing processes.

Conclusion

The axial fan flanging industry is undergoing significant changes driven by increasing demand for energy-efficient solutions and improved air quality. ALTRON, as a prominent player in this field, offers innovative solutions to address the challenges and trends that define this industry. Their advanced flanging machines not only ensure precision and consistency but also enhance operational efficiency, customization, and energy efficiency. ALTRON’s dedication to the industry’s evolving needs makes them a leading choice for companies looking to excel in the production of high-performance axial fans.