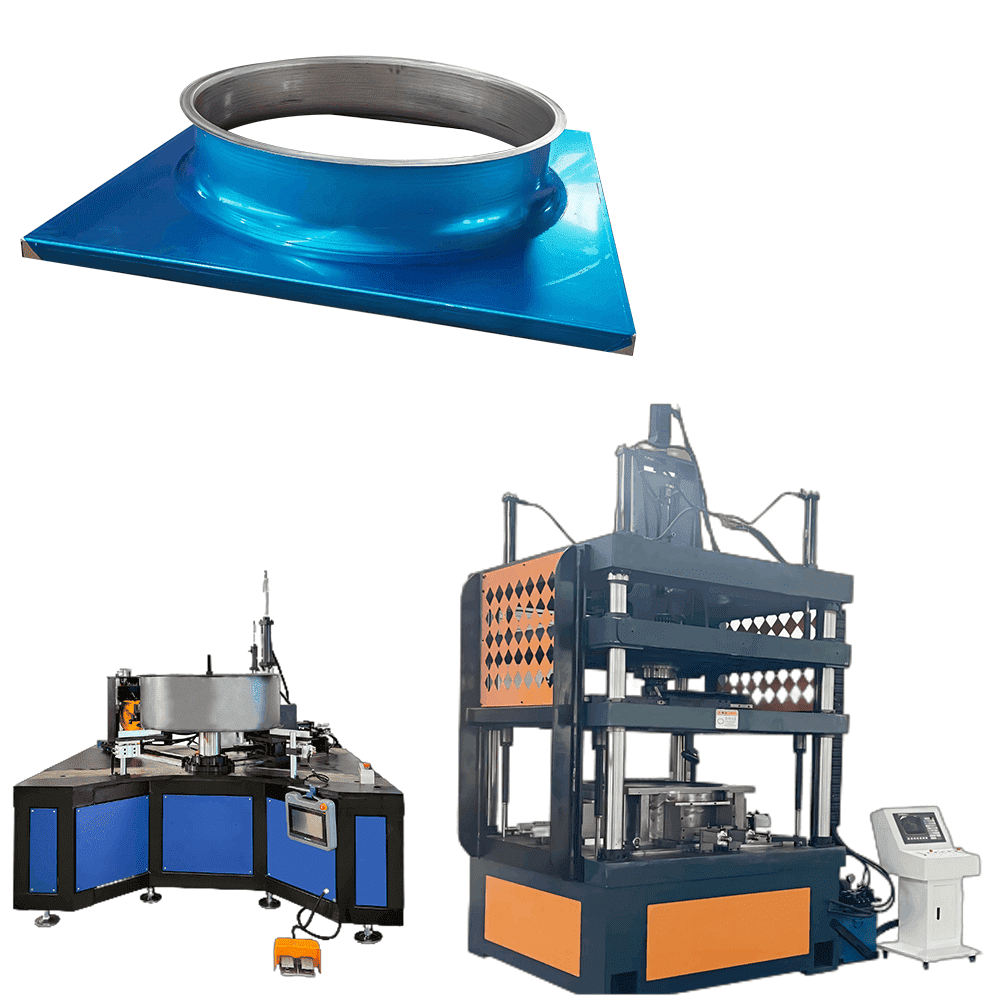

CNC Inner Spinning Machine

Altron‘s CNC Inner Spinning Machine is customized for the Industrial Fans industry!

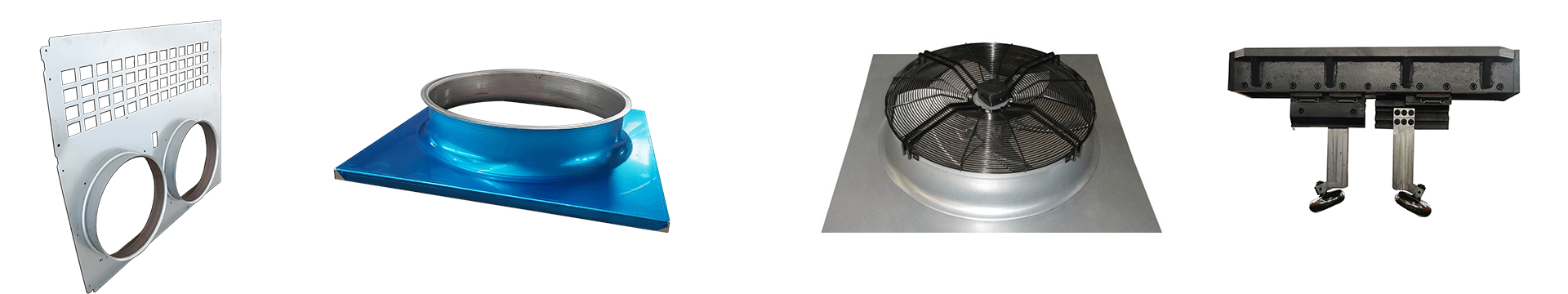

Processable fan industry accessories: Air Inlet Funnel, Impeller Shoruds, Air Conditioning Fan Panel, Air Conditioning Fan Guide Plate, Negative Pressure Blower Outlet, Cabinet Fan Air Outlet Panel...

Customized for different market demands, we currently have 2 models: Siemens CNC System & mechanical PLC .

Metal Inner Spinning Machine Features

- Process: square & irregular metal sheets are fixed, and the internal spinning mechanism forms the metal inner hole.

- Capacity: Straight Edge, Arc, Small Flanging And Flaring;

- Material: aluminum, iron, copper, stainless steel;

- Spinning range: Plate Width 200-2200mm; Max Spinning Inner Hole 2000mm; Thickness 1-3mm;

- Advantages of internal spinning: lower mold cost and higher efficiency compared to deep drawing; short development cycle.

- Deep drawing comparison: metal sheet is flat after metal spinning, and the internal stress deformation caused by deep drawing is small.