CNC Metal Spinning Machine in China: Best Service for You

In the realm of metalworking, precision and efficiency are paramount. Traditional methods often struggle to meet the demands of modern manufacturing. Enter CNC metal spinning machines, a revolutionary technology that streamlines the process of shaping metal components with unparalleled accuracy. At the forefront of this innovation stands ALTRON, a leading manufacturer based in China. Let’s delve into the world of ALTRON’s CNC Metal Spinning Machine in China and explore their remarkable capabilities.

ALTRON’s Multi-Roller Powerful Spinning Machines

ALTRON’s multi-roller powerful spinning machines represent a pinnacle of engineering excellence. These machines boast multiple rollers meticulously synchronized to manipulate metal with extraordinary precision. Under the command of advanced CNC technology, they can seamlessly produce intricate shapes and contours, meeting the most demanding specifications of modern industries.

Precision Engineering ALTRON’s multi-roller powerful spinning machines epitomize precision engineering. Each component is crafted with meticulous attention to detail, ensuring flawless performance and repeatability. The CNC controls enable operators to achieve micron-level accuracy, guaranteeing consistency across every batch of manufactured parts.

Versatile Applications From aerospace components to architectural elements, ALTRON’s multi-roller powerful spinning machines cater to a diverse range of industries. Their versatility allows for the production of complex geometries, such as domes, cones, and hemispheres, opening doors to endless possibilities in design and functionality.

Enhanced Efficiency By automating the spinning process, ALTRON’s machines significantly enhance efficiency and productivity. Operators can program intricate designs directly into the CNC system, reducing setup times and minimizing material waste. This streamlined workflow translates into faster turnaround times and lower production costs, giving manufacturers a competitive edge in today’s fast-paced market.

ALTRON’s Fans Spinning Machines

Ventilation systems play a crucial role in various industrial and commercial settings, requiring components that are both efficient and durable. ALTRON’s fans spinning machines are specifically engineered to meet these demanding requirements, delivering high-quality fan blades with unmatched precision.

Optimized Performance ALTRON’s fans spinning machines are optimized for maximum performance. By leveraging CNC technology, they ensure uniformity in blade dimensions and profiles, resulting in enhanced airflow efficiency and reduced noise levels. Whether for industrial cooling systems or HVAC applications, these meticulously crafted fan blades guarantee superior performance and reliability.

Customization Capabilities In addition to standard fan designs, ALTRON’s machines offer extensive customization capabilities. From blade pitch to diameter, manufacturers can tailor each component to meet specific performance criteria and aesthetic preferences. This flexibility enables the creation of bespoke solutions that address unique challenges across diverse industries.

Quality Assurance ALTRON prioritizes quality assurance throughout the manufacturing process. Stringent inspection protocols ensure that every fan blade meets rigorous standards for dimensional accuracy and surface finish. By upholding uncompromising quality control measures, ALTRON instills confidence in its products, earning the trust of customers worldwide.

ALTRON’s Ventilation Flanging Machines

Flanges play a critical role in joining ductwork and piping systems, requiring precise fabrication to ensure leak-free connections. ALTRON’s ventilation flanging machines are engineered to deliver flawless flanges with tight tolerances, meeting the stringent requirements of modern ventilation systems.

Seamless Integration ALTRON’s ventilation flanging machines seamlessly integrate into existing production lines, streamlining the manufacturing process. Their CNC Metal Spinning Machine in China controls enable operators to program flange dimensions with ease, ensuring consistency across large-scale production runs. Whether for ductwork in industrial facilities or ventilation systems in commercial buildings, these machines deliver precision-engineered flanges that withstand the rigors of daily use.

High-Speed Production In today’s fast-paced manufacturing environment, efficiency is key. ALTRON’s ventilation flanging machines excel in high-speed production, enabling manufacturers to meet tight deadlines without compromising quality. Their robust construction and advanced automation capabilities ensure uninterrupted operation, minimizing downtime and maximizing output.

Versatile Functionality Beyond standard flange sizes, ALTRON’s machines offer versatile functionality to accommodate diverse application requirements. Whether producing circular, oval, or rectangular flanges, they can adapt to various ductwork configurations with ease. This versatility makes them indispensable tools for HVAC contractors, sheet metal fabricators, and industrial manufacturers alike.

ALTRON’s Full Functional Single Roller Spinning Machine

In the realm of metal spinning, ALTRON’s full functional single roller spinning machine stands out for its simplicity and versatility. Designed for small to medium-scale production, this machine offers a cost-effective solution for manufacturers seeking precision-engineered components without the complexity of multi-roller systems.

Compact Design ALTRON’s full functional single roller spinning machine features a compact design that fits seamlessly into tight manufacturing spaces. Despite its smaller footprint, it delivers impressive performance and reliability, making it an ideal choice for workshops and production facilities with limited floor space.

Ease of Operation One of the key advantages of ALTRON’s single roller spinning machine is its ease of operation. With intuitive controls and user-friendly interfaces, operators can quickly master the spinning process, minimizing training times and maximizing productivity. Whether producing prototypes or small-batch runs, this machine offers unparalleled ease of use for manufacturers of all skill levels.

Cost-Effective Solution For manufacturers seeking a cost-effective solution for metal spinning, ALTRON’s single roller machine provides exceptional value. Its simplified design and efficient operation translate into lower upfront costs and reduced maintenance expenses over time. By optimizing resources without compromising quality, it empowers businesses to remain competitive in today’s dynamic marketplace.

ALTRON’s Double Roller Symmetry Spinning Machine

Symmetrical components require specialized equipment to ensure uniformity and precision. ALTRON’s double roller symmetry spinning machine is specifically designed to meet these exacting standards, enabling manufacturers to produce symmetrical parts with unparalleled accuracy and efficiency.

Symmetry Optimization ALTRON’s double roller spinning machine employs advanced algorithms to optimize symmetry in spun components. By precisely controlling roller movements and material flow, it achieves symmetrical profiles with micron-level accuracy, eliminating deviations and irregularities. This level of precision is essential for applications where symmetry is critical, such as automotive components and precision instruments.

High-Speed Spinning In addition to symmetrical accuracy, ALTRON’s CNC Metal Spinning Machine in China excels in high-speed spinning, allowing for rapid production of symmetrical parts without sacrificing quality. Its robust construction and advanced servo motors ensure smooth operation at elevated speeds, minimizing cycle times and maximizing throughput. Whether producing wheel rims or aerospace components, manufacturers can rely on ALTRON’s machine to deliver symmetrical perfection with unmatched efficiency.

Customization Flexibility Despite its focus on symmetry, ALTRON’s double roller spinning machine offers flexibility for customization. Manufacturers can adjust parameters such as wall thickness, diameter, and taper angle to meet specific design requirements and performance criteria. This customization flexibility enables the creation of bespoke components tailored to the unique needs of each application, ensuring optimal functionality and performance.

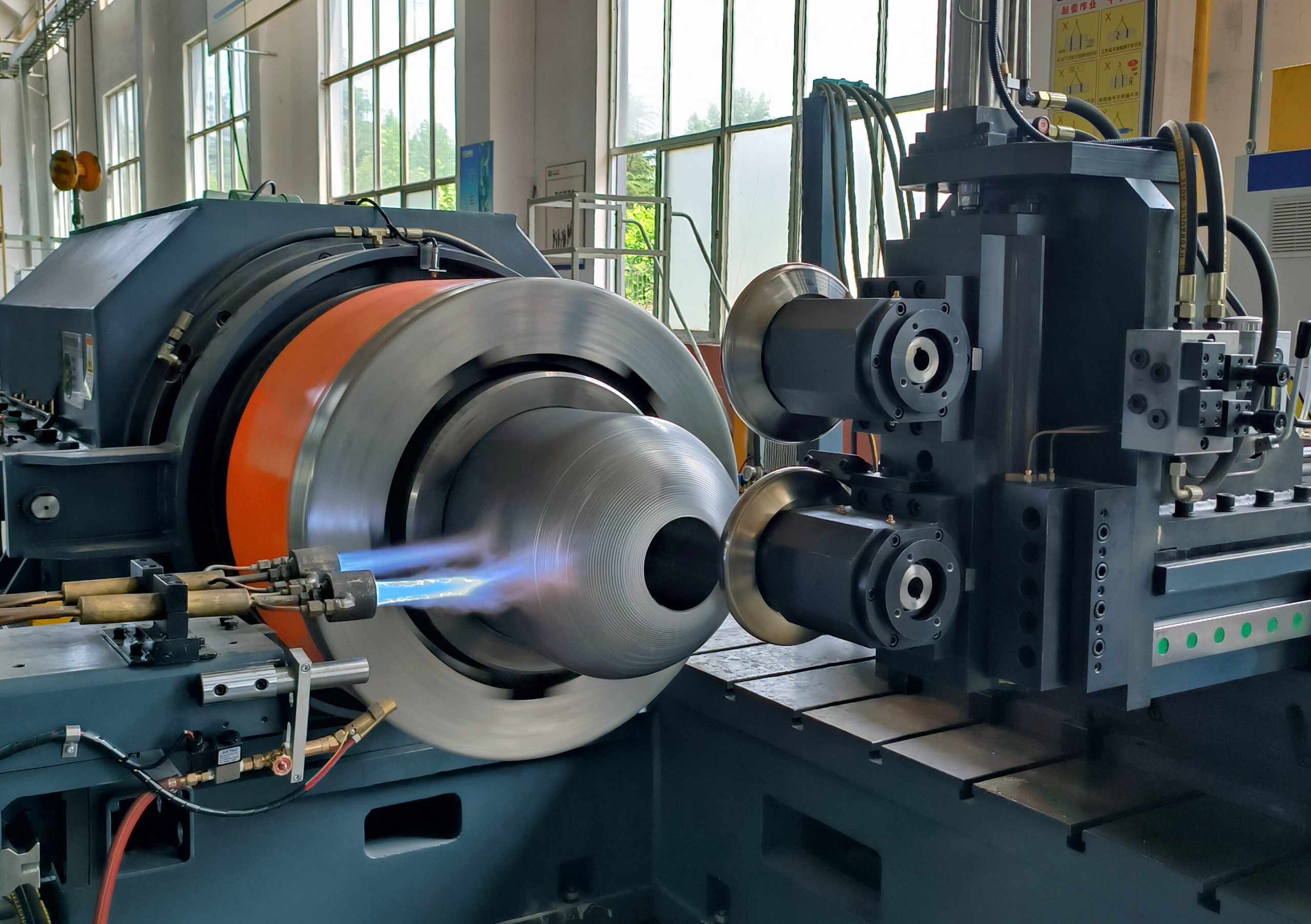

ALTRON’s High-Pressure Gas Cylinder Spinning Machines

ALTRON’s high-pressure gas cylinder spinning machines represent a pinnacle of engineering ingenuity. These machines are meticulously designed to produce gas cylinders with exceptional strength, reliability, and precision. Powered by advanced CNC controls, they enable manufacturers to meet stringent safety standards and regulatory requirements with ease.

Enhanced Safety Safety is paramount in the production of high-pressure gas cylinders. ALTRON’s spinning machines incorporate advanced safety features and fail-safes to prevent accidents and ensure operator well-being. From automated tooling changes to real-time monitoring systems, every aspect of these machines is engineered to prioritize safety without compromising productivity.

Optimized Efficiency In addition to safety, ALTRON’s spinning machines deliver unmatched efficiency in gas cylinder production. Their high-speed spinning capabilities, coupled with precise CNC controls, enable rapid fabrication of cylinders with consistent wall thickness and dimensional accuracy. This efficiency not only reduces manufacturing costs but also accelerates time-to-market, giving manufacturers a competitive edge in the industry.

Customization Flexibility ALTRON’s spinning machines offer unparalleled flexibility for customization. Whether producing cylinders for industrial gases, medical applications, or aerospace propulsion systems, manufacturers can tailor each component to meet specific performance criteria and regulatory standards. From alloy selection to surface finishing, ALTRON’s machines empower manufacturers to create bespoke solutions that exceed customer expectations.

ALTRON’s High-Performance Double Arms Metal Spinning Machine

For manufacturers seeking exceptional performance and versatility, ALTRON’s high-performance double arms metal spinning machine is the ultimate solution. This state-of-the-art equipment combines precision engineering with advanced automation to deliver superior results across a wide range of applications.

Dual-Arm Configuration ALTRON’s double arms metal spinning machine features a dual-arm configuration, allowing for simultaneous spinning of multiple components. This innovative design maximizes productivity while maintaining precision and accuracy. Whether producing symmetrical parts or complex geometries, manufacturers can rely on ALTRON’s machine to deliver consistent results with unmatched efficiency.

Advanced Automation Automation is at the core of ALTRON’s high-performance spinning machine. Integrated CNC controls and servo motors enable precise control over every aspect of the spinning process, from tooling adjustments to material feed rates. This automation not only reduces labor costs but also minimizes human error, ensuring reproducible results with minimal intervention.

Versatile Applications From automotive components to architectural features, ALTRON’s double arms metal spinning machine caters to a diverse range of industries and applications. Its versatility allows for the production of everything from decorative trim pieces to functional components with complex geometries. Whether shaping aluminum, stainless steel, or titanium, manufacturers can trust ALTRON’s machine to deliver exceptional results every time.

Horizontal Wheel Metal Spinning Machine

ALTRON’s horizontal wheel metal spinning machine offers a unique approach to metal spinning, with a horizontal orientation that provides distinct advantages in certain applications. This innovative design, coupled with advanced CNC technology, opens new possibilities for manufacturers seeking precision and efficiency in metal shaping.

Efficient Material Handling The horizontal wheel configuration of ALTRON’s spinning machine facilitates efficient material handling and loading. Operators can easily position workpieces onto the spinning wheel without the need for complex fixturing or tooling. This streamlined workflow minimizes setup times and maximizes productivity, making it ideal for high-volume production runs.

Consistent Results Despite its unconventional orientation, ALTRON’s horizontal wheel spinning machine delivers consistent results with unparalleled precision. The CNC controls enable operators to program intricate geometries and tool paths, ensuring uniformity in part dimensions and surface finish. Whether producing automotive rims or lighting fixtures, manufacturers can trust ALTRON’s machine to meet the most demanding specifications.

Space-Saving Design In addition to its performance advantages, ALTRON’s horizontal wheel spinning machine features a space-saving design that maximizes floor space utilization. Its compact footprint makes it suitable for workshops and manufacturing facilities with limited space constraints. Despite its small size, this machine packs a punch, delivering high-speed spinning capabilities and exceptional reliability.

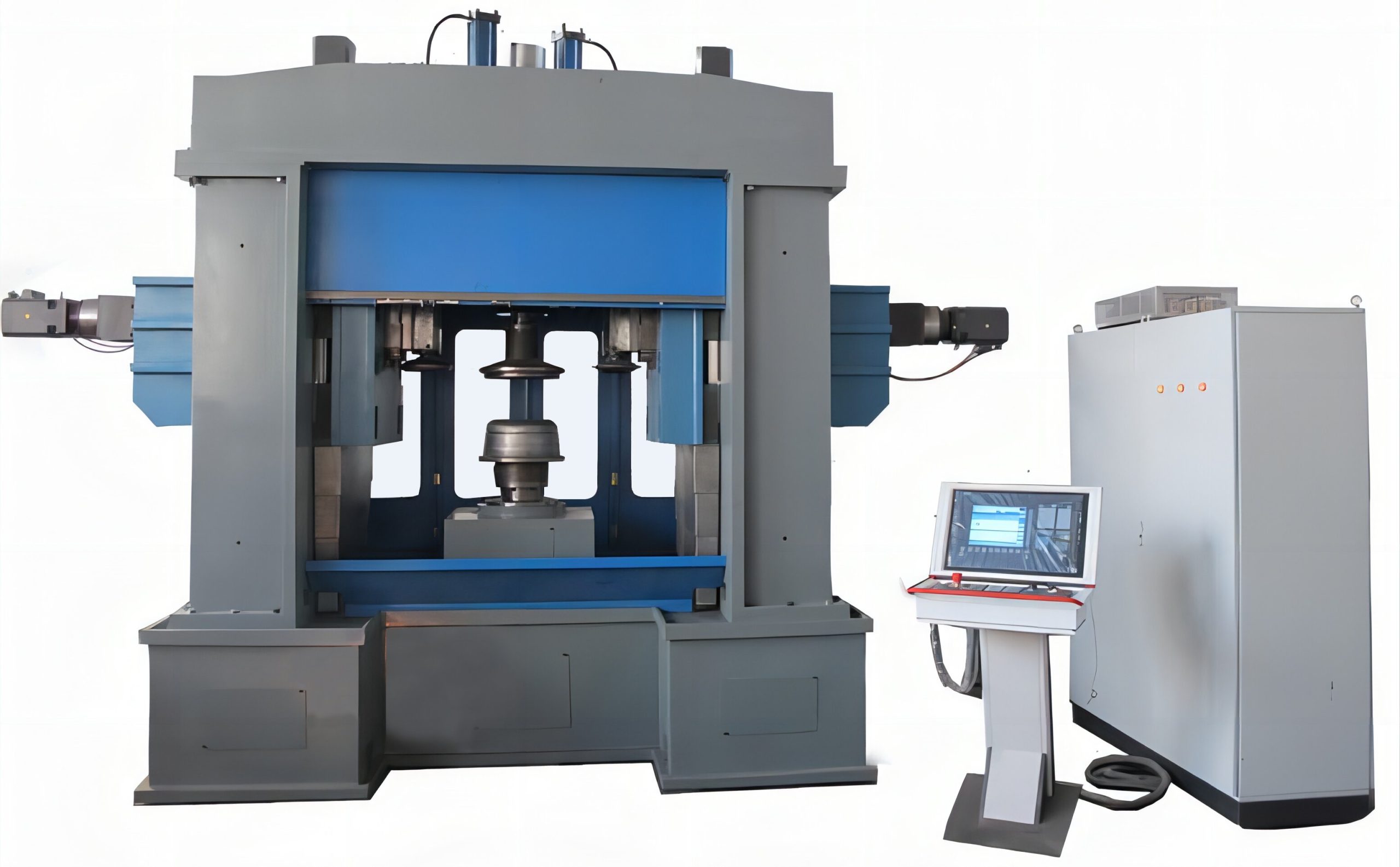

Vertical Wheel Metal Spinning Machine

Vertical wheel metal spinning machines are renowned for their ability to produce large, symmetrical components with unparalleled precision. ALTRON’s vertical wheel spinning machine builds upon this legacy, offering advanced CNC controls and automation to meet the evolving needs of modern manufacturing.

Symmetrical Component Production ALTRON’s vertical wheel spinning machine excels in the production of symmetrical components such as hemispheres, cones, and domes. Its vertical orientation allows for uniform material flow and tooling pressure, ensuring symmetrical profiles with micron-level accuracy. Whether for aerospace applications or architectural features, manufacturers can rely on ALTRON’s machine to deliver flawless results every time.

High-Speed Spinning Despite its focus on symmetry, ALTRON’s vertical wheel spinning machine boasts impressive high-speed spinning capabilities. Equipped with powerful servo motors and precision bearings, it can achieve rapid spindle speeds without sacrificing accuracy or reliability. This high-speed performance enables manufacturers to meet tight production deadlines and maximize throughput without compromising quality.

Advanced CNC Controls At the heart of ALTRON’s vertical wheel spinning machine lies advanced CNC controls that empower operators to achieve optimal results with ease. From programming complex geometries to adjusting tooling parameters on the fly, the CNC system provides unparalleled flexibility and control. This level of automation not only reduces setup times but also minimizes human error, ensuring consistent quality across every batch of manufactured parts.

Axial Fan CNC Flanging Machine

Flanges are essential components in axial fan assembly, providing secure connections between fan blades and motor shafts. ALTRON’s axial fan CNC flanging machine streamlines the production of these critical components, offering precision engineering and automation to meet the demands of modern fan manufacturing.

Seamless Integration ALTRON’s CNC flanging machine seamlessly integrates into existing production lines, enhancing efficiency and productivity. Its modular design allows for easy customization to accommodate various fan sizes and configurations. Whether producing industrial cooling fans or HVAC systems, manufacturers can rely on ALTRON’s machine to deliver consistent results with minimal downtime.

Precision Flange Fabrication Flanges produced by ALTRON’s CNC machine boast unparalleled precision and dimensional accuracy. The advanced CNC controls enable operators to program flange dimensions with micron-level precision, ensuring a perfect fit and alignment with fan blades and motor shafts. This precision fabrication minimizes vibration and ensures smooth operation, prolonging the lifespan of axial fan assemblies.

Automated Workflow ALTRON’s CNC flanging machine features advanced automation capabilities that streamline the manufacturing process from start to finish. From material handling and tooling changes to flange forming and finishing, every step of the workflow is automated to maximize efficiency and minimize labor costs. This automated approach not only reduces production time but also improves consistency and quality, ensuring customer satisfaction with every fan assembly.

Conclusion

In the realm of metal spinning, ALTRON’s CNC Metal Spinning Machine in China represent the pinnacle of innovation and excellence. From multi-roller powerful spinning machines to compact single roller systems, ALTRON offers a comprehensive range of solutions to meet the diverse needs of modern manufacturing. With their precision engineering, versatility, and efficiency, these machines empower manufacturers to push the boundaries of what’s possible, ushering in a new era of metalworking excellence.