Are You Curious About the Unseen Precision of CNC Spinning Factory?

CNC spinning technology has revolutionized the metal forming industry, offering precision and efficiency in the production of various components. Among the leading players in this field is CNC Spinning Factory ALTRON, an engineering manufacturer based in China.

With a focus on industrial fan automation production line solutions, ALTRON has been at the forefront of research and development since its inception. This blog will delve into the CNC spinning process employed by ALTRON, the applications of this technology, and the stringent quality control measures that contribute to the factory’s success.

CNC Spinning Process: 2024 Best CNC Spinning Factory

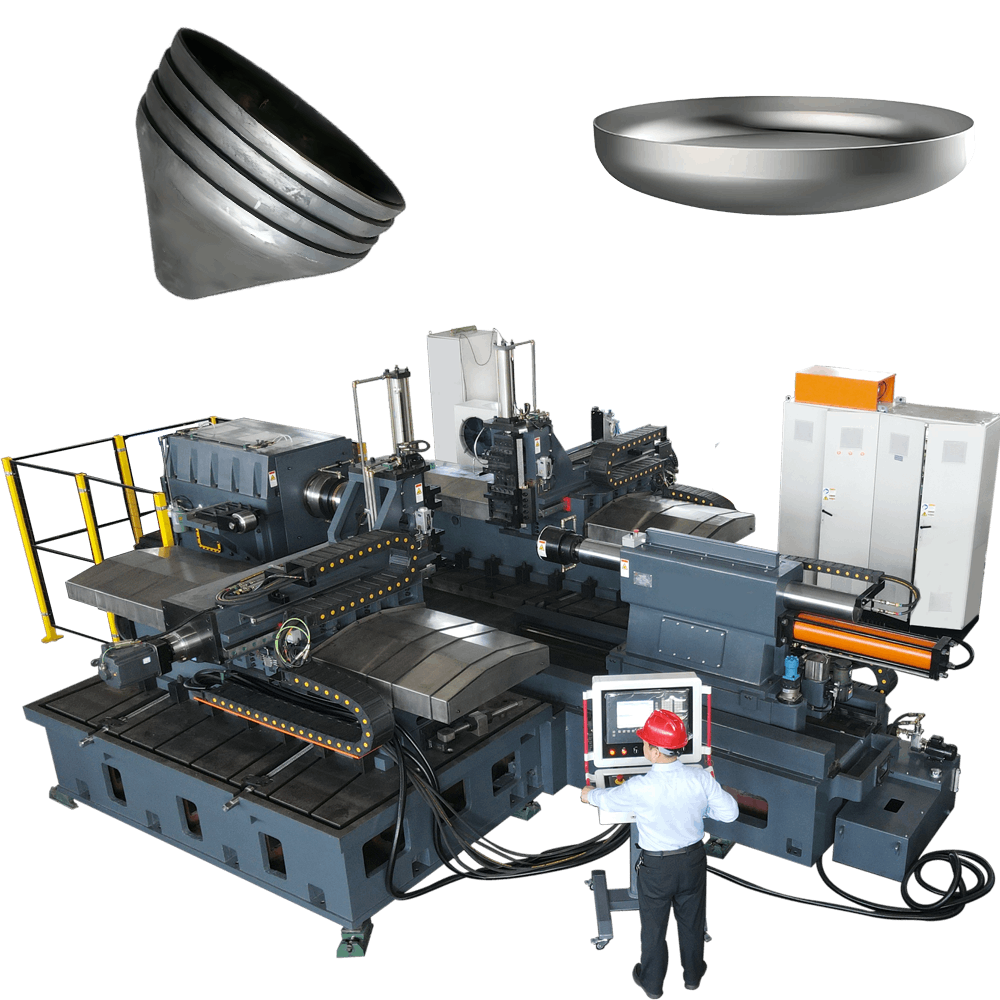

At the heart of ALTRON’s operations lies the CNC spinning process, a cutting-edge technology that has transformed metal forming. This process involves the use of computer numerical control (CNC) machines to shape flat metal discs into three-dimensional objects. The key components include a spinning lathe, a mandrel, and various tooling options. The metal disc is clamped onto the spinning lathe, and the CNC machine precisely controls the movement of the spinning tool, forming the metal into the desired shape.

The advantages of CNC spinning over traditional methods are significant. The process allows for greater design flexibility, reduced material waste, and enhanced precision. CNC Spinning Factory ALTRON’s CNC spinning technology ensures consistency in product dimensions, a crucial factor in industries requiring uniform and high-quality components.

Applications of CNC Spinning: 2024 Popular CNC Spinning Factory

ALTRON’s CNC spinning technology finds applications across a diverse range of industries. From aerospace to automotive, and from lighting to HVAC systems, CNC spinning proves its versatility. The ability to manufacture complex shapes with tight tolerances makes it a preferred choice for industries demanding precision.

For example, in the automotive sector, ALTRON’s CNC spinning technology is used to produce intricate components such as exhaust systems and wheel covers. In the lighting industry, it contributes to the creation of lampshades with unique designs. The adaptability of CNC spinning allows ALTRON to cater to the specific needs of each industry, providing customized solutions for metal products.

Quality Control and Precision: 2024 Leading CNC Spinning Factory

In the realm of CNC spinning, quality control is paramount. ALTRON employs rigorous quality assurance measures to ensure that each product meets the highest standards. From material inspection to the final product, every step undergoes meticulous scrutiny. This commitment to quality has positioned ALTRON as a trusted provider in the industry.

Precision is a hallmark of CNC spinning technology, and ALTRON excels in delivering products with exacting specifications. The combination of advanced machinery and skilled technicians allows for the production of components with consistent dimensions and superior surface finishes. ALTRON’s dedication to precision extends beyond manufacturing to encompass the entire customer experience.

ALTRON: A Leader in CNC Spinning

Founded in the early stages of fan parts spinning equipment development, ALTRON has grown into a powerhouse in the CNC spinning industry. Located in Jiangsu/Wuxi, with a sales company in Guangzhou, the factory spans over 12,000 square meters. The company’s technical team, comprised of core technicians, specializes in metal forming, offering comprehensive solutions for various processes.

ALTRON’s innovative culture and emphasis on research and development set it apart in the competitive landscape. The company’s engineers focus on providing turnkey solutions for metal products, including metal spinning, stamping and stretching, metal cold forming, metal polishing, and automatic welding. This holistic approach allows ALTRON to cater to the diverse needs of its clientele.

Technology Advancements: 2024 Good CNC Spinning Factory

As CNC spinning technology continues to evolve, ALTRON remains at the forefront of innovation. Recent advancements in CNC spinning technology have been instrumental in enhancing efficiency and product quality. ALTRON has implemented state-of-the-art CNC machines equipped with advanced control systems, allowing for more precise and intricate designs. Additionally, the integration of automation and robotics in the spinning process has streamlined production, reducing lead times and minimizing errors.

The adoption of computer-aided design (CAD) and computer-aided manufacturing (CAM) software has further elevated ALTRON’s capabilities. These technologies enable the translation of complex designs into precise instructions for CNC machines, ensuring unparalleled accuracy in the manufacturing process. Such advancements not only contribute to the efficiency of the factory but also empower ALTRON to take on projects with increasingly intricate specifications.

Case Studies: World’s Best CNC Spinning Factory

Real-life examples speak volumes about the capabilities of a CNC spinning factory. ALTRON has completed numerous projects across various industries, showcasing its expertise and versatility. One notable case involved the production of complex aluminum components for a leading aerospace company. The challenge lay in achieving intricate geometries while adhering to stringent tolerances. ALTRON’s team of skilled technicians and advanced CNC spinning technology ensured the project’s success, earning accolades from the client.

Customer testimonials further underscore ALTRON’s commitment to excellence. Clients consistently praise the factory’s responsiveness, attention to detail, and ability to overcome challenges. These case studies and testimonials serve as a testament to ALTRON’s reliability and proficiency in delivering high-quality CNC spun products.

Sustainability Practices: Best 2024 CNC Spinning Factory

Environmental responsibility is a core value at CNC Spinning Factory ALTRON, reflected in the adoption of sustainable practices. The factory prioritizes the use of eco-friendly materials, opting for recyclable metals and exploring innovative solutions to reduce environmental impact. Energy-efficient processes, such as the optimization of CNC machine operations and the incorporation of renewable energy sources, contribute to the factory’s commitment to sustainability.

Waste reduction initiatives are another aspect of ALTRON’s environmental stewardship. The factory employs efficient material utilization techniques, minimizing waste during the CNC spinning process. This dedication to sustainability aligns with the growing demand for eco-conscious manufacturing practices, positioning ALTRON as a responsible player in the CNC spinning industry.

Industry Trends and Insights: Quality CNC Spinning Factory 2024

The CNC spinning industry is dynamic, influenced by shifting market demands and technological advancements. CNC Spinning Factory ALTRON keeps a keen eye on industry trends to adapt and stay ahead. As markets increasingly emphasize lightweight materials, ALTRON aligns its R&D efforts to explore innovative alloys and composite materials. The rise of smart manufacturing and the Internet of Things (IoT) also shapes ALTRON’s approach, with the integration of data analytics for predictive maintenance and process optimization.

Insights into the future of CNC spinning technology suggest a continued focus on automation, artificial intelligence, and sustainability. ALTRON’s commitment to staying abreast of these trends positions the factory as a reliable partner for industries seeking cutting-edge solutions in CNC spinning.

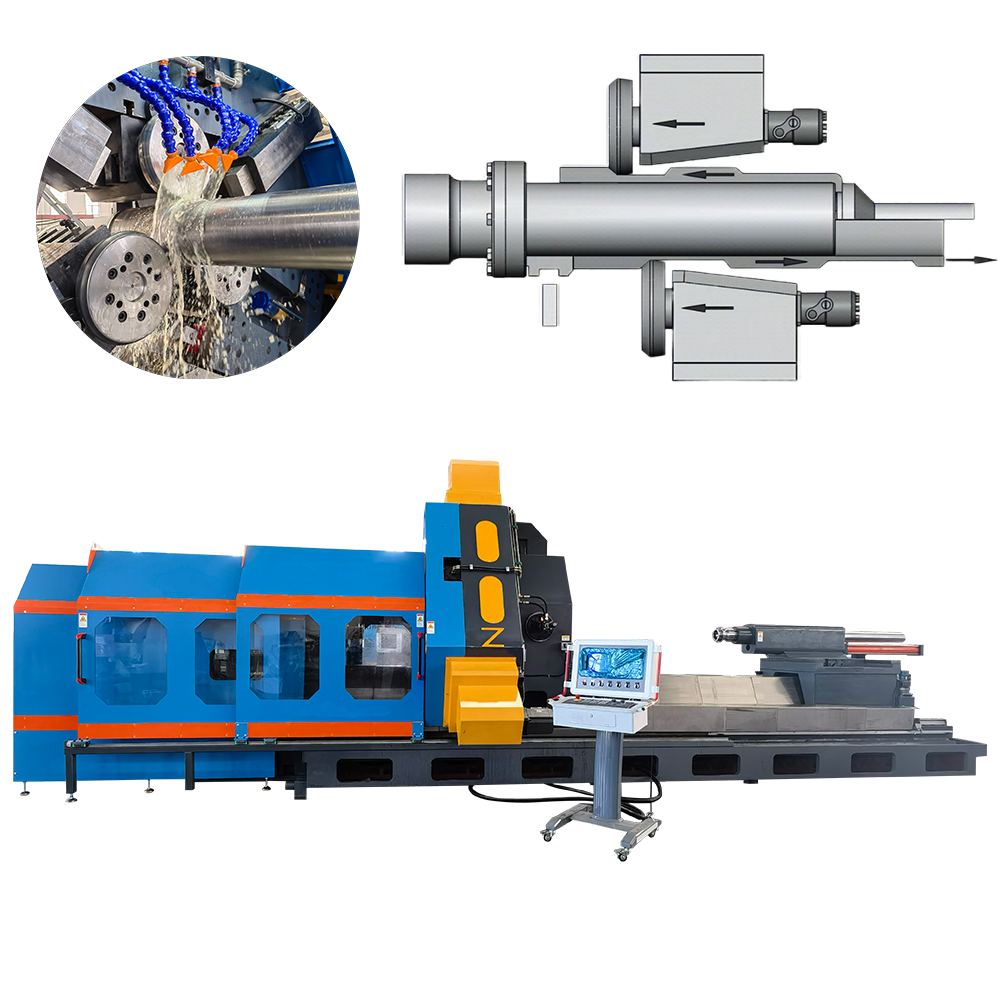

Crafting Excellence with Single Wheel CNC Spinning Machines

At the heart of ALTRON’s CNC Spinning Factory lies the pinnacle of precision – the Single Wheel CNC Spinning Machine. These sophisticated machines are engineered to perfection, offering unparalleled control and accuracy in the metal spinning process. With cutting-edge technology and a commitment to quality, ALTRON ensures that every spun component meets the highest industry standards.

1. Precision Redefined

The Single Wheel CNC Spinning Machine at ALTRON boasts advanced features that redefine precision in metal shaping. Its computer-controlled system allows for intricate designs and complex geometries, ensuring that each spun piece is a masterpiece of accuracy. The machine’s single wheel configuration enhances efficiency, enabling the production of high-quality components with unmatched consistency.

2. Versatility in Application

From automotive parts to aerospace components, the Single Wheel CNC Spinning Machine at ALTRON caters to a wide range of industries. Its versatility makes it the go-to solution for manufacturers seeking customized, intricate metal components. With the ability to work with various materials, including aluminum, stainless steel, and copper, ALTRON’s CNC Spinning Factory stands as a beacon of adaptability in the manufacturing world.

Elevating Precision: Double Wheel CNC Spinning Machines

ALTRON’s commitment to excellence extends beyond the single wheel configuration to the Double Wheel CNC Spinning Machine. This powerhouse of precision takes metal spinning to new heights, offering enhanced productivity and expanded capabilities.

1. Dual Wheels, Double Efficiency

The dual-wheel configuration of ALTRON’s CNC Spinning Machine ensures increased productivity without compromising precision. The synchronized movement of the two wheels allows for simultaneous shaping, reducing production time while maintaining the highest standards of accuracy. This makes the Double Wheel CNC Spinning Machine an ideal choice for high-volume manufacturing.

2. Complex Designs, Seamless Execution

With the ability to handle more complex designs and larger workpieces, the Double Wheel CNC Spinning Machine at ALTRON opens up new possibilities in metal shaping. Whether it’s intricate flanges, seamless curves, or geometric patterns, this machine tackles every challenge with ease, showcasing the seamless execution of precision engineering.

Revolutionizing Spinning: 3-Wheel CNC Spinning Machines

As a testament to ALTRON’s commitment to innovation, the 3-Wheel CNC Spinning Machine takes metal shaping to the next dimension. This tri-wheel marvel combines precision with versatility, offering a dynamic solution for a myriad of applications.

1. Tri-Wheel Dynamics

ALTRON’s 3-Wheel CNC Spinning Machine introduces a tri-wheel configuration that revolutionizes the metal spinning process. The three-wheel system allows for enhanced control over the shaping process, providing manufacturers with the flexibility to create intricate designs and complex geometries with utmost precision.

2. Unmatched Versatility

From small-scale components to large-diameter pieces, the 3-Wheel CNC Spinning Machine at ALTRON showcases unmatched versatility. Its dynamic capabilities make it suitable for a diverse range of industries, from aerospace to healthcare. The ability to work with various materials ensures that ALTRON’s CNC Spinning Factory remains a versatile hub for customized metal components.

Conclusion

In conclusion, CNC Spinning Factory ALTRON stands as a testament to the transformative power of CNC spinning technology. The factory’s commitment to precision, quality control, and innovation has propelled it to the forefront of the industry. With a mission to provide customized solutions and turnkey projects, ALTRON continues to shape the future of metal forming, setting new standards in the CNC spinning arena.