Difficult problems and solutions for spinning machine

1. How to solve the several major causes of the tail bounce of the spinning machine?

The tail top of the spinning machine tool is very easy to cause chattering. The following are the reasons for the spinning machine manufacturers to analyze the chatter caused by the tail top of the CNC lathe and the relative treatment methods.

2. What are the hazards of spinning machine tail flutter to spinning products?

3. the main reason for the main shaft of the spinning machine to get stuck in the process of large-scale strong spinning

-1. How to solve the several major causes of the tail bounce of the spinning machine?

The tail top of a spinning machine tool is very easy to cause chattering. The following are some reasons and relative treatment methods for the spinning machine manufacturer to analyze the chatter caused by the tail top of the CNC lathe.

1. An error occurred in the actual operation of the CNC lathe, and the cutter wheel hit the tail jack shaft, causing the tail jack shaft to deform.

2. The precision of the tail top and tail top shaft is not high enough.

3. The tail shaft rolling bearing is damaged and destroyed, and there will be noise when the tail shaft rotates.

4. The installation precision of the spindle bearing mold shell and flange plate is not good, which promotes the tail flutter.

-2. What are the hazards of spinning machine tail flutter to spinning products?

The tail jump of the spinning machine will have a certain impact on the spinning forming, mainly due to the following factors:

1. Stainless steel has a poor elongation rate and high stress. When the tail jumps, the root will break due to uneven stress.

2. The aluminum material has low hardness, and the bottom of the spinning product will be scratched due to the tail jump during the spinning process.

3. The jump of the tail top will cause insufficient contact area between the material and the tail top, and the spinning force will cause the material to move.

4. The tail vibration will endanger the precision of the specifications after the product is formed, and the diameter precision of the bottom of the product will decrease.

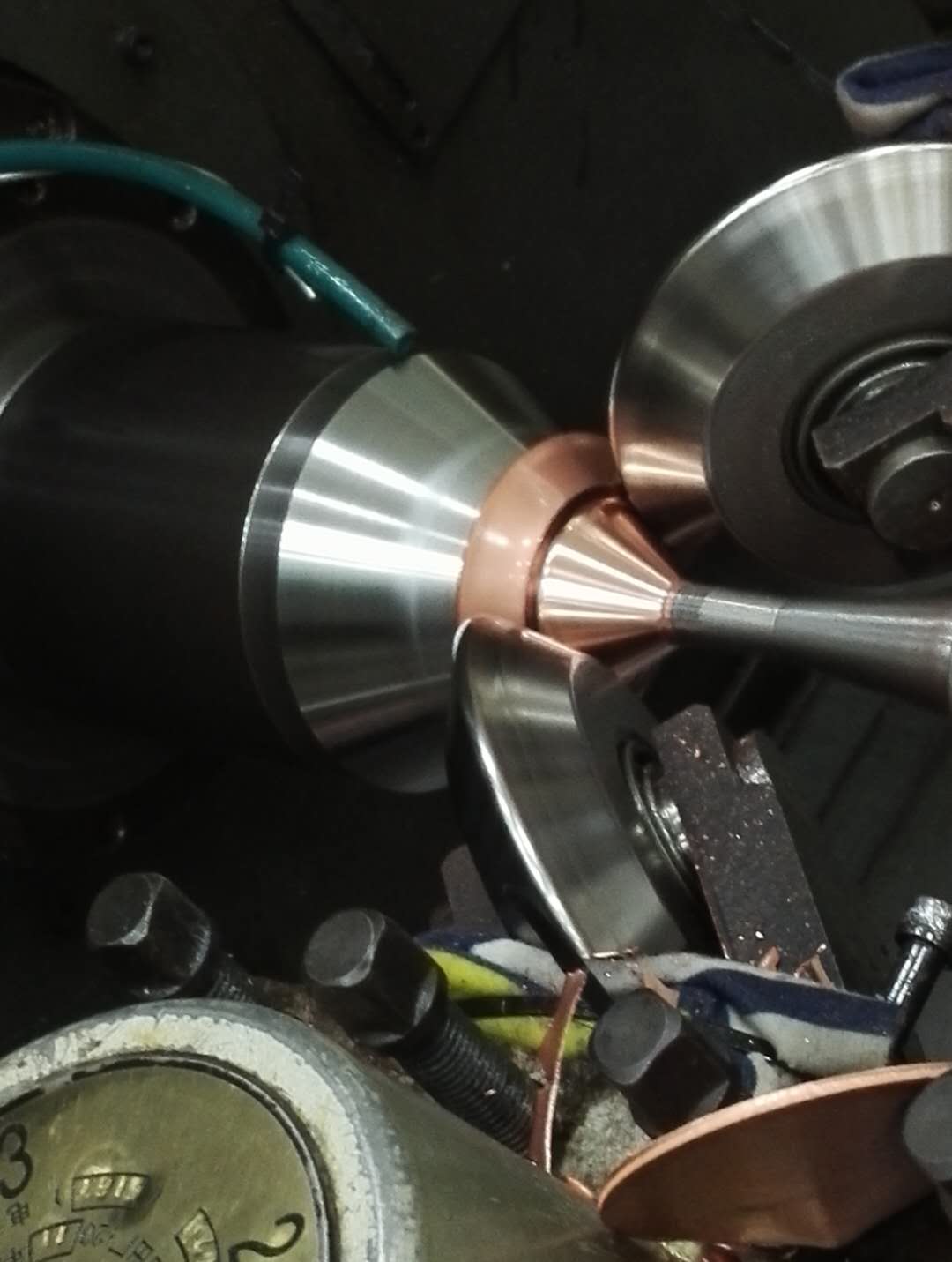

-3. the main reason for the main shaft of the spinning machine to get stuck during the large-scale strong spinning

1. The weight of the spinning mold is not reduced, and the quality of the mold is too large.

2. The belt of the spindle motor becomes loose after being used for too long, just adjust the pre-tightening force.