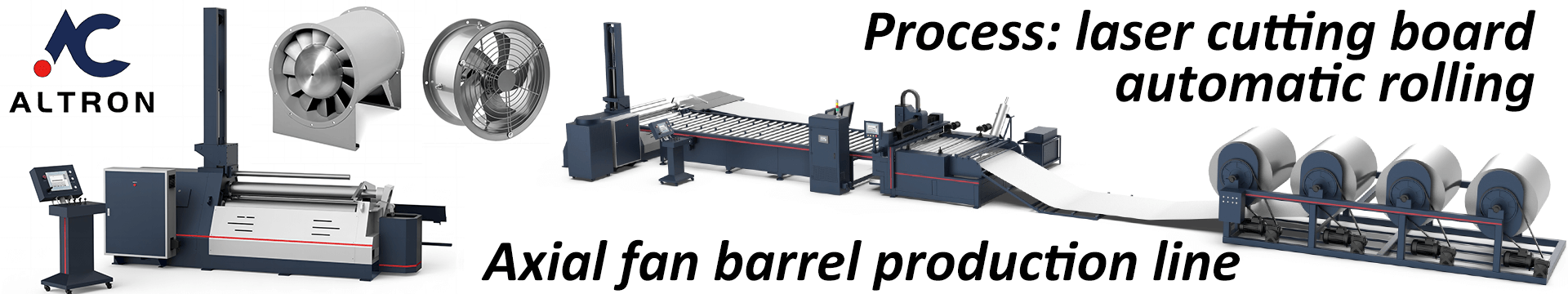

Axial Fan production line upgrade(Feeding, Rolling, Welding, Flanging)

Overview:

This is a customer site in Shandong, China. The customer needs to improve the automation level of the axial flow fan. The solution is to upgrade the customer’s original single machine to an axial flow fan production line. The main functions are: Feeding, Rolling, Welding, and Flanging.

Effect:

The human resources are greatly reduced, and the work of the original 8 people is reduced to 3 people. The processing rhythm can be adjusted to the ratio of rolling and straight seam welding to 1:2 (for example, rolling takes 1.5 minutes and welding takes three minutes). The plan needs to be configured One rolling machine and two welding equipment, so that the beat of each workpiece can ensure efficiency.

promote:

This is a video of the first continuous action test after the axial flow fan duct production line was upgraded. It is necessary to record the rhythm of different processes to meet the customer’s production capacity requirements.

Upgrading an Axial Fans Production Line for automated axial flow fans in a factory begins with investing in cutting-edge technology. This includes the incorporation of modern automation systems, the utilization of robotic equipment, and the implementation of advanced control systems. These technological enhancements undoubtedly contribute to enhancing production efficiency and maintaining consistent product quality.

In addition to technology, the skill level and adaptability of the workforce play a pivotal role in the successful upgrade of the production line. It is imperative to train employees comprehensively to ensure they are proficient in operating the newly acquired equipment, have a thorough understanding of the upgraded systems, and adhere to updated safety protocols. Continuous training and education programs should be put in place to keep the workforce up-to-date.

Strict quality control processes are equally vital during the upgrade process. Regular monitoring and testing of the equipment, along with thorough inspection protocols, are necessary to guarantee that the enhanced production line consistently yields high-quality axial flow fans.

In conclusion, upgrading production lines for automated axial flow fans necessitates a pragmatic and well-planned approach. By addressing these essential factors, manufacturers can enhance their competitive edge, elevate product quality, and meet the ever-evolving demands of the industry.