What Makes CNC Flanging Machine the Preferred Choice for AXIAL FANS?

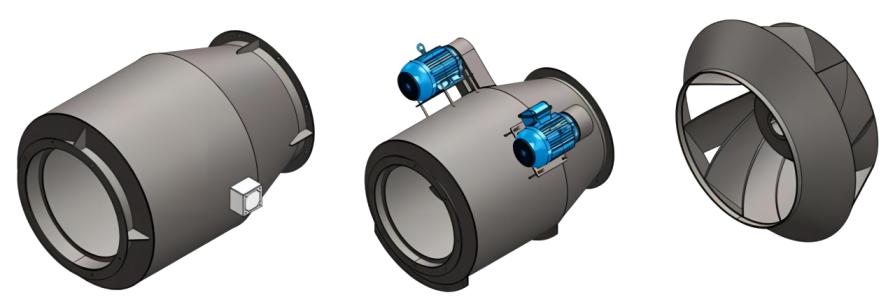

Axial fans, a crucial component in various industrial and commercial applications, have been a driving force behind efficient air circulation. These fans, characterized by their axial flow design, draw air parallel to the fan’s axis and propel it in the same direction. The straightforward mechanism of axial fans makes them ideal for cooling applications, ventilation systems, and air conditioning units.

Axial fans come in various shapes and sizes, catering to diverse needs across industries. Their efficiency and performance are paramount, and the manufacturing process plays a pivotal role in ensuring these qualities are met.

Understanding AXIAL FANS Manufacturing

Manufacturing axial fans involves intricate processes to achieve the desired performance standards. Among these processes, CNC (Computer Numerical Control) flanging machines have emerged as a game-changer in the production of axial fans.

CNC Flanging Machine: The Art Behind ALTRON’s Precision

ALTRON, a leading manufacturer in the realm of axial fans, has embraced CNC flanging machines to elevate the precision and efficiency of their manufacturing process. These machines operate with exceptional accuracy and reliability, ensuring each axial fan meets the stringent quality standards set by the industry.

The CNC flanging machine employed by ALTRON operates through computer-controlled processes, where intricate designs and patterns are executed with unparalleled precision. This technology has significantly reduced the margin of error in manufacturing, leading to a consistent and high-quality output.

The Working Mechanism of CNC Flanging Machines for AXIAL FANS

CNC flanging machines revolutionize the manufacturing process by automating the flanging, bending, and shaping of the axial fan components. These machines interpret digital designs and execute them with meticulous attention to detail. The precision achieved through CNC technology ensures uniformity in the production of each axial fan, contributing to enhanced performance and reliability.

The process begins with the input of a digital design into the CNC system. The machine, guided by the programmed instructions, precisely flanges the edges of the fan blades and housing. This intricate shaping is critical for optimizing aerodynamics and maximizing the efficiency of the axial fan.

Key Features of ALTRON’s CNC Flanging Machine for Axial Fan Production

1. Unmatched Precision

ALTRON’s CNC Flanging Machine stands out for its unparalleled precision. The machine is equipped with advanced sensors and control systems that ensure every bend and fold is executed with microscopic accuracy. This precision is crucial in the production of axial fans, where even the slightest deviation can impact performance.

2. Versatility in Material Processing

One of the standout features of ALTRON’s CNC Flanging Machine is its ability to process a wide range of materials. From aluminum to stainless steel, the machine can seamlessly handle different materials used in axial fan components. This versatility provides manufacturers with the flexibility to choose the best material for their specific application without compromising on the quality of the final product.

3. High-Speed Operation

Time is of the essence in the manufacturing world, and ALTRON’s CNC Flanging Machine understands this well. With a high-speed operation, the machine can rapidly process sheets and strips, significantly reducing the production time for axial fans. This efficiency not only boosts productivity but also ensures timely delivery of products to meet market demands.

4. User-Friendly Interface

While the technology behind CNC machines is complex, ALTRON has designed its CNC Flanging Machine with a user-friendly interface. The intuitive controls and programming interface make it easier for operators to set up the machine for different production runs. This user-centric design enhances the overall efficiency of the manufacturing process.

Material Mastery: What CNC Flanging Machines Can Process

1. Aluminum

ALTRON’s CNC Flanging Machine effortlessly handles aluminum, a popular choice for axial fan components due to its lightweight and corrosion-resistant properties. The machine ensures precise shaping and forming, producing components that meet the stringent quality standards required for industrial applications.

2. Stainless Steel

For applications where durability and resistance to corrosion are paramount, stainless steel is the material of choice. ALTRON’s CNC Flanging Machine excels in processing stainless steel, creating axial fan components that can withstand harsh environmental conditions without compromising on performance.

3. Galvanized Steel

Galvanized steel, coated with a layer of zinc for added protection against corrosion, is another material within the capabilities of ALTRON’s CNC Flanging Machine. This ensures that axial fans produced using this material maintain their structural integrity over an extended lifespan.

4. Mild Steel

Known for its versatility and cost-effectiveness, mild steel finds its application in various industries. ALTRON’s CNC Flanging Machine can efficiently process mild steel, providing manufacturers with an economical yet reliable option for axial fan production.

Elevating Efficiency: How CNC Flanging Machines Improve AXIAL FANS Manufacturing

1. Precision in Design Execution:

CNC flanging machines bring an unprecedented level of precision to the manufacturing process. The accuracy in executing intricate designs directly translates to enhanced aerodynamics and improved overall performance of axial fans.

2. Consistency Across Production:

The automated nature of CNC technology ensures that each axial fan produced is an exact replica of the approved design. This consistency is invaluable, especially in large-scale production, where maintaining uniformity is a constant challenge.

3. Reduced Turnaround Time:

Traditional manufacturing methods often involve time-consuming manual processes. CNC flanging machines, on the other hand, operate swiftly and efficiently, reducing the overall turnaround time for manufacturing axial fans.

4. Cost-Efficiency:

While the initial investment in CNC technology might be substantial, the long-term benefits in terms of reduced waste, increased efficiency, and consistent quality contribute to significant cost savings for manufacturers like ALTRON.

Advantages of CNC Flanging Machines in Axial Fan Production

1. Unprecedented Precision

The foremost advantage of utilizing a CNC Flanging Machine for axial fan production lies in its ability to deliver unparalleled precision. The machine operates under computer numerical control, executing programmed instructions with meticulous accuracy. This precision is paramount in the manufacturing of axial fans, ensuring that each component is shaped and formed to exact specifications, ultimately enhancing the fan’s overall performance.

2. Consistent Quality Across Different Materials

Axial fan components come in various materials, ranging from aluminum to stainless steel. ALTRON’s CNC Flanging Machine showcases a remarkable capability to handle this diversity. Whether it’s the lightweight yet durable aluminum or the corrosion-resistant stainless steel, the machine ensures consistent quality across different materials, giving manufacturers the flexibility to choose the best material for their specific application without compromising on the end product’s quality.

3. Increased Efficiency and Productivity

Time is a valuable commodity in the manufacturing world, and CNC Flanging Machines excel in optimizing it. ALTRON’s machine, in particular, operates at high speeds, significantly reducing production times for axial fans. This not only boosts efficiency but also enhances overall productivity, allowing manufacturers to meet market demands promptly.

Handling Diversity: Can a CNC Flanging Machine Accommodate Different Sizes and Shapes?

1. Tailored to Varied Dimensions

ALTRON’s CNC Flanging Machine is engineered to handle the diverse landscape of axial fan components. Whether it’s large or small, the machine accommodates different sizes with ease. This flexibility is crucial in catering to the varied requirements of industries where axial fans find applications, ensuring that manufacturers can produce fans of different dimensions without the need for extensive retooling or adjustments.

2. Shaping the Unconventional

Axial fan components often come in intricate and unconventional shapes to optimize airflow. ALTRON’s CNC Flanging Machine rises to the challenge by offering the capability to handle various shapes. The machine’s adaptability allows it to shape components according to the unique designs required for specific axial fan models, providing manufacturers with the freedom to innovate without compromising on efficiency.

The Art of Programming: How CNC Flanging Machines Are Programmed for Axial Fan Manufacturing

1. Digital Precision: Programming the Machine

Programming a CNC Flanging Machine for axial fan manufacturing involves a digital dance of precision. Skilled operators input detailed instructions into the machine’s computerized system, specifying the dimensions, angles, and shapes required for each component. This programming step is crucial, as it dictates how the machine will manipulate the raw material to produce the desired axial fan components.

2. CAD/CAM Integration

In many modern CNC Flanging Machines, programming is facilitated through Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) integration. CAD allows designers to create detailed digital models of the axial fan components, while CAM translates these models into machine-readable code. This seamless integration ensures that the programmed instructions accurately reflect the intended design, minimizing the risk of errors during production.

3. Iterative Refinement

Programming for CNC Flanging Machines often involves an iterative refinement process. Skilled operators review and test the initial programs, making adjustments as needed to achieve the desired precision and quality. This iterative approach ensures that the CNC Flanging Machine consistently produces axial fan components that meet the exact specifications laid out in the programming phase.

The Fierce Competition in AXIAL FANS Manufacturing

As the demand for axial fans continues to grow, the competition among manufacturers intensifies. The incorporation of advanced technologies, such as CNC flanging machines, has become a distinguishing factor in this competitive landscape.

Manufacturers not leveraging the advantages of CNC technology risk falling behind in terms of both quality and efficiency. ALTRON’s strategic adoption of CNC flanging machines has positioned them at the forefront of the industry, setting a standard for others to follow.

In the race to produce high-performance axial fans, the integration of cutting-edge technologies is not merely an option but a necessity. The competition is not just about the final product but also about the innovation and precision involved in the manufacturing process.

In Conclusion

CNC flanging machines have emerged as a cornerstone in the manufacturing of axial fans, bringing unprecedented precision and efficiency to the production process. ALTRON’s strategic embrace of this technology exemplifies how innovation can be a driving force in staying ahead in the competitive landscape of axial fans manufacturing.

As industries continue to demand more reliable and efficient axial fans, the role of CNC flanging machines becomes increasingly pivotal. These technological marvels not only streamline production but also contribute to the evolution of axial fans, ensuring they remain at the forefront of air circulation technology.