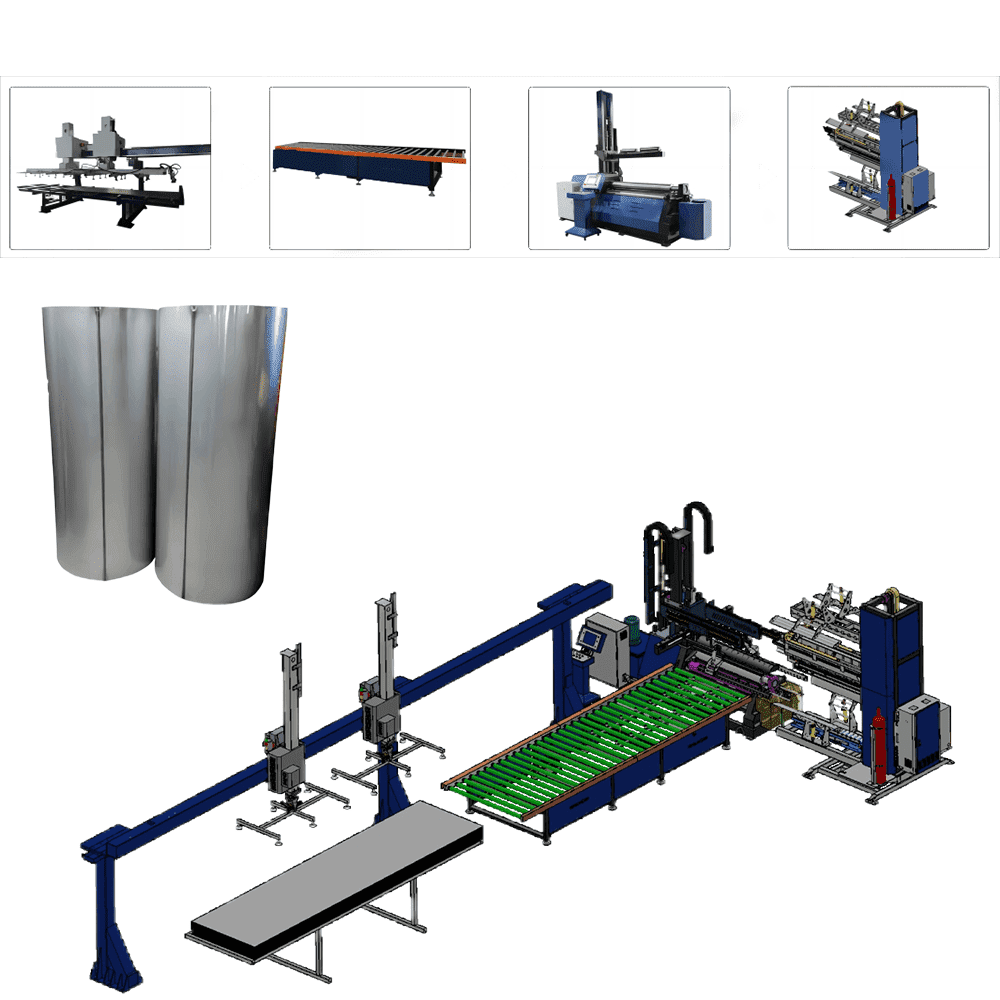

Centrifual Fan Production Line(Spinning, Flanging, Forming, Rolling, Welding)

Introduction to ALTRON’s Centrifugal Fan Production Line: Centrifugal fans are a critical component of various industrial and commercial systems, from HVAC to manufacturing processes. These fans are known for their efficiency and versatility. ALTRON, a leading manufacturer in the industry, has developed an advanced Centrifual Fan Production Line(Spinning, Flanging, Forming, Rolling, Welding,) that incorporates various processes, including Spinning, Flanging, Forming, Rolling, and Welding. In this blog, we will delve into these processes and how they help maximize both quality and output in centrifugal fan production.

ALTRON’s centrifugal fan production line exemplifies the importance of each step in creating high-quality fans. By mastering the spinning, flanging, forming, rolling, and welding processes, they have been able to produce fans that excel in performance, durability, and reliability. These tips and techniques can serve as valuable insights for manufacturers in the field, highlighting the significance of precision, quality control, and material selection. As ALTRON continues to innovate, its centrifugal fans are sure to remain at the forefront of the industry.

Spinning – Where It All Begins: Centrifual Fan Production Line(Spinning, Flanging, Forming, Rolling, Welding,)

Spinning is the initial step in the centrifugal fan production line. In this process, a flat metal sheet is transformed into a curved blade, which plays a critical role in the fan’s performance. ALTRON has mastered the art of spinning, and here are some essential tips for a successful spinning operation:

- Precision Tooling:ALTRON employs precision tooling to achieve the desired blade curvature. This ensures consistent and high-quality fan blades.

- Material Selection: Careful selection of materials is crucial. ALTRON uses a variety of materials, including stainless steel and aluminum, depending on the specific requirements of the fan.

- Quality Control:Regular quality checks throughout the spinning process are essential to ensure that the blades meet the necessary specifications.

Flanging – Shaping the Edges: Centrifual Fan Production Line(Spinning, Flanging, Forming, Rolling, Welding,)

Flanging is the next step in the production line, where the edges of the fan blades are shaped and reinforced. ALTRON’s expertise in flanging is evident in its centrifugal fan products. Here are some tips for achieving effective flanging:

- Consistent Flange Width: Maintaining a consistent flange width is essential to ensure the uniformity and structural integrity of the fan blades.

- Proper Alignment: Accurate alignment of the flanges is crucial for the final assembly of the fan. ALTRON uses advanced alignment systems to achieve this.

- Customization:ALTRON offers customization options for flange design to cater to specific customer requirements.

Forming – Bringing It All Together: Centrifual Fan Production Line(Spinning, Flanging, Forming, Rolling, Welding,)

The forming process involves shaping and curving the blades into the desired configuration. This step is critical in determining the fan’s performance. ALTRON’s approach to forming sets them apart in the industry. Here are some tips for a successful forming operation:

- CNC Technology:ALTRON employs Computer Numerical Control (CNC) technology for precise blade forming. This guarantees the desired shape and performance consistency.

- Airfoil Profile: Tailoring the airfoil profile to match the fan’s intended application is essential for optimizing efficiency and airflow.

- Quality Assurance: Rigorous quality checks at this stage ensure that the formed blades meet the specifications and quality standards.

Rolling – Enhancing Durability: Centrifual Fan Production Line(Spinning, Flanging, Forming, Rolling, Welding,)

Rolling is a crucial step in enhancing the structural integrity and durability of centrifugal fan blades. ALTRON employs advanced rolling techniques to ensure its fans can withstand demanding conditions. Here are some rolling tips:

- Uniform Thickness:Maintaining a uniform thickness across the fan blades is essential to ensure structural integrity and balance.

- Material Compatibility:Selecting materials with the right properties is vital to achieve the desired rolling results. ALTRON considers factors such as ductility and hardness.

- Heat Treatment: Appropriate heat treatment can further enhance the durability and resilience of the fan blades, making them suitable for various industrial applications.

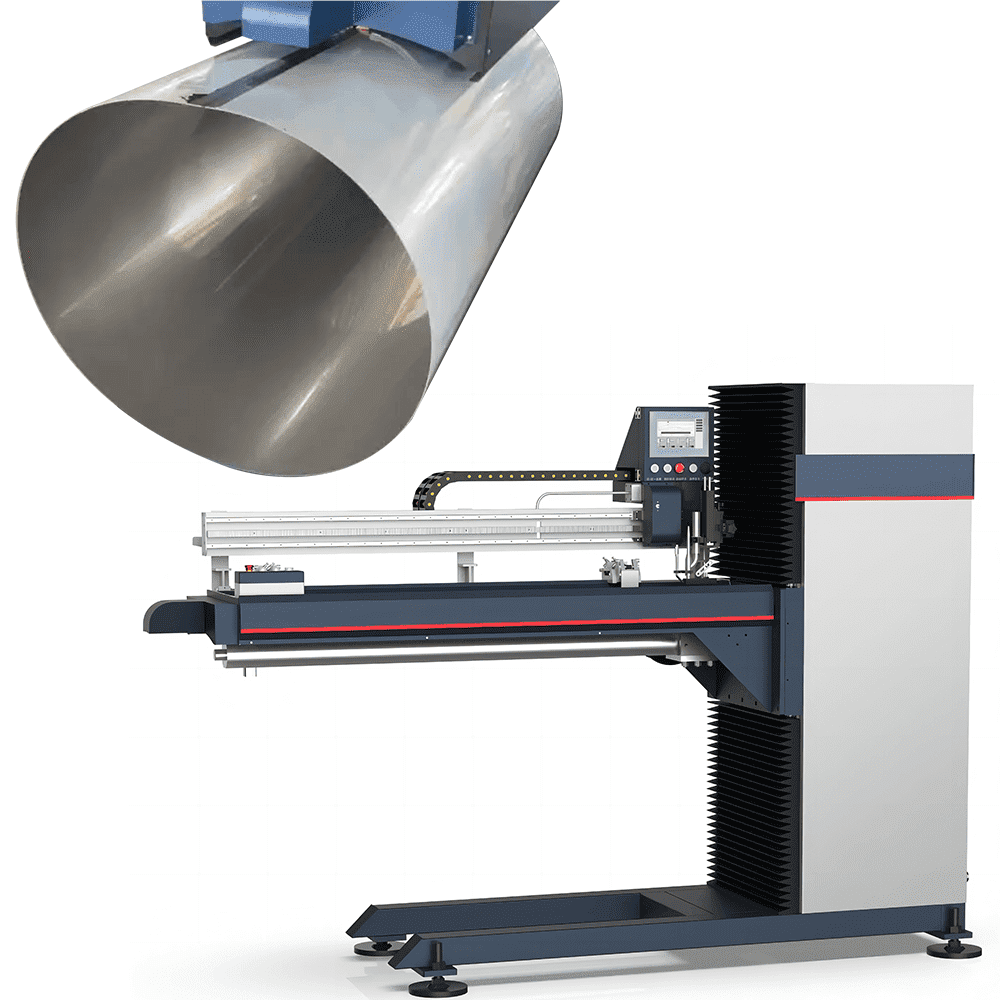

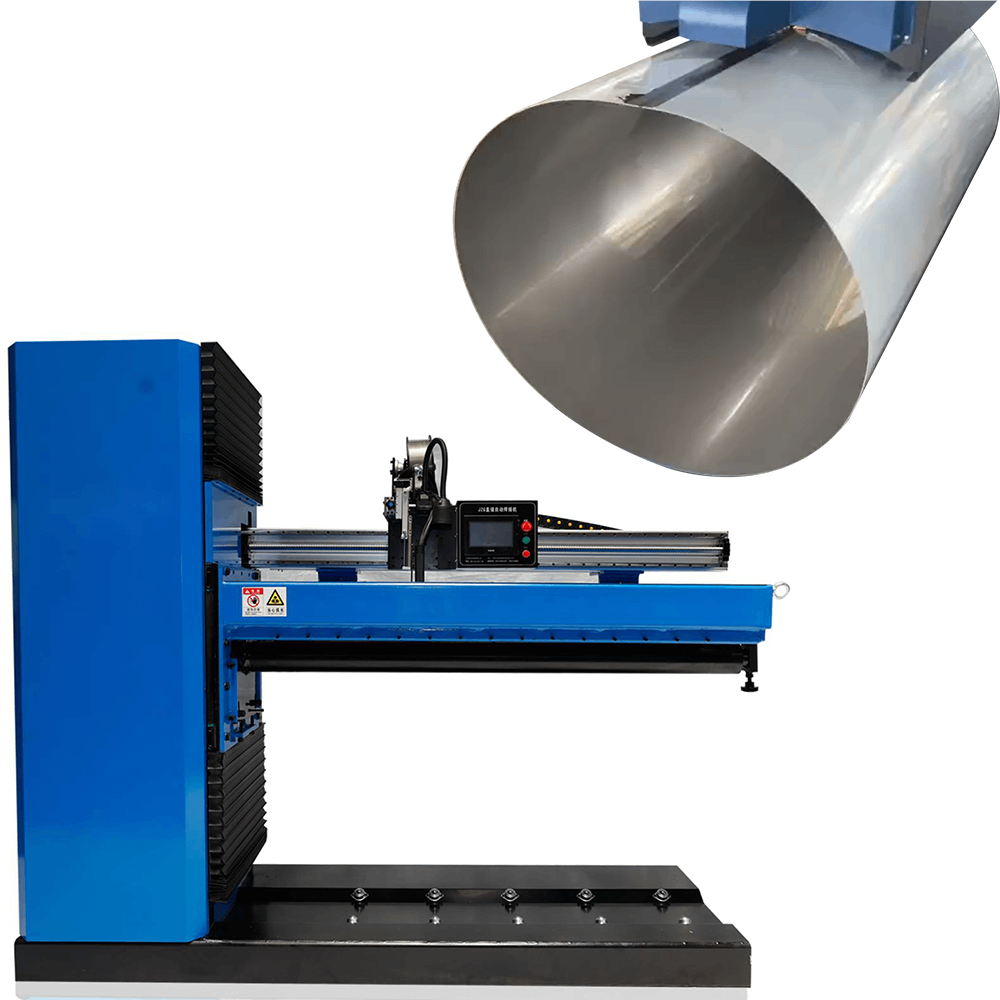

Welding Wonders – Ensuring Strength and Reliability: Centrifual Fan Production Line(Spinning, Flanging, Forming, Rolling, Welding,)

The final step in the Centrifual Fan Production Line(Spinning, Flanging, Forming, Rolling, Welding,) is welding, which is responsible for joining the fan components together. ALTRON’s expertise in welding techniques ensures the strength and reliability of its fans. Here are some welding tips:

- Welding Methods:ALTRON employs various welding methods, such as TIG (Tungsten Inert Gas) and MIG (Metal Inert Gas) welding, depending on the material and application. The choice of method can significantly impact the quality of the weld.

- Quality Control: Stringent quality control measures are taken to inspect and test the welds, ensuring that they meet the required standards for strength and integrity.

- Avoiding Distortion: Minimizing distortion during the welding process is crucial to maintaining the fan’s balance and performance.

Centrifugal Fan Production Line Innovations: Forming the Future

1. Cutting-Edge Technology and Precision: Centrifual Fan Production Line(Spinning, Flanging, Forming, Rolling, Welding,)

ALTRON’s centrifugal fan production line is driven by cutting-edge technology and a commitment to precision. Each step in the production process is carefully designed to ensure that the final product meets the highest quality standards. The integration of state-of-the-art machinery and skilled craftsmanship is at the core of ALTRON’s success in the industry.

2. Quality Assurance and Compliance: Centrifual Fan Production Line(Spinning, Flanging, Forming, Rolling, Welding,)

Quality is paramount in centrifugal fan production, especially for applications where performance and safety are critical. ALTRON’s production line incorporates rigorous quality control processes to ensure that each fan meets or exceeds industry standards. These measures encompass material testing, dimension verification, and performance testing to guarantee the reliability of the final product.

3. Customization Options: Centrifual Fan Production Line(Spinning, Flanging, Forming, Rolling, Welding,)

ALTRON understands that each customer’s needs may vary, and their centrifugal fan requirements are unique. To address this, the production line is adaptable and allows for customization. Whether it’s altering the size, materials, or other specifications, ALTRON’s production line can cater to a wide range of customer demands.

4. Environmental Responsibility: Centrifual Fan Production Line(Spinning, Flanging, Forming, Rolling, Welding,)

In today’s environmentally conscious world, ALTRON is committed to minimizing its environmental footprint. The centrifugal fan production line adheres to environmentally friendly practices, reducing waste and energy consumption. By choosing ALTRON’s centrifugal fans, customers can be assured of a product that aligns with their sustainability goals.

Conclusion

ALTRON’s Centrifual Fan Production Line(Spinning, Flanging, Forming, Rolling, Welding,) stands out as a beacon of innovation and quality in the industry. With Spinning, Flanging, Forming, Rolling, and Welding processes at its core, ALTRON manufactures high-performance centrifugal fans that find applications in various industries. The focus on precision, quality, and customization ensures that ALTRON’s fans are tailored to meet the specific needs of customers while also being environmentally responsible. When it comes to maximizing quality and output in centrifugal fan production, ALTRON is at the forefront, forming the future of the industry.