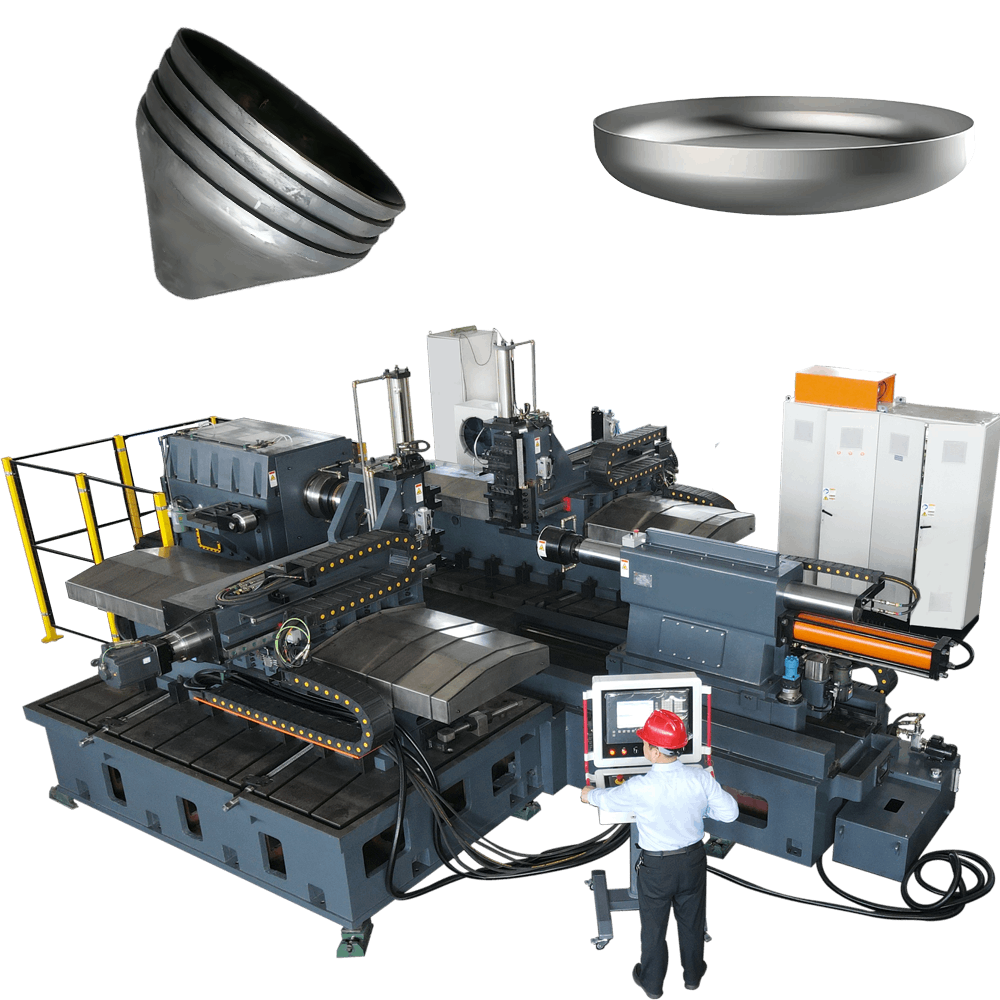

Double Roller CNC spinning Machines Parameters

Model No.

|

Max. Material Dia. (mm)

|

Radial Stroke (mm)

|

Axial Stroke (mm)

|

Roller Thrust (KN)

|

Tailstock Force (KN)

|

Spindle Power (KN)

|

Spindle Speed (RPM)

|

Material Thickness (mm)Aluminum/Carbon Steel/SUS

|

| ACD-600 |

600 |

260 |

1100 |

40 |

20 |

18.5 |

50-1000 |

6 / 4 / 3 |

| ACD-800 |

1300 |

400 |

1600 |

60 |

50 |

30 |

50-800 |

8 / 5 / 4 |

| ACD-1200 |

1650 |

500 |

800 |

80 |

50 |

37 |

30-500 |

10 / 6 / 4.5 |

| ACD-1600 |

1800 |

600 |

1000 |

120 |

70 |

45 |

30-450 |

14 / 8 / 5.5 |

| ACD-2000 |

2000 |

750 |

1250 |

140 |

100 |

75 |

30-400 |

14 / 10 / 7 |

| ACD-2500 |

2500 |

850 |

2050 |

200 |

140 |

132 |

10-300 |

30 / 20 / 15 |

| ACD-3500 |

3500 |

950 |

2550 |

300 |

140 / 200 |

200 |

10-300 |

40 / 25 / 20 |

How to Choose Double Roller CNC Spinning Machines

Double roller metal spinning machines are widely used in metal forming processes with high precision, high wall thickness and material strength! Chang Jian’s applications are in the fields of military industry, aerospace, large machinery, etc. Representative materials include titanium alloy, special high temperature alloy, nickel-based alloy, Hastelloy, stainless steel and other high-strength material forming processes!

- Calculate the blank diameter according to the product drawing and select the CNC metal spinning machine model.

- Determine the machine model according to the wall thickness of the blank material to be spun and the theoretical thrust required for forming.

- Select the metal forming machine structure according to the material and shape: single roller, double roller, multi-roller metal spinning machine or special customization!

- Formulate a plan based on the metal spinning process. Conventional spinning, water circulation spinning, and hot metal spinning all require the design and customization of different protective devices!

- When confirming the machine plan, Altron will assist you in selecting the appropriate machine model, analyzing the drawing parts, and determining the final processing plan!