Axial Flow Fans CNC Flanging Punching Machine ACFB-1604

CNC Axial Fans Flanging And punching

|

Machine Name |

CNC Flanging Punching Machines |

|

Model |

AC FB1604-1600MM |

|

Application Industry |

Axial Fan, Subway Fan, Tunnel Fan, Jet Fan |

|

Technical Service |

Complete the test in the early stage; provide online and offline training in the later stage, and complete the turnkey project. |

|

Technical Guidance |

Online 24 hours a day/ Conference To Solve Pre-Sales Problems. |

|

Project Progress |

30-120 days |

|

Relevant Files |

ALTRON_AUTO Catalog-Industrial Blower Machinery Turnkey Project |

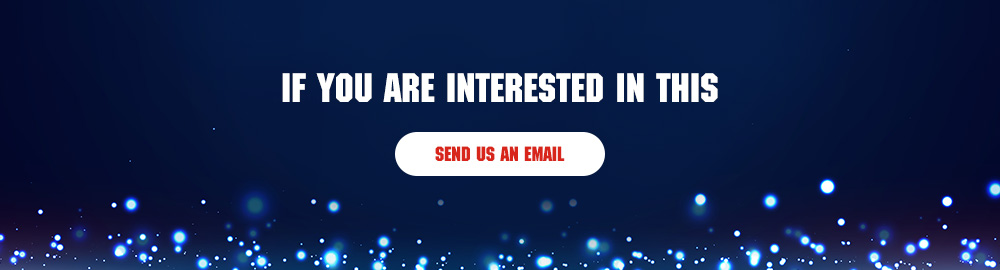

Industrial Fans A-Z Project:

1 CNC Rolling machine 2 Seam Welding machine 3 Axial Flow Fans Forming Production Line, 4 CNC Flanging Machines, 5 CNC Spinning Machine,6 AI Automatic Welding,

- ADAVANTAGES

- PARAMETERS

- CUSTOMER TESTIMONIALS

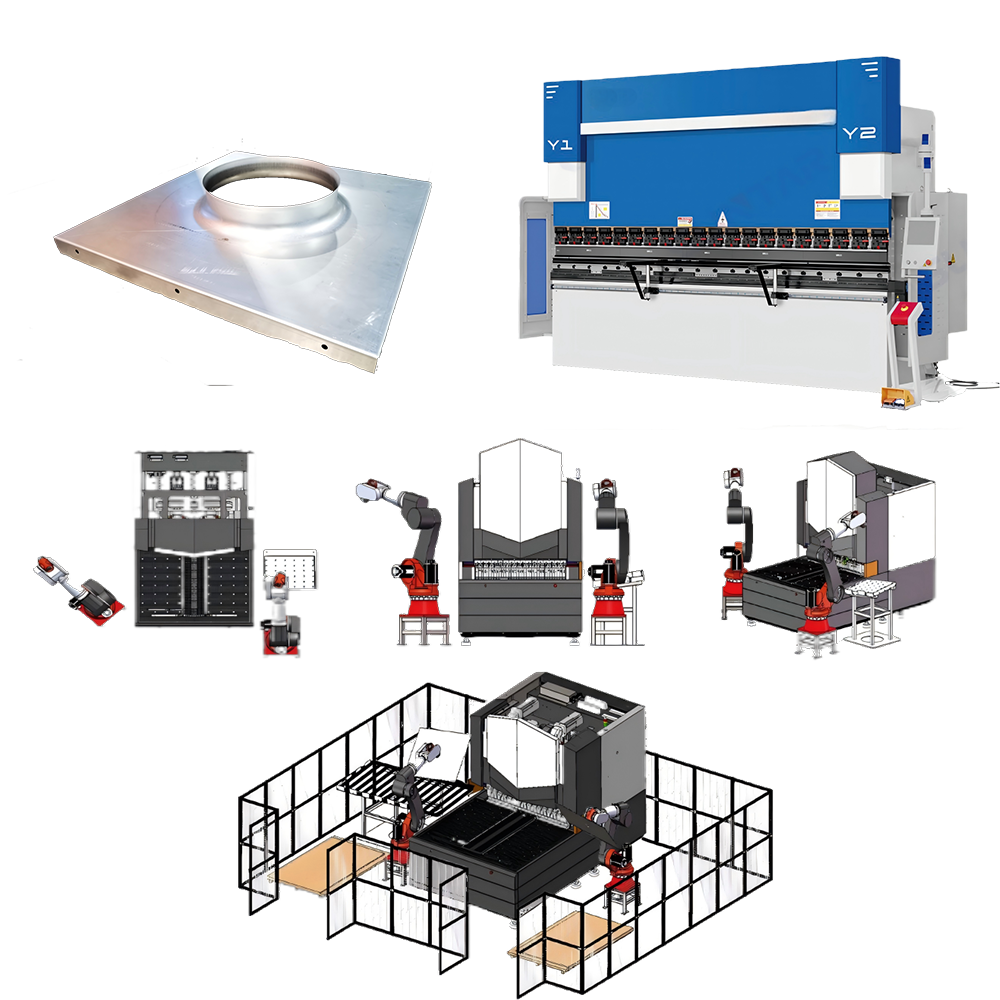

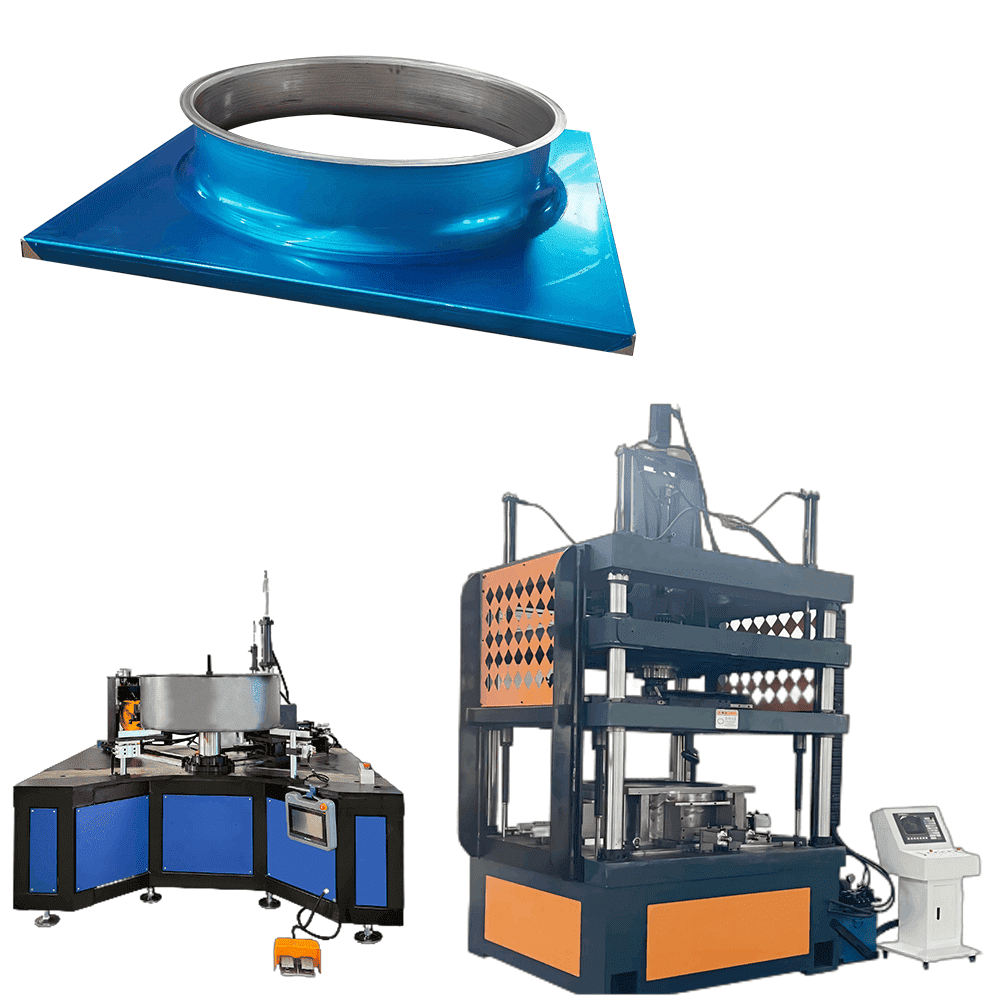

Altron’s Axial Flow Fans Flanging CNC Flanging and Punching Machine ACFB-1604 is a cutting-edge and efficient solution designed for precise and reliable flanging operations. With its advanced features and robust construction, it delivers exceptional performance in various applications.

Key Features of the Axial Fans CNC Flanging Punching Machine ACFB-1604:

-

CNC Control System: Equipped with a state-of-the-art CNC control system, the ACFB-1604 provides precise control over the flanging process. The user-friendly interface allows for easy programming and adjustment of parameters, ensuring accuracy and consistency in every flange formation.

-

Versatile Flanging Capabilities: The machine is capable of handling a wide range of flanging tasks, including straight flanging, curved flanging, and multi-angle flanging. It is suitable for flanging various materials such as steel, aluminum, stainless steel, and more, making it highly adaptable to different project requirements.

-

High Precision and Stability: The ACFB-1604 is engineered to deliver outstanding precision and stability. It maintains tight tolerances, ensuring consistent and uniform flange dimensions. The robust construction and high-quality components contribute to the machine’s stability and durability, even under demanding working conditions.

-

Efficient Production: With its optimized design and advanced control system, the ACFB-1604 maximizes production efficiency. It offers fast cycle times and high-speed flanging capabilities, enabling manufacturers to meet tight production schedules without compromising on quality.

Video of CNC Flanging and Punching Machine

Application scenarios of ACFB 1604 CNC flanging machine

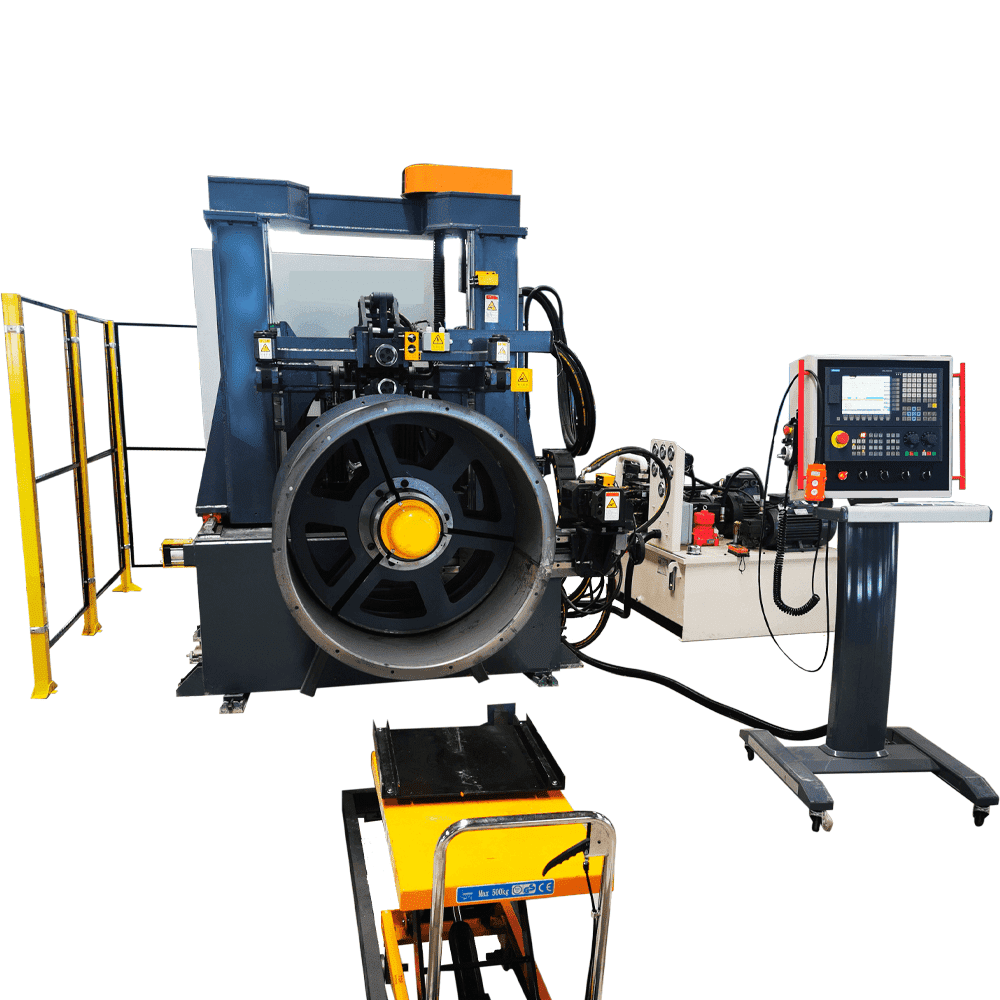

The ALTRON FB series two wheel flanging machine offers versatile flanging and piercing capabilities at any angle, including windpipes, tubes, and cones. It can handle flanging and spinning for curved surfaces with multiple tracking. Ideal for constructing windpipes, wind collectors, and pipe flahub wheels. This highly integrated and modular series operates with stability and reliability, producing highly homogeneous goods with CNC division punching and compatibility with other products.

Configuration

Standard Configuration

- SIEMENS CNC 808D / 828D

- SIEMENS Servo Motor & Drive

- ATOS Hydraulic Servo Valve

- CNC Precise Punching System

- APEX Servo Reducer

- Hydraulic Position Assembly

- Hydraulic Punching Assembly

- Hydraulic Station & Air Cooling System

- Self-developed Spinning CAD

- Control System Remote Maintenance

Select Configuration

- Auto Punching Assembly

- Flange Plasma Cutting Assembly

- Cars for Loading and Changing Ends

- Video Monitoring System

- Air Conditioner for Hydraulic Station

| Model No. |

Max. Dia. (mm) |

Min. Dia. (mm) |

Max. Length (mm) |

Min. Length (mm) |

Max. Punching Dia. (mm) |

| ACFB-1605 | 1600 | 380 | 1500 | 100 | 20 |

| ACFB-2008 | 2000 | 580 | 1800 | 200 | 20 |

| ACFB-2512 | 2500 | 580 | 2000 | 350 | 24 |

| ACSKFB-3012 | 3000 | 580 | 2000 | 350 | 24 |

| Model No. |

Material Thickness (mm) |

Flanging Force (KN) |

Clamping System (KN) |

Arc Radius (mm) |

Arc Radius (mm) |

| ACFB-1605 | 2-5 | 30 | 40 | ≤50 | 30 |

| ACFB-2008 | 2-8 | 60 | 50 | ≤80 | 45 |

| ACFB-2512 | 2-12 | 80 | 100 | ≤80 | 55 |

| ACSKFB-3012 | 2-12 | 100 | 120 | ≤200 | 60 |

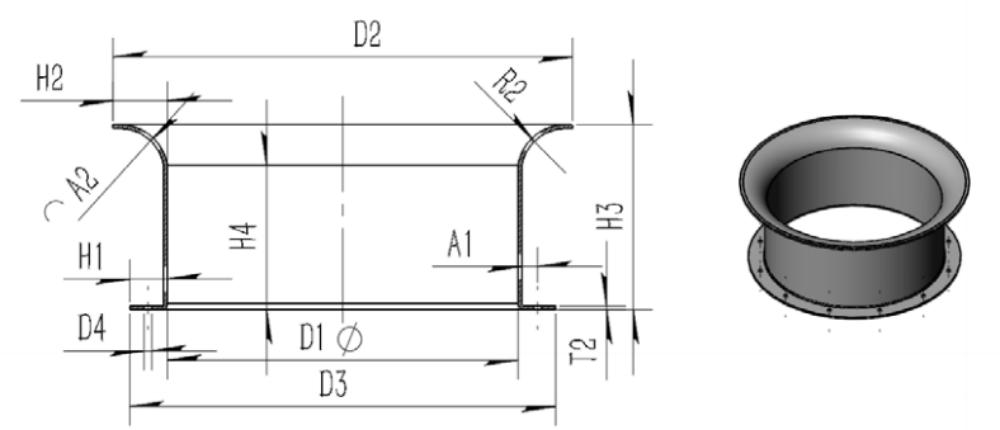

Schematic diagram of axial flow fan duct

- D1: 380—1600mm

- D2=D3: max 1700mm

- H1: max 70mm

- H2: max 80mm

- H3: 1250mm

- R2: 1.5T2—-50mm

- T2: max 5mm A2: max 100(arc length)

Flanging angle 0-92 degrees, program control, steplessly adjustable”

Machine Configuration Parameters

-

Marcley

★★★★★Post a review on Aug 21, 2022 From Bolivia

I highly recommend the ALTRON FB series two wheel flanging machine. As a manufacturer in the HVAC industry, precision and efficiency are crucial to our operations. The ALTRON FB machine has delivered exceptional results for our flanging needs.

-

Arthur Zonneveld

★★★★★Post a review on Fec 21, 2022 From Mauritius

It can handle various materials and angles with ease, enabling us to create strong and reliable connections in our air ducts and ventilation systems.

-

Nicolas Vazquez

★★★★★Post a review on jul 21, 2022 From Uruguay

The machine’s stability and dependability have significantly improved our production processes. We are impressed with its versatility and the ability to flange and spin curves with multiple tracking. The ALTRON FB machine has become an integral part of our manufacturing operations

-

OSCAR URBANEJA

★★★★★Post a review on Oct 10, 2022 From Venezuela

The ALTRON FB series flanging machine has been a game-changer for our company. Its highly integrated and modular design provides seamless operation and exceptional reliability. We have experienced consistent and dependable performance, resulting in highly homogeneous goods