Axial Fan Manufacturing Machine Services(Thailand & Indonesia)

In 2025, as the market demand for industrial axial fans continues to rise! The production efficiency of the original manual production and semi-automatic machines can no longer meet the needs of production and manufacturing!

Altron specializes in industrial fan metal forming and automated welding! Custom-Built Machinery Turnkey Solutions For Industrial Fan | Engineered & Manufactured In-House Till Floor Implementation!

Altron Service Project

I have completed machine installation training and technical support for multiple industrial fan manufacturers, including Kruger and its subsidiary Ferrari, in Thailand and Indonesia! Altron upholds technology and service above all else! Help customers achieve technological breakthroughs and improve both production and quality!

- The internal spinning of EC fan panels significantly reduces the cost of expensive hydraulic deep drawing molds and the time cycle for new product development!

- Automated production machine configuration for axial flow ventilation fans! Equip the existing warehouse and sales company with independent production capabilities!

- The significant efficiency improvement of axial flow fans! Upgrade the old machine! Increase production by 2-4 times! More stable quality!

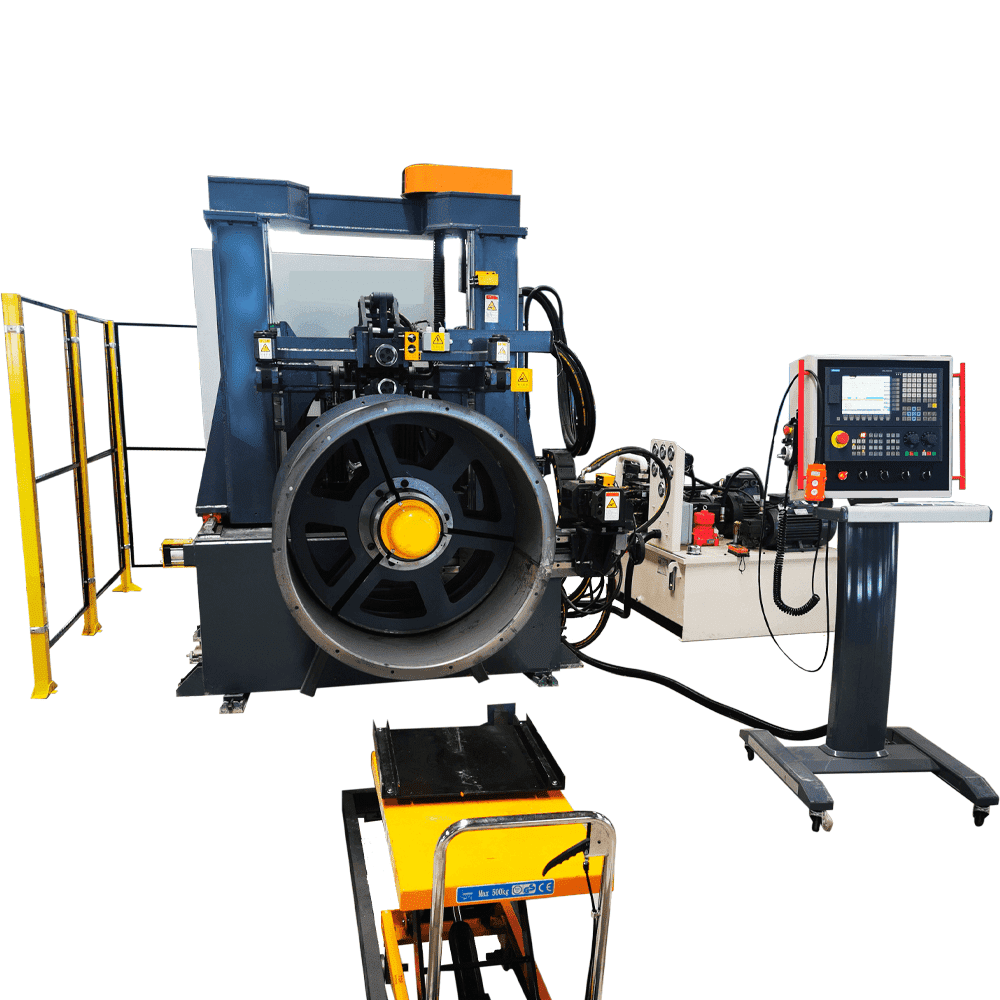

CNC Metal Internal Spinning Machine

The CNC internal spinning machine mainly solves the overall forming of rectangular metal panels, and can spin process single hole or porous EC fan panels, or metal panels for air conditioning refrigeration equipment!

Its original job was to fix rectangular plates in the internal spinning mold, fix the material with a mechanical pressing plate, and rotate the metal spinning wheel at high speed and perform multiple spinning and stretching according to the Siemens CNC system program, which is the opposite of the working principle of ordinary spinning!

By optimizing the spinning technology and process, the thinning rate has been significantly reduced! The thinnest position of the 2mm raw material after spinning is about 1.7mm (spinning height 230mm), with a thinning rate of 85%!

This machine has received deep praise from Kruger Industrial Fans! Currently, S&P is also in talks for a new internal rotation solution!

Ferrari Has A New Factory In Indonesia!

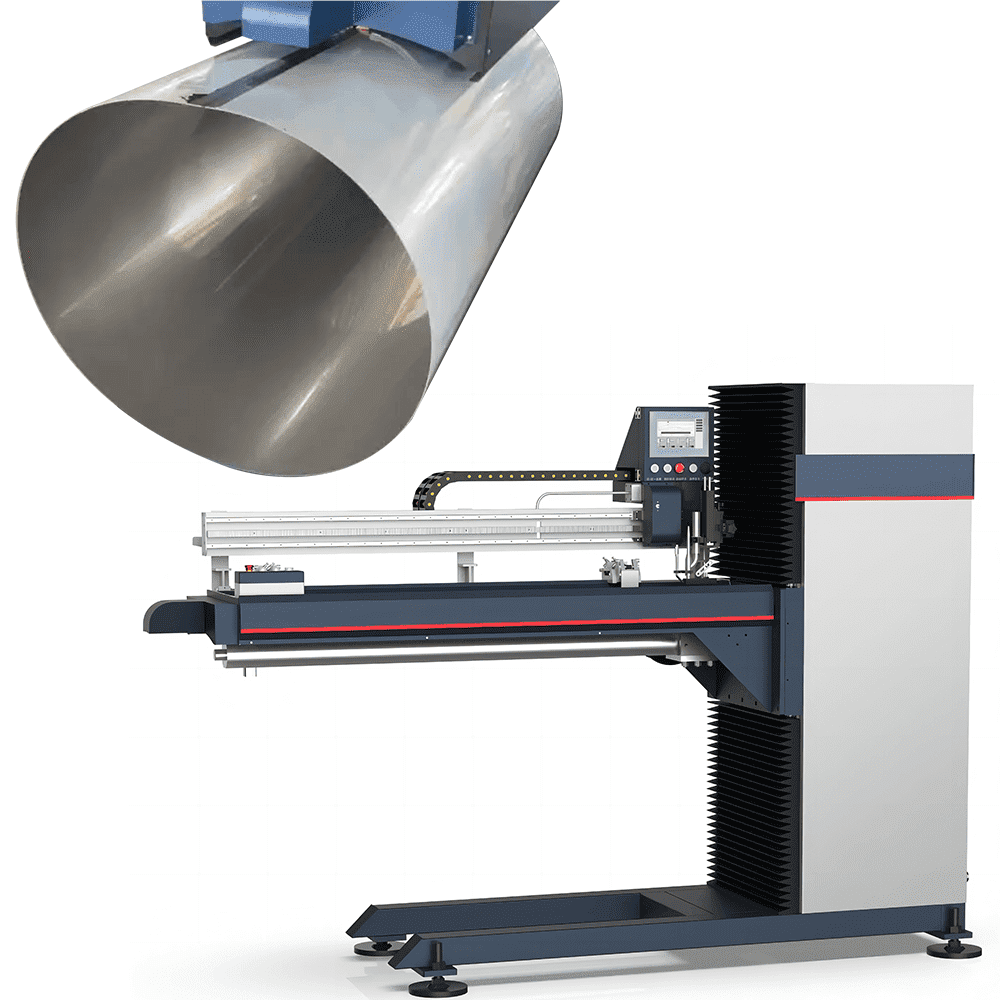

Ferrari is a product production line of Kruger in Indonesia! The brand new factory has invested three machines for ventilation fans, including CNC hydraulic coiling machines, seam welding (gas shielded welding), and multi-functional PLC controlled flanging punching machines!

This axial flow ventilation fan is a new product design from Kruger!Altron provides Ferrari with partially automated rounding and welding of air ducts, with small horn mouth flanging!

Semi automatic production mode composed of individual machines! By working with a small number of ordinary workers, stable welding and automated metal forming production can be achieved! Suitable for the initial stage of industrial axial flow fan manufacturers!

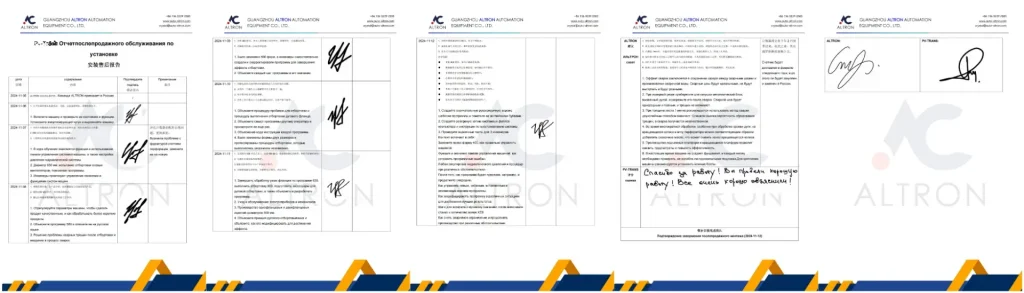

Altron’s Technical Services And Training For Fan Manufacturer

When the machine is transported to the factory, it will be planned according to the actual needs of different factories!

Altron engineers will arrange different training plans according to the production of different products, and customize training plans based on the actual situation of industrial fan manufacturers’ factories!

- The training schedule for each day will be completed the day before and communicated with the factory management in a timely manner!

- Customer engineers encounter problems! Altron will allow customers to independently solve problems while ensuring safety, allowing them to quickly resolve any future issues they may encounter!

- Continuously exposing problems! Continuously transmitting process technology and experience through the process of problem-solving! Let engineers quickly establish different experience accumulations!

- Throughout the entire training cycle, there is new content for training every day! Altron insists on having customer engineers take notes! Continuously deepen the ability to master new technologies!

- At the end of the day and starting from the next day, Altron’s technical manager will conduct small assessments and tests on the previous skills based on different situations to ensure that key technologies are not forgotten.

- On the last day of the project training, Altron will plan a complete assessment, which will be independently operated by factory engineers!

Mainly for factory inspection, the current engineers’ mastery of new equipment, responsible Altron completes the work for the manufacturer!

Altron hopes that every project as a whole will receive 100% customer recognition! And help the factory achieve profitability!

The Orders For Axial Fans Have Increased

In the current manufacturing industry, labor costs in factories are constantly rising! The era of relying mainly on technical workers for production has become a thing of the past!

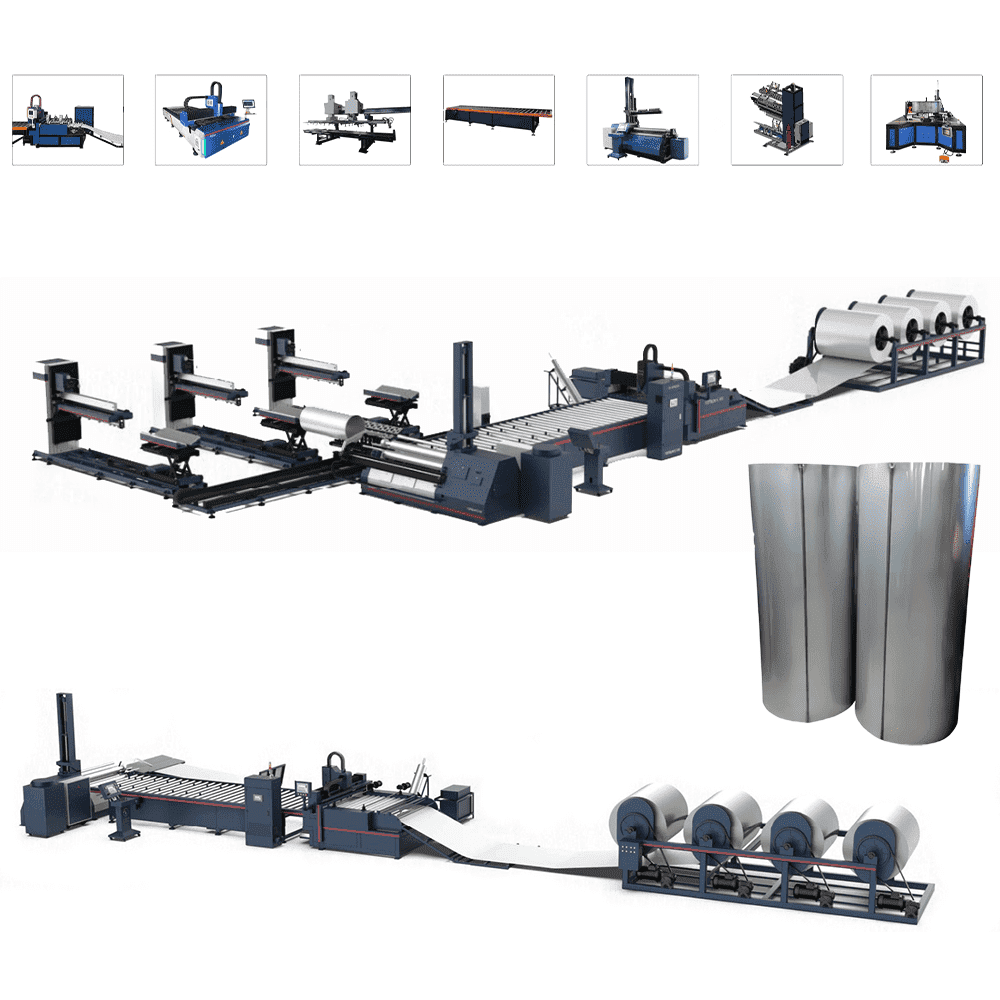

The stable production of machines is an inevitable trend in the future! Altron provides fully automated axial fan production lines and semi-automatic customized production solutions for axial fan manufacturers! Can meet the actual production needs of axial flow fans in different factories!

Altron provides comprehensive automation production solutions for different ventilation and industrial centrifugal, axial flow fans, etc! From blueprint to turnkey project plan!

Choosing Altron to help you complete the factory upgrade and construction of industrial fans is not just about closing orders! This is the beginning of long-term cooperation and technical support!

Let your factory provide product quality and gain recognition from the end market! This is the original intention and mission of Altron!