AXIAL FANS Rolling China: Efficient Airflow Solutions

Axial fans are indispensable components across various industries, providing essential airflow solutions for ventilation, cooling, and HVAC systems. These fans, known for their simple yet effective design, play a significant role in maintaining optimal conditions in diverse environments. Among the countries leading the charge in manufacturing and innovation within this field, China stands out prominently, showcasing its engineering prowess and manufacturing capabilities on a global scale.

Understanding AXIAL FANS Rolling China:

1.1 Definition and Basic Functioning:

Axial fans are mechanical devices designed to move air or gas parallel to the shaft around which the blades rotate. Unlike centrifugal fans that generate airflow perpendicular to the axis of rotation, axial fans propel air in the same direction as the fan’s axis. This straightforward mechanism allows for efficient airflow management in various applications.

1.2 Applications Across Industries:

The versatility of axial fans finds application in a multitude of industries. From maintaining proper ventilation in industrial settings to regulating temperature in HVAC systems and cooling electronic components, axial fans are integral to ensuring optimal working conditions. Their efficiency in moving large volumes of air with relatively low pressure makes them indispensable in environments where airflow is paramount.

1.3 Importance of Efficiency and Design:

Efficiency and design are paramount in axial fan technology. Improvements in blade design, motor efficiency, and overall aerodynamics directly impact the performance and energy consumption of axial fans. As industries continue to prioritize sustainability and energy efficiency, advancements in fan design play a crucial role in meeting these evolving demands.

China’s Engineering Powerhouse:

2.1 Emergence as a Global Manufacturing Hub:

China’s ascent as a global manufacturing powerhouse is undeniable. The country’s vast manufacturing infrastructure, skilled workforce, and conducive business environment have attracted multinational corporations and fueled its rapid industrial growth. This has positioned China at the forefront of various industries, including the production of axial fans.

2.2 Factors Contributing to Dominance:

Several factors contribute to China’s dominance in engineering and manufacturing. These include robust government support, investment in infrastructure, access to raw materials, and a large pool of skilled labor. Additionally, China’s emphasis on innovation and technological advancement has propelled its industries to international prominence, making it a preferred destination for manufacturing ventures.

2.3 Investment in Research and Development (R&D):

China’s commitment to research and development (R&D) is evident in its efforts to drive innovation across various sectors, including axial fan technology. Government initiatives, academic institutions, and private enterprises collaborate to advance research in aerodynamics, materials science, and manufacturing processes. This concerted investment fosters continuous improvement and enhances China’s competitiveness in the global market.

The Role of Rolling in Axial Fan Manufacturing:

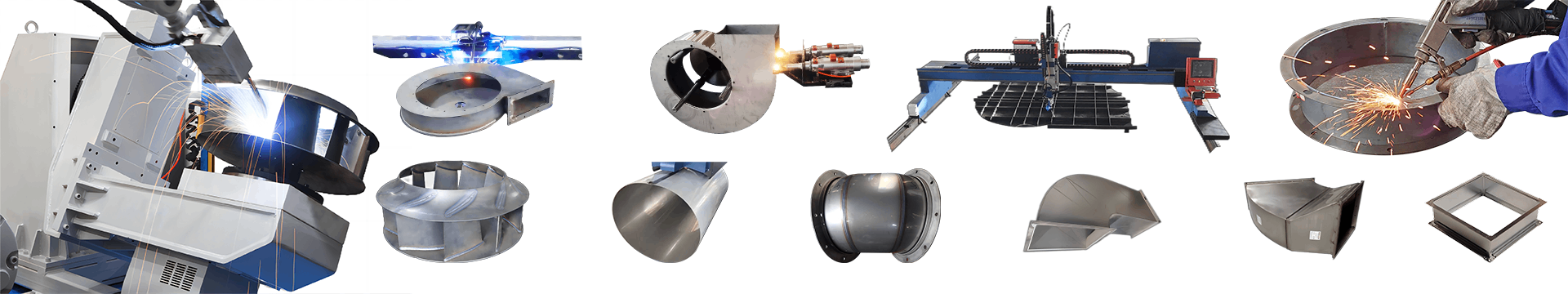

3.1 Explanation of the Rolling Process:

Rolling is a crucial manufacturing process employed in the production of axial fans. This method involves shaping metal sheets or strips into desired forms by passing them through a series of rollers. In axial fan manufacturing, rolling is utilized to fabricate fan blades, casings, and other components with precision and consistency.

3.2 Advantages of Rolling:

Rolling offers several advantages in axial fan manufacturing. Firstly, it enables the production of complex shapes with high dimensional accuracy, ensuring uniformity across multiple units. Additionally, the efficiency of the rolling process contributes to cost-effectiveness, as it reduces material waste and enhances productivity. Moreover, the mechanical properties of rolled components often surpass those produced by alternative methods, resulting in durable and reliable fan assemblies.

3.3 Comparison with Other Manufacturing Methods:

While rolling is a preferred method in axial fan manufacturing, other techniques such as stamping, forging, and machining also find application depending on the specific requirements of the application. Each method has its advantages and limitations concerning precision, production rate, and material utilization. However, the versatility and efficiency of rolling make it a preferred choice for producing intricate components essential for axial fan performance.

Axial Fan Manufacturing Hubs in China:

4.1 Overview of Key Regions:

China’s axial fan manufacturing industry is concentrated in several key regions known for their industrial prowess and logistical advantages. Coastal provinces such as Guangdong, Zhejiang, and Jiangsu are among the prominent hubs due to their proximity to major ports, facilitating efficient transportation of goods. Additionally, cities like Shanghai, Shenzhen, and Hangzhou serve as epicenters of technological innovation and manufacturing expertise, attracting a plethora of axial fan manufacturers.

4.2 Factors Influencing Manufacturing Location:

Several factors influence the choice of manufacturing location for axial fan producers in China. Access to skilled labor, availability of raw materials, infrastructure development, and proximity to target markets are primary considerations. Additionally, favorable government policies, tax incentives, and support for industrial clusters play a crucial role in attracting businesses to specific regions. Furthermore, the presence of established supply chains and collaborative ecosystems further enhances the appeal of certain manufacturing locations.

4.3 Case Studies of Successful Manufacturers:

Numerous successful axial fan manufacturers in China serve as exemplars of the industry’s capabilities. Companies like ALTRON have built reputations for excellence through a combination of innovative design, quality manufacturing, and customer-centric approaches. By leveraging advanced technologies and embracing sustainable practices, these manufacturers have garnered international recognition and secured partnerships with leading enterprises across various sectors. Their success underscores China’s position as a global leader in axial fan production.

Quality Control and Regulations:

5.1 Discussion on Quality Control Measures:

Quality control is paramount in China’s axial fan manufacturing industry to ensure product reliability, performance, and safety. Manufacturers implement stringent quality management systems encompassing raw material inspection, production processes, and final product testing. Advanced testing facilities and techniques are employed to validate performance metrics, including airflow, noise levels, and energy efficiency. By adhering to rigorous quality standards, manufacturers uphold their reputation for excellence and gain the trust of customers worldwide.

5.2 Overview of Regulations and Standards:

China’s axial fan industry operates within a regulatory framework governed by national and international standards. Key regulations such as the China Compulsory Certification (CCC) and industry-specific standards ensure compliance with safety and performance requirements. Additionally, international standards such as ISO 9001 for quality management and ISO 14001 for environmental management guide manufacturers in achieving operational excellence and sustainability. By aligning with these regulations and standards, companies demonstrate their commitment to delivering high-quality products and maintaining competitive advantages in global markets.

5.3 Importance of Compliance:

Compliance with quality control measures, regulations, and standards is imperative for China’s axial fan manufacturers to maintain global competitiveness and uphold customer trust. By consistently delivering products that meet or exceed industry benchmarks, manufacturers differentiate themselves in a crowded marketplace and forge long-term relationships with customers. Moreover, adherence to regulatory requirements enhances product safety and reliability, reducing the risk of liabilities and recalls. As the industry evolves, continuous improvement in quality control practices and regulatory compliance remains essential for sustaining growth and fostering industry leadership.

Sustainability and Environmental Considerations:

6.1 Efforts to Reduce Environmental Impact:

In response to growing environmental concerns, the axial fan manufacturing industry in China has been actively implementing measures to reduce its ecological footprint. Manufacturers like ALTRON are investing in energy-efficient production processes, optimizing resource utilization, and minimizing waste generation. By adopting eco-friendly practices such as recycling and waste reduction initiatives, these companies aim to mitigate the environmental impact of their operations and contribute to a greener manufacturing ecosystem.

6.2 Adoption of Eco-Friendly Materials and Practices:

The shift towards sustainability in axial fan manufacturing involves the adoption of eco-friendly materials and manufacturing practices. Manufacturers are exploring alternatives to traditional materials, opting for recyclable and biodegradable options wherever feasible. Furthermore, eco-conscious production methods such as water-based coatings, solvent-free adhesives, and low-emission manufacturing processes are gaining traction, reducing environmental pollutants and minimizing carbon emissions. Through these initiatives, the industry is aligning with global sustainability goals and fostering responsible stewardship of natural resources.

6.3 Contribution to Energy Conservation and Sustainability Goals:

Axial fans play a significant role in energy conservation and sustainability efforts across various industries. By efficiently circulating air, optimizing ventilation, and enhancing thermal management systems, these fans contribute to reduced energy consumption and greenhouse gas emissions. In applications such as building HVAC systems, industrial processes, and electronic cooling, energy-efficient axial fans help minimize environmental impact while improving indoor air quality and comfort. As governments and industries worldwide prioritize sustainability, the demand for eco-friendly axial fan solutions continues to grow, driving innovation and market expansion.

Future Trends and Opportunities:

7.1 Predictions for Axial Fan Technology in China:

The future of axial fan technology in China is marked by continued innovation, driven by emerging trends and evolving market demands. Advancements in materials science, aerodynamics, and smart technologies will shape the next generation of axial fans, enhancing performance, reliability, and energy efficiency. Furthermore, the integration of Internet of Things (IoT) connectivity and artificial intelligence (AI) capabilities will enable intelligent fan control and predictive maintenance, optimizing operational efficiency and reducing downtime. As China remains at the forefront of technological innovation, the axial fan industry is poised for significant advancements in the years ahead.

7.2 Potential Areas for Growth and Innovation:

Several areas present opportunities for growth and innovation within the axial fan industry in China. Expansion into emerging markets such as renewable energy, electric vehicles, and data centers offers new avenues for fan application and development. Additionally, the demand for high-performance, miniature axial fans for portable electronics and medical devices is expected to rise, driven by advancements in miniaturization and IoT connectivity. Moreover, the increasing focus on indoor air quality and thermal comfort in residential and commercial buildings creates opportunities for innovative ventilation solutions tailored to modern living environments. By anticipating market trends and consumer needs, manufacturers can position themselves for success in these burgeoning sectors.

7.3 Opportunities for Collaboration and Partnerships:

Collaboration and partnerships present valuable opportunities for Chinese axial fan manufacturers to expand their global presence and leverage complementary expertise. Strategic alliances with research institutions, technology providers, and industry stakeholders facilitate knowledge exchange, accelerate innovation, and enhance market penetration. Moreover, collaborations with international companies enable access to new markets, technologies, and distribution channels, fostering mutually beneficial relationships and driving collective growth. By embracing collaboration as a catalyst for innovation and market expansion, Chinese axial fan manufacturers can capitalize on emerging opportunities and maintain their position as leaders in the global airflow solutions market.

Conclusion:

Axial fans play a pivotal role in numerous industries, offering efficient airflow solutions vital for maintaining optimal conditions. China’s engineering prowess and manufacturing capabilities have positioned it as a leader in the production and innovation of axial fan technology. Through investment in research and development and the adoption of advanced manufacturing techniques like rolling, China continues to drive progress in this critical field, contributing to advancements in global airflow management and environmental sustainability. As the demand for energy-efficient solutions grows, the collaboration between industry stakeholders and technological innovators will further propel the evolution of axial fan technology, shaping the future of air movement and climate control worldwide.