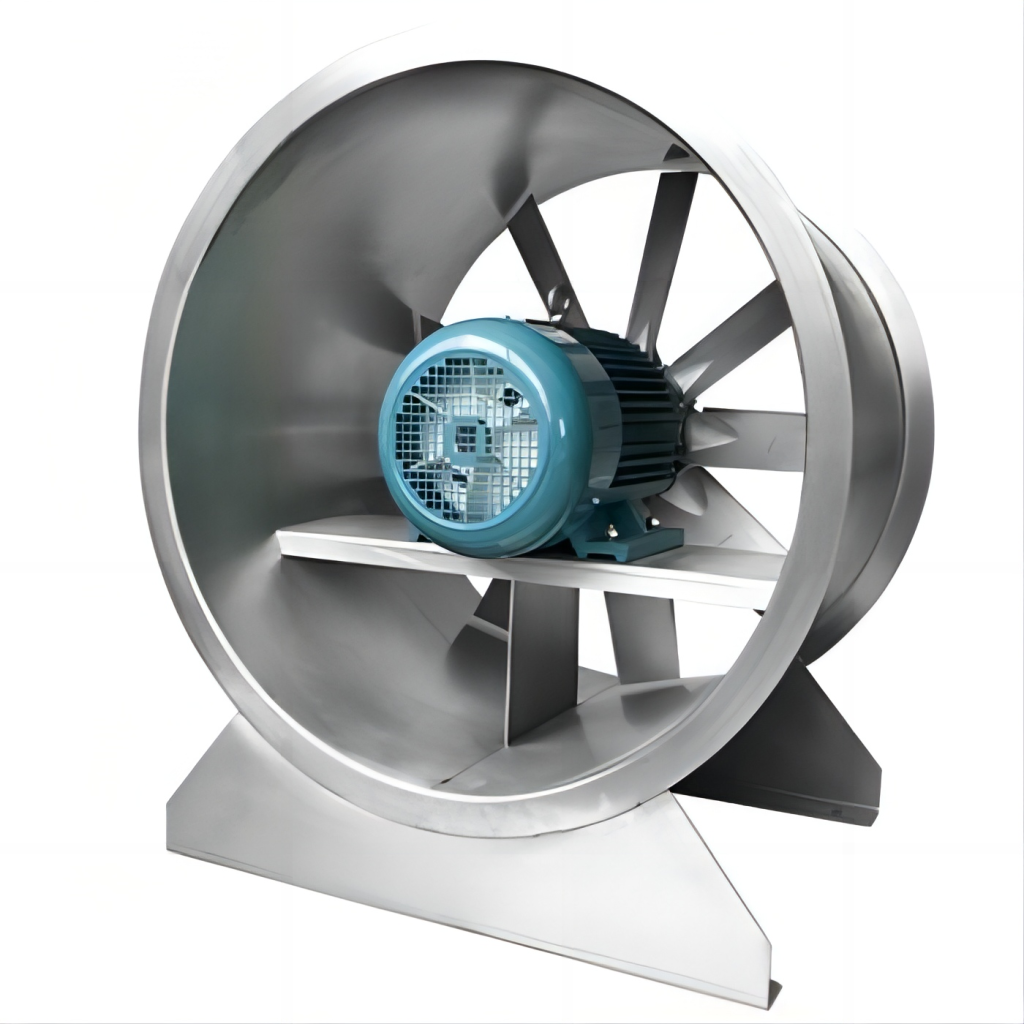

CNC Flanging Machines Processing in Axial Flow Fan Applications

Industrial axial flow fans play a crucial role in various applications, from subway tunnel ventilation to laboratory environments. The precision and efficiency of these fans depend heavily on the manufacturing processes involved. This blog explores the application of CNC flanging machines in the production of axial flow fans, delving into specific sectors like subway tunnels, fire prevention, environmental sustainability, laboratories, duct ventilation, mixed flow blades, jet fans, and ultra-efficient stainless steel axial flow fans.

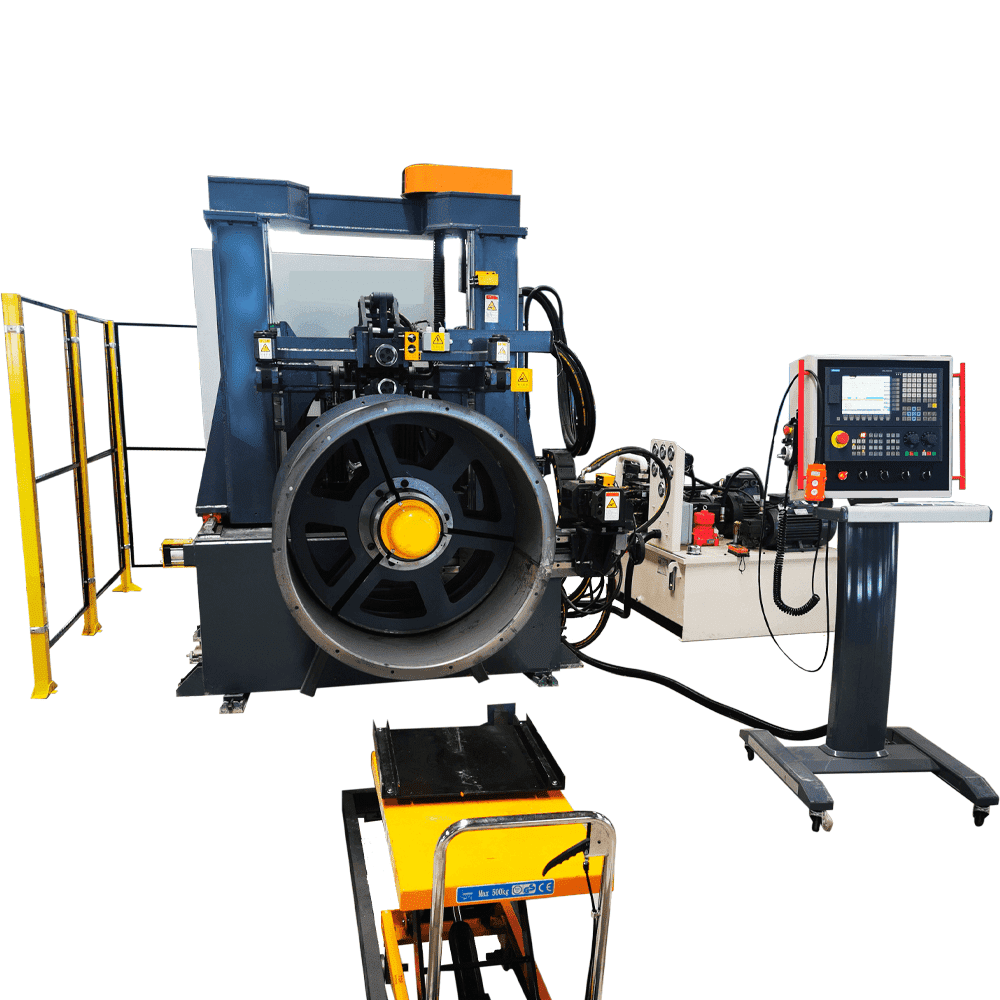

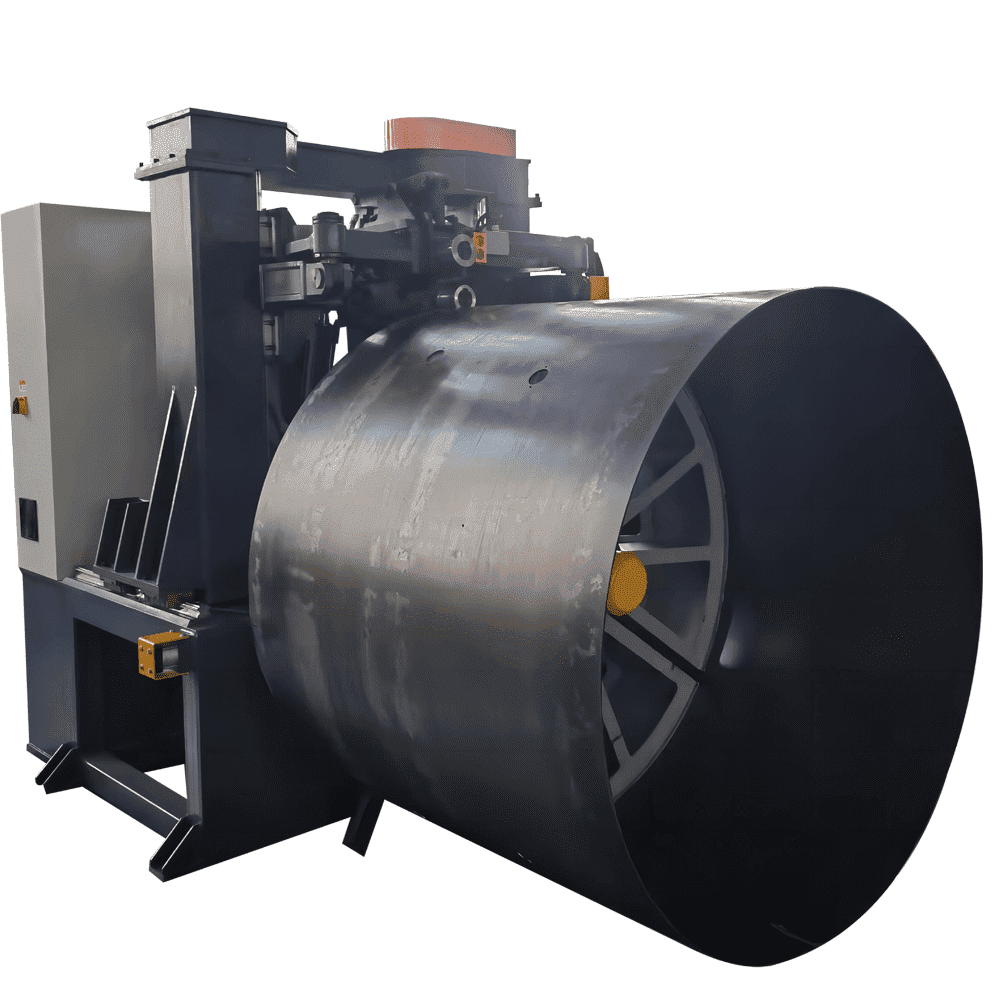

1. Application of CNC Flanging Machine in Industrial Axial Flow Fans

In industrial settings, the demand for efficient air movement is paramount. CNC flanging machines emerge as key players in enhancing the manufacturing process of axial flow fans. These machines provide precise control over the flanging process, ensuring uniformity and accuracy in the production of fan components. The result is a more reliable and efficient axial flow fan, contributing to improved industrial ventilation systems.

2. Subway Tunnel Axial Flow Fans

Subway tunnels present unique challenges for axial flow fan applications. The need for efficient air circulation to maintain optimal air quality is critical in underground transportation systems. CNC flanging machines enable the production of axial flow fans tailored to the specific requirements of subway tunnels. With precise control over flange dimensions, these fans provide reliable and consistent airflow, contributing to a safer and more comfortable subway environment.

3. Fire Axial Flow Fans

In fire prevention applications, axial flow fans play a vital role in controlling smoke and maintaining a safe environment for evacuation. CNC flanging machines contribute to the production of fire axial flow fans with precision-cut components. The accuracy in flange dimensions ensures the seamless integration of these fans into fire prevention systems, enhancing their effectiveness in emergency situations.

4. Environmentally Friendly Industrial Axial Flow Fans

The growing emphasis on environmental sustainability calls for innovative solutions in industrial processes. CNC flanging machines play a role in the production of environmentally friendly axial flow fans by ensuring the efficient use of materials and reducing waste. The precision in flanging contributes to the overall reliability and longevity of these fans, aligning with the global push for eco-friendly industrial practices.

5. Laboratory Ventilation Axial Flow Fans

Laboratories demand strict control over air quality and ventilation. CNC flanging machines aid in the production of axial flow fans tailored to laboratory environments. The precision in flange dimensions ensures that these fans integrate seamlessly into ventilation systems, providing optimal airflow control. This contributes to maintaining a controlled and safe environment within laboratories where precision is paramount.

6. Duct Ventilation Axial Flow Fans

Duct ventilation systems rely on axial flow fans for efficient air movement through ducts. CNC flanging machines are instrumental in producing these fans with precision-engineered components. The accurate flanging process ensures a tight fit within ducts, optimizing the performance of ventilation systems. The result is improved airflow and energy efficiency in industrial and commercial settings relying on ducted ventilation.

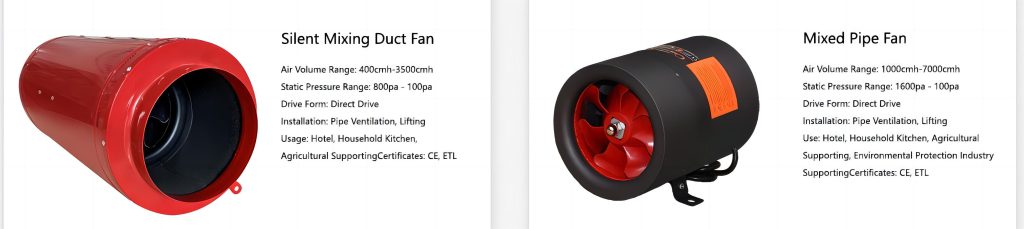

7. Mixing Duct Axial Flow Fans (Mixed Flow Blades)

Mixed flow blades in axial flow fans are designed for specific applications requiring a combination of axial and radial airflow. CNC flanging machines contribute to the production of these specialized fans with precision in flange dimensions. The ability to control the flanging process allows for the creation of mixed-flow blades that cater to the unique needs of industries requiring a hybrid approach to airflow.

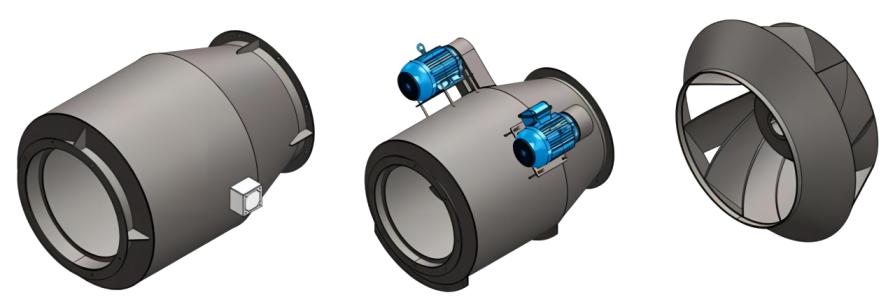

8. Jet Fans

Jet fans are essential for managing airflow in confined spaces such as parking garages and tunnels. CNC flanging machines ensure the production of jet fans with accurate flange dimensions, enabling optimal performance in these challenging environments. The precision in manufacturing contributes to the effectiveness of jet fans in maintaining air circulation and safety in enclosed spaces.

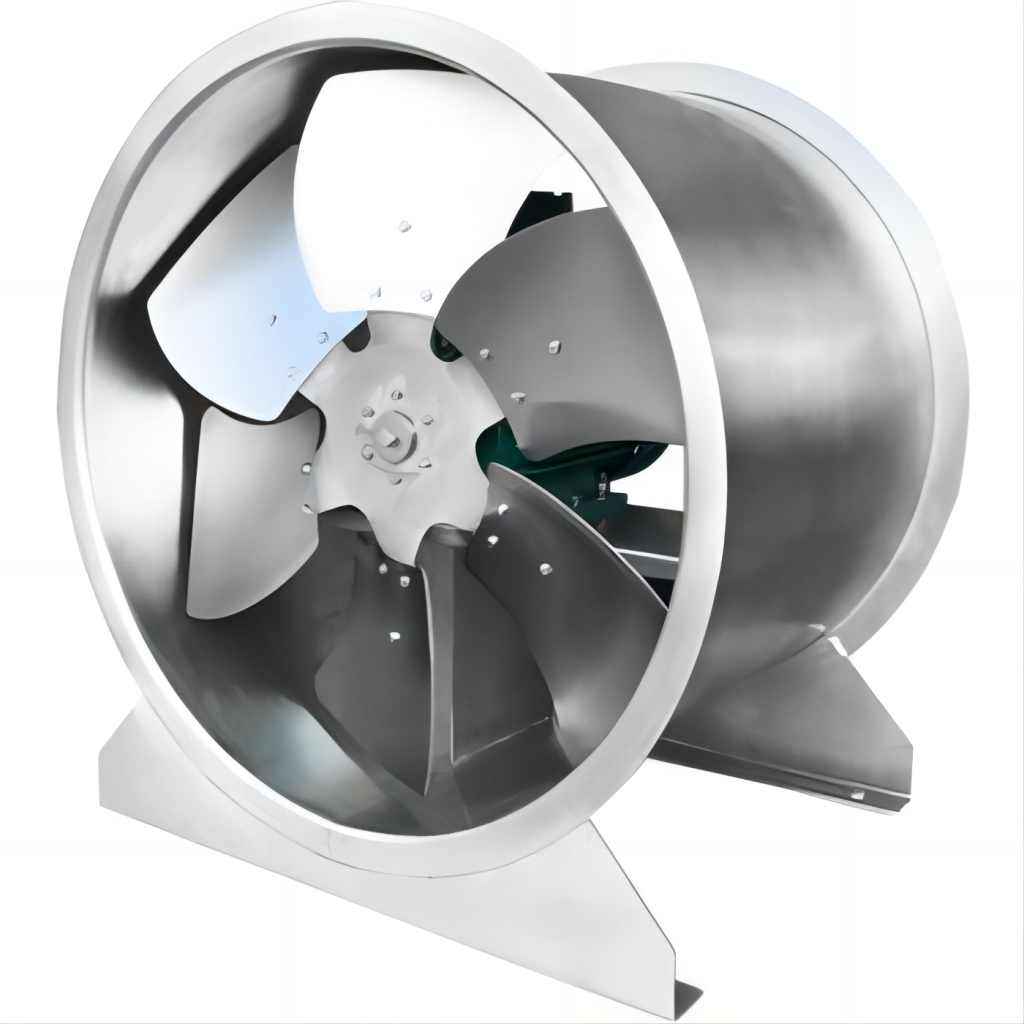

9. Ultra-Efficient Stainless Steel Axial Flow Fans

In corrosive or demanding environments, ultra-efficient stainless steel axial flow fans are crucial for longevity and reliability. CNC flanging machines play a pivotal role in shaping stainless steel components with precision. The accurate flanging process ensures a tight fit and robust construction, making these fans resistant to corrosion and suitable for a wide range of industrial applications.

Axial Flow Fan Application’s Conclusion

The application of CNC flanging machines in the production of axial flow fans has a significant impact on various industries. From subway tunnels to laboratories, these machines contribute to the precision and efficiency of fan components, ensuring optimal performance in diverse applications. As technology continues to advance, the role of CNC flanging machines in enhancing axial flow fan manufacturing processes will undoubtedly play a crucial role in shaping the future of ventilation systems across industries.