How Versatile Are CNC High Speed Flanging Machines Across Different Industries?

Unlock the transformative power of CNC high-speed flanging machines across diverse industries. Explore precision manufacturing in automotive, energy, rail transportation, and beyond. From efficiency enhancements to innovation drivers, discover how CNC flanging technology is reshaping manufacturing processes. Embrace the potential for growth and excellence with ALTRON AUTO, a premier manufacturer of CNC high-speed flanging machines.

Revolutionizing Automotive Manufacturing: The Role of CNC High-Speed Flanging Machines

1.1 Introduction

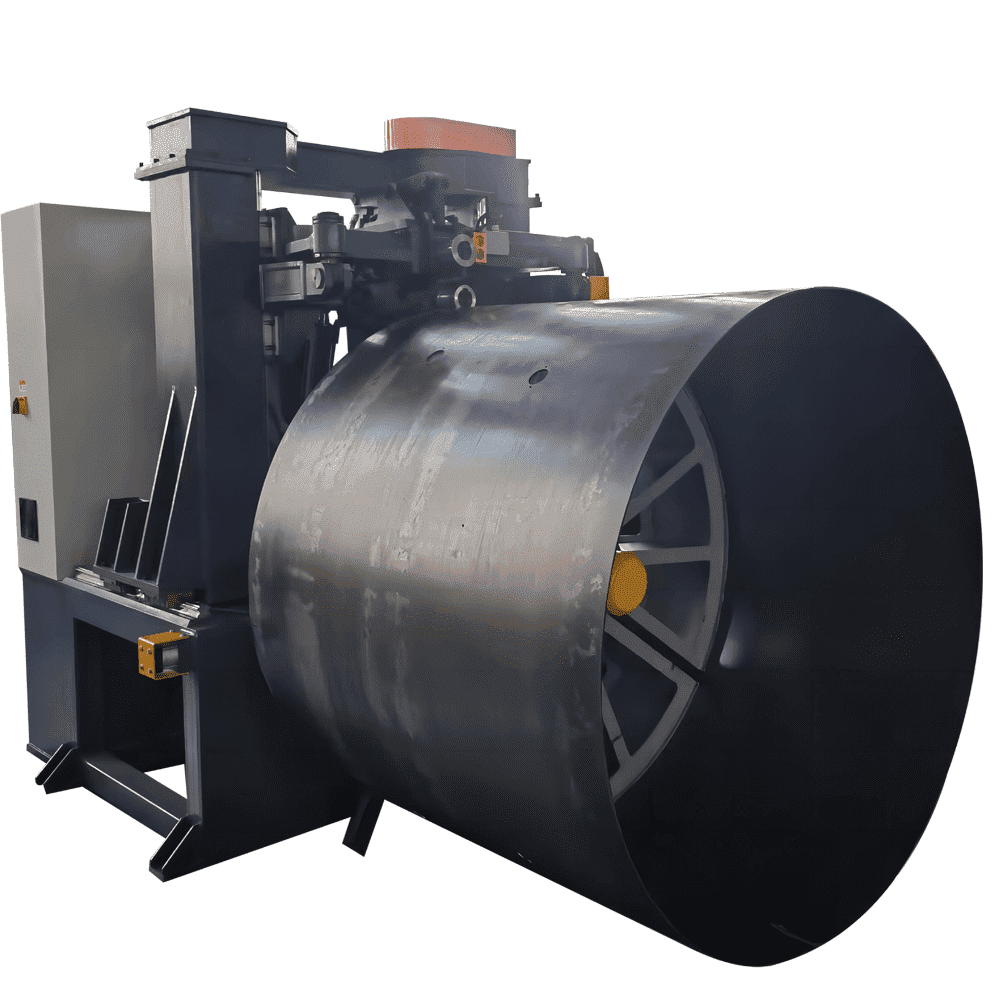

In the dynamic landscape of automotive manufacturing, precision and efficiency are paramount. Each component must meet stringent quality standards to ensure the safety and performance of vehicles. Among the myriad of technologies driving this precision, CNC High-Speed Flanging Machines stand out as indispensable tools. These machines play a pivotal role in shaping critical components like exhaust systems, chassis parts, and body panels with impeccable accuracy, revolutionizing the way automotive manufacturers produce their vehicles.

1.2 Enhancing Precision and Efficiency

At the heart of CNC High-Speed Flanging Machines lies their ability to deliver unparalleled precision and efficiency. By utilizing computer numerical control (CNC) technology, these machines execute intricate forming operations with utmost accuracy, ensuring that each component meets exact specifications. This precision not only enhances the quality of automotive parts but also streamlines the manufacturing process, leading to significant time and cost savings.

1.3 Case Studies in Automotive Excellence

Automotive companies worldwide have embraced CNC High-Speed Flanging Machines to optimize their production processes and stay ahead in a fiercely competitive market. One such example is ALTRON AUTO, a leading manufacturer in the automotive sector. By integrating CNC flanging technology into their production lines, ALTRON AUTO has achieved remarkable improvements in component accuracy and production efficiency. This adoption has not only elevated the quality of their products but has also positioned them as industry leaders in automotive manufacturing.

1.4 Exploring Possibilities

As automotive manufacturers continue to seek ways to enhance their production processes, the role of CNC High-Speed Flanging Machines becomes increasingly significant. By leveraging the precision and efficiency offered by these machines, companies can meet the growing demands of the automotive market while staying ahead of the competition. Automotive manufacturers must explore the possibilities offered by CNC flanging technology and embrace it as a cornerstone of their manufacturing operations.

Precision at its Finest: Enhancing Sheet Metal Fabrication with CNC Flanging Technology

2.1 Importance of Precision in Sheet Metal Fabrication

In industries ranging from HVAC systems to electronics manufacturing, precision is the cornerstone of sheet metal fabrication. Every bend, curve, and cut must be executed with meticulous accuracy to ensure the functionality and longevity of the final product. In this context, CNC Flanging Technology emerges as a game-changer, offering unparalleled precision in shaping and forming metal sheets for a wide range of applications.

2.2 Versatility and Adaptability

One of the key advantages of CNC Flanging Machines lies in their versatility and adaptability. These machines can handle different types of metals, including aluminum, stainless steel, and titanium, as well as varying sheet thicknesses with ease. This versatility makes CNC flanging technology suitable for a diverse range of industries, from aerospace to consumer electronics, where precision and quality are non-negotiable.

2.3 Success Stories in Sheet Metal Fabrication

Across industries, companies are reaping the benefits of integrating CNC Flanging Technology into their sheet metal fabrication processes. Whether it’s achieving tighter tolerances, reducing material waste, or accelerating production timelines, the impact of CNC flanging machines is undeniable. By embracing this technology, companies can unlock new levels of efficiency and precision in their sheet metal fabrication operations, setting new standards for quality and innovation.

2.4 Embracing Innovation

In the ever-evolving landscape of sheet metal fabrication, staying ahead means embracing innovation. Companies that invest in CNC High-Speed Flanging Machines gain a competitive edge by delivering superior products with unmatched precision and efficiency. It’s time for companies in the sheet metal fabrication sector to recognize the transformative potential of CNC flanging technology and seize the opportunities it presents for growth and excellence.

Setting Sail with Precision: The Impact of CNC Flanging Machines on the Marine Industry

3.1 Challenges in Marine Metalworking

Shipbuilding and marine engineering present unique challenges in metalworking, where precision and reliability are paramount. From constructing hulls and decks to fabricating bulkheads and structural components, the marine industry demands the highest standards of craftsmanship and accuracy. In this context, CNC Flanging Machines emerge as indispensable tools, enabling shipbuilders to meet the rigorous demands of marine applications with confidence and precision.

3.2 Precision for Performance

In the marine industry, the consequences of imprecise metalwork can be dire, affecting not only the structural integrity of vessels but also their performance and safety at sea. CNC Flanging Machines address these concerns by delivering precision and consistency in shaping metal components for ship construction. Whether it’s forming complex curves or creating seamless joints, these machines ensure that every part meets exact specifications, enhancing the overall reliability and performance of marine vessels.

3.3 Excellence in Shipbuilding

Leading shipbuilding companies around the world have recognized the transformative potential of CNC Flanging Machines in optimizing their production processes. By integrating these machines into their operations, shipbuilders have achieved significant improvements in efficiency, quality, and cost-effectiveness. From luxury yachts to commercial vessels, the impact of CNC flanging technology is evident in every aspect of marine construction, driving innovation and excellence across the industry.

3.4 Charting a Course for Innovation

As the marine industry continues to evolve, the role of CNC Flanging Machines will only grow in importance. By embracing these advanced technologies, shipbuilders can unlock new levels of precision, efficiency, and reliability in their production processes, setting new standards for excellence in marine engineering. It’s time for stakeholders in the marine industry to chart a course for innovation and explore the possibilities offered by CNC High-Speed Flanging Machines for the future of shipbuilding.

Powering Precision: The Role of CNC Flanging Machines in the Energy Sector

4.1 Precision Manufacturing in Energy

The energy sector, encompassing power generation, oil and gas extraction, and renewable energy systems, demands nothing short of absolute precision in manufacturing. From turbines and pipelines to solar panels and wind turbines, every component must meet stringent specifications to ensure optimal performance and safety. In this landscape, CNC Flanging Machines emerge as essential tools, empowering manufacturers to fabricate parts with impeccable accuracy for critical applications across the energy sector.

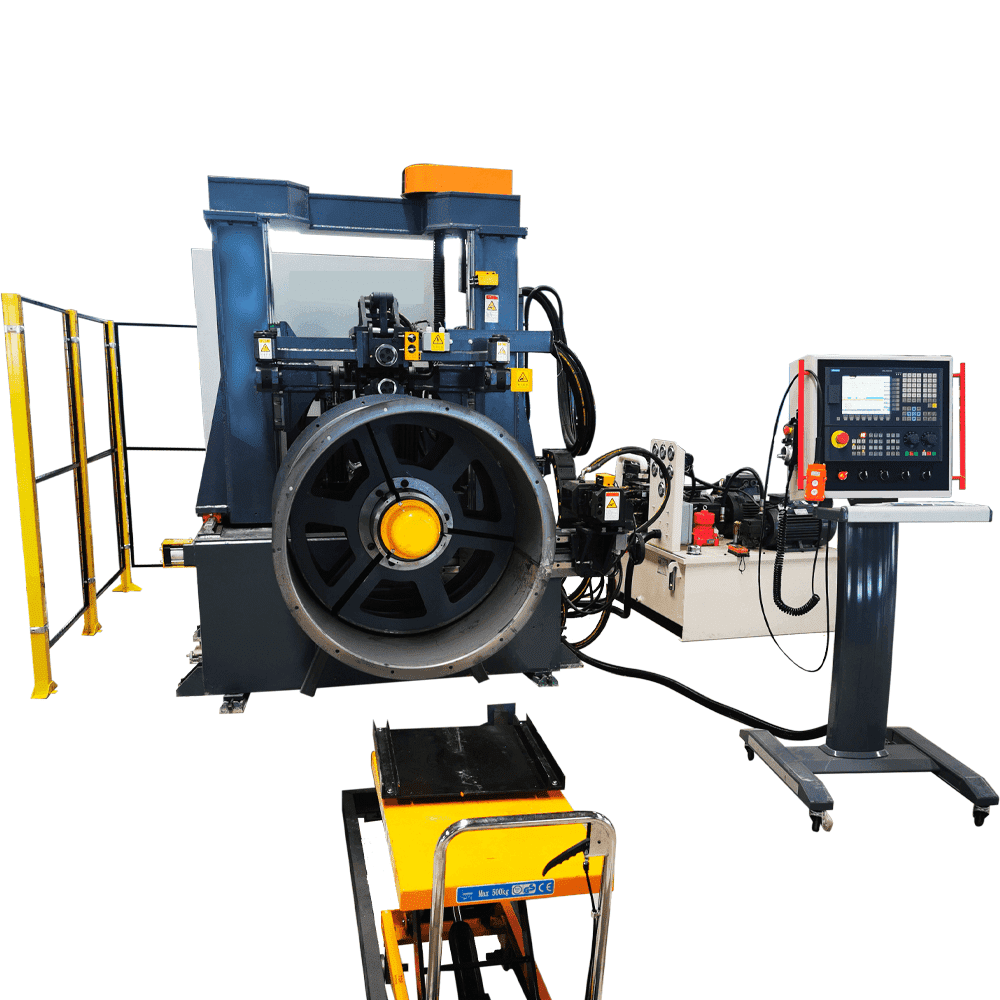

4.2 Enabling Precision Manufacturing

CNC Flanging Machines play a pivotal role in enabling precision manufacturing in the energy sector. By utilizing advanced computer numerical control technology, these machines execute complex forming operations with micron-level accuracy, ensuring that each component meets exact specifications. Whether it’s fabricating turbine blades, pipeline fittings, or solar panel frames, CNC flanging technology delivers the precision needed to drive efficiency and reliability in energy sector manufacturing.

4.3 Real-World Impact

Real-world examples abound where CNC Flanging Machines have proven instrumental in enhancing efficiency and quality in energy sector manufacturing. From reducing lead times and material waste to improving part consistency and reliability, the benefits of integrating CNC flanging technology are undeniable. Companies across the energy sector have experienced significant cost savings and competitive advantages by embracing these advanced manufacturing solutions, positioning themselves as leaders in their respective fields.

4.4 Unlocking Competitive Advantages

The adoption of CNC High-Speed Flanging Machines offers not only cost savings but also competitive advantages for companies in the energy sector. By streamlining production processes, minimizing errors, and maximizing throughput, these machines enable manufacturers to stay ahead in a rapidly evolving industry. With the ability to produce high-quality components at scale, companies can meet growing demands while maintaining a competitive edge in the market.

4.5 Embracing Innovation

The invitation is extended to companies in the energy sector to embrace CNC flanging technology for improved productivity and performance. By investing in these advanced manufacturing solutions, companies can unlock new levels of efficiency and precision, driving innovation and excellence in energy sector manufacturing. It’s time for stakeholders to seize the opportunities offered by CNC High-Speed Flanging Machines and power the future of precision manufacturing in the energy sector.

Keeping the Wheels Turning: How CNC Flanging Machines Drive Innovation in Rail Transportation

5.1 Complex Metalworking in Rail Transportation

The rail transportation industry relies on complex metalworking processes to fabricate components essential for the safe and efficient operation of rail systems. From railcar components and locomotive parts to railway infrastructure, precision and reliability are paramount. In this demanding environment, CNC Flanging Machines play a crucial role, enabling manufacturers to meet the exacting standards required for rail transportation applications.

5.2 Utilization in Rail Manufacturing

CNC Flanging Machines find wide-ranging applications in the fabrication of railcar components, locomotive parts, and railway infrastructure. Whether it’s forming seamless joints for railcar bodies, creating precise fittings for braking systems, or shaping structural components for railway tracks, these machines deliver the accuracy and consistency needed to ensure the safety and reliability of rail systems. In an industry where even the slightest deviation can have far-reaching consequences, CNC flanging technology provides peace of mind for manufacturers and operators alike.

5.3 Benefits of Precision and Reliability

Case studies and success stories abound demonstrating the benefits of integrating CNC flanging technology into rail manufacturing processes. Companies that have embraced these advanced manufacturing solutions have experienced improvements in efficiency, quality, and safety across their operations. By producing components with unparalleled precision and reliability, manufacturers can enhance the performance and longevity of rail systems, keeping the wheels turning smoothly for passengers and freight alike.

5.4 Driving Innovation in Rail Manufacturing

The invitation is extended to stakeholders in the rail transportation sector to explore the capabilities of CNC High-Speed Flanging Machines for advancing their operations. By harnessing the precision and reliability offered by these machines, manufacturers can drive innovation and excellence in rail manufacturing, setting new standards for safety, efficiency, and sustainability. It’s time for the rail transportation industry to embrace the possibilities offered by CNC flanging technology and propel the future of rail transportation forward.

Precision Engineering Across Industries: The Versatility of CNC Flanging Machines

6.1 Diverse Applications

CNC Flanging Machines demonstrate remarkable versatility across various manufacturing sectors, including defense, construction, and industrial machinery. From fabricating armored vehicle components to forming structural elements for skyscrapers, these machines find applications in a diverse range of industries where precision and reliability are paramount. By addressing common challenges such as tight tolerances, complex geometries, and material variability, CNC flanging technology offers a versatile solution for manufacturers across different sectors.

6.2 Addressing Industry Challenges

In industries as diverse as defense, construction, and industrial machinery, manufacturers face a myriad of challenges in metalworking processes. Whether it’s meeting strict regulatory requirements, accommodating design changes, or optimizing production efficiency, CNC Flanging Machines offer a versatile solution for addressing these challenges. With the ability to handle various materials, thicknesses, and geometries, these machines empower manufacturers to tackle complex fabrication tasks with confidence and precision.

6.3 Illustrating Versatility

Specific examples and case studies illustrate the versatility and adaptability of CNC Flanging Machines in different manufacturing contexts. From fabricating precision components for military vehicles to forming structural elements for large-scale construction projects, the applications of CNC flanging technology are as diverse as the industries it serves. By showcasing these examples, manufacturers can gain insights into how CNC flanging technology can address their specific needs and drive productivity, quality, and bottom-line results.

6.4 Exploring Possibilities

The invitation is extended to companies in diverse manufacturing sectors to explore the possibilities offered by CNC flanging technology for their specific needs. Whether it’s improving production efficiency, enhancing part quality, or reducing manufacturing costs, CNC High-Speed Flanging Machines offer a versatile solution for addressing the unique challenges faced by manufacturers across different industries. It’s time for companies to embrace the transformative potential of CNC flanging technology and unlock new opportunities for innovation and growth.

Conclusion

CNC high-speed flanging machines represent a transformative force across various industries, from automotive to energy, rail transportation, and beyond. With their precision engineering and efficiency-enhancing capabilities, these machines drive innovation and excellence in manufacturing processes. Companies embracing CNC flanging technology stand to benefit from improved productivity, enhanced quality, and cost savings. As the manufacturing landscape continues to evolve, the versatility and reliability of CNC high-speed flanging machines position them as indispensable tools for unlocking new opportunities and achieving sustainable growth.