CNC Flanging And Punching Machine ACFB-2008

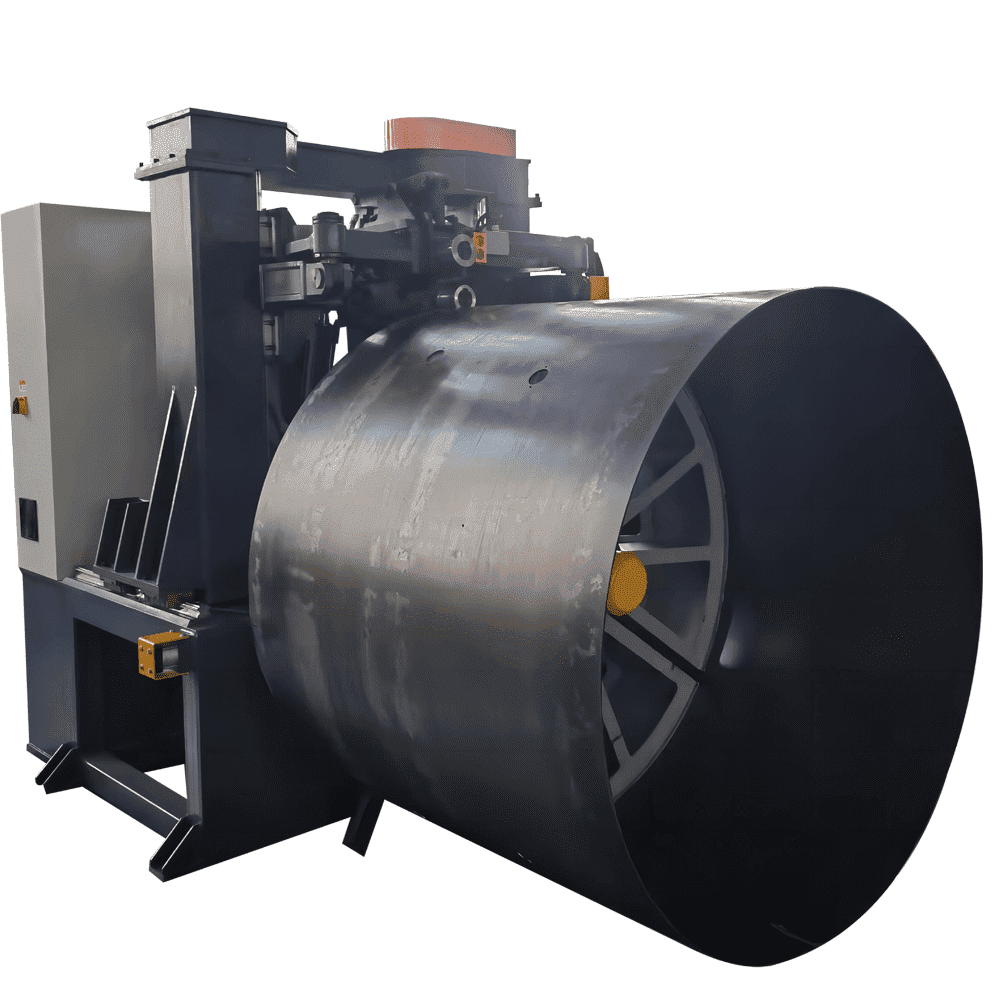

Horizontal Flanging Machine Forming And Punching For Centrifugal Fans & Axial Fans

Machine Name | CNC Horizontal Flanging Machine |

Model | ACFB 2008-2000MM |

Application Industry | Axial Fan, Subway Fan, Tunnel Fan, Jet Fan |

Technical Service | Complete the test in the early stage; provide online and offline training in the later stage, and complete the turnkey project. |

Technical Guidance | Online 24 hours a day / Conference To Solve Pre-Sales Problems. |

Project Progress | 30-120 days |

Relevant Files | ALTRON_AUTO Catalog-Industrial Blower Machinery Turnkey Project |

Industrial Fans A-Z Project:

1 CNC Rolling machine 2 Seam Welding machine 3 Axial Flow Fans Forming Production Line, 4 CNC Flanging Machines, 5 CNC Spinning Machine,6 AI Automatic Welding,

- ADAVANTAGES

- PARAMETERS

- CUSTOMER TESTIMONIALS

The Horizontal Flanging Machine ACFB-2008 is an advanced machine designed for flanging and punching of axial fans. It is produced for the needs of industrial fans, HVAC and general manufacturing industries, where accurate and reliable flanging and stability of mass production are essential.

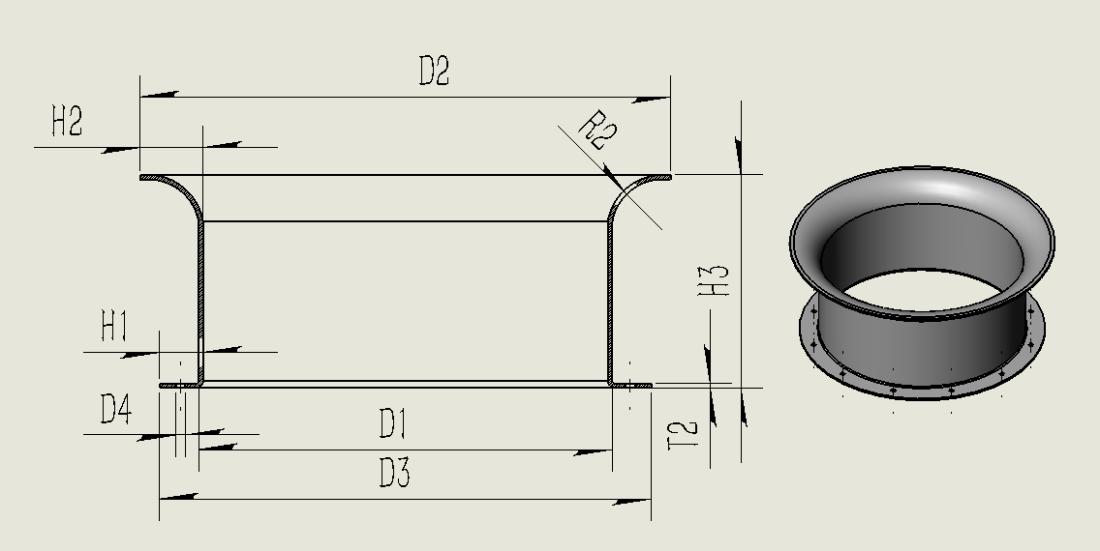

CNC Flanging Machines-Altron’s ACFB 2008: flanging forming and punching of Axial Flow Fans ducts with a diameter of 560-2000mm. Flanging from 0-92°.It is a must-have automated flange flanging machine for all industrial fan manufacturers.

Key Features of the Horizontal Flanging Machine ACFB-2008:

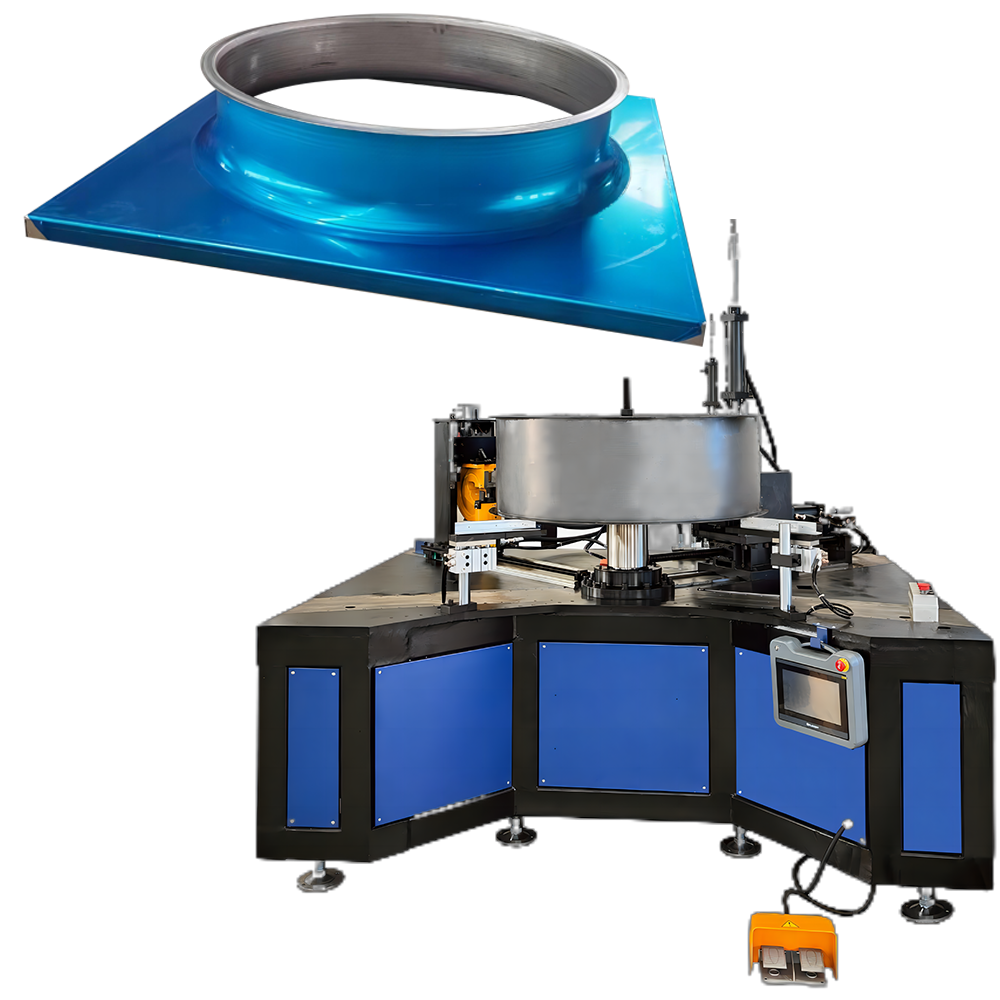

CNC Control System: Equipped with a state-of-the-art CNC control system, the ACFB-2008 offers precise and automated control over the flanging process. This advanced control ensures consistent and accurate results, minimizing operator error.

High Precision Flanging: The machine delivers exceptional precision in flange formation, thanks to its advanced technology and robust construction. It maintains tight tolerances, allowing for precise and uniform flange dimensions.

Versatile Flanging Capabilities: The ACFB-2008 is capable of handling a wide range of materials, including steel, aluminum, stainless steel, and more. It accommodates various thicknesses and flange sizes, making it adaptable to different project requirements.

Efficient Production: With its advanced CNC control and efficient design, Altron ACFB-2008 optimizes production processes. It reduces cycle times and increases productivity, allowing for faster and more efficient flanging operations.

User-Friendly Interface: The machine features a user-friendly interface that simplifies programming, operation, and monitoring of the flanging process. The intuitive controls enable operators to set parameters, customize flange profiles, and make adjustments with ease.

Video of CNC Flanging and Punching Machine

The ALTRON FB series double wheel flanging machine is a versatile and reliable solution for the production of axial flow fan tubes, suitable for flanging and piercing operations at any angle from 0 to 92°. It is designed to meet the production of various applications, such as ducts, tubes, cones, etc. Handling curved flanging and metal spinning tasks with multiple trajectories makes it a major production machine for the production of large ducts, wind collectors for large fans, pipe hemming wheels and similar parts.

This series is characterized by its highly integrated and modular design, ensuring seamless operation and dependable performance. The ALTRON FB machines exhibit exceptional stability and reliability throughout the flanging process, delivering consistent results for manufacturers.

Application scenarios of ACFB 2008 CNC Flanging Machine

Configuration

Standard Configuration

- SIEMENS CNC 808D / 828D

- SIEMENS Servo Motor & Drive

- ATOS Hydraulic Servo Valve

- CNC Precise Punching System

- APEX Servo Reducer

- Hydraulic Position Assembly

- Hydraulic Punching Assembly

- Hydraulic Station & Air Cooling System

- Self-developed Spinning CAD

- Control System Remote Maintenance

Select Configuration

- Auto Punching Assembly

- Flange Plasma Cutting Assembly

- Cars for Loading and Changing Ends

- Video Monitoring System

- Air Conditioner for Hydraulic Station