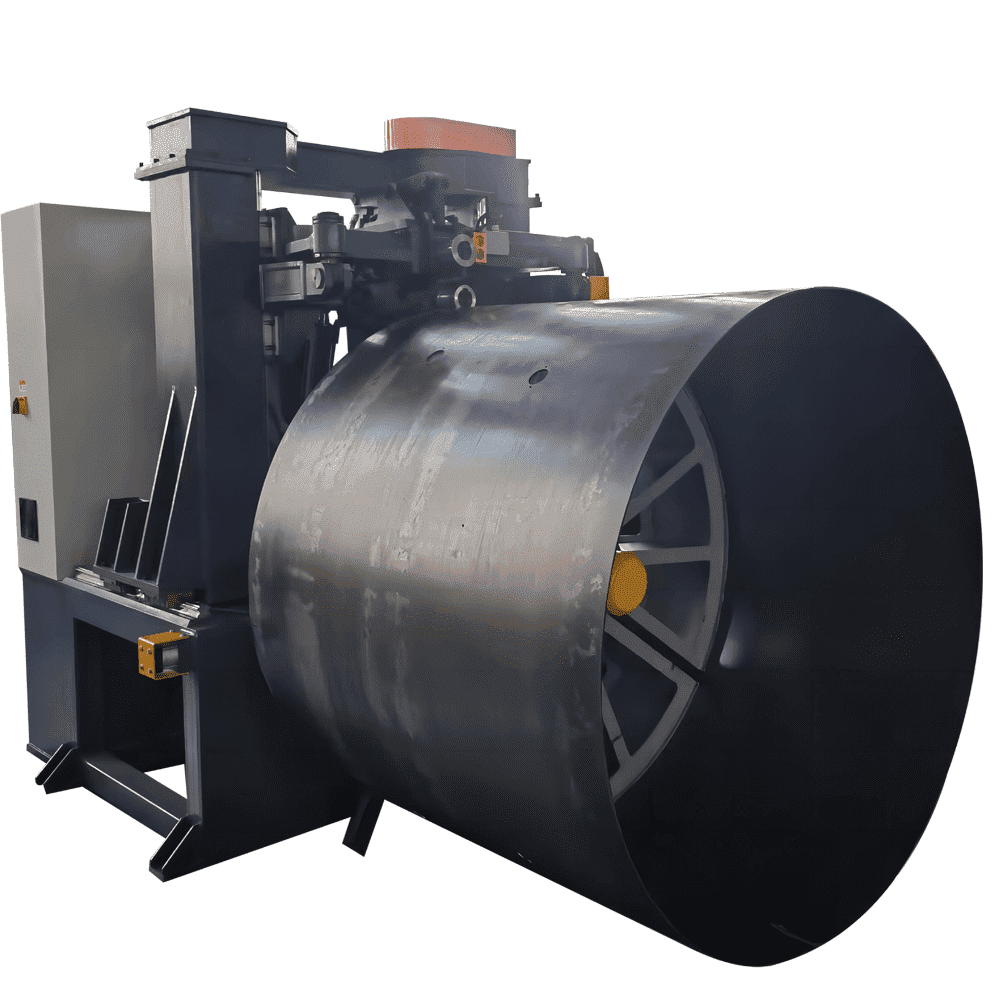

CNC Flanging Machine: Precision and Versatility in Manufacturing

CNC Flanging Machine is a valuable asset to any industry that uses flanges. The ACFB-3012 model from ALTRON exemplifies the precision, versatility, and reliability of modern CNC Flanging Machine. In this blog post, we will cover the ins and outs of this product, as well as its application in real-life scenarios.

What’s a CNC Flanging Machine?

CNC Flanging Machine, like the ACFB-3012, is a sophisticated piece of equipment designed to streamline and optimize flanging operations. They rely on Computer Numerical Control (CNC) systems to automate and precisely control the flanging process. These machines are engineered to create high-quality and consistent flanges, which are essential in various industrial applications.

Applications of CNC Flanging Machine

1. CNC Flanging in the Automotive Industry

In the automotive sector, precision is paramount. CNC Flanging Machines find extensive use in fabricating components like exhaust systems, ensuring that flanges fit seamlessly, preventing leaks, and ensuring optimal engine performance. Moreover, these machines can be programmed to work with various materials, including steel and aluminum, adapting to the diverse needs of the automotive industry.

2. CNC Flanging in the Manufacturing Sector:

In general manufacturing, CNC Flanging Machines are used to create flanges in various components, such as panels, tanks, and enclosures. The precision offered by these machines ensures that the resulting products meet exact specifications and can be seamlessly integrated into larger assemblies.

3. CNC Flanging in the Metal Fabrication:

Metal fabricators employ CNC Flanging Machines to create flanges on sheet metal components. Whether it’s for HVAC ductwork, architectural features, or industrial machinery, these machines deliver precise flanges that enhance structural integrity and functionality.

Flanging Machine Use: The CNC Flanging Machine ACFB-3012

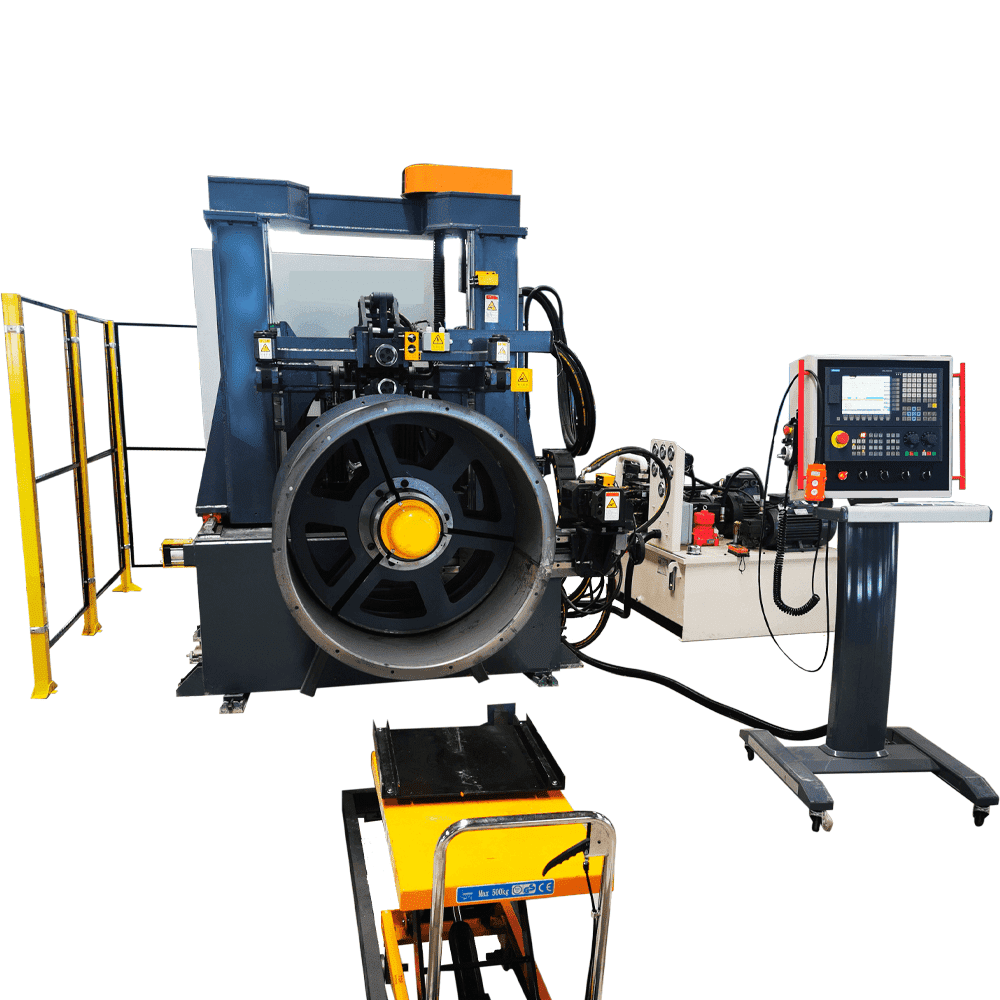

The CNC Flanging Machine ACFB-3012 is a technologically advanced and versatile machine designed for precision flanging operations. It plays a crucial role in industries where precise and high-quality flanges are required, ensuring that products meet stringent quality standards. Let’s take a closer look at the key features that set it apart.

1. CNC Control: Precision at Your Fingertips

At the heart of the ACFB-3012 lies its sophisticated CNC control system. This system empowers operators to input precise specifications for the desired flange effortlessly. Once programmed, the CNC system takes control, orchestrating the entire flanging process with unmatched accuracy. This automation minimizes the need for constant operator intervention, ensuring consistent and precise results, every time.

2. High Precision: Meeting Tight Tolerances

When it comes to manufacturing, precision is non-negotiable. The ACFB-3012 is engineered to deliver exceptional precision in flanging operations. Its CNC control, combined with high-quality components and advanced technology, enables tight tolerances and consistent flange dimensions. Manufacturers can rely on this machine to produce components that meet the strictest quality standards.

3. Versatility: Handling a Diverse Range of Materials

Manufacturers often work with various materials, and the ACFB-3012 is well-equipped to handle this diversity. Whether you’re working with steel, aluminum, or stainless steel, this machine is up to the task. Its versatility extends beyond material types; it can accommodate different thicknesses and flange sizes, making it suitable for a wide range of industrial applications.

4. Efficient Production: Saving Time and Resources

In today’s fast-paced manufacturing environment, efficiency is a game-changer. The ACFB-3012 is designed for high efficiency and productivity. Its automated CNC control system not only ensures precision but also reduces cycle times. This optimization of the production process translates to increased output, ultimately saving both time and resources.

5. User-Friendly Interface: Simplifying Operation

While the ACFB-3012 is a technologically advanced machine, its user interface is designed with operators in mind. The intuitive controls make programming, operation, and monitoring of the flanging process a breeze. Operators can easily set parameters, customize flange profiles, and adjust settings with ease, ensuring a seamless production workflow.

CNC Flanging Machine: Understanding the Working Principle

To truly appreciate the CNC Flanging Machine ACFB-3012, it’s essential to understand its working principle. This machine operates based on a well-defined sequence of steps:

- Inputting Specifications: The operator or programmer inputs the desired flange specifications into the CNC control system. This includes details like the flange dimensions, angles, and any specific requirements.

- CNC System Processing:The CNC system processes the instructions provided, meticulously calculating the tool’s movements and actions required to create the flange according to the programmed specifications.

- Positioning the Tool:The flanging tool is then precisely positioned over the metal sheet. This positioning is critical to ensuring that the flange is created in the correct location on the sheet.

- Applying Pressure:With the metal sheet securely in place, the flanging tool descends and applies pressure to the edge of the metal sheet. This pressure deforms the sheet, shaping it into the desired flange according to the programmed specifications.

- Rotating or Moving the Tool:Depending on the complexity of the flange required, the tool head can rotate or move along different axes. This flexibility allows the machine to create flanges of various shapes and sizes with pinpoint accuracy.

Cost Considerations: Investing in Efficiency — CNC Flanging Machine

It’s no secret that CNC Flanging Machines can be expensive investments. However, these machines offer significant long-term cost savings through increased efficiency and precision. Let’s break down the cost considerations:

1. Initial Investment: CNC Flanging Machine

The upfront cost of acquiring a CNC Flanging Machine like the ACFB-3012 can be substantial. Manufacturers need to budget for this capital expenditure, taking into account factors like the machine’s specifications and capabilities.

2. Long-Term Savings: CNC Flanging Machine

Where the true value shines is in the long-term savings. CNC Flanging Machines, with their automated precision, reduce material waste and minimize errors. They also optimize production times, leading to increased output. Over time, these efficiency gains translate into substantial cost savings.

3. Enhanced Quality: CNC Flanging Machine

Precision and consistency in flanging operations mean fewer defective components and a reduced need for rework. This not only saves on material costs but also enhances product quality and reputation.

4. Competitive Advantage: CNC Flanging Machine

Investing in advanced machinery like the ACFB-3012 gives manufacturers a competitive edge. They can offer higher-quality products, meet tighter deadlines, and win more contracts, ultimately increasing revenue.

CNC Flanging Machine Manufacturer: ALTRON

ALTRON, a renowned manufacturer in the CNC machinery industry, has set the standard with the ACFB-3012 CNC Flanging Machine. Their commitment to precision, versatility, and user-friendliness make ALTRON a trusted name in the world of manufacturing.

ALTRON goes beyond manufacturing CNC Flanging Machines; they offer comprehensive technical service and support to ensure their machines perform optimally. From initial testing to online and offline training, ALTRON is committed to helping clients achieve their production goals. Their technical guidance is available round the clock, and they are well-equipped to manage turnkey projects, ensuring seamless integration of CNC Flanging Machines into existing manufacturing processes.

Conclusion

CNC Flanging Machine like the ACFB-3012 from ALTRON has revolutionized the manufacturing landscape by offering precision, versatility, and efficiency. Their applications span across industries, from automotive to aerospace, playing a vital role in ensuring the quality and reliability of various components. As technology continues to advance, CNC Flanging Machines will remain at the forefront of precision manufacturing, powering the industries that drive our modern world.