Decoding the Centrifugal Blower Fan Impeller: Innovation and Precision

Centrifugal blower fan impellers stand as essential components in various industrial and commercial applications, facilitating the efficient movement of air or gas within systems. These impellers, characterized by their dynamic design and construction, play a crucial role in enhancing airflow performance and system efficiency. In this article, we delve into the intricacies of centrifugal blower fan impellers, exploring their diverse applications and the precision manufacturing processes behind them, with a particular focus on ALTRO, a leading manufacturer in this field.

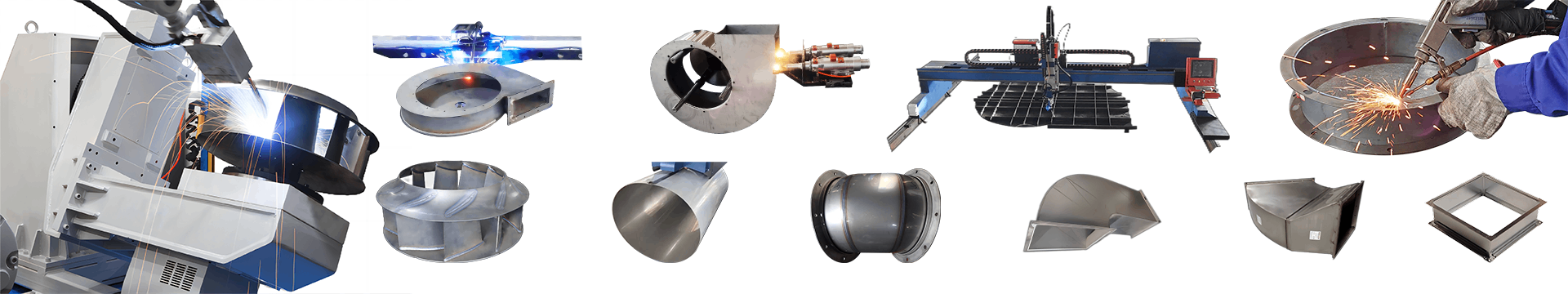

Advancing Technology in Aluminum Mixed Flow Fan Impeller Welding

1.1 Innovative Welding Techniques

The welding of aluminum mixed flow fan impellers represents a significant advancement in centrifugal fan technology. ALTRO employs state-of-the-art welding techniques to join aluminum components seamlessly, ensuring structural integrity and durability. By leveraging precision welding processes, ALTRO enhances impeller performance and longevity, meeting the demands of modern industrial applications with unparalleled reliability.

1.2 Enhancing Material Compatibility

Aluminum’s lightweight and corrosion-resistant properties make it an ideal choice for mixed flow fan impellers. ALTRO’s expertise in aluminum welding enables the fabrication of impellers that withstand harsh operating conditions while maintaining optimal performance. Through precise control of welding parameters and material selection, ALTRO delivers impellers that excel in efficiency, durability, and environmental resilience.

1.3 Sustainable Manufacturing Practices

In addition to performance considerations, ALTRO prioritizes sustainability in aluminum impeller welding. By optimizing energy consumption and minimizing waste generation during the welding process, ALTRO reduces its environmental footprint while delivering high-quality, eco-friendly solutions to its customers. Through continuous innovation and adherence to sustainable practices, ALTRO sets the standard for responsible manufacturing in the centrifugal fan industry.

Precision Forming of Galvanized Sheet Metal Centrifugal Fan Volute

2.1 Crafting Volute Components

The volute, or casing, of a centrifugal fan plays a crucial role in directing airflow and maximizing efficiency. ALTRO employs precision forming techniques to shape galvanized sheet metal into intricate volute components that exhibit exceptional dimensional accuracy and structural integrity. Through advanced forming processes, ALTRO ensures seamless integration of volutes with impellers, optimizing airflow performance and system efficiency.

2.2 Galvanized Sheet Metal Advantages

Galvanized sheet metal offers numerous advantages in volute fabrication, including corrosion resistance, durability, and ease of forming. ALTRO leverages these properties to produce volutes that withstand the rigors of industrial environments while maintaining their functionality and appearance over extended periods. By incorporating galvanized sheet metal into volute manufacturing, ALTRO enhances product reliability and customer satisfaction.

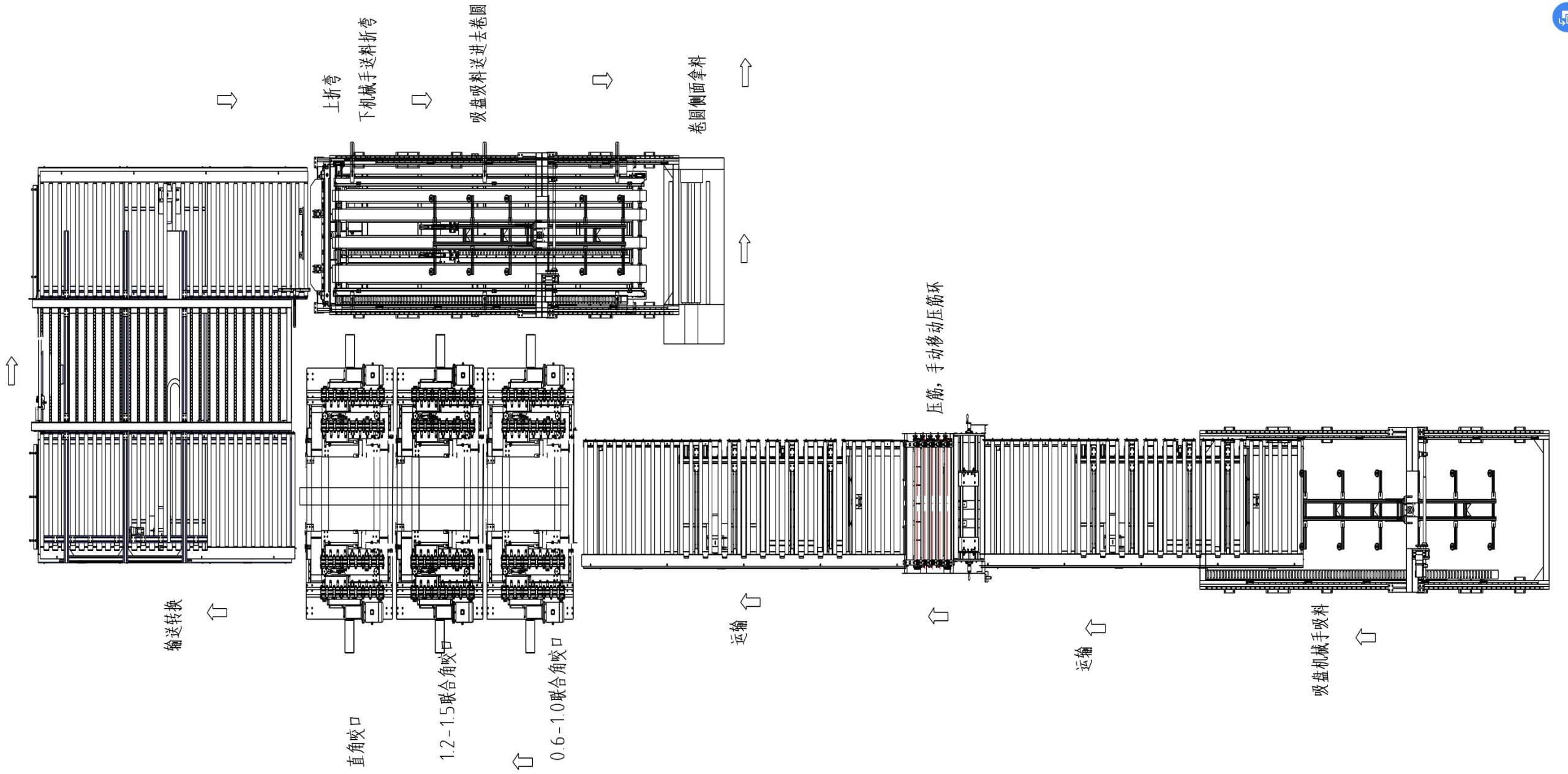

2.3 Streamlined Production Lines

ALTRO’s centrifugal fan volute forming line represents the epitome of efficiency and precision in manufacturing. Through the integration of automated machinery and advanced production techniques, ALTRO achieves unparalleled consistency and quality in volute production. By streamlining production lines and optimizing workflow, ALTRO reduces lead times and enhances customer responsiveness, positioning itself as a leader in centrifugal fan component manufacturing.

Engineering Excellence in Centrifugal Fan Housing Forming

3.1 Optimizing Housing Design

The housing of a centrifugal fan serves as the foundation for impeller operation, providing structural support and facilitating airflow management. ALTRO’s engineering team employs advanced design principles to create housing configurations that maximize airflow efficiency while minimizing energy consumption and noise generation. Through computational modeling and iterative prototyping, ALTRO refines housing designs to meet the evolving needs of its customers and industries.

3.2 Advanced Forming Technologies

ALTRO’s centrifugal fan housing forming process combines precision engineering with advanced manufacturing technologies to produce housings of unparalleled quality and performance. By leveraging techniques such as roll forming, stamping, and CNC machining, ALTRO achieves precise dimensional tolerances and surface finishes, ensuring seamless integration with impellers and other system components. Through continuous investment in forming technologies, ALTRO remains at the forefront of centrifugal fan housing innovation.

3.3 Customization and Adaptability

ALTRO’s flexible manufacturing capabilities enable the production of custom centrifugal fan housings tailored to specific customer requirements and application scenarios. Whether it’s adapting housing dimensions to fit existing system constraints or incorporating specialized features for enhanced performance, ALTRO collaborates closely with customers to deliver solutions that meet their unique needs. By offering a diverse range of housing options and customization capabilities, ALTRO empowers customers to optimize their airflow systems for maximum efficiency and productivity.

Pioneering Carbon Steel Large Diameter Centrifugal Fan Impellers

4.1 Strength and Reliability in Carbon Steel

Carbon steel impellers offer exceptional strength and durability, making them well-suited for large diameter centrifugal fan applications. ALTRO’s expertise in carbon steel fabrication enables the production of impellers that withstand heavy-duty industrial environments while delivering reliable performance over extended operational lifespans. By employing high-quality materials and precision manufacturing techniques, ALTRO ensures that its carbon steel impellers meet the highest standards of quality and reliability.

4.2 Precision Machining and Balancing

ALTRO’s carbon steel impeller manufacturing process incorporates precision machining and dynamic balancing to achieve optimal performance and efficiency. Each impeller undergoes meticulous machining to achieve precise dimensional tolerances and surface finishes, ensuring compatibility with its designated application. Subsequent dynamic balancing procedures eliminate vibration and instability, enhancing impeller reliability and extending equipment life.

4.3 Versatility in Application

Carbon steel large diameter centrifugal fan impellers find application across a wide range of industries, including HVAC, industrial ventilation, and air pollution control. ALTRO’s comprehensive understanding of customer needs and industry requirements enables the design and production of impellers that excel in diverse operating environments. Whether it’s delivering high-volume airflow in industrial settings or maintaining precise airflow control in commercial buildings, ALTRO’s carbon steel impellers offer unmatched versatility and performance.

Crafting Precision: Multi-Blade Centrifugal Fan Impeller Sample

5.1 Design and Engineering Excellence

The creation of a multi-blade centrifugal fan impeller sample represents a pinnacle of design and engineering excellence. ALTRON’s team of experts meticulously designs each impeller, considering factors such as blade shape, angle, and curvature to optimize airflow performance. Through computational fluid dynamics (CFD) analysis and iterative prototyping, ALTRON refines impeller designs to achieve maximum efficiency and reliability in real-world applications.

5.2 Material Selection and Durability

In the manufacturing of multi-blade centrifugal fan impeller samples, ALTRON prioritizes material selection to ensure durability and longevity. By utilizing high-quality materials with superior mechanical properties, such as aerospace-grade aluminum alloys or stainless steel, ALTRON creates impellers capable of withstanding demanding operating conditions without compromising performance. Through rigorous testing and quality control measures, each impeller sample undergoes scrutiny to meet the highest standards of durability and reliability.

5.3 Precision Machining and Balancing

ALTRON’s commitment to precision extends to the machining and balancing of multi-blade centrifugal fan impeller samples. Advanced CNC machining techniques are employed to achieve tight tolerances and smooth surface finishes, ensuring optimal airflow performance and minimal energy consumption. Subsequent dynamic balancing procedures eliminate vibration and ensure impeller stability, guaranteeing smooth and efficient operation in every application.

Automating Precision: Multi-Blade Centrifugal Fan Automatic Blade Forming Machine

6.1 Revolutionizing Blade Forming Processes

The introduction of a multi-blade centrifugal fan automatic blade forming machine revolutionizes the manufacturing process, enhancing efficiency and precision. ALTRON’s state-of-the-art machinery utilizes advanced automation technology to form impeller blades with unparalleled accuracy and consistency. Through computer-controlled processes, each blade is precisely shaped to optimize airflow characteristics, resulting in impellers that deliver superior performance and energy efficiency.

6.2 Optimizing Production Efficiency

The automation of blade forming processes streamlines production workflows, allowing ALTRON to meet the growing demand for multi-blade centrifugal fan impellers with increased efficiency. By reducing manual labor and human error, automatic blade forming machines ensure uniformity and repeatability in impeller production, resulting in cost savings and shorter lead times for customers. ALTRON’s investment in automation technology underscores its commitment to delivering high-quality impellers while maintaining competitive pricing and market responsiveness.

6.3 Continuous Innovation and Advancement

ALTRON’s multi-blade centrifugal fan automatic blade forming machine represents a testament to continuous innovation and advancement in manufacturing technology. Through ongoing research and development efforts, ALTRON seeks to further enhance the capabilities of its automation systems, incorporating new features and functionalities to improve productivity and product quality. By staying at the forefront of technological innovation, ALTRON ensures that its impellers remain at the cutting edge of performance and efficiency in the centrifugal fan industry.

Precision in Production: Multi-Blade Centrifugal Fan Hub Stamping Line

7.1 Hub Stamping for Structural Integrity

The hub of a multi-blade centrifugal fan impeller is a critical component that provides structural integrity and support for the blades. ALTRON’s hub stamping line utilizes advanced stamping techniques and precision tooling to produce hubs of exceptional quality and dimensional accuracy. By stamping hubs from high-strength materials such as carbon steel or aluminum alloys, ALTRON ensures that impellers exhibit superior durability and reliability in demanding applications.

7.2 Ensuring Consistency and Quality

ALTRON’s hub stamping line is equipped with stringent quality control measures to ensure consistency and quality in every hub produced. Automated inspection systems monitor hub dimensions and tolerances, identifying any deviations from specifications and facilitating corrective action. By adhering to strict quality standards throughout the stamping process, ALTRON guarantees that each impeller hub meets the requirements of its intended application, providing customers with peace of mind and confidence in product performance.

7.3 Flexibility and Customization

Despite the high degree of automation in hub stamping, ALTRON remains flexible and responsive to customer needs, offering customization options to meet specific requirements. Whether it’s adjusting hub dimensions to accommodate unique system configurations or incorporating special features for enhanced performance, ALTRON collaborates closely with customers to deliver tailored solutions. By leveraging its expertise in hub stamping and manufacturing, ALTRON empowers customers to optimize their centrifugal fan systems for maximum efficiency and reliability.

Conclusion: Elevating Airflow Technology with ALTRO

Centrifugal blower fan impellers represent the cornerstone of modern airflow technology, driving efficiency, productivity, and environmental sustainability across diverse industries. Through innovation, precision engineering, and a commitment to excellence, ALTRO continues to push the boundaries of centrifugal fan technology, delivering solutions that exceed customer expectations and industry standards. As industries evolve and demand for efficient airflow solutions grows, ALTRO remains at the forefront of innovation, shaping the future of air movement and environmental control.