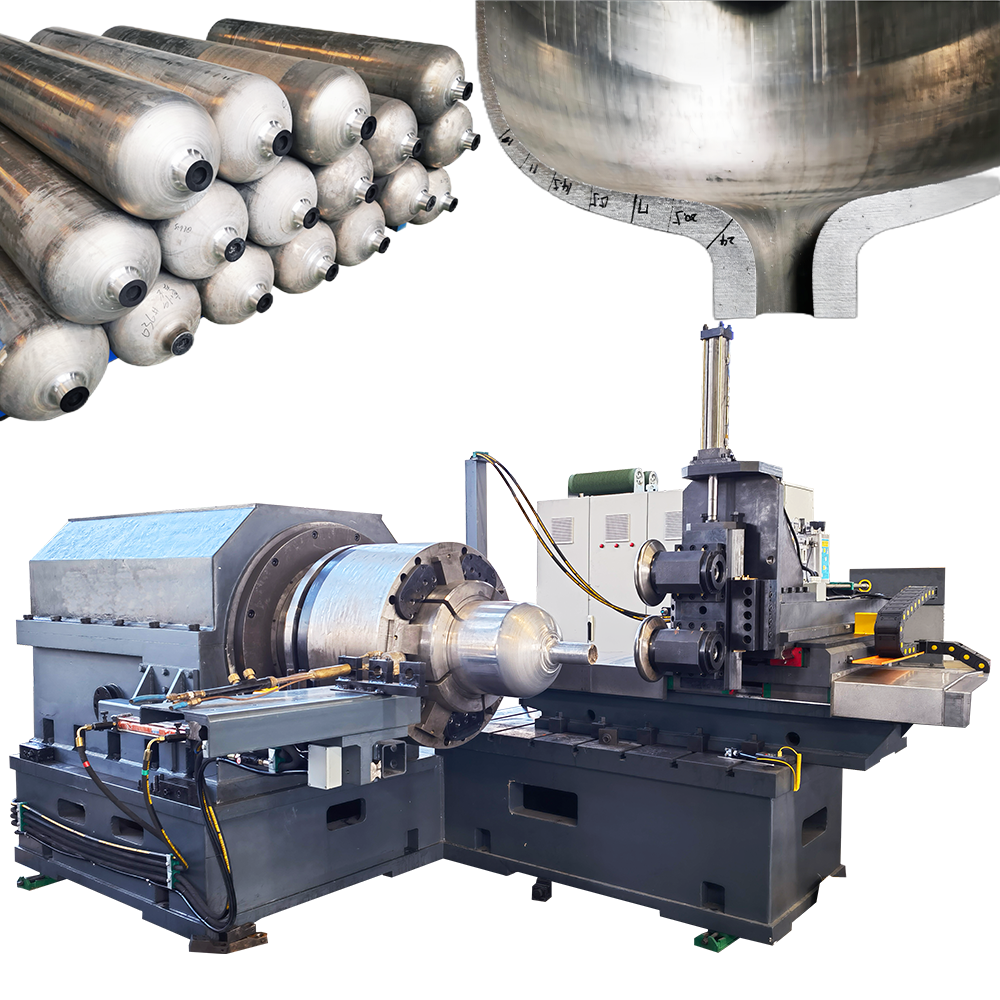

CNC Metal Spinning Machine -Double Roller AC-2500

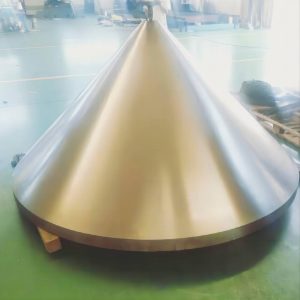

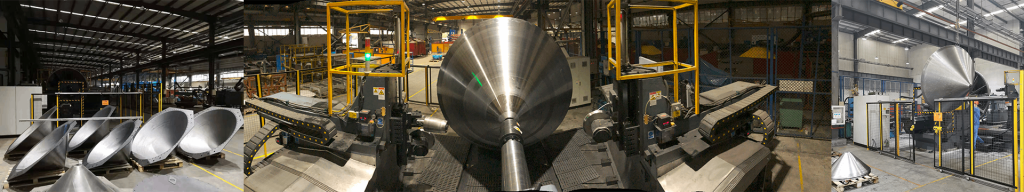

CNC Metal Spinning for Large Cones -Grain Machinery Hopper

|

Machine Name |

Double Roller CNC Spinning Machine |

|

Model |

AC-D2500(diameter max Ф2700;aluminum-Max 30mm; carbon steel-Max 20mm) |

|

Application Industry |

(Aerospace, military weapons, medical, Machinery, construction, firefighting, musical instruments, handicrafts, auto parts, pressure vessels) |

|

Technical Service |

Complete the test in the early stage; provide online and offline training in the later stage, and complete the turnkey project. |

|

Technical Guidance |

Online 24 hours a day/7*24 Pre-sales technical service |

|

Project Progress |

30-120 days |

|

Relevant Files |

ALTRON_AUTO Catalog-Industrial Blower Machinery Turnkey Project |

- ADAVANTAGES

- PARAMETERS

- CUSTOMER TESTIMONIALS

CNC Spinning Machine AC-D2500 is a large CNC spinning machine customized for an Italian WAMGROUP! The company is mainly engaged in the development and manufacture of bulk solid handling and processing equipment and equipment components. The machine is used in the factory located in Wuxi, China. Its Wuxi factory mainly provides WAMGROUP with logistics and transportation parts processing and production, such as large cone funnels, bag openers, silo activators, FIBC fillers and unloaders, active silo bottoms, rotary silo unloaders, and other large metal accessories…

CNC Metal Spinning Cases:

AC-D2500 can spin with a rotary diameter of 2700mm and can spin stainless steel, carbon steel, aluminum alloy, and other special alloy materials; the machine adopts a dual-channel symmetrical 45° inclined worktable design, mainly to increase the spinning thrust, with a total power of up to 195KW. It is a heavy-duty CNC spinning machine!

CNC Spinning Machine Working Video

Key Features of The CNC Spinning Machine AC-D2500:

- Dual-wheel configuration for simultaneous spinning operations and increased productivity.

- CNC system for precise control, programming, and real-time monitoring of the spinning process.

- Large working area and versatile tooling options for the production of complex geometries and customized parts.

- Robust construction and high-quality components for long-term durability and reliability.

- Advanced safety features for operator protection and accident prevention.

Introduction of Metal Spinning Solution

Product introduction:

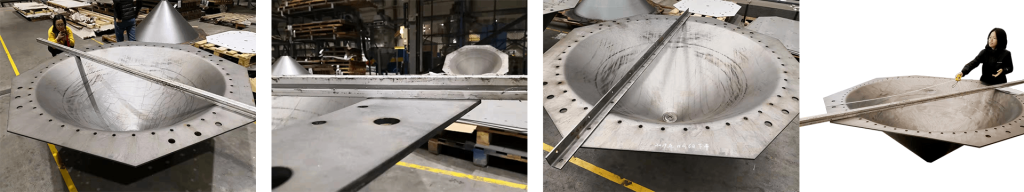

- Product name: Large industrial cone funnel, used in solid material transportation machinery

- Metal spinning sheet non-circular material;

- Material thickness 8/10/12/14mm;

- Raw material: carbon steel/stainless steel;

Key points of metal spinning technology:

This Metal Spinning case is a turnkey project provided by Altron for WAM from preliminary project-mechanical design to mass production of products; during the service period, engineers from both sides maintained continuous communication to ensure that the project was delivered to the customer’s factory on time, with guaranteed quality and high efficiency.

Manufacturing and cost of metal spinning molds:

- Design: The mold adopts cast steel + CR12 structure;

- Processing technology: casting, rough turning, processing, semi-finishing, dynamic balancing, heat treatment, finishing mold installation position, and finishing the mold surface on the spinning machine;

- Mold auxiliary: The maximum mold diameter of this product is 2500mm, and the support structure is installed on both sides of the CNC spinning machine spindle; this improves the service life of the mold and the inclination of the spindle to the mold;

- Mold cost and quality: Considering the processing technology of ultra-large diameter molds, we cannot fully use high-performance mold material steels such as CR12 or H13 with high quality requirements, due to cost factors!

- This mold adopts a comprehensive solution of price and quality: the front section uses the CR12 forging process, and the back section uses the cast steel process:

1. The shear force and friction between the front end material and the mold are large, and materials with higher hardness and wear resistance are used, with a hardness of up to 62°.

2. The back section adopts lost foam casting process, pouring molten iron with steel elements, and the maximum hardness after heat treatment can reach 56°.

The two main parts of the mold are processed and treated separately, and finally assembled before semi-finishing turning.

|

|

|

|

Metal Spinning Processes and Solutions:

The metal spinning process for cone-shaped workpieces uses shear spinning; there are many differences between ordinary round materials and multi-deformed materials:

- Circular material shear metal spinning: Use the traditional shearing process, calculate the gap between the spinning roller and the mold, and let the metal material perform a single metal spinning under the thrust of the spinning roller and the rotation of the main shaft;

- Polygonal metal shear metal spinning: Different from traditional shearing metal spinning, the tensile properties and flow direction of the metal will change, resulting in changes in the flatness and size of the square flange and the hole position;

What Problems Will Occur In Metal Spinning Cones?

- During CNC metal spinning, the outer diameter of the product is larger than the theoretical value!

- During CNC metal spinning, the height of the product increases!

- The surface spinning texture of the metal spinning cone is uneven!

- The mold and spinning roller vibrate during metal spinning!

- The flange surface flatness of the metal spinning product is poor!

How does Altron solve the metal spinning problem?

The outer diameter of the product is too large:

the main reason is that the metal material does not fit the mold during the spinning process; It is necessary to adjust the gap between the spinning tool wheel and the mold, and adjust the gap compensation based on experience and actual rebound values!

Product height increase:

The main reason is that the shear thinning pressure of the metal material during the spinning process is too large, causing the metal to flow in the opposite direction;

Increase the gap between the spinning tool wheel and the mold so that the metal material is in a state that just fits the mold; Detection method: A mark can be made at the position of the hydraulic cylinder to determine whether the metal has reverse stretching during the spinning process.

The surface spinning texture of the cone is poor:

the main reason is that the diameter of the small end and the large end of the mold is very different! The linear speed between the spinning roller and the mold does not match;

The metal spinning program needs to be adjusted to a gradual speed, commonly known as a constant linear speed! During the spinning process, the small diameter part is fed at a high speed, and the spindle speed and feed speed are gradually reduced while the metal is spinning in the direction of the large diameter! Or use the horizontal linear speed formula for programming!

The mold and spinning roller vibrate:

mainly due to the mismatch between the spindle S speed and the feed F speed. The reason is that the spindle speed is too high.

During the spinning process, the feed speed F value can be reduced by a percentage until the vibration is reduced, because the feed ratio is only adjusted by 10%. When spinning the next workpiece, the F data should be adjusted, the speed should be appropriately reduced, and the film adhesion between the workpiece and the mold should be checked.

Poor flatness of flange surface is also the core problem of this project:

The poor flatness is caused by multiple factors, mainly divided into 5 core explanations!

- The flatness of metal raw materials needs to be leveled by a flattening machine;

- The gap between the spinning wheel and the mold during the spinning process is controlled to allow the metal plate to be sheared and spun at a vertical angle;

- The shape and angle of the metal spinning roller. This product uses a 750-degree spinning wheel angle and a spinning wheel structure with a large arc surface on the back to provide stable support for the metal sheet;

- The spinning process requires the use of coolant to cool the spinning process so that the temperature of the mold and the cutter wheel is in a stable state! High temperature will cause the mold to expand;

- There are subtle changes in the processing and turnover of metal sheets during transportation and different processes! After spinning, we use a flat roller to roll and flatten the back of the flange surface, which greatly improves the flatness quality of the flanges spun in batches!

WAMgroup’s Altron AC-D2500 CNC spinning machine production situation:

The project was delivered on November 6, 2019, and the customer completed the acceptance and received the trial right of the machine!

The CNC spinning machine AC-D2500 has brought unlimited efficiency and cost savings to the company! The Italian headquarters uses machines from Lefeld, Germany. Our spinning machines are only one-fifth of the price, but the functionality and product precision of the large funnel metal spinning in the WAM project are much higher than the German machines!

The machine has been used well so far, without mechanical and electrical problems; when WAM develops new product processes, Altron provides technical support and solutions.

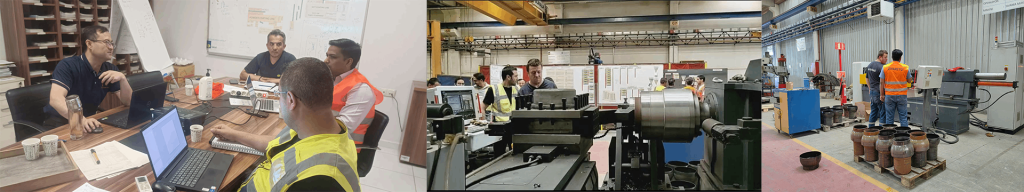

Turkey Wam, India WAM Metal Spinning Technology Training

In 2022, Altron sold two AC-1300 expansion spinning machines to Turkey WAM and India WAM respectively. It is a heavy-duty single-roller metal spinning machine customized for expansion spinning of transport pipelines.

Altron’s technical engineers were invited by Turkey Wam and India WAM to go to the Turkish factory to conduct systematic technical training on equipment operation and maintenance for engineers from both companies.

The WAM engineers who participated in the training said that this training learned a lot of practical technology, enhanced their professional knowledge in the practical operation of CNC spinning equipment, and also solved some problems that bothered them and learned a lot of practical operating skills.

Altron’s Factory Video

Altron provides customized CNC Metal Spinning Machine. All spin machines with diameters less than 3800mm have successful cases & customer factories for visits.

please contact me and Joby engineers will give you a detailed plan.

Configuration

Standard Configuration

- SIEMENS CNC 828D/ 840D

- SIEMENS Servo Motor & Drive

- Asynchronous Servo Spindle Motor

- Two Turrets Tool Setting Simultaneously

- APEX Servo Reducer

- High Strength Ductile Iron Sliding Table

- Blanks Center Assembly

- Back Roller Assembly

- CNC Tool Turret

- Hydraulic Station & Air Cooling System

- Air Unload Assembly

- Self-developed Spinning System

- Control System Remote Maintenance

Select Configuration

- Spindle Spinning Cylinder

- Trimming Tool Assembly

- Air Conditioner for Hydraulic Station

- Hot Spinning Parts Under 700℃

- Teach In & Play Back System

| Model No. |

Max. Material Dia. (mm) |

Radial Stroke (mm) |

Axial Stroke (mm) |

Roller Thrust (KN) |

Tailstock Force (KN) |

Spindle Power (KN) |

Spindle Speed (RPM) |

Material Thickness AL./carbon steel/SUS (mm) |

| ACD-600 | 600 | 260 | 1100 | 40 | 20 | 18.5 | 50-1000 | 6 / 4 / 3 |

| ACD-800 | 1300 | 400 | 1600 | 60 | 50 | 30 | 50-800 | 8 / 5 / 4 |

| ACD-1200 | 1650 | 500 | 800 | 80 | 50 | 37 | 30-500 | 10 / 6 / 4.5 |

| ACD-1600 | 1800 | 600 | 1000 | 120 | 70 | 45 | 30-450 | 14 / 8 / 5.5 |

| ACD-2000 | 2000 | 750 | 1250 | 140 | 100 | 75 | 30-400 | 20 / 12 / 7 |

| ACD-2500 | 2500 | 850 | 2050 | 200 | 140 | 132 | 10-300 | 30 / 20 / 15 |

| ACD-3500 | 3500 | 950 | 2550 | 300 | 140 / 200 | 200 | 10-300 | 40 / 25 / 20 |

Machine Configuration Parameters

Technical Specification

Hardware Configuration Machine Configuration

-

Marcley

★★★★★Post a review on Aug 21, 2022 From Bolivia

I have been using the ALTRON series double wheel spinning machine for several months now, and I am extremely impressed with its performance. The machine effortlessly handles blanks up to 2700mm in diameter with incredible accuracy, giving me consistently excellent surface quality.

-

Arthur Zonneveld

★★★★★Post a review on Fec 21, 2022 From Mauritius

The symmetrical spinning force and pressure distribution provide excellent shock protection to the spindle, giving me peace of mind regarding its durability. It’s truly ideal for manufacturing long and thin goods as well as cone-shaped products. I highly recommend the ALTRON series for its reliability, versatility, and top-notch results.

-

Nicolas Vazquez

★★★★★Post a review on jul 21, 2022 From Uruguay

The ALTRON series double wheel spinning machine has been a game-changer for our production line. Its ability to handle blanks up to 2700mm in diameter with great accuracy has allowed us to take on larger and more complex projects with ease. The machine’s shock protection system ensures smooth and stable operation, increasing the lifespan of the spindle.

-

OSCAR URBANEJA

★★★★★Post a review on Oct 10, 2022 From Venezuela

We particularly appreciate its versatility, as it can process thinning and lengthening barrel blanks for seamless thin tubes, and even perform hardening treatments. The combination of the high-end SIEMENS control system and the user-friendly programming software makes operating the machine a breeze. It has definitely exceeded our expectations.