CNC Metal Spinning Machine Suppliers: ROI with ALTRON

Metal spinning, a precision metalworking technique, has undergone a remarkable transformation with the advent of Computer Numerical Control (CNC) technology. CNC metal spinning machines have revolutionized the manufacturing industry by enhancing precision, efficiency, and productivity. In this blog, we delve into the world of CNC metal spinning machine suppliers, focusing particularly on ALTRON, while conducting a comprehensive cost analysis and exploring the potential return on investment (ROI).

What are CNC Metal Spinning Machines?

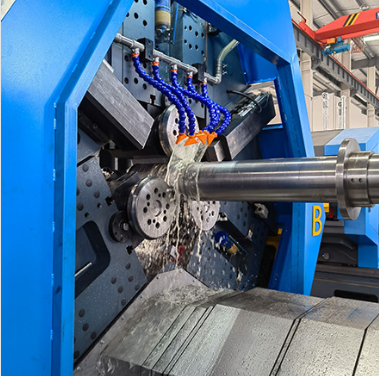

CNC metal spinning machines are a blend of traditional craftsmanship and cutting-edge technology. These machines are designed to shape sheet metal into desired forms, primarily through the use of rotating mandrels and tools. The precision offered by CNC technology elevates the quality and repeatability of spun metal components, making them indispensable across a myriad of industries, from automotive to lighting, and even architectural elements.

ALTRON is actively involved in developing innovations that cater to the demand for intricate and diverse metal shapes. The future of CNC metal spinning will witness the use of advanced materials beyond traditional metals, such as composites and alloys. This expansion of material possibilities will enable manufacturers to create lightweight yet durable components for various industries.

Artificial Intelligence (AI) is making its mark on CNC metal spinning technology. Suppliers are exploring AI algorithms to predict potential defects or irregularities in spun metal parts. ALTRON’s research and development efforts in this area aim to enhance precision, reduce material wastage, and further elevate the quality of spun metal components.

Cost Factors in CNC Metal Spinning

Investing in CNC metal spinning technology involves a multifaceted cost analysis. ALTRON, a prominent CNC metal spinning machine supplier, offers machines that vary in price based on their specifications and capabilities. The initial investment includes the machine’s cost, tooling expenses, and setup charges. It’s crucial to assess the machine’s compatibility with your manufacturing needs, ensuring that it aligns with the complexity and volume of your projects.

Maintenance is another vital cost consideration. Regular upkeep of CNC metal spinning machines, including lubrication, component replacement, and calibration, helps extend their operational life and sustain optimal performance. ALTRON’s machines are known for their durability and reliability, potentially minimizing long-term maintenance expenses.

Energy consumption is a factor that affects both operational costs and environmental impact. CNC metal spinning machines are designed to be energy-efficient, with features like variable speed drives and power-saving modes. CNC metal spinning machine suppliers like ALTRON emphasizes sustainable manufacturing solutions, and their machines often incorporate energy-efficient technologies, thus potentially leading to reduced energy expenses.

Technical Skills of CNC Metal Spinning Machines

- Programming Precision:CNC metal spinning machines rely on intricate programming to dictate the shaping process. Manufacturers like ALTRON excel in developing programming that considers factors like material properties, desired dimensions, and geometries. The precision of these programs ensures consistent, high-quality results.

- Material Expertise:Different metals exhibit unique behaviors during the spinning process. Suppliers like ALTRON possess in-depth knowledge of various materials, including aluminum, stainless steel, and copper. This expertise helps in selecting the right material for each project, optimizing the spinning process for enhanced efficiency and product durability.

- Tooling Design:Crafting precise tooling for metal spinning is a crucial skill. ALTRON’s expertise lies in designing and manufacturing tooling that meets the specific requirements of each project. Well-designed tooling ensures that the metal is formed accurately and consistently, minimizing waste and rework.

- Machine Calibration: Calibration is essential to achieve accurate results. CNC metal spinning machines must be calibrated to account for variables like material thickness, tool wear, and environmental conditions. ALTRON’s technical team excels in fine-tuning these machines, ensuring the final products meet tight tolerances.

- Process Optimization:Achieving efficiency without compromising quality is a hallmark of CNC metal spinning. Suppliers like ALTRON focus on optimizing the spinning process by fine-tuning parameters such as spindle speed, feed rate, and tool pressure. This optimization results in reduced cycle times and cost-effective production.

The ALTRON Advantage: Precision and Performance

ALTRON stands out as a leading CNC metal spinning machine suppliers, offering a range of machines tailored to different production requirements. Their machines are lauded for their precision, versatility, and user-friendly interfaces. ALTRON’s commitment to innovation is evident in its incorporation of advanced CNC technology, enabling intricate metal shaping with minimal operator intervention.

Exploring ROI Potential

The return on investment for CNC metal spinning machines is a compelling aspect for manufacturers seeking long-term viability. While the initial investment might seem substantial, the enhanced production capabilities and quality improvements can lead to significant gains over time. ALTRON’s machines, known for their efficiency and rapid production cycles, can contribute to faster project completion and quicker time-to-market, potentially translating into higher revenues.

Reduced material wastage is another factor contributing to ROI. CNC metal spinning machines, guided by precise computer-controlled movements, minimize errors that might lead to material scrap. ALTRON’s machines excel in material utilization, ensuring that raw materials are maximized, and waste is minimized.

What sets ALTRON apart is its holistic approach to CNC metal spinning:

- Tailored Solutions:ALTRON collaborates closely with clients to understand their specific needs. This allows them to offer tailor-made CNC metal spinning solutions, optimizing the entire manufacturing process.

- Technical Support:ALTRON’s technical team offers comprehensive support, from installation to operation. This ensures that manufacturers can harness the full potential of their CNC metal spinning machines.

- Continuous Innovation:The field of CNC metal spinning is ever-evolving. ALTRON keeps pace with technological advancements, incorporating the latest innovations into its machines to offer cutting-edge capabilities.

Conclusion

CNC metal spinning machines have redefined the art of metalworking, and ALTRON stands as a distinguished CNC metal spinning machine suppliers in this domain. The cost analysis involving machine prices, maintenance, tooling, and energy consumption is a critical aspect of the decision-making process. As the manufacturing industry continues to evolve, investing in CNC metal spinning technology from suppliers like ALTRON can potentially yield impressive returns on investment, setting the stage for a future of efficient, precise, and sustainable metal component production.