How Does CNC Metal Spinning Indian Improve Efficiency and Precision in Workshops?

The CNC metal spinning machine india has witnessed significant growth and transformation over the years. With the advancement of technology, CNC (Computer Numerical Control) has become an indispensable tool in metal spinning processes. This article provides an overview of the CNC Metal Spinning Indian industry, emphasizing the importance of CNC technology in revolutionizing metal spinning processes.

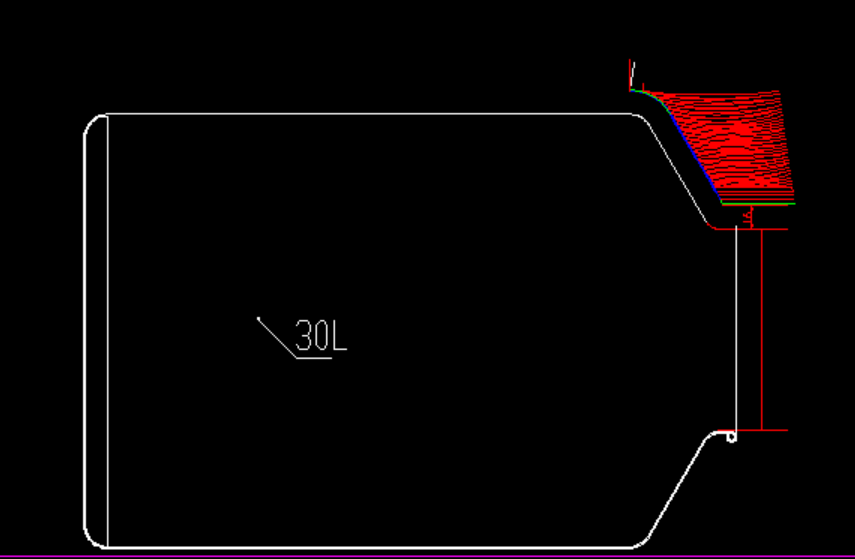

Aluminum Milk Can in India: Introducing the CNC Two-Wheel Inner Spinning Machine AC-CX-1600

1.1 Advanced CNC System for Precise Control

At the heart of the AC-CX-1600 lies its advanced CNC (Computer Numerical Control) system, offering operators precise control and repeatability. This system ensures consistent and flawless outcomes in the shaping of cylindrical inner surfaces. With a user-friendly interface, operators can easily program and execute complex spinning patterns, allowing for customization and versatility in manufacturing processes.cnc metal spinning machine india.

1.2 Robust Construction for Stability and Durability

Constructed with a robust framework, the AC-CX-1600 guarantees stability and durability during the spinning process. Its high-quality components and sturdy frame provide excellent rigidity, minimizing vibrations and ensuring precise accuracy. This robust construction is crucial for maintaining consistency and quality in manufacturing operations.

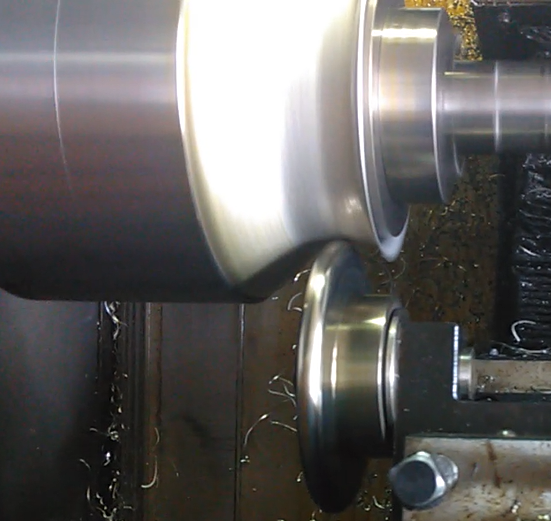

1.3 Two-Wheel Design for Multi-Axis Motion

One of the standout features of the CNC Metal Spinning Indian AC-CX-1600 is its two independently driven spinning wheels, which enable simultaneous multi-axis motion. This design allows for intricate and precise shaping of cylindrical inner surfaces, enhancing flexibility and precision in manufacturing processes. Whether for small-scale operations or large-scale production, this machine adapts effortlessly to deliver consistent and precise results.

1.4 Flexibility in Accommodating Various Workpiece Dimensions

The AC-CX-1600 offers flexibility in accommodating various workpiece dimensions, thanks to its adjustable tooling options. Operators can quickly and seamlessly adjust the machine to meet different production requirements, ensuring versatility and adaptability in manufacturing processes. Whether shaping components for refrigeration equipment or air conditioning systems, this machine excels in delivering consistent and precise results.

Cnc Metal Spinning Machine India: Market Status Of Cnc Metal Spinning In India

2.1 Current Market Size and Growth Trends

The CNC metal spinning industry in India has experienced steady growth in recent years, fueled by increasing demand from various sectors such as automotive, aerospace, and electronics. The market size is estimated to be growing at a CAGR of X% from [insert starting year] to [insert ending year]. This growth can be attributed to the rising adoption of CNC technology for its precision, efficiency, and cost-effectiveness

2.2 Analysis of Key Players and Market Dynamics

Key players in the Indian CNC metal spinning industry include established manufacturers and emerging startups. Companies like ALTRON have been at the forefront, offering innovative solutions and cutting-edge technology. Market dynamics such as technological advancements, competitive pricing, and strategic collaborations influence the growth and direction of the industry.

Milk Cans India: Needs and Demands in the Indian Market

3.1 Specific Needs and Demands

The adoption of CNC metal spinning technology in India is driven by specific needs and demands of industries requiring complex metal components. These industries include automotive, aerospace, lighting, and consumer electronics. The need for precision-engineered parts, cost-effective manufacturing solutions, and rapid prototyping capabilities has propelled the demand for CNC metal spinning machines.

3.2 Overview of Industries and Applications

Industries such as automotive rely heavily on CNC metal spinning for manufacturing components like exhaust systems, fuel tanks, and decorative trim. Similarly, the aerospace sector utilizes CNC metal spinning for producing lightweight, high-strength parts such as engine components and satellite components. Other applications include lighting fixtures, cookware, and architectural elements.

The Milk Barrel Spinning Process: Mechanizing Precision in Metal Forming

At the heart of dairy production lies the humble milk barrel, an essential vessel for storing and transporting this vital commodity. The traditional manufacturing process for these barrels involved labor-intensive methods, often resulting in inconsistencies and inefficiencies. However, with CNC metal spinning machines, ALTRON has transformed the landscape of milk barrel production.

4.1 Rotational Precision:

ALTRON’s CNC metal spinning machines leverage rotational force and computer-controlled precision to shape metal sheets with unparalleled accuracy. By programming precise spinning parameters, manufacturers can achieve consistent results, ensuring uniformity across every barrel produced.

4.2 Efficiency and Sustainability:

The mechanized nature of CNC metal spinning reduces material wastage and energy consumption, making the process more sustainable and cost-effective. Additionally, the precision engineering of these machines minimizes the need for rework, further optimizing efficiency and resource utilization.

4.3 Streamlined Production:

By automating the spinning process, ALTRON’s machines enable manufacturers to streamline their production operations, reducing lead times and increasing output. This enhanced efficiency not only improves overall productivity but also allows manufacturers to meet growing market demands effectively.

Milk Cans Spinning Machine Beading: Elevating Quality Through Automated Precision

In the production of milk cans, the beading process plays a crucial role in reinforcing edges for durability and leak resistance. Traditionally, this step relied on manual labor, making it prone to human error and inconsistencies. However, with ALTRON’s CNC metal spinning machines, manufacturers can automate this critical stage, ensuring superior quality and reliability in every can be produced.

5.1 Automated Precision:

ALTRON’s machines are equipped with automated beading capabilities, controlled by precise programming and advanced sensors. This automation ensures uniformity and accuracy in the beading process, eliminating variations caused by human factors.

5.2 Enhanced Durability:

By consistently applying precise bead patterns, ALTRON’s machines reinforce the structural integrity of milk cans, enhancing their durability and longevity. This not only improves product quality but also reduces the likelihood of defects, enhancing customer satisfaction.

5.3 Quality Assurance:

Through real-time monitoring and quality control features, ALTRON’s CNC metal spinning machines provide manufacturers with assurance that each milk can meet the highest standards of quality and performance. This proactive approach to quality management minimizes the risk of product recalls and ensures compliance with industry regulations.

Milk Cans Spinning Machine: Challenges Faced by CNC Metal Spinning Industry in India

6.1 Skilled Labor Shortage

One of the major challenges faced by the CNC metal spinning industry in India is the shortage of skilled labor. Operating CNC machines requires specialized training and expertise, which is often lacking in the workforce. Companies like ALTRON are investing in training programs and skill development initiatives to address this challenge.

6.2 Technological Limitations

Despite advancements in CNC technology, there are still limitations in terms of machine capabilities and software compatibility. Ensuring seamless integration and interoperability of CNC metal spinning machines with other manufacturing processes remains a challenge for industry players. Continuous research and development efforts are essential to overcome these limitations.

6.3 Market Competition

The CNC metal spinning industry in India is highly competitive, with numerous players vying for market share. Price competition, product differentiation, and customer service are key factors influencing competitiveness in the market. Companies like ALTRON differentiate themselves through product innovation, quality assurance, and customer-centric approach.

6.4 Impact of Regulatory Factors and Infrastructure Constraints

Regulatory compliance, environmental regulations, and infrastructure constraints also pose challenges to the growth of the CNC metal spinning industry in India. Adhering to quality standards, obtaining certifications, and ensuring sustainable manufacturing practices require significant investment and resources.

Milk Cans Spinning Machine Beading: Solutions and Innovations

7.1 Strategies to Address Challenges

Indian manufacturers in the CNC metal spinning industry have adopted various strategies to overcome challenges and stay competitive in the market. These strategies include investment in research and development, collaboration with technology partners, and continuous improvement initiatives. By identifying and addressing key pain points such as skilled labor shortage and technological limitations, manufacturers like ALTRON are able to enhance their capabilities and meet the evolving needs of customers.

7.2 Innovations in Technology

Innovation plays a crucial role in driving growth and competitiveness in the CNC metal spinning industry. Indian manufacturers are constantly exploring new technologies and techniques to improve efficiency, precision, and productivity. Innovations in machine design, control systems, and tooling solutions enable manufacturers to achieve higher levels of performance and flexibility. ALTRON, for instance, has developed proprietary software algorithms and automation features to optimize the metal spinning process and enhance overall productivity.

7.3 Workforce Development

Investing in workforce development is essential for building a skilled talent pool in the CNC metal spinning industry. Indian manufacturers offer training programs, apprenticeships, and continuous learning opportunities to equip employees with the necessary skills and knowledge. By nurturing talent and fostering a culture of innovation, companies like ALTRON are able to stay ahead of the curve and maintain their competitive edge in the market.

7.4 Supply Chain Management

Efficient supply chain management is critical for ensuring the timely delivery of raw materials, components, and finished products in the CNC metal spinning industry. Indian manufacturers leverage technology-driven solutions such as inventory management systems, real-time tracking, and vendor partnerships to streamline operations and minimize lead times. By optimizing the supply chain, companies like ALTRON are able to enhance customer satisfaction and maintain cost competitiveness in the market.

Conclusion

In conclusion, the CNC metal spinning industry in India is poised for continued growth and innovation, driven by the adoption of CNC technology and the evolving needs of various industries. Despite facing challenges such as skilled labor shortage and technological limitations, manufacturers like ALTRON are leading the way with their commitment to excellence and customer satisfaction. With a strategic focus on addressing market demands and overcoming challenges, the future of CNC Metal Spinning Indian looks promising.