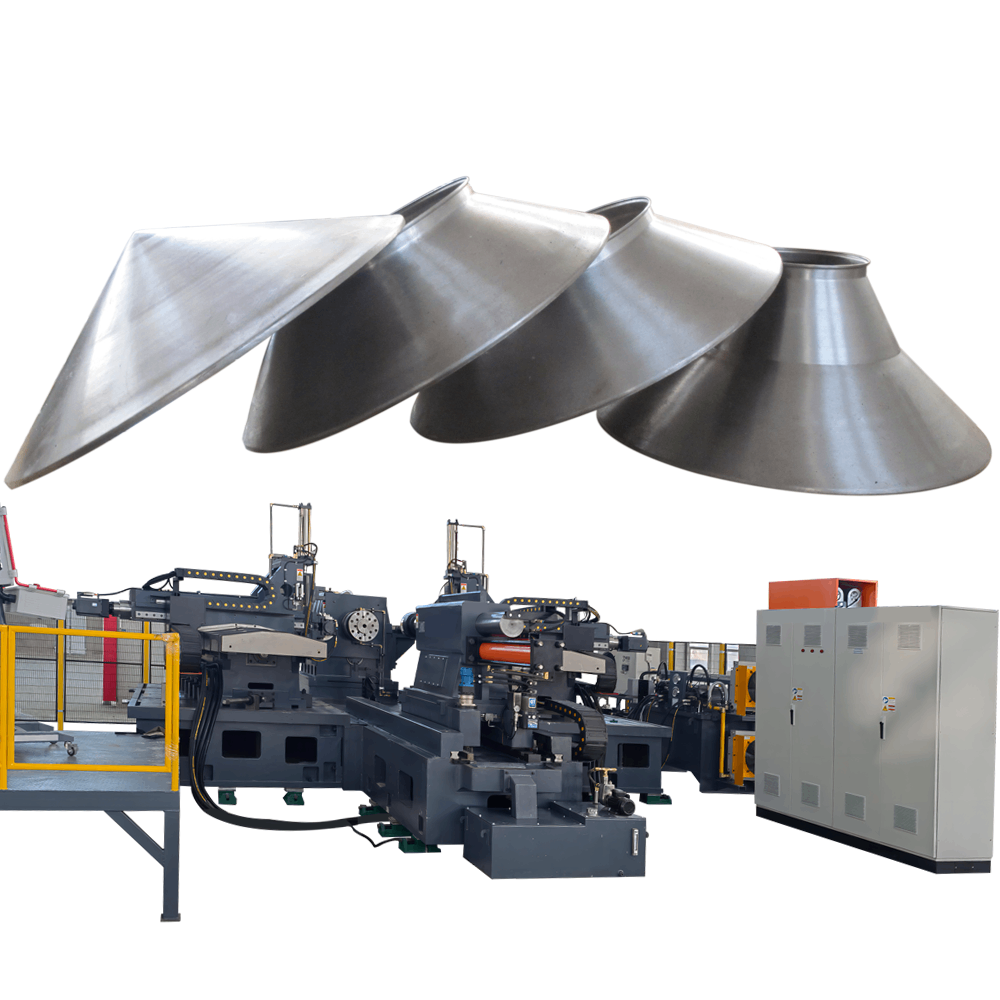

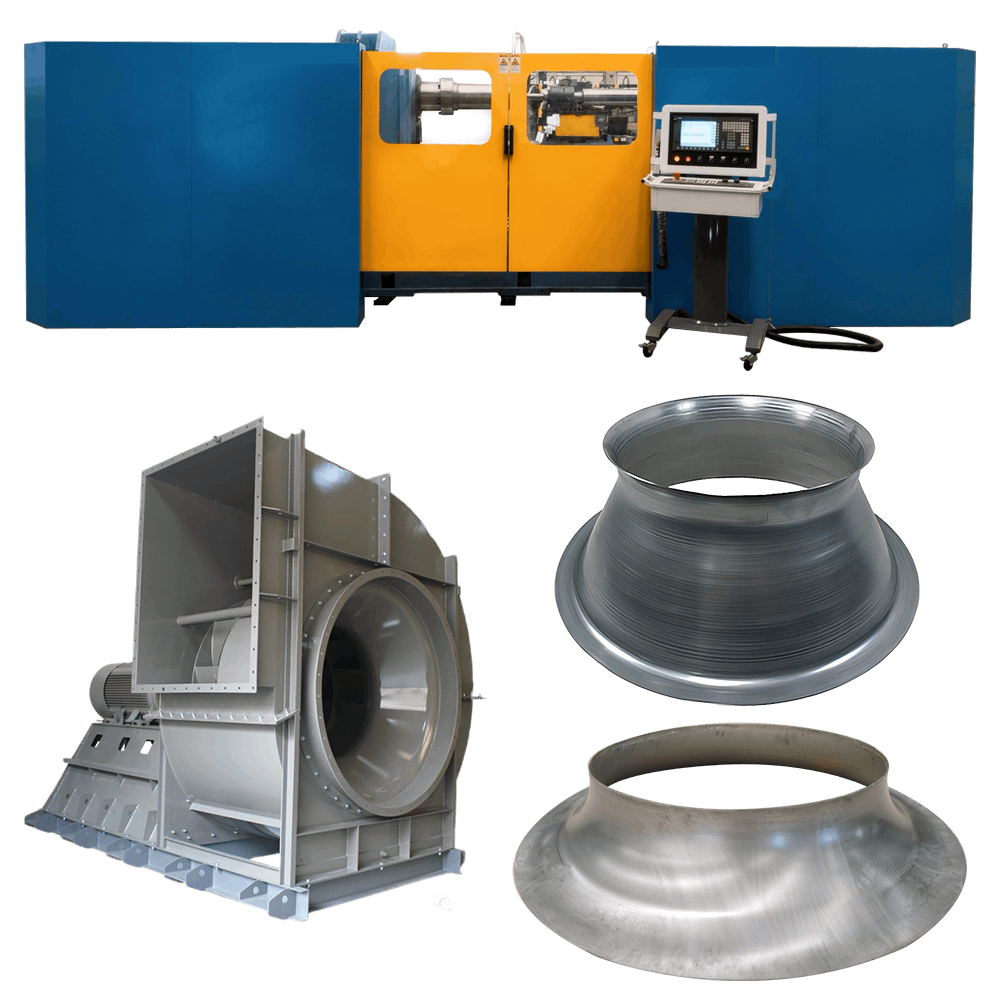

CNC Metal Spinning Machine -Double Roller AC-D2000

Customized Large Metal Spinning For Construction

|

Machine Name |

Double Roller CNC Spinning Machine |

|

Model |

AC-D2000 (diameter max Ф2000;aluminum-Max 20mm; carbon steel-Max 12mm) |

|

Application Industry |

(Aerospace, military weapons, medical, furniture, lighting, construction, fire fighting, musical instruments, handicrafts, auto parts, pressure vessels) |

|

Technical Service |

Complete the test in the early stage; provide online and offline training in the later stage, and complete the turnkey project. |

|

Technical Guidance |

Online 24 hours a day 7*24 Pre-sales technical service |

|

Project Progress |

30-120 days |

|

Relevant Files |

ALTRON_AUTO Catalog-Industrial Blower Machinery Turnkey Project |

- ADAVANTAGES

- PARAMETERS

- CUSTOMER TESTIMONIALS

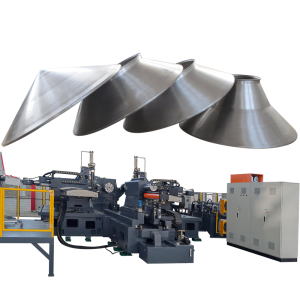

CNC Metal Spinning Machine – Double Roller AC-D2000 is a double-channel large-diameter horizontal CNC metal spinning machine. The double-side drive is driven by 4 high-power servo motors with a rated thrust of 250KN*2+300KN*2. It can spin metal plates with a diameter of 100-2000mm and process materials such as aluminum, iron, copper, carbon steel, stainless steel, alloys and other special materials. It is a medium-to-large CNC spinning machine with a total power of up to 180KW.

AC-D2000 CNC Metal Spin Machine serves large machinery and equipment manufacturers such as construction, hardware, automobiles, fans, and military industry. The AC-D2000 CNC spinning machine is equipped with a heavy-duty spindle reverse thrust mechanism, which plays a key role in the processing of large funnels or metal spinning rotating workpieces with large diameter flanges!

This machine serves Zhonghuan Inspection and Testing Co., Ltd. and has jointly invested in the production of spare parts in the field of military equipment with many companies! Altron strictly keeps the company’s product technical information confidential and prohibits the promotion of related drawings and other technical information!

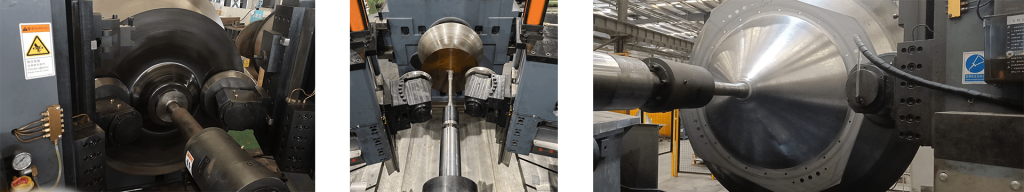

CNC Spinning Machine Working Video

Large Metal Spinning Features:

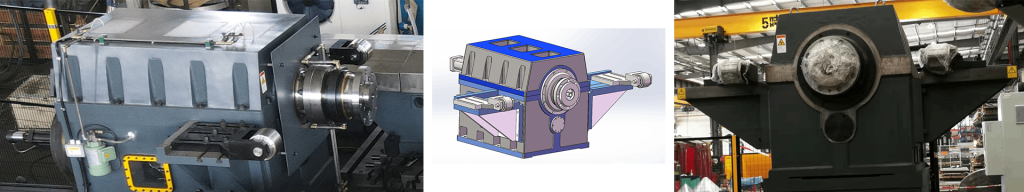

Large Metal Spinning‘s Headstock

- It adopts heavy-load design, and the overall frame box adopts integral casting process;

- The main shaft transmission gear and bearing parts are designed with forced lubrication system, and each key lubrication position is equipped with flow sensor and lubrication fault monitoring system. Guarantee the performance of the main shaft;

- The main shaft is equipped with 132KW servo motor to ensure the stable output of large-scale metal spinning process;

- When balancing large-diameter spinning, the main shaft is subject to large tilting force. The mold support mechanism is designed on both sides of the machine tool spindle box to effectively improve the life of the main shaft. The material removal mechanism can also be installed according to the actual process;

- The center of the main shaft is designed with a discharge push rod with a stroke of 0-200mm (on the large-diameter product spinning machine, the traditional pneumatic demoulding mechanism is ineffective. The machine is equipped with a discharge power rotary cylinder);

Large Metal Spinning‘s Machine Frame:

- The bidirectional slide part of the frame is equipped with T-slots to adjust the angle and position of the machine workbench to achieve the best state when spinning products with different processes;

- The AC-D2000 CNC spinning machine supports water circulation spinning processing, and is equipped with water retaining and large-flow coolant recovery;

- Anti-slip nets are laid on the operating part of the spinning machine to prevent operators from accidentally slipping during water circulation spinning;

Large Metal Spinning‘s Tailstock:

- The tailstock has a stroke of 600mm and a maximum ejector force of 200KN;

- The tailstock is driven forward and backward by a hydraulic motor, with a stroke of 1900mm, controlled by a program and equipped with a hydraulic locking mechanism.

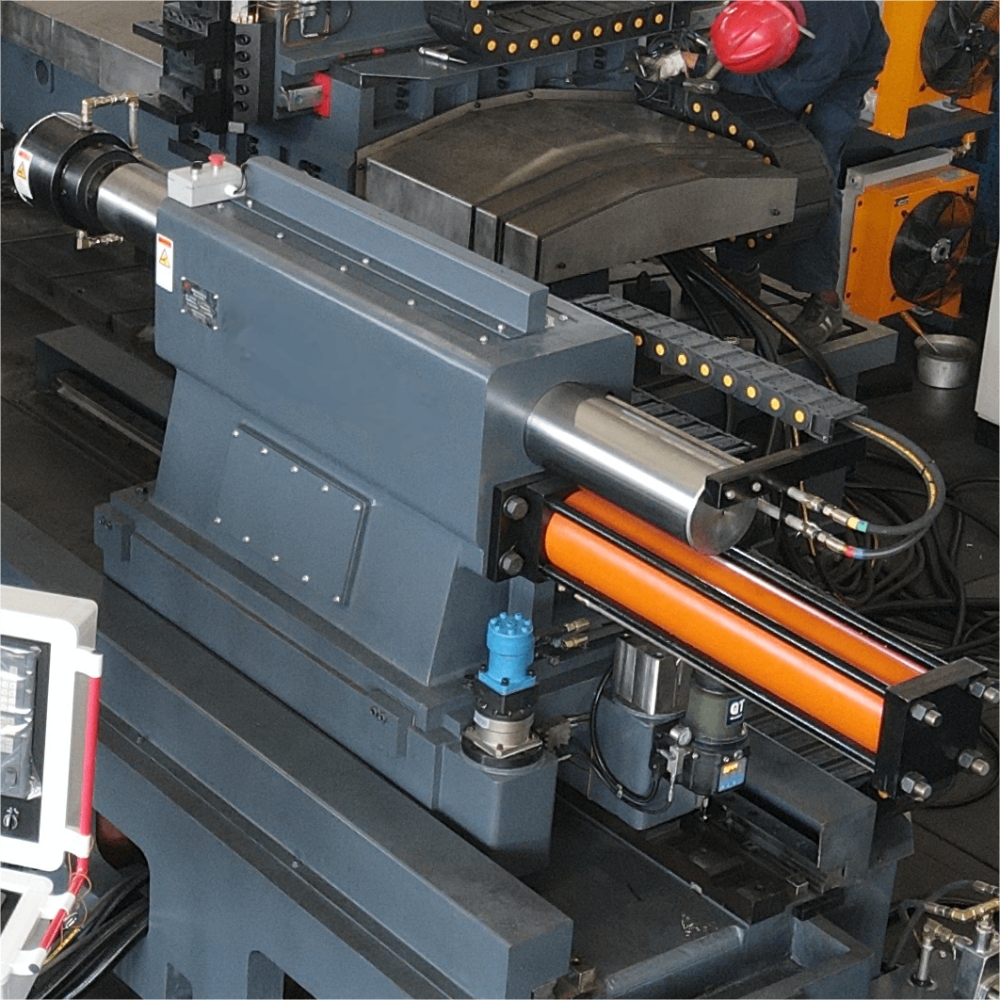

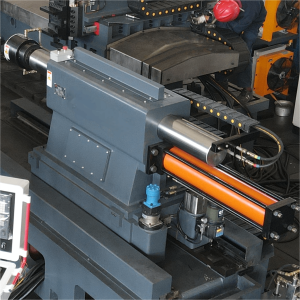

Large Metal Spinning‘s Slider:

- The spinning roller adopts a left-right symmetrical layout, with 2+2 stations on one side and hydraulic lifting tool change. It is designed with an oil cooling system to prevent the roller bearings from overheating during spinning;

- The power is equipped with 4 Siemens 1FT7 series servo motors and S120 drive system;

- The guide rail adopts 65 roller heavy-duty guide rails, each rail is equipped with 3 sliders to improve the seismic performance, and the lead screw adopts 10020 heavy-duty lead screw;

- The reducer is equipped with Taiwan APEX;

- The heating gun adopts the German Messer 5# heating torch, which can be moved manually;

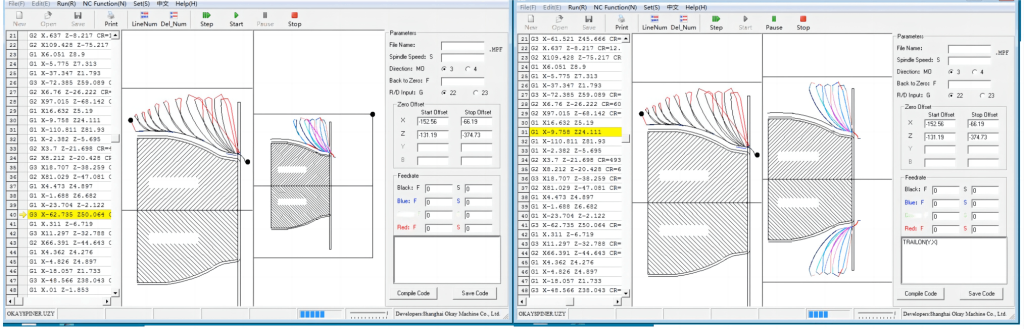

Large Metal Spinning’s programming software and operation

- The control system is equipped with Siemens 840D;

- The spinning software supports single-channel or upper-channel synchronization mode; all spinning trajectories and G-code programs are fully automatically produced.

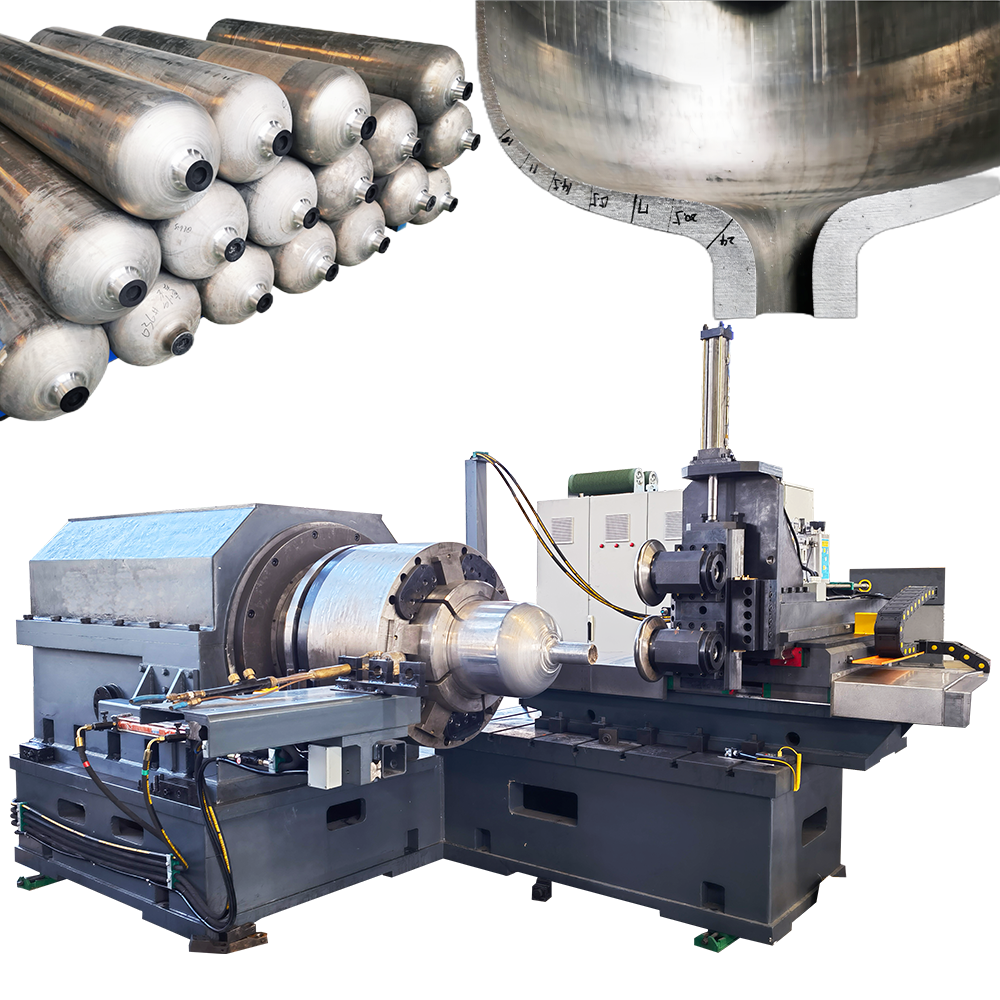

Processed products

It is inconvenient to publicize due to confidential matters!

For more metal spinning samples, please see the product video!

Large Metal Spinning Machine Installation Site

This is a picture of the on-site assembly of a large CNC spinning machine in Altron’s factory in Central. It is a factory built from scratch, a brand new project, and the AC-D2000 CNC spinning machine is the first large machine to enter the Central factory!

Altron’s engineers followed up the entire process from the construction of the foundation of the large CNC spinning machine, the layout of water and electricity, to the transportation and assembly of the machine, to ensure that the machine is successfully put into production in the customer’s factory!

Altron’s Factory Video

Altron provides customized CNC Metal Spinning Machine. All spin machines with diameters less 3800mm have successful cases & customer factories for visits .

please contact me and Joby engineers will give you a detailed plan.

Configuration

Standard Configuration

- SIEMENS CNC 828D

- SIEMENS Servo Motor & Drive

- Asynchronous Servo Spindle Motor

- Two Turrets Tool Setting Simultaneously

- APEX Servo Reducer

- High Strength Ductile Iron Sliding Table

- Blanks Center Assembly

- Back Roller Assembly

- CNC Tool Turret

- Hydraulic Station & Air Cooling System

- Air Unload Assembly

- Self-developed Spinning System

- Control System Remote Maintenance

Select Configuration

- Spindle Spinning Cylinder

- Trimming Tool Assembly

- Air Conditioner for Hydraulic Station

- Hot Spinning Parts Under 700℃

- Teach In & Play Back System

| Model No. |

Max. Material Dia. (mm) |

Radial Stroke (mm) |

Axial Stroke (mm) |

Roller Thrust (KN) |

Tailstock Force (KN) |

Spindle Power (KN) |

Spindle Speed (RPM) |

Material Thickness AL./carbon steel/SUS (mm) |

| ACD-600 | 600 | 260 | 1100 | 40 | 20 | 18.5 | 50-1000 | 6 / 4 / 3 |

| ACD-800 | 1300 | 400 | 1600 | 60 | 50 | 30 | 50-800 | 8 / 5 / 4 |

| ACD-1200 | 1650 | 500 | 800 | 80 | 50 | 37 | 30-500 | 10 / 6 / 4.5 |

| ACD-1600 | 1800 | 600 | 1000 | 120 | 70 | 45 | 30-450 | 14 / 8 / 5.5 |

| ACD-2000 | 2000 | 750 | 1250 | 140 | 100 | 75 | 30-400 | 20/ 12 / 7 |

| ACD-2500 | 2500 | 850 | 2050 | 200 | 140 | 132 | 10-300 | 30 / 20 / 15 |

| ACD-3500 | 3500 | 950 | 2550 | 300 | 140 / 200 | 200 | 10-300 | 40 / 25 / 20 |

Machine Configuration Parameters

Technical Specification

Tailstock

Workpiece lubrication

Hardware Configuration Machine Configuration

Germany Yifu ball screw

-

Marcley

★★★★★Post a review on Aug 21, 2022 From Bolivia

The symmetrical spinning force and pressure distribution provide excellent shock protection to the spindle, giving me peace of mind regarding its durability. It’s truly ideal for manufacturing long and thin goods as well as cone-shaped products. I highly recommend the ALTRON series for its reliability, versatility, and top-notch results.

-

Arthur Zonneveld

★★★★★Post a review on Fec 21, 2022 From Mauritius

We particularly appreciate its versatility, as it can process thinning and lengthening barrel blanks for seamless thin tubes, and even perform hardening treatments. The combination of the high-end SIEMENS control system and the user-friendly programming software makes operating the machine a breeze. It has definitely exceeded our expectations.

-

Nicolas Vazquez

★★★★★Post a review on jul 21, 2022 From Uruguay

We invested in the ALTRON series double wheel spinning machine, and it has been a remarkable addition to our workshop. The machine’s ability to handle blanks up to 3500mm in diameter with great accuracy and surface quality has greatly improved our productivity and customer satisfaction.

-

OSCAR URBANEJA

★★★★★Post a review on Oct 10, 2022 From Venezuela

Its symmetrical spinning force and pressure distribution provide excellent shock protection, ensuring the spindle’s longevity. We find it ideal for manufacturing long and thin goods, as well as cone-shaped products. The integration of the SIEMENS control system and programming software has made the machine highly intuitive and easy to use. We highly recommend the ALTRON series for anyone in need of precision and reliability in their spinning operations.