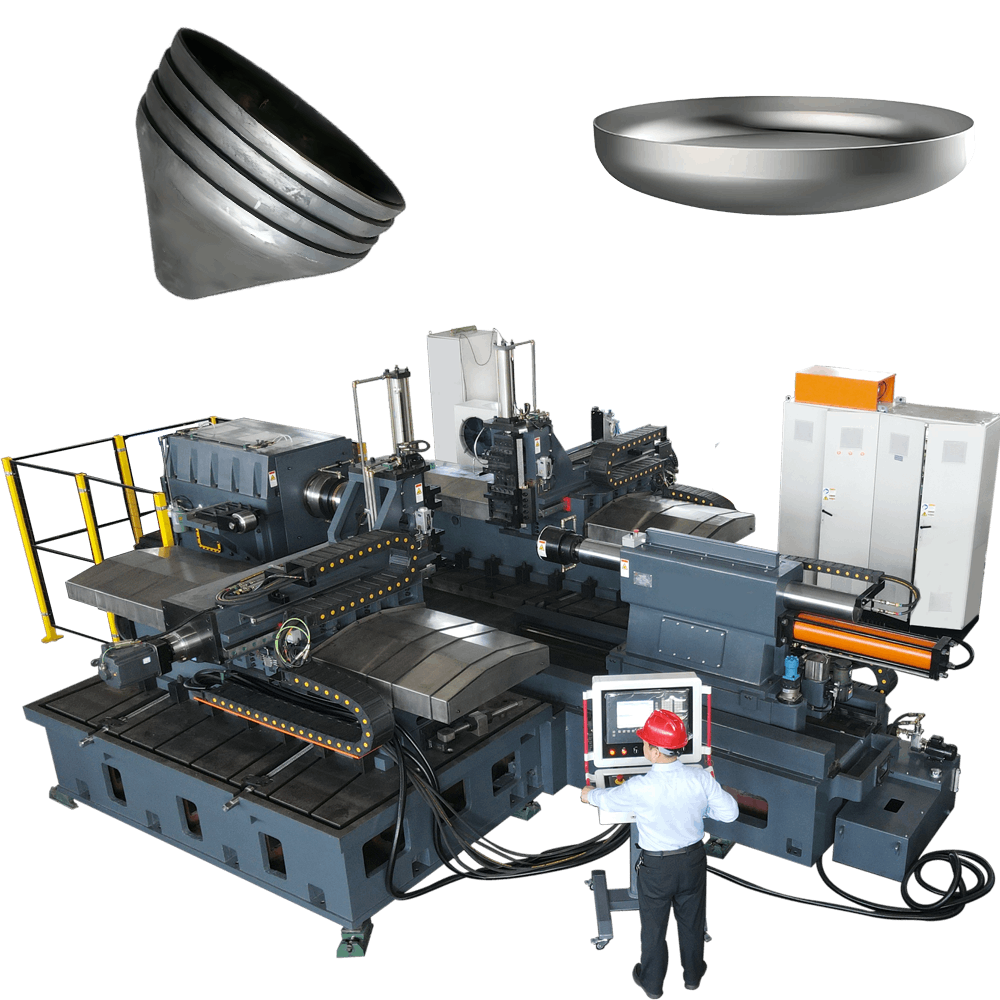

CNC Metal Spinning Machine

Altron’s has more than 15 years of experience in manufacturing CNC metal spinning machine. Currently, it mainly produces five categories of metal spinning machines: Engineer Joby provides 7*24H online pre-sales meeting solution!

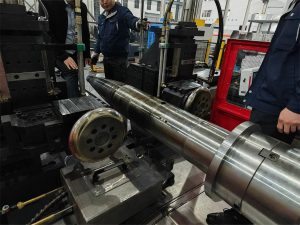

- Single Roller CNC Spinning Machines

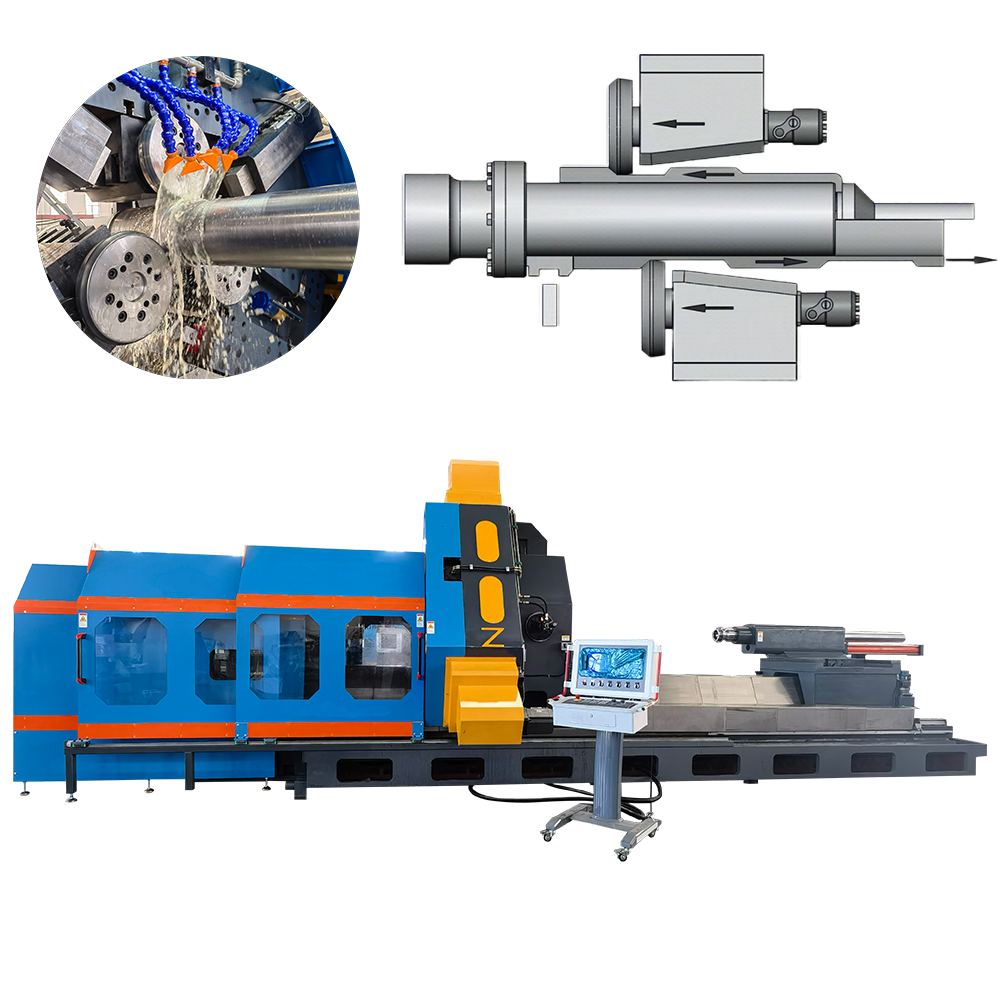

- Double Wheel CNC Spinning Machine

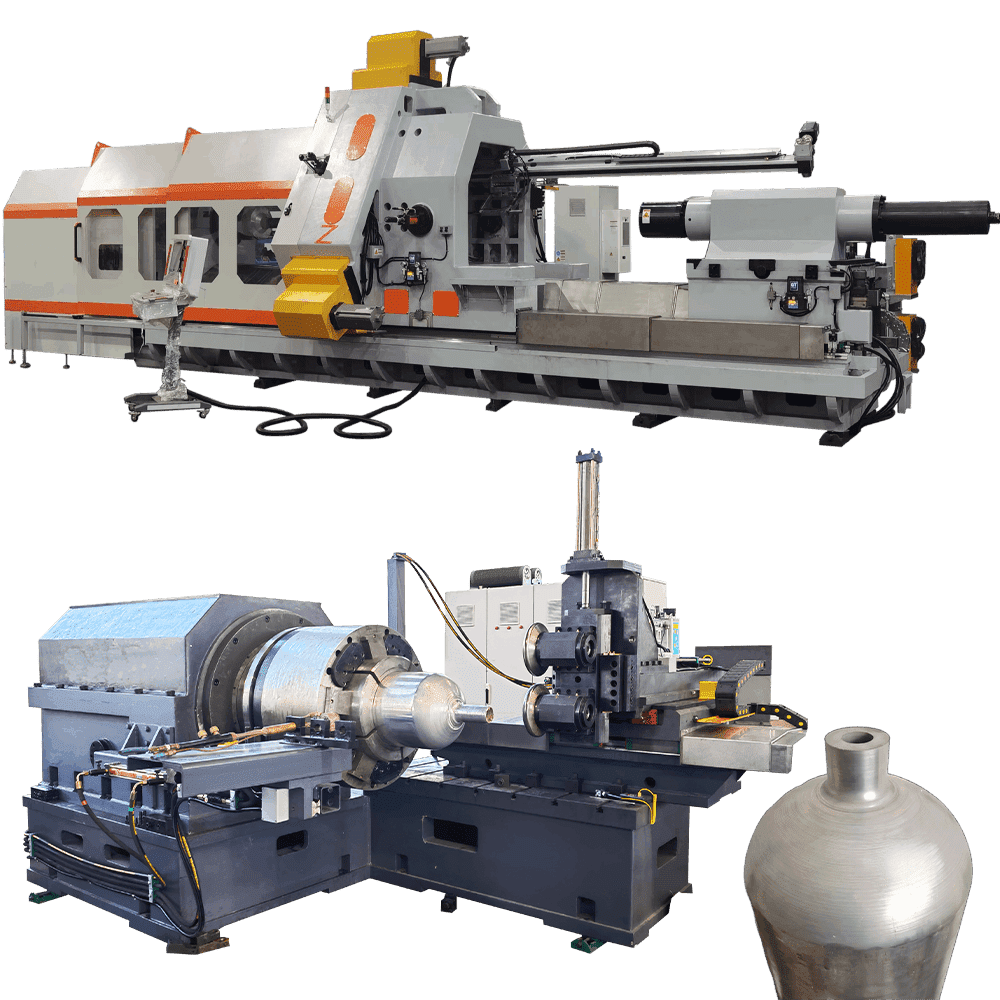

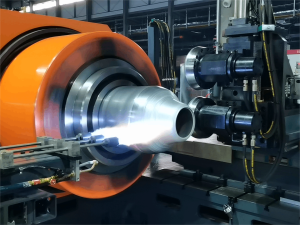

- Multi-roller CNC Flow Forming Machines

- Necking CNC Metal Spinning Machine

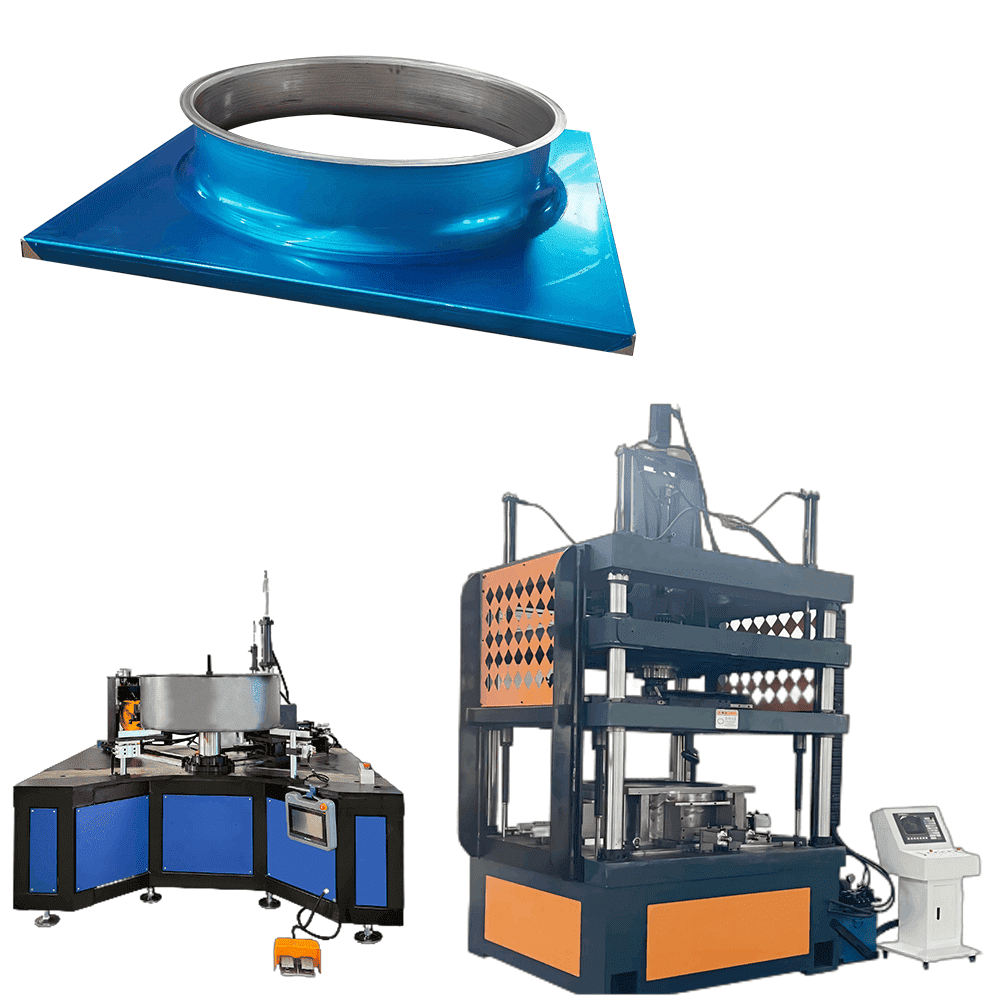

- Square Blank Inner Spinning Machine

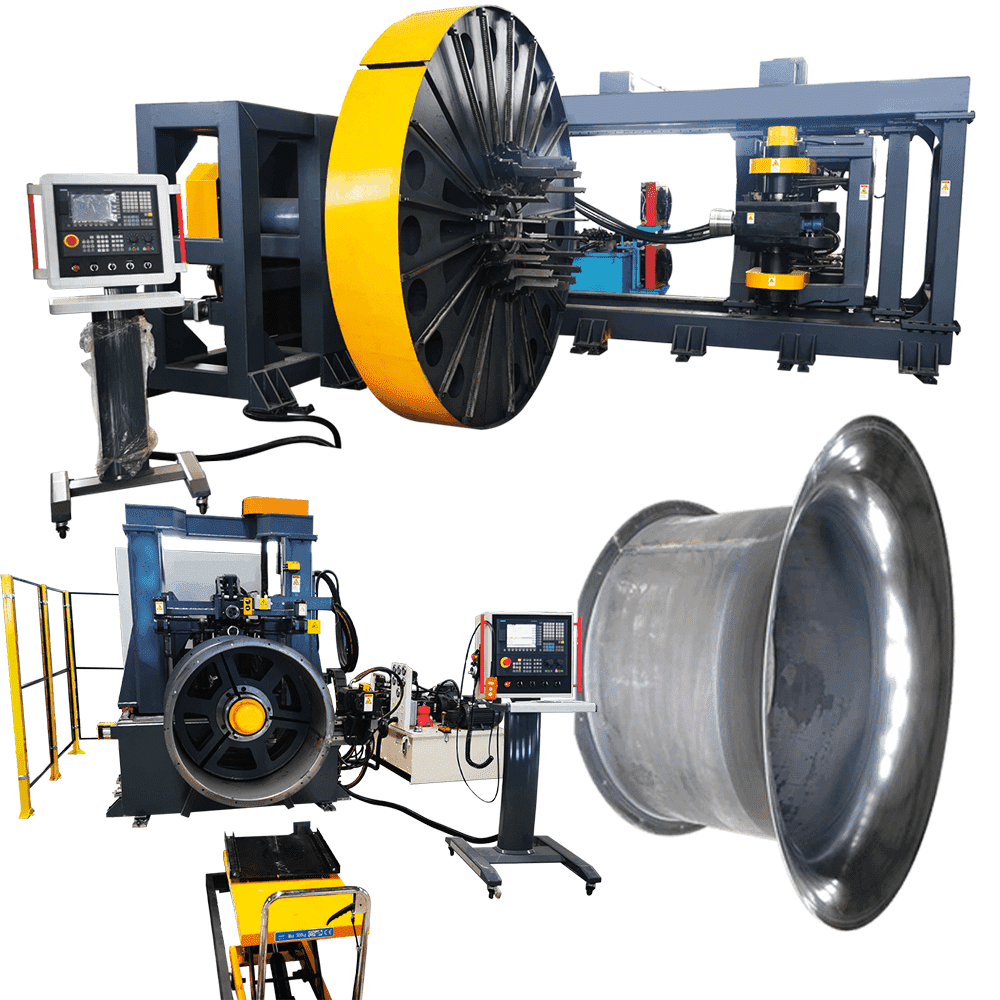

- Automobile Hub Metal Spinning Machine

Industry Introduction CNC Metal Spin Forming Machine

Application: Military, Aerospace, Aviation Weapons, Medical, Furniture, Lighting, Building, Fire, Musical Instruments, Crafts, Automotive Parts, Pressure Vessel, etc.

Material: Aluminum, Copper, Carbon Steel, Alloy Steel, Stainless Steel, Titanium, Non-Ferrous Metals And Other Alloy Materials.

Machine spinning capacity: diameter range 0-3800mm; thickness range: 0.3-40mm