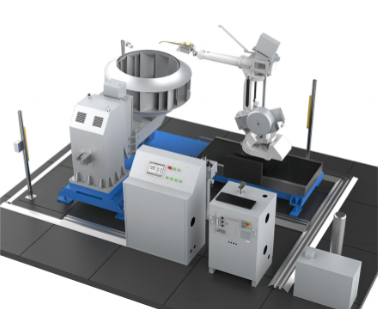

Factory Centrifugal Fan: Custom Solutions to Meet All Your Needs

Centrifugal fans, a crucial component in various industrial processes and HVAC systems, play a pivotal role in maintaining efficient airflow and ventilation. ALTRON, a renowned manufacturer in the field, presents this comprehensive guide to operating and maintaining centrifugal fans effectively. By understanding their operation and implementing proper maintenance practices, you can extend the lifespan of your equipment and ensure optimal performance.

The modern industrial landscape is an ever-evolving hub of productivity, where efficiency is the name of the game. Centrifugal fans lead the race among the machines and devices that are employed in various sectors, showcasing remarkable capabilities. From providing optimal indoor air quality to facilitating effective heat exchange, these powerful tools have found their way into numerous fields, each bringing its own contribution to amplifying operational efficiency. ALTRON, renowned for its innovations in this domain, has been producing top-tier centrifugal fans that meet the changing demands of industries across the globe.

Unveiling the Mechanism: How Centrifugal Fans Work

Centrifugal fans, often referred to as “squirrel cage fans,” are designed to generate high-pressure airflow. Unlike axial fans that move air parallel to the axis of rotation, centrifugal fans draw air into the center of the fan and then expel it at a perpendicular angle to the incoming air stream. This unique mechanism allows them to create a higher pressure differential, making them ideal for applications where increased air pressure is essential. From HVAC systems in commercial buildings to industrial ventilation and air pollution control, centrifugal fans find utility across various sectors.

Applications Across Industries: Where Centrifugal Fans Excel

1. HVAC Systems and Indoor Air Quality

Maintaining a comfortable indoor environment is paramount for productivity and well-being. Centrifugal fans play a crucial role in heating, ventilation, and air conditioning (HVAC) systems, ensuring optimal air circulation and temperature regulation. By efficiently moving air through filters, coils, and ducts, these fans contribute to enhanced indoor air quality, making them indispensable in both residential and commercial settings.

2. Industrial Ventilation and Exhaust

In industrial settings, proper ventilation is vital for maintaining a safe and healthy work environment. Centrifugal fans are employed to remove fumes, dust, and other airborne contaminants from manufacturing facilities, ensuring the well-being of workers and compliance with environmental regulations. Their ability to handle a wide range of airflows and pressures makes them suitable for diverse industrial applications.

3. Heat Exchange and Industrial Processes

Centrifugal fans are also integral to heat exchange processes, such as cooling and drying applications. Industries that involve thermal processing, such as metallurgy and food production, rely on these fans to facilitate efficient heat transfer. By maintaining consistent airflow over heat exchange surfaces, they enhance the overall efficiency of industrial processes.

Selecting the Right Centrifugal Fan: Factors to Consider

Selecting the right centrifugal fan for your application is crucial. Factors such as airflow requirements, static pressure, and temperature conditions should be considered. ALTRON offers a range of fan models designed for specific industrial needs, ensuring optimal performance and energy efficiency.

Choosing the appropriate centrifugal fan for a specific application involves careful consideration of various factors:

- Airflow Requirements:Determining the required airflow rate is essential in selecting the fan size and design that can effectively meet the demands of the system.

- Static Pressure:Different applications require different levels of static pressure. Centrifugal fans are available in various configurations to handle high-pressure and low-pressure systems.

- Efficiency and Energy Consumption:ALTRON’s fans are designed for optimal efficiency, contributing to reduced energy consumption and operational costs over the long term.

- Maintenance Needs:Centrifugal fans should be easy to maintain to minimize downtime. ALTRON’s fans often feature user-friendly designs that facilitate maintenance and cleaning.

Tips for Operating Centrifugal Fans:

Centrifugal fans, also known as radial fans, operate by converting kinetic energy into potential energy. As air enters the fan’s inlet, the impeller’s rotation accelerates the air outward, creating a high-velocity airstream. This kinetic energy is then transformed into static pressure, pushing the air through the system. It’s essential to grasp this basic principle to ensure proper operation.

1. Start-Up Procedures:

When starting a centrifugal fan, it’s vital to gradually increase the speed to avoid sudden load changes. This prevents mechanical stress on the fan and the connected system. Ensure that all safety interlocks and guards are in place before operation.

2. Monitoring and Control:

Continuous monitoring of fan performance is essential. ALTRON’s centrifugal fans often come equipped with advanced control systems that allow you to adjust speed, airflow, and other parameters. Regularly check for vibrations, unusual noises, and deviations from expected performance levels.

3. Avoid Operating at Extremes:

Operating a centrifugal fan at extremely high or low speeds can lead to inefficiencies and premature wear. Follow the manufacturer’s recommendations for optimal operating ranges, which can enhance energy efficiency and prolong the fan’s lifespan.

Centrifugal Fan Maintenance:

1. Regular Cleaning:

Dust, debris, and contaminants can accumulate on the fan blades and housing, reducing airflow efficiency. Regular cleaning using non-abrasive methods can prevent this buildup and maintain optimal fan performance.

2. Lubrication:

Proper lubrication of the fan’s bearings and moving parts is crucial to prevent friction-related issues. Consult the manufacturer’s guidelines for recommended lubricants and intervals. ALTRON’s centrifugal fans often feature self-lubricating systems for added convenience.

3. Belt and Drive Maintenance:

If your centrifugal fan operates using belts and pulleys, ensure proper tension and alignment. Over time, belts can wear out and lose tension, leading to reduced efficiency. Regularly inspect and replace worn belts to prevent downtime and maintain consistent performance.

Conclusion: Shaping Tomorrow’s Industries

ALTRON’s journey into the future of centrifugal fan technology is marked by a relentless pursuit of excellence. Through their collaboration with research institutions and industry partners, they are ushering in a new era of fan performance, reliability, and sustainability. The integration of smart features, advanced materials, and innovative aerodynamics not only showcases their dedication to pushing the boundaries but also reinforces their role as a driving force behind the industrial landscape’s transformation. As industries continue to evolve, ALTRON’s centrifugal fan innovations stand as a testament to the limitless possibilities that lie ahead.