Beyond Boundaries: Future Trends in CNC Powerful Metal Necking Spinning Machine

Metal necking spinning machines are indispensable tools in the realm of metalworking, revolutionizing the way intricate metal shapes are crafted with precision and efficiency. At the forefront of this technology stands CNC (Computer Numerical Control), a pivotal advancement that has elevated the capabilities of metalworking machinery. A CNC powerful metal necking spinning machine, manufactured by ALTRON, embodies this innovation, offering unparalleled accuracy and versatility in shaping metal components.

Introduction to CNC Metal Necking Spinning Machines

1.1 Overview of Metal Necking Spinning Machines

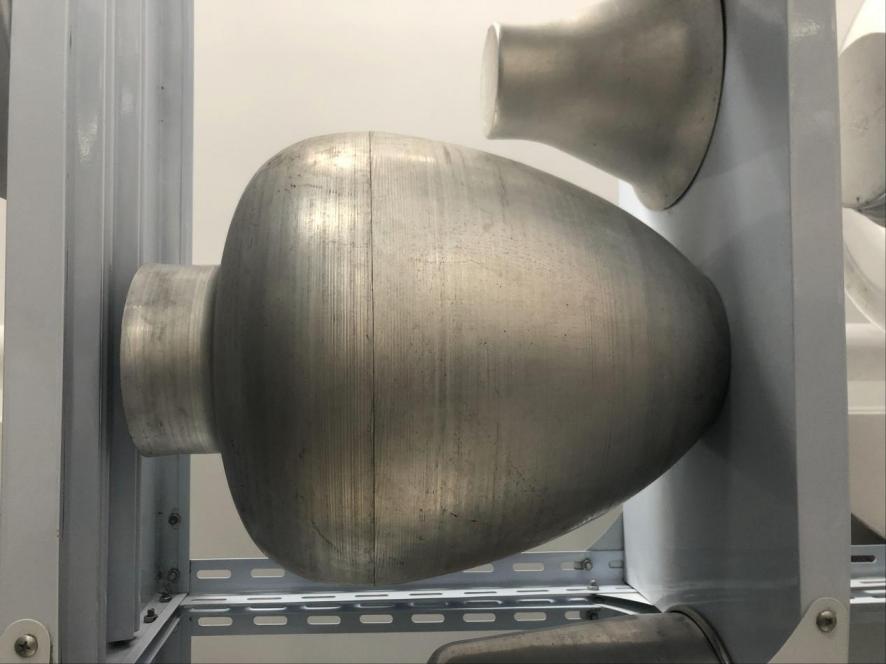

Metal necking spinning machines operate on the principle of forcing a metal disc or tube over a rotating mandrel to form a desired shape. The necking process involves gradually reducing the diameter of the metal, creating tapered or conical profiles. This technique is commonly used in industries such as aerospace, automotive, home appliances, and custom metal fabrication to produce a wide range of components.

1.2 Importance of CNC Technology in Metalworking

CNC technology integrates computer control into machining processes, enabling precise and automated production. In the context of metal necking spinning machines, CNC facilitates intricate shaping and ensures consistent quality across multiple iterations. The ability to program complex geometries easily enhances productivity and reduces reliance on manual labor, making CNC an indispensable tool for modern metalworking operations.

Advantages of Using CNC Metal Necking Spinning Machines

2.1 Precision and Accuracy in Metal Shaping

CNC metal necking spinning machines offer unparalleled precision, allowing for the creation of intricate shapes with tight tolerances. The computer-controlled process ensures uniformity and repeatability, minimizing errors and achieving high-quality results consistently.

2.2 Increased Productivity and Efficiency

Compared to manual methods, CNC metal necking spinning machines significantly boost productivity by streamlining the production process. Automated operations reduce the need for manual intervention, leading to faster turnaround times and increased output capacity.

2.3 Versatility in Producing Complex Metal Shapes

The flexibility of CNC programming empowers manufacturers to produce a wide variety of complex metal shapes using a single machine. Whether it’s creating intricate designs for aerospace components or forming customized profiles for architectural purposes, CNC metal necking spinning machines excel in versatility.

2.4 Reduction in Material Waste and Production Costs

By optimizing material usage and minimizing scrap, CNC metal necking spinning machines contribute to cost savings and resource efficiency. The precise control over the shaping process reduces material waste, leading to higher material utilization rates and lower production costs.

Key Components of CNC Metal Necking Spinning Machines

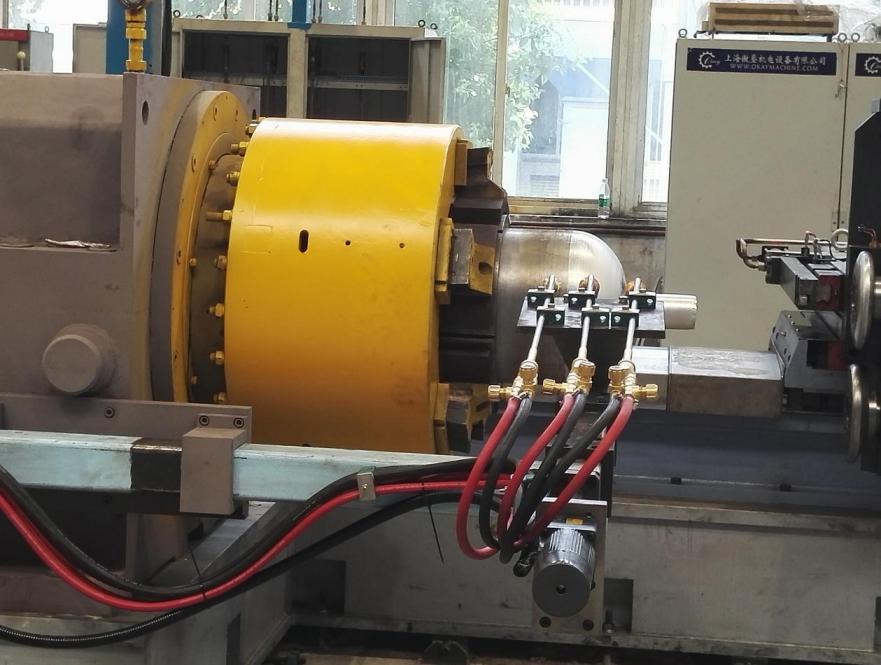

3.1 Detailed Explanation of CNC Control System

The CNC control system serves as the brain of the metal necking spinning machine, translating digital instructions into precise movements of the spinning mandrel and rollers. It comprises software and hardware components that enable operators to program and monitor the machining process with ease.

3.2 Components of the Spinning Machine

The spinning mandrel, spinning rollers, and support structures form the core components of a CNC metal necking spinning machine. The spinning mandrel serves as the central axis around which the metal workpiece rotates, while the spinning rollers apply pressure to shape the metal. Support structures provide stability and rigidity to the machine during operation.

3.3 Importance of Tooling and Dies

Tooling and dies play a crucial role in the necking process, determining the final shape and dimensions of the metal component. Precision-engineered tooling ensures consistent results and prolongs the lifespan of the machine by minimizing wear and tear.

Applications of CNC Metal Necking Spinning Machines

4.1 Industry Fan Manufacturing

In the aerospace industry, CNC metal necking spinning machines produce a wide range of components, including engine parts and ductwork. The ability to form complex shapes with precision makes these machines indispensable in manufacturing critical aerospace components.

4.2 Automotive Industry

In the automotive industry, CNC metal necking spinning machines are employed in the production of exhaust pipes and fuel tanks. The high efficiency and accuracy of these machines enable manufacturers to meet stringent quality standards while maintaining cost-effectiveness.

4.3 Home Appliances

CNC metal necking spinning machines find applications in shaping metal parts for home appliances such as refrigerators and washing machines. From forming intricate components to creating seamless finishes, these machines play a vital role in the production of durable and aesthetically pleasing appliances.

4.4 Custom Metal Fabrication

In the realm of custom metal fabrication, CNC metal necking spinning machines offer limitless possibilities for creating unique designs for art and architectural purposes. Whether it’s crafting bespoke sculptures or architectural features, these machines empower designers and fabricators to bring their creative visions to life.

Operating a CNC Metal Necking Spinning Machine

Operating a CNC metal necking spinning machine requires precision, attention to detail, and adherence to established procedures. ALTRON’s powerful CNC metal necking spinning machines are designed to streamline the production process while ensuring optimal performance and quality control.

5.1 Setup and Calibration Procedures

Before initiating the machining process, operators must perform setup and calibration procedures to prepare the CNC metal necking spinning machine for operation. This involves aligning the spinning mandrel and rollers, verifying tooling and die specifications, and calibrating CNC parameters to match the desired shapes and dimensions of the metal components.

5.2 Loading and Securing Metal Blanks

Once the machine is calibrated, operators load metal blanks onto the spinning mandrel and secure them in place using clamps or fixtures. Proper positioning and alignment of the metal blanks are crucial to ensure uniform shaping and prevent material distortion during the spinning process.

5.3 Programming CNC Parameters

Programming CNC parameters is a critical step in operating a metal-necking spinning machine. Operators input specific instructions into the CNC control system, defining the speed, pressure, and trajectory of the spinning mandrel and rollers. This programming dictates the final shape and dimensions of the metal components being produced.

5.4 Monitoring the Spinning Process

Throughout the spinning process, operators must closely monitor the machine’s operation to ensure quality control and prevent potential issues. This involves observing the metal blanks as they are shaped, adjusting CNC parameters as needed to maintain consistency, and inspecting finished components for defects or irregularities.

Maintenance and Troubleshooting of CNC Metal Necking Spinning Machines

Regular maintenance of CNC metal necking spinning machines is essential to ensure optimal performance and longevity. ALTRON’s machines are engineered for durability and reliability, but routine upkeep is necessary to mitigate wear and prevent malfunctions.

6.1 Regular Maintenance Tasks

Scheduled maintenance tasks include lubricating moving parts, inspecting and replacing worn components, and cleaning debris or contaminants from the machine’s surfaces. By adhering to a comprehensive maintenance schedule, operators can minimize downtime and extend the lifespan of the equipment.

6.2 Common Issues and Troubleshooting

Despite meticulous maintenance, CNC metal necking spinning machines may encounter occasional issues during operation. Common problems include tooling wear, material slippage, and programming errors. Operators are trained to troubleshoot these issues efficiently, identifying root causes and implementing corrective measures to resume production promptly.

6.3 Importance of Proper Lubrication and Cleanliness

Proper lubrication and cleanliness are paramount to the longevity and performance of CNC metal necking spinning machines. Lubricants reduce friction between moving parts, preventing premature wear and ensuring smooth operation. Additionally, maintaining a clean working environment minimizes the risk of contamination and preserves the machine’s precision and accuracy.

Comparative Analysis: CNC vs. Traditional Metal Necking Spinning Methods

When comparing CNC metal necking spinning machines to traditional manual methods, several key differences emerge in terms of efficiency, precision, and cost-effectiveness.

7.1 Efficiency and Precision Differences

CNC metal necking spinning machines offer unparalleled efficiency and precision compared to manual techniques. The automated nature of CNC machining allows for faster production rates and tighter tolerances, resulting in higher-quality finished products with minimal variation.

7.2 Labor Costs and Skill Requirements

While CNC metal necking spinning machines require initial programming and setup by skilled operators, they ultimately reduce labor costs and skill requirements compared to manual methods. With CNC technology, fewer operators are needed to oversee production, and less specialized training is required to operate the equipment effectively.

7.3 Quality Consistency and Repeatability

One of the most significant advantages of CNC metal necking spinning machines is their ability to deliver consistent quality and repeatability across multiple production runs. CNC programming ensures that each component is manufactured to precise specifications, eliminating variability and reducing the risk of defects or inconsistencies.

Future Trends in CNC Metal Necking Spinning Technology

As technology continues to advance, the future of CNC metal necking spinning machines holds exciting possibilities for innovation and improvement. ALTRON remains at the forefront of these developments, driving advancements in CNC control systems, artificial intelligence integration, and sustainable manufacturing practices.

8.1 Advancements in CNC Control Systems and Software

Advancements in CNC control systems and software promise to enhance the capabilities and versatility of metal necking spinning machines. ALTRON is committed to developing intuitive user interfaces, advanced programming features, and seamless integration with other manufacturing technologies to optimize productivity and efficiency.

8.2 Integration of Artificial Intelligence

The integration of artificial intelligence (AI) into CNC metal necking spinning machines enables predictive maintenance and process optimization. By analyzing real-time data and identifying patterns, AI algorithms can anticipate potential issues before they occur, minimizing downtime and maximizing uptime.

8.3 Potential for 3D Metal Printing and Additive Manufacturing

The potential of 3D metal printing and additive manufacturing in spinning technology opens up new possibilities for complex geometries and custom designs. ALTRON is exploring integrating 3D printing capabilities into CNC metal neck spinning machines. Create complex components with unprecedented precision and efficiency.

8.4 Environmental Considerations

In addition to technological progress. Environmental factors also play a crucial role in shaping the future of CNC metal neck spinning technology. ALTRON is committed to developing sustainable manufacturing practices that combine energy-saving solutions and environmentally friendly materials. to minimize environmental impact while maximizing operational efficiency.

Conclusion

In conclusion, CNC powerful metal necking spinning machines represent the pinnacle of innovation in metalworking technology. These machines are known for their precision, efficiency and versatility. Will shape the future of manufacturing across industries, driving advancements in product quality, cost-effectiveness and design flexibility. As a leading manufacturer in its field, ALTRON continues to push the boundaries of what is possible. Helping manufacturers reach new heights of excellence in metal fabrication.