CNC Metal Spinning Machine -Double Roller AC-D1200

CNC Spinning Lathe For Hot Metal Spinning

|

Machine Name |

Double Roller CNC Spinning Machine |

|

Model |

AC-D1200(diameter max Ф1650;aluminum-Max 10mm; carbon steel-Max 6mm) |

|

Application Industry |

(Aerospace, military weapons, medical, furniture, lighting, construction, firefighting, musical instruments, handicrafts, auto parts, pressure vessels,) |

|

Technical Service |

Complete the test in the early stage; provide online and offline training in the later stage, and complete the turnkey project. |

|

Technical Guidance |

Online 24 hours a day/ 7*24 Pre-sales technical service |

|

Project Progress |

30-120 days |

|

Relevant Files |

ALTRON_AUTO Catalog-Industrial Blower Machinery Turnkey Project |

- ADAVANTAGES

- PARAMETERS

- CUSTOMER TESTIMONIALS

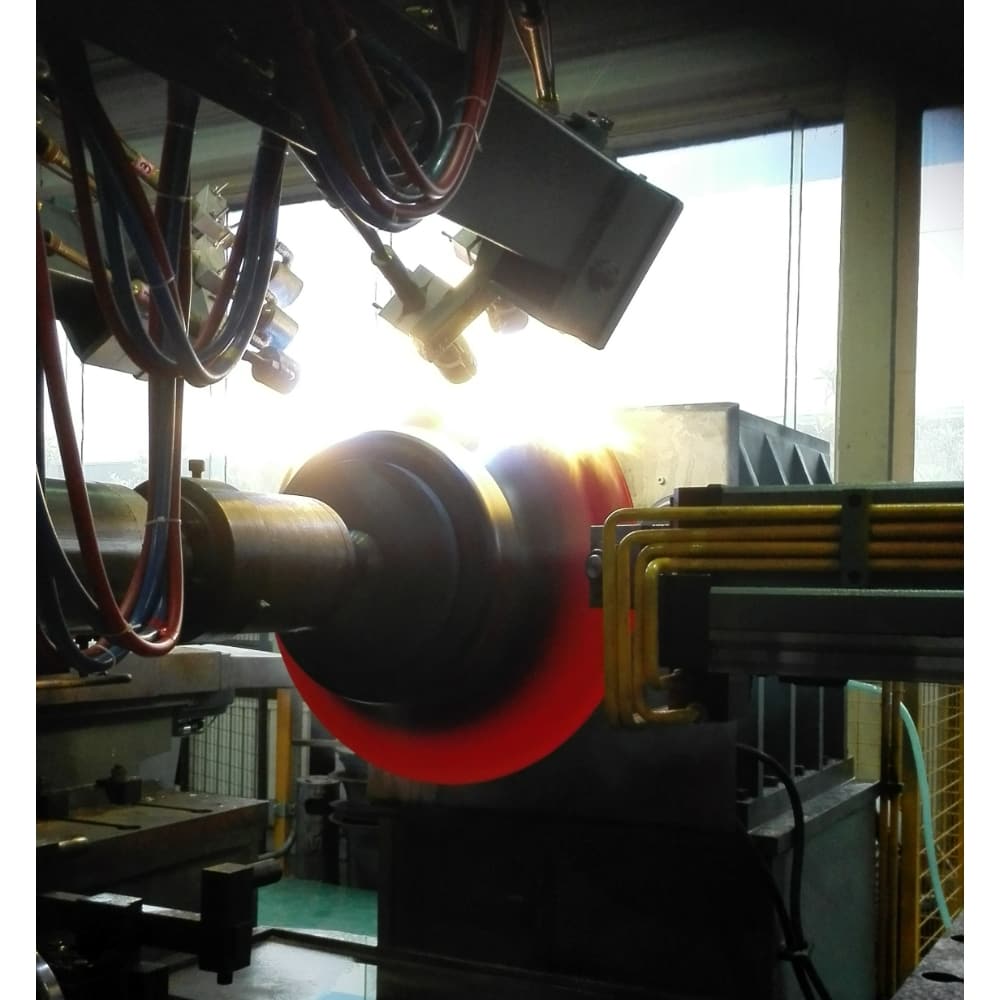

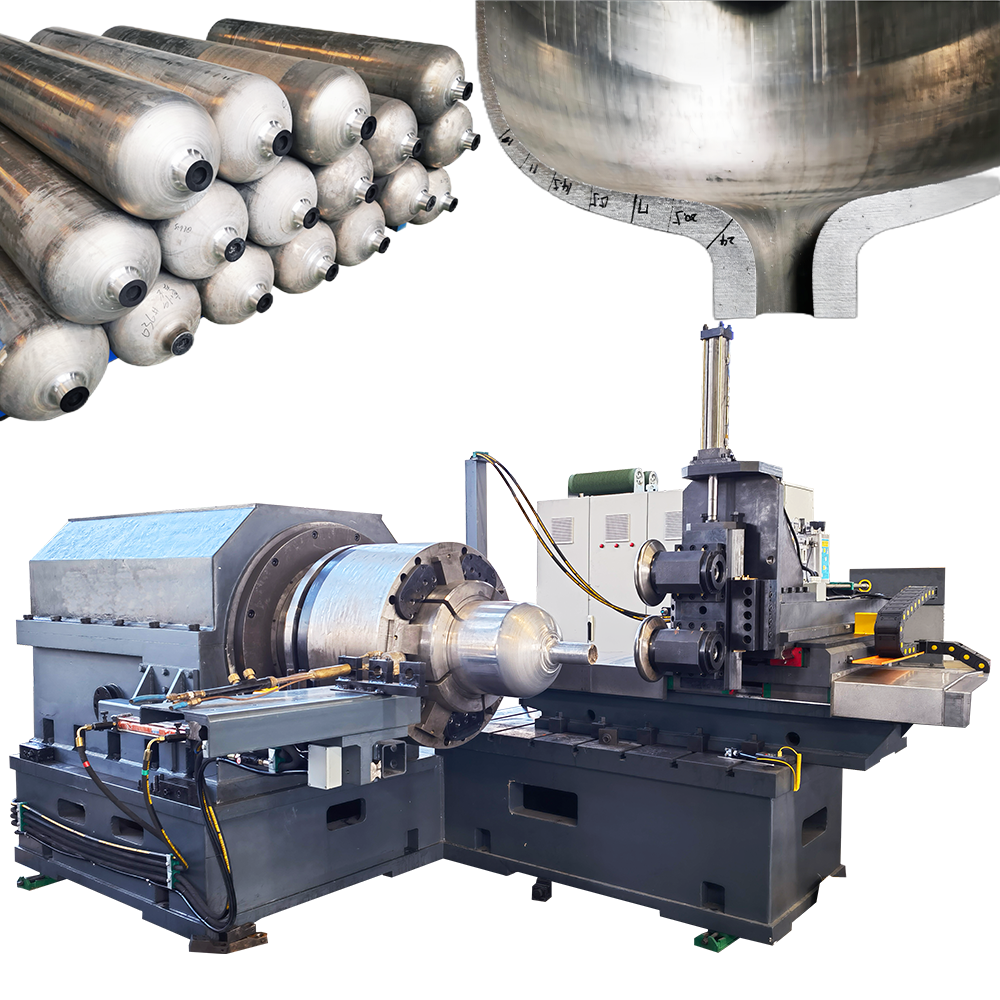

CNC Metal Spinning Machine -Double Roller AC-D1200 was used for special alloy material testing and R&D testing for the German HC Starck factory in Taicang, Jiangsu, China in the early days!

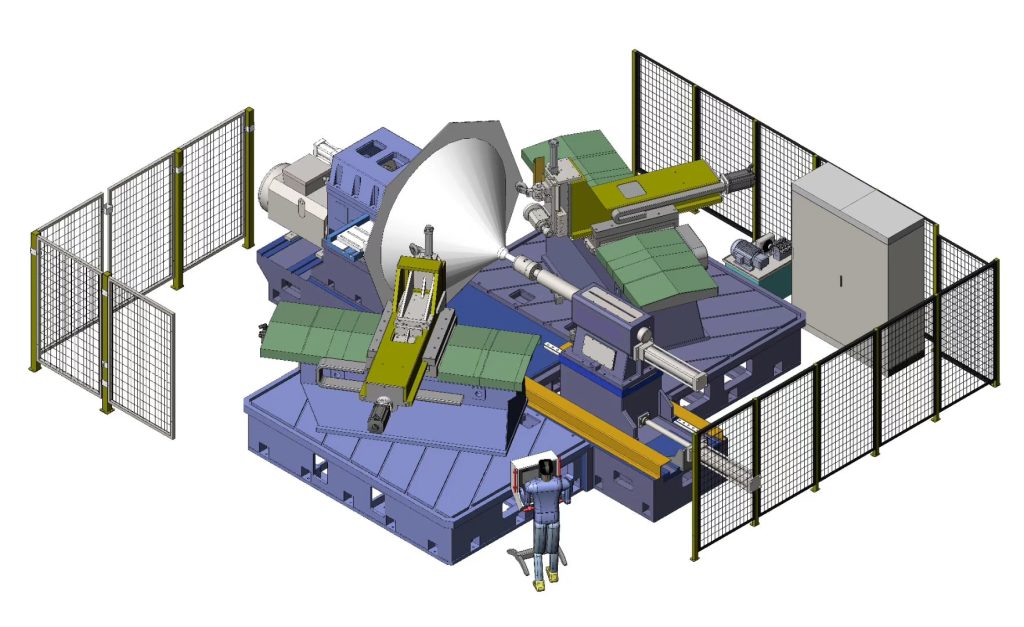

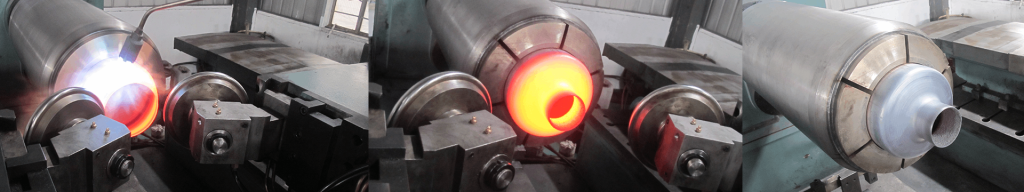

After multiple generations of upgrades, the AC-D1200 machine can spin a 1650mm wafer diameter, and can spin a 5mm special alloy at the limit of the heated metal spinning state.

The machine’s spinning roller is designed with a water-cooling structure to ensure that the machine can spin stably in a long-term high-temperature state! Equipped with a water cooler to cool down the key heated positions such as the cutter wheel mandrel.

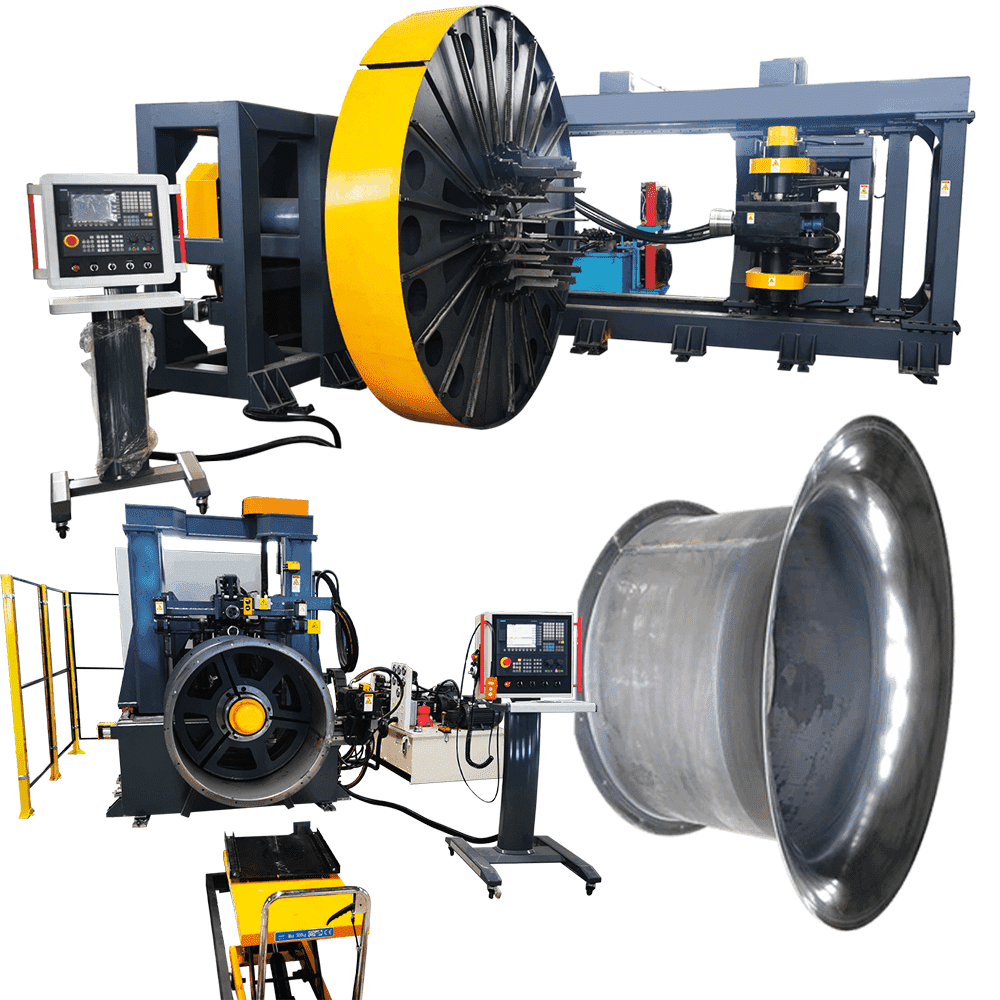

The machine is designed as a fixed tool holder + 4-station rotating turret structure; the fixed cutter wheel shaft has a large thrust, which plays a major thrust role in metal spinning forming. The tool holder on the other side can be automatically rotated and replaced, which enhances the flexibility of the CNC spinning machine, such as trimming, turning, beading and other functional actions.

CNC Spinning Lathe Video

Altron will customize your personalized CNC spinning machine according to your needs.

CNC spinning lathe equipment customization service

- Drawing data, diameter, length, wall thickness, material grade and other information provided by customers;

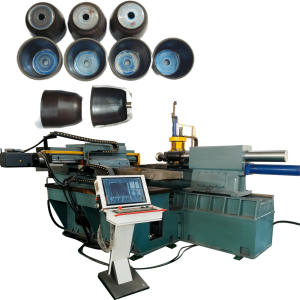

- Altron selects machines with different processes according to product information: CNC spinning machines with single, double, multiple, and spinning rollers:

- CNC Neck shrinking Spinning Machine for Hydrogen Energy Industry,

- CNC Spinning Machine for Automobile Forging Spinning Hub,

- CNC Flanging machine for Ventilation and Fan Industry, Internal Spinning machine…

- Spindle selection;

- Spindle auxiliary device selection;

- Auxiliary unloading options

- Work slide selection and angle placement;

- Turret layout and number of workstations;

- Tailstock function;

- Hydraulic or servo drive mode;

Design of CNC Spinning Machine

Auxiliary functions:

For example, if the machine does not have an automatic heating system, when producing special parts, it can only be heated manually, which is very easy to cause dangerous accidents and poses a great safety hazard! When purchasing equipment, all possibilities must be taken into consideration when designing the machine.

- Automatic heating equipment;

- Water cooling device;

- Oil cooling device;

- Loading and unloading rails;

- Selection of fixtures;

- Punching mechanism;

- Other special function customization

Metal Spinning sample For Different Materials:

In recent years, Altron has been exposed to more special material applications: This is a very challenging experiment. The raw materials are expensive. CNC spinning factory engineers need to have rich experience and master the properties of different materials, their metal flow and deformation. It is a very profound technology!

|

|

|

|

|

|

|

|

|

Altron’s Factory Video

please contact me and Joby engineers will give you a detailed plan.

Configuration

Standard Configuration

- SIEMENS CNC 828D

- SIEMENS Servo Motor & Drive

- Asynchronous Servo Spindle Motor

- Two Turrets Tool Setting Simultaneously

- APEX Servo Reducer

- High Strength Ductile Iron Sliding Table

- Blanks Center Assembly

- Back Roller Assembly

- CNC Tool Turret

- Hydraulic Station & Air Cooling System

- Air Unload Assembly

- Self-developed Spinning System

- Control System Remote Maintenance

Select Configuration

- Spindle Spinning Cylinder

- Trimming Tool Assembly

- Air Conditioner for Hydraulic Station

- Hot Spinning Parts Under 700℃

- Teach In & Play Back System

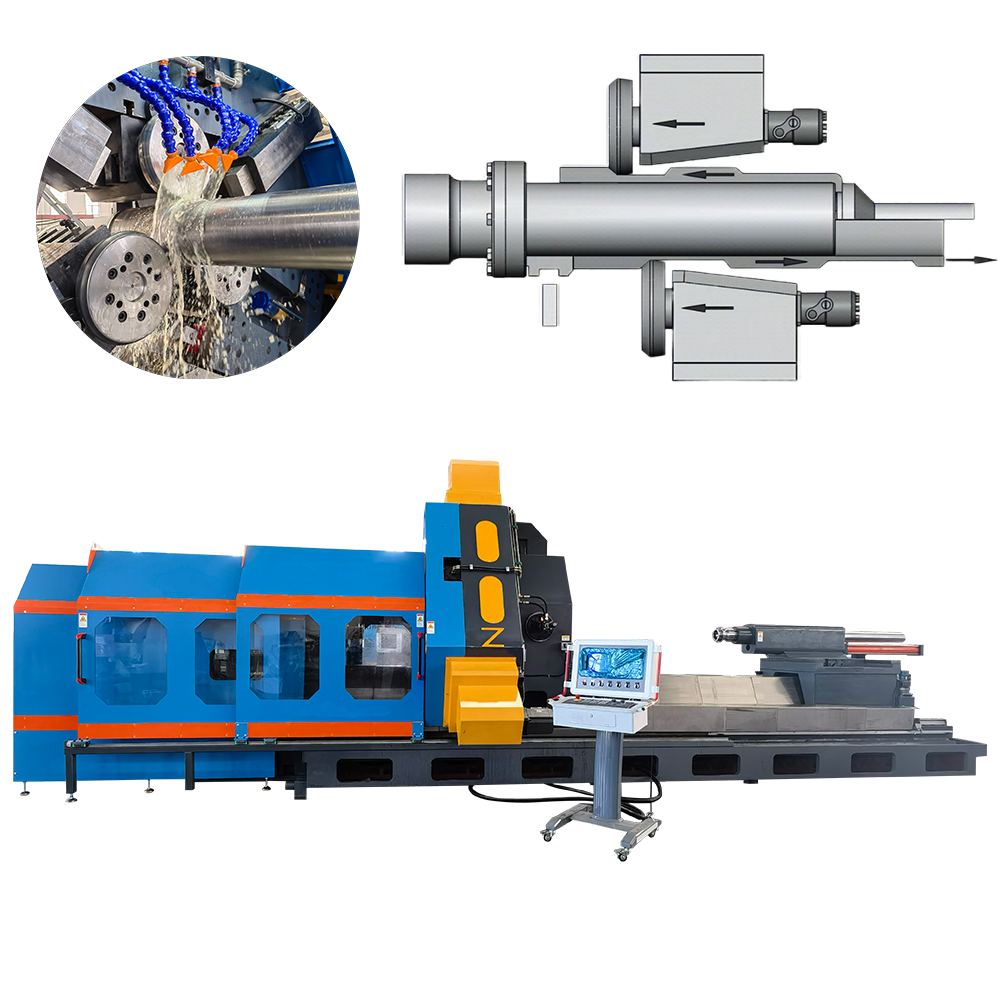

| Model No. |

Max. Material Dia. (mm) |

Radial Stroke (mm) |

Axial Stroke (mm) |

Roller Thrust (KN) |

Tailstock Force (KN) |

Spindle Power (KN) |

Spindle Speed (RPM) |

Material Thickness AL./carbon steel/SUS (mm) |

| ACD-600 | 600 | 260 | 1100 | 40 | 20 | 18.5 | 50-1000 | 6 / 4 / 3 |

| ACD-800 | 1300 | 400 | 1600 | 60 | 50 | 30 | 50-800 | 8 / 5 / 4 |

| ACD-1200 | 1650 | 500 | 800 | 80 | 50 | 37 | 30-500 | 10 / 6 / 4.5 |

| ACD-1600 | 1800 | 600 | 1000 | 120 | 70 | 45 | 30-450 | 14 / 8 / 5.5 |

| ACD-2000 | 2000 | 750 | 1250 | 140 | 100 | 75 | 30-400 | 14 / 10 / 7 |

| ACD-2500 | 2500 | 850 | 2050 | 200 | 140 | 132 | 10-300 | 30 / 20 / 15 |

| ACD-3500 | 3500 | 950 | 2550 | 300 | 140 / 200 | 200 | 10-300 | 40 / 25 / 20 |

-

Marcley

★★★★★Post a review on Aug 21, 2022 From Bolivia

Its symmetrical spinning force and pressure distribution provide excellent shock protection, ensuring the spindle’s longevity. We find it ideal for manufacturing long and thin goods, as well as cone-shaped products.

-

Arthur Zonneveld

★★★★★Post a review on Fec 21, 2022 From Mauritius

The integration of the SIEMENS control system and programming software has made the machine highly intuitive and easy to use. We highly recommend the ALTRON series for anyone in need of precision and reliability in their spinning operations.

-

Nicolas Vazquez

★★★★★Post a review on jul 21, 2022 From Uruguay

The ALTRON series double wheel spinning machine has been a game-changer for our production line. Its ability to handle blanks up to 3500mm in diameter with great accuracy has allowed us to take on larger and more complex projects with ease. The machine’s shock protection system ensures smooth and stable operation, increasing the lifespan of the spindle.

-

OSCAR URBANEJA

★★★★★Post a review on Oct 10, 2022 From Venezuela

I have been using the ALTRON series double wheel spinning machine for several months now, and I am extremely impressed with its performance. The machine effortlessly handles blanks up to 3500mm in diameter with incredible accuracy, giving me consistently excellent surface quality.