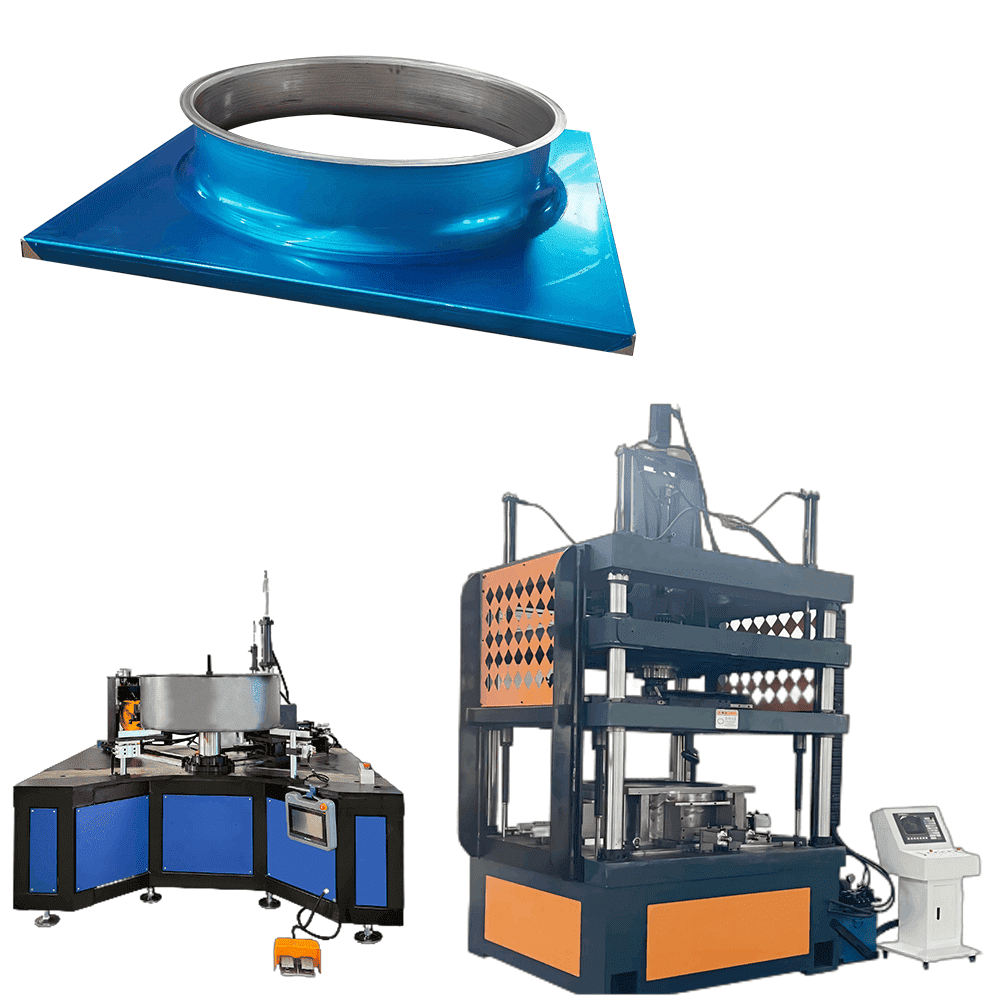

CNC Metal Spinning Machine -Double Roller AC-D1100

Metal Spinning Lathe for Military Industry

|

Machine Name |

Double Roller CNC Spinning Machine |

|

Model |

AC-D1100(diameter max Ф600;aluminum-Max 10mm; carbon steel-Max 6mm) |

|

Application Industry |

(Aerospace, military weapons, medical, furniture, lighting, construction, firefighting, musical instruments, handicrafts, auto parts, pressure vessels,) |

|

Technical Service |

Complete the test in the early stage; provide online and offline training in the later stage, and complete the turnkey project. |

|

Technical Guidance |

Online 24 hours a day/ 7*24 Pre-sales technical service |

|

Project Progress |

30-120 days |

|

Relevant Files |

ALTRON_AUTO Catalog-Industrial Blower Machinery Turnkey Project |

- ADAVANTAGES

- PARAMETERS

- CUSTOMER TESTIMONIALS

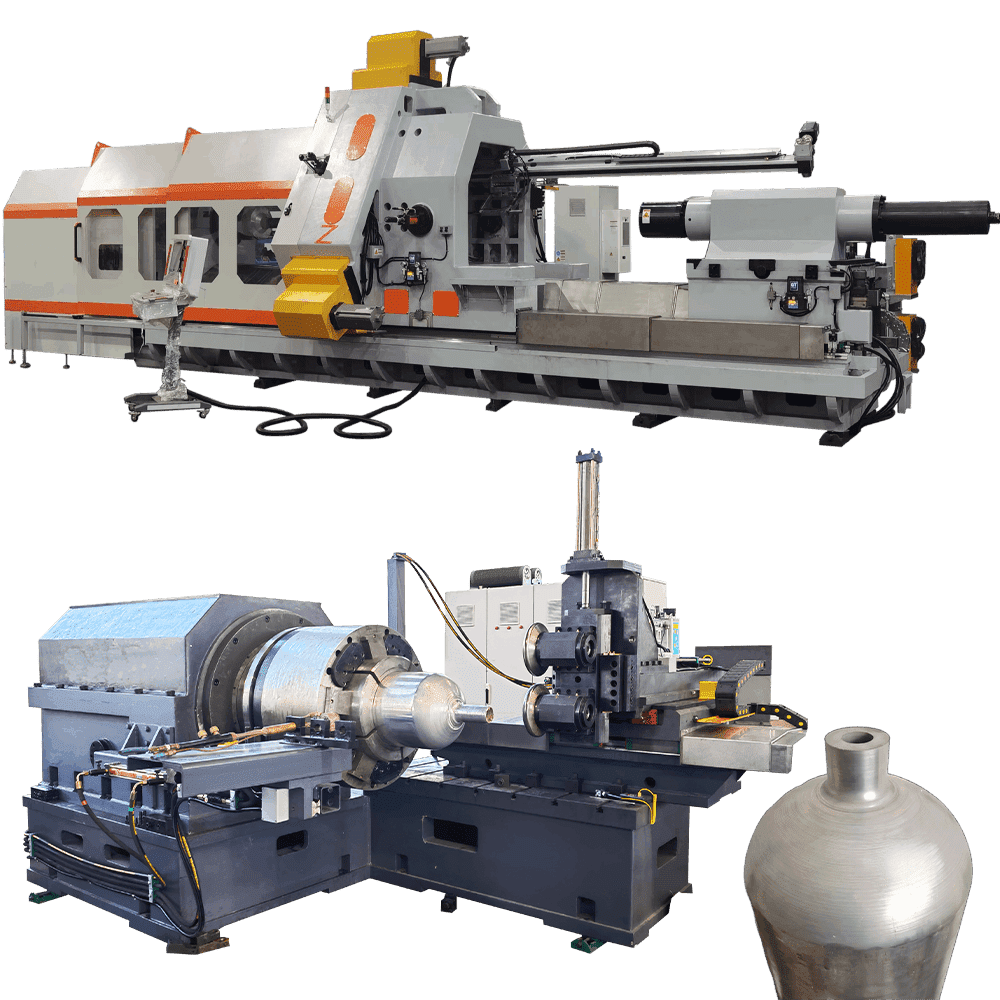

Metal Spinning Lathe Double Roller CNC is a specially customized machine, and the length can be customized according to the actual spinning process for different products! Horizontal double-wheel spinning is conducive to strong thinning of pipes. The double rollers can run independently in the horizontal direction, or they can run simultaneously. The double rollers are controlled by 2 servo motors separately in the horizontal direction.

The turret adopts a dovetail hydraulic up and down sliding structure, which is suitable for spinning thicker metal materials. The 2+2 layout can realize different process solutions such as automatic spinning necking and diameter reduction. It can automatically complete product trimming, curling, turning and other processes in sequence according to process requirements.

Machine parameters:

- Dual-wheel thrust 2×18 tons, stable operation, dual-wheel dual motion,

- Double-sided 2-station, strong process flexibility,

- Equipment weight 21 tons

- Processing method: horizontal dual-wheel CNC spinning

- Raw material effective diameter: maxФ1100mm

- Control method: Siemens 828D CNC

- Workpiece programming: Software “SpinningCAD”

- Feed power: Siemens 1KF7 series servo motor

- Drive control: Siemens S120 series servo drive

- Spindle power: 37KW AC motor

- Spindle control: Siemens G120 series inverter

- Tool rest: 2-station tool rest on the left and right sides

- Slide: HIWIN linear roller slide

- Screw: HIWIN ball screw

Metal Spinning For Venturi Video

If you have any technical questions about hot forming metal spinning, please contact me and Joby engineers will give you a detailed plan.

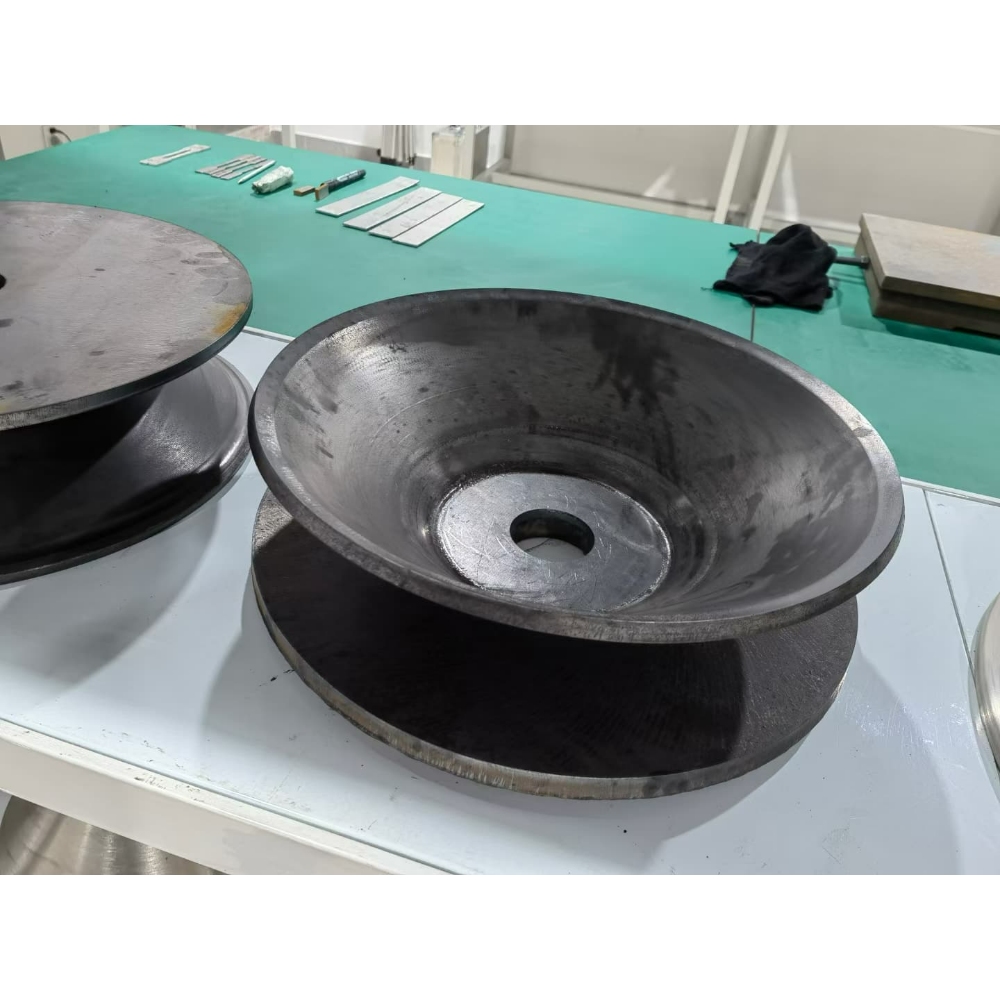

Metal Spinning Project Case Introduction:

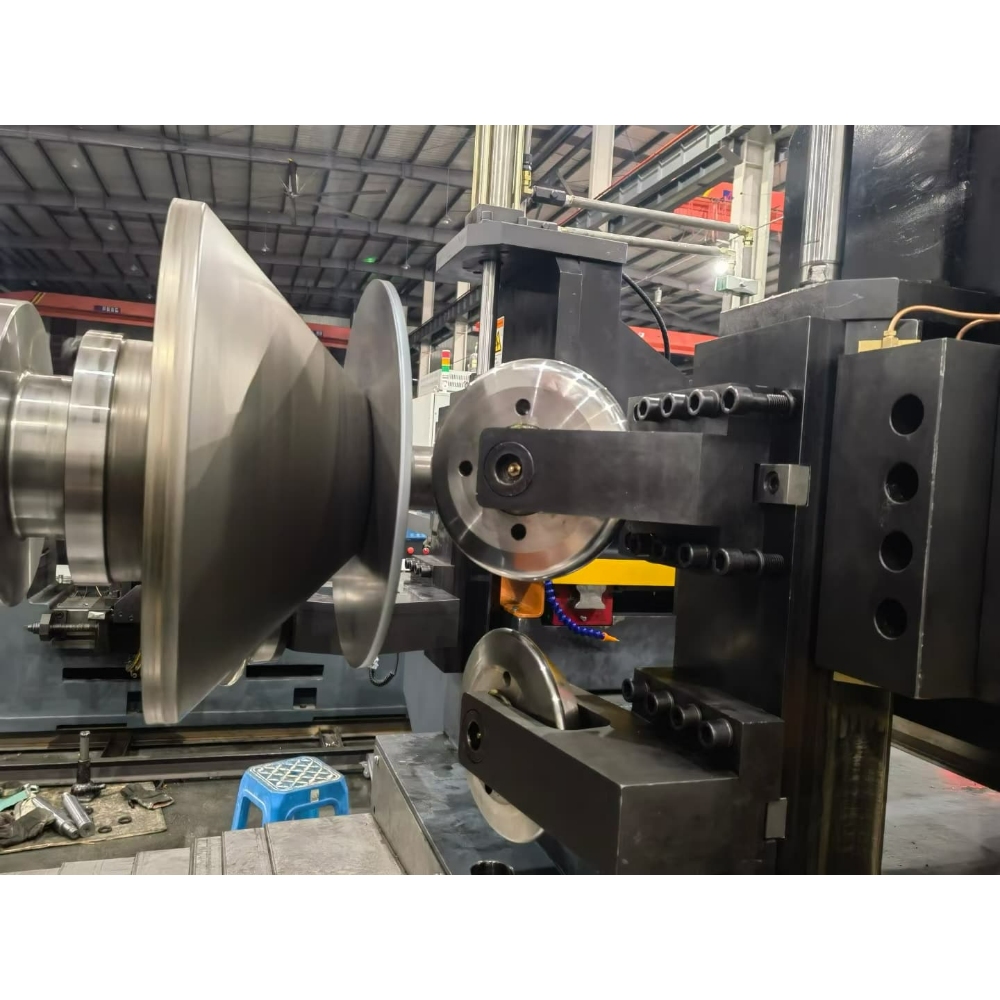

This military product must adopt the hot forming spinning process. The best choice is to use symmetrical CNC metal spinning lathe, which can avoid the heating problem of spinning tools!

This project is equipment sent to Russia, including a 3-wheel spinning machine!

In the heavy and large spinning project plan, we are almost customer-centric and customize the machine according to the customer’s

- actual production process requirements!

- Large metal spinning project service:

- Accept customer drawings and technical documents;

- Altron engineers strictly review drawings; and develop reliable solutions;

- Feedback and communication with customers, description of project plans;

- Support preliminary experimental processes (when similar machines are in the factory), so that customers have no worries;

- Confirm the contract and production order;

- Complete the machine production on time; notify the customer, go to the factory for inspection, and conduct tests; actively cooperate

- with customers to improve the machine;

- Must test 1-2 products in the factory, and test whether the performance of each part of the machine meets the standards!

- Notify the customer after meeting the delivery requirements, go to the factory for inspection again, and inform the customer that a

- certain part has been rectified according to the customer’s requirements.

- When the equipment arrives at the customer’s site, our engineers will arrive at the factory on the date specified by the customer and assist the customer in the installation and commissioning of the equipment!

Altron’s Factory Video

Configuration

Standard Configuration

- SIEMENS CNC 828D

- SIEMENS Servo Motor & Drive

- Asynchronous Servo Spindle Motor

- Two Turrets Tool Setting Simultaneously

- APEX Servo Reducer

- High Strength Ductile Iron Sliding Table

- Blanks Center Assembly

- Back Roller Assembly

- CNC Tool Turret

- Hydraulic Station & Air Cooling System

- Air Unload Assembly

- Self-developed Spinning System

- Control System Remote Maintenance

Select Configuration

- Spindle Spinning Cylinder

- Trimming Tool Assembly

- Air Conditioner for Hydraulic Station

- Hot Spinning Parts Under 700℃

- Teach In & Play Back System

| Model No. |

Max. Material Dia. (mm) |

Radial Stroke (mm) |

Axial Stroke (mm) |

Roller Thrust (KN) |

Tailstock Force (KN) |

Spindle Power (KN) |

Spindle Speed (RPM) |

Material Thickness AL./carbon steel/SUS (mm) |

| ACD-600 | 600 | 260 | 1100 | 40 | 20 | 18.5 | 50-1000 | 6 / 4 / 3 |

| ACD-800 | 1300 | 400 | 1600 | 60 | 50 | 30 | 50-800 | 8 / 5 / 4 |

| ACD-1200 | 1650 | 500 | 800 | 80 | 50 | 37 | 30-500 | 10 / 6 / 4.5 |

| ACD-1600 | 1800 | 600 | 1000 | 120 | 70 | 45 | 30-450 | 14 / 8 / 5.5 |

| ACD-2000 | 2000 | 750 | 1250 | 140 | 100 | 75 | 30-400 | 14 / 10 / 7 |

| ACD-2500 | 2500 | 850 | 2050 | 200 | 140 | 132 | 10-300 | 30 / 20 / 15 |

| ACD-3500 | 3500 | 950 | 2550 | 300 | 140 / 200 | 200 | 10-300 | 40 / 25 / 20 |

-

Marcley

★★★★★Post a review on Aug 21, 2022 From Bolivia

Its symmetrical spinning force and pressure distribution provide excellent shock protection, ensuring the spindle’s longevity. We find it ideal for manufacturing long and thin goods, as well as cone-shaped products.

-

Arthur Zonneveld

★★★★★Post a review on Fec 21, 2022 From Mauritius

The integration of the SIEMENS control system and programming software has made the machine highly intuitive and easy to use. We highly recommend the ALTRON series for anyone in need of precision and reliability in their spinning operations.

-

Nicolas Vazquez

★★★★★Post a review on jul 21, 2022 From Uruguay

The ALTRON series double wheel spinning machine has been a game-changer for our production line. Its ability to handle blanks up to 3500mm in diameter with great accuracy has allowed us to take on larger and more complex projects with ease. The machine’s shock protection system ensures smooth and stable operation, increasing the lifespan of the spindle.

-

OSCAR URBANEJA

★★★★★Post a review on Oct 10, 2022 From Venezuela

I have been using the ALTRON series double wheel spinning machine for several months now, and I am extremely impressed with its performance. The machine effortlessly handles blanks up to 3500mm in diameter with incredible accuracy, giving me consistently excellent surface quality.