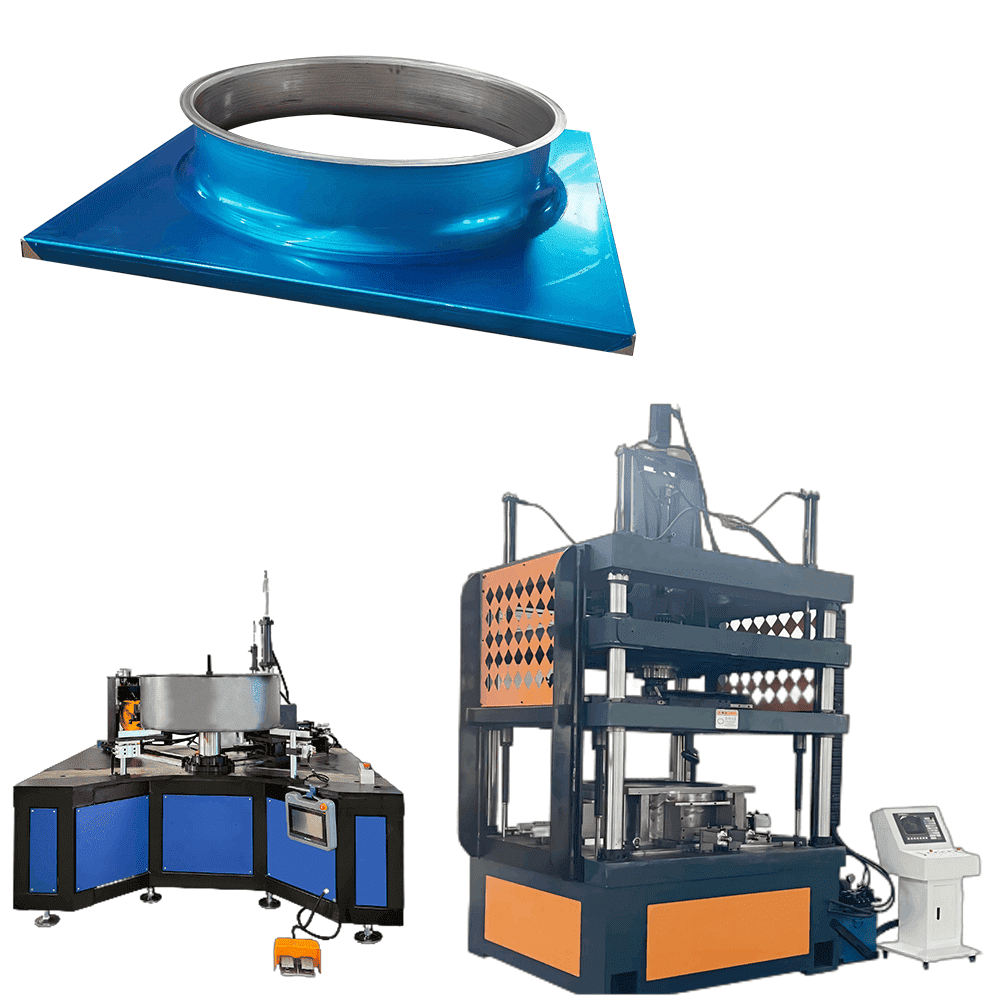

CNC Inner Spinning Machine -Diens System

inner spinning machine for Industrial Air-Conditioning Fans

|

Machine Name |

Square Blank Inner Spinning Machine |

|

Model |

AC-CX-1600 |

|

Application Industry |

wall-mounted axial fan, roof fans , kitchen fans, Box fans, HVAC Condenser Fan, Frame axial flow fan… |

|

Technical Service |

Complete the test in the early stage; provide online and offline training in the later stage, and complete the turnkey project. |

|

Technical Guidance |

Online 24 hours a day/Online Conference To Solve Pre-Sales Problems. |

|

Project Progress |

30-120 days |

|

Relevant Files |

ALTRON_AUTO Catalog-Industrial Blower Machinery Turnkey Project |

- ADAVANTAGES

- PARAMETERS

- CUSTOMER TESTIMONIALS

Altron’s AC NX-1600 CNC inner spinning machine is specially designed and produced for the inner hole spinning of the air inlet reinforcement plate of the air conditioner ventilator! The plate is fixed, and the spinning wheel rotates inside the plate to perform metal spinning!

Single or multiple holes can be spun on a rectangular metal plate! The CNC system can accurately complete the internal spinning of complex curves such as straight edges and arc edges!

AC NX-1600 CNC Inner Spinning Machine Video

Advantages Of AC NX-1600 CNC Inner Spinning Machine

- CNC numerical control system control,

- Servo hydraulic drive,

- The machine has stable performance, and the holding force of the plate during the internal rotation process is very important!

- Multi-specification program storage, easy to call,

- 4-column guide, with the stability of deep drawing machinery,

- Straight edge, arc edge, expansion buckle, curling and other processes,

- Special customized bearings to reduce the spindle transmission power,

Structure Of AC NX-1600 CNC Inner Spinning Machine

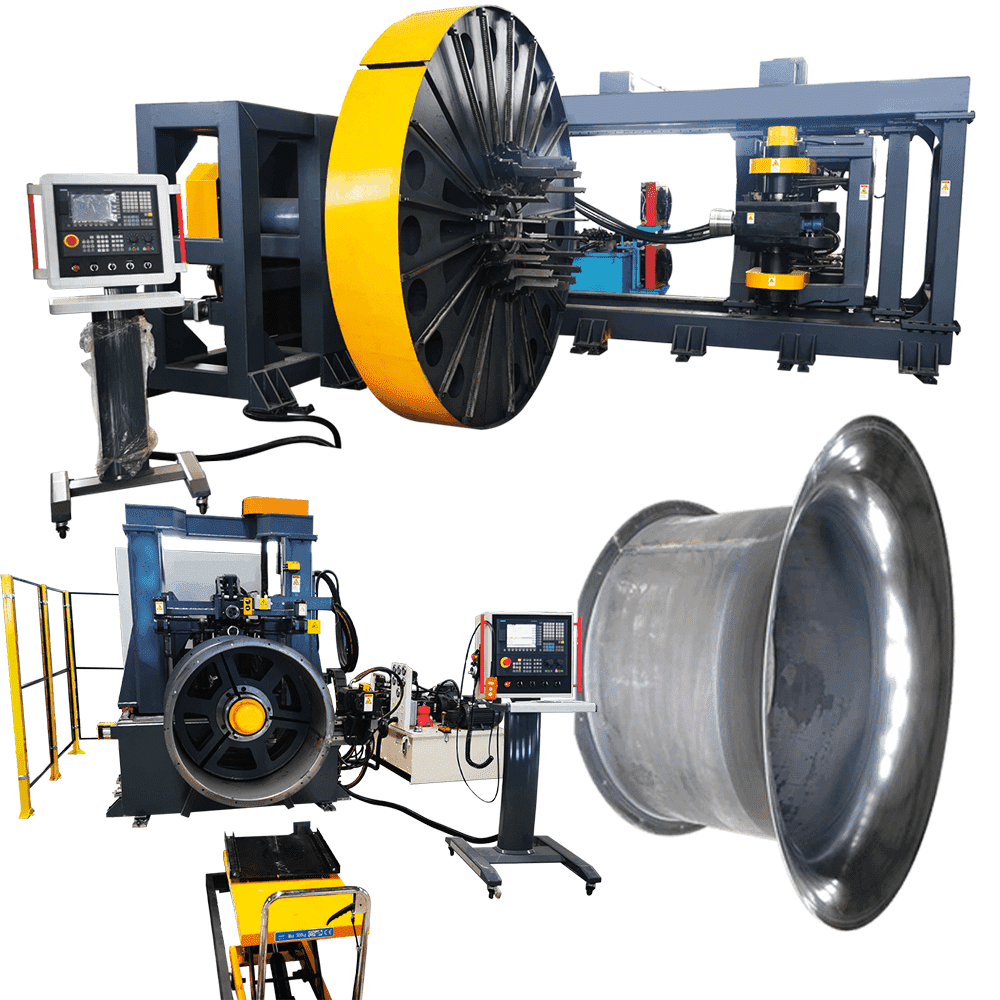

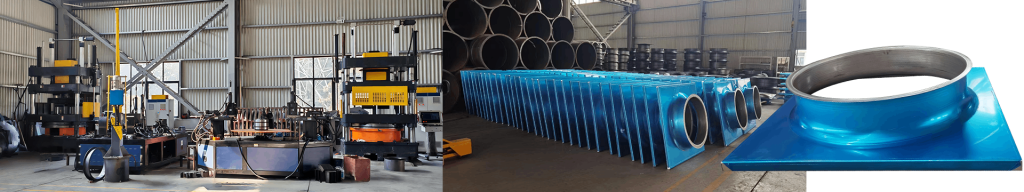

Application Of inner Spinning Machine In Industrial Air-Conditioning Fans

Spinning machine is a metal plastic forming machine, which is used to deform metal sheet into the required shape through rotation and pressure. It is suitable for various metal materials, including stainless steel, aluminum, iron, etc.

Material forming:

Spinning can process metal flat sheet into the shape and size required by industrial air-conditioning fan panel. Including air inlet and outlet.

Improve production efficiency:

The high efficiency of the spinning machine can quickly complete mold development! Suitable for the current customized industrial fan trend

Functional design:

In addition to using expensive deep drawing, Chuantong’s industrial air-conditioning fan panel also uses welding or rivet production process, which is lower in cost, but the ventilation performance, dust and water resistance are poor, and more considerations need to be made in design!

The overall panel produced by inner spinning does not have these problems! It saves costs compared to deep drawing process and has higher quality than welding and riveting process.

Combination production mode of internal rotation machine and turning machine

Machine Configuration Parameters

AC-CX-1600 CNC two-wheel internal spinning machine ALTRON

1. Bearing NSK

2. Contactor chint

3. Relay and spring

4. Control system Tynes

5. Touch screen Veylon 10 inch touch screen

6. Servo motor seven branches 37KW B3

7. Hydraulic system Taiwan

8. Spin wheel CR12

9. Silver on guide rail

10. Hydraulic station oil pump motor 3KW

-

Marcley

★★★★★Post a review on Aug 21, 2022 From Bolivia

The AC-CX-1600 CNC Two-Wheel Inner Spinning Machine has revolutionized our production process. It has enabled us to effortlessly shape the tuyeres and protective covers for our refrigeration equipment and air conditioner fans with exceptional precision and efficiency.

-

Arthur Zonneveld

★★★★★Post a review on Fec 21, 2022 From Mauritius

We are extremely satisfied with the performance of the AC-CX-1600 machine. Its ability to carry out flanging forming on square and rectangular boards has streamlined our production of air outlets, saving us time and effort

-

Nicolas Vazquez

★★★★★Post a review on jul 21, 2022 From Uruguay

The AC-CX-1600 has exceeded our expectations in terms of reliability and quality. Its user-friendly interface and advanced CNC system have made the spinning process of our tuyeres and protective covers seamless and highly accurate.

-

OSCAR URBANEJA

★★★★★Post a review on Oct 10, 2022 From Venezuela

Thanks to the AC-CX-1600, we have achieved remarkable productivity and consistency in shaping various components for our refrigeration and air conditioning units. It has become an essential asset in our manufacturing process