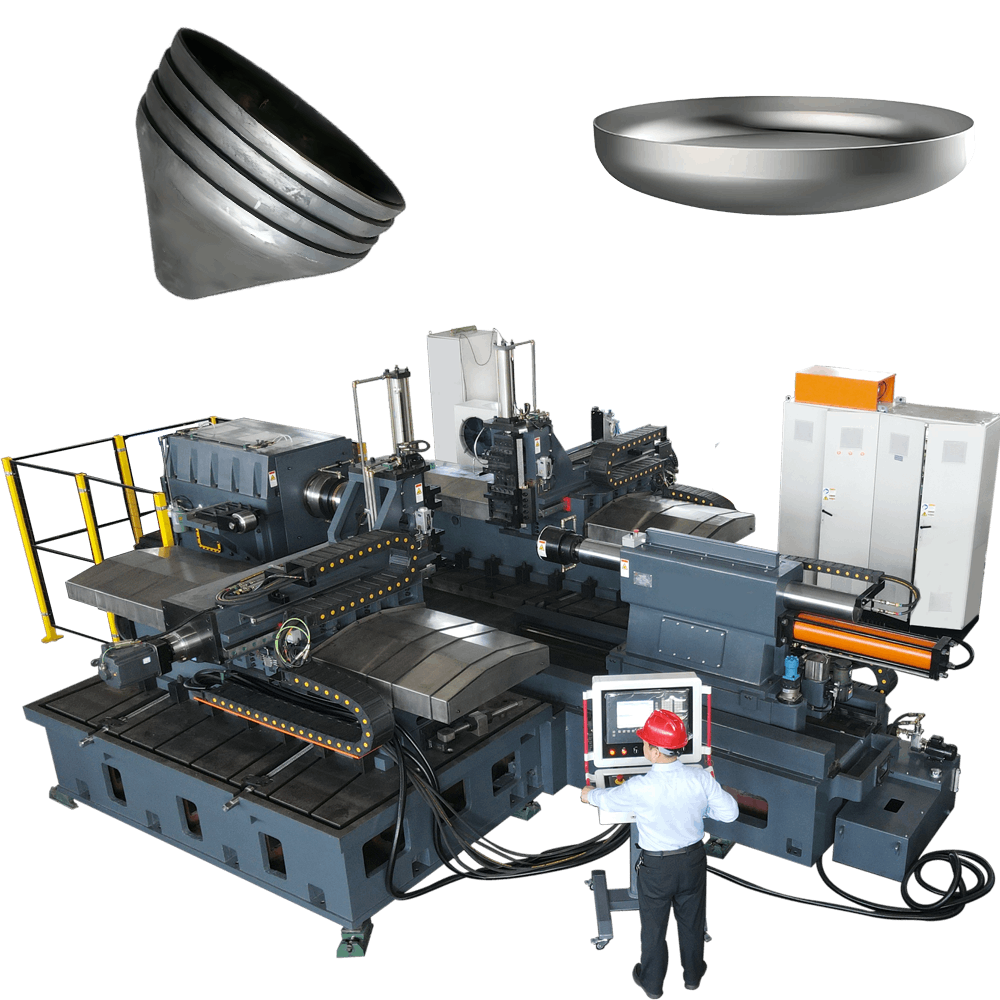

Double Wheel CNC Spinning Machine D-3500

CNC Metal Spinning Machine For Heads & Tank

|

Machine Name |

Double Roller CNC Spinning Machine |

|

Model |

AC-D3500 (diameter max Ф3500;aluminum-Max 40mm; carbon steel-Max 25mm) |

|

Application Industry |

(Aerospace, military weapons, medical, furniture, lighting, construction, fire fighting, musical instruments, handicrafts, auto parts, pressure vessels) |

|

Technical Service |

Complete the test in the early stage; provide online and offline training in the later stage, and complete the turnkey project. |

|

Technical Guidance |

Online 24 hours a day/7*24 Pre-sales technical service |

|

Project Progress |

30-120 days |

|

Relevant Files |

ALTRON_AUTO Catalog-Industrial Blower Machinery Turnkey Project |

- ADAVANTAGES

- PARAMETERS

- CUSTOMER TESTIMONIALS

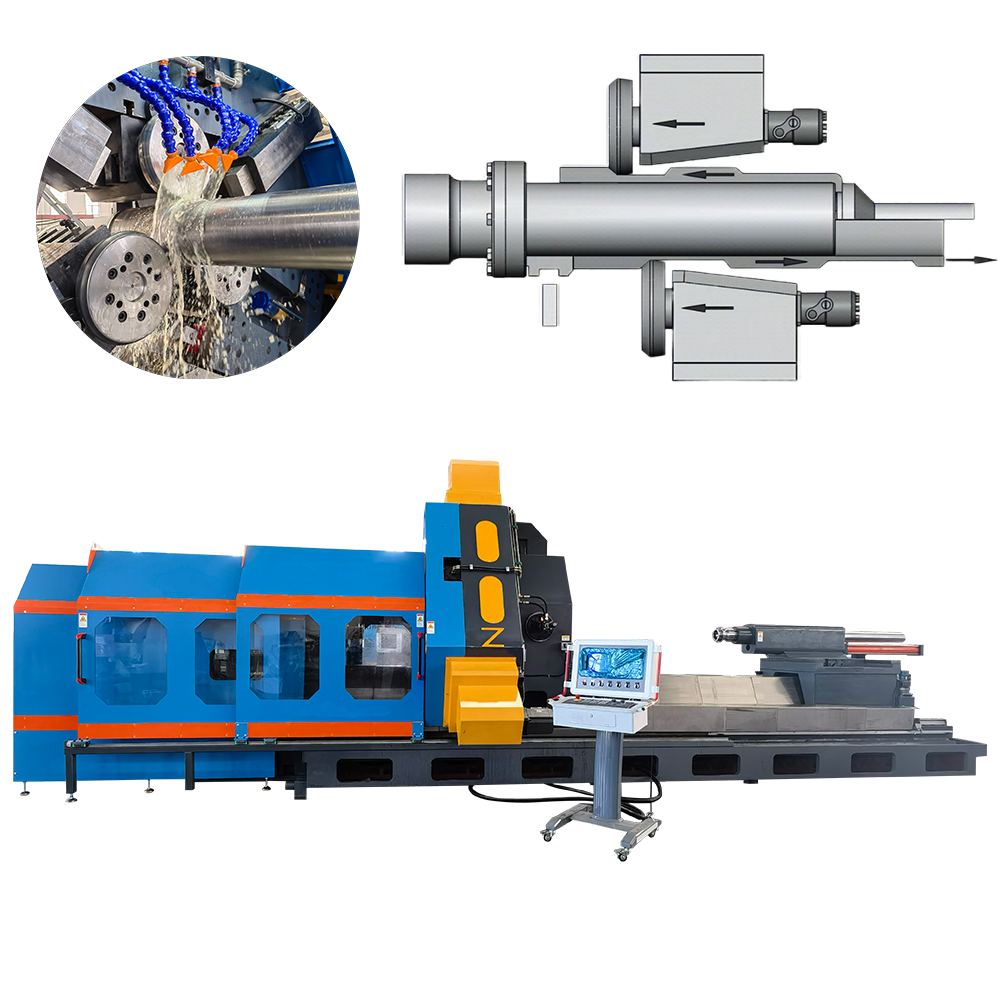

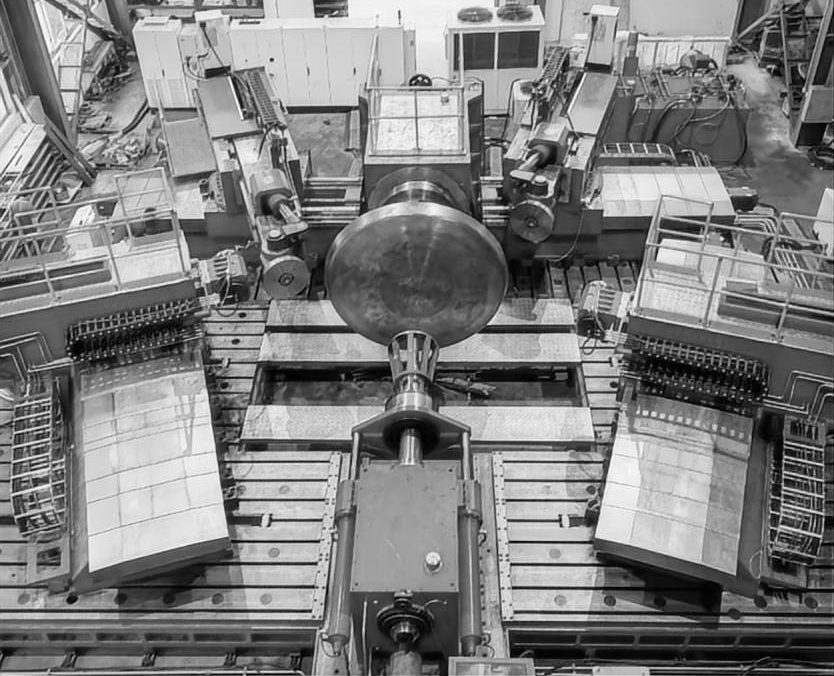

CNC Metal Spinning Machine – Double Roller AC-D3500 is a double-channel large-diameter horizontal CNC metal spinning machine. The double-side drive is driven by 4 high-power servo motors with a rated thrust of 280KN*2+300KN*2. It can spin metal plates with a diameter of 100-3500mm and process materials such as aluminum, iron, copper, carbon steel, stainless steel, alloys and other special materials. It is a large CNC spinning machine with a total power of up to 200KW.

This CNC spinning machine serves Jiuzhou Head Forging Co., Ltd., specializing in the production of boiler and pressure vessel heads of different specifications, materials and shapes. The machine can be used by large machinery and equipment manufacturers such as construction, hardware, automobiles, fans, military industry, pressure vessels, etc.; AC-D3500 CNC spinning machine is equipped with a heavy-duty spindle reverse thrust mechanism and a double tailstock structure, which plays a key role in spinning large curved workpieces and large spinning molds.

CNC Spinning Machine Working Video

Features of CNC spinning machine:

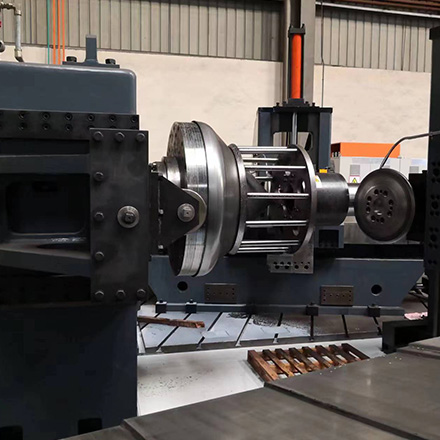

- Heavy-duty spindle box, equipped with mold rollover support frame;

- High-strength ductile iron casting frame, the machine is mainly composed of 3 large plates, the machine body and the left and right side spinning mechanism;

- 2+2 layout heavy-duty spinning machine mechanism, equipped with a single-side thrust of over 300KN;

- The spindle rotation diameter is 3600mm, and it can metal spin 3500mm round plates;

- Equipped with Siemens 840D CNC system and Siemens original servo motor;

- Free CNC Metal Spinning programming software;

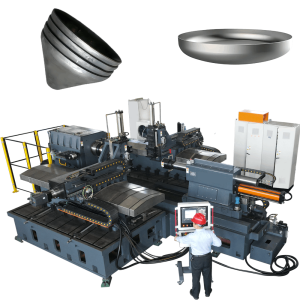

Application of CNC spinning machine in head industry

Classification of heads

- SPHERICAL HEAD

- DISH-SHAPED PLATE

- SEGMENTED HEAD

- CONICAL HEAD

- HEMISPHERICAL HEAD

- SPHERICAL CROWN HEAD

- CONICAL HEAD

- HIGH STRAIGHT EDGE HEAD

- SPHERICAL BOTTOM

- FLAT BOTTOM

- DUPLEX STEEL SPHERICAL HEAD WELDING

ETC.

Head Manufacturing: CNC Metal Spinning Vs Deep Drawing

Currently, the main methods for manufacturing large heads are metal CNC spinning, hydraulic spinning and deep drawing, each of which has different advantages.

Advantages of metal spinning heads:

- Low mold investment cost

- Larger diameter heads;

- Relatively low manufacturing cost;

- Suitable for making some thin-walled or large-sized heads;

- The same mold can manufacture heads of different thicknesses and similar sizes;

- The time cycle is relatively short, suitable for some single-piece or small-batch production;

- The molding quality of the head is good and there are no wrinkles;

Advantages of deep-drawn heads:

- High efficiency, suitable for the production of large quantities of small-sized heads

Head installation:

drum press and spinning machine are special machines designed for heads

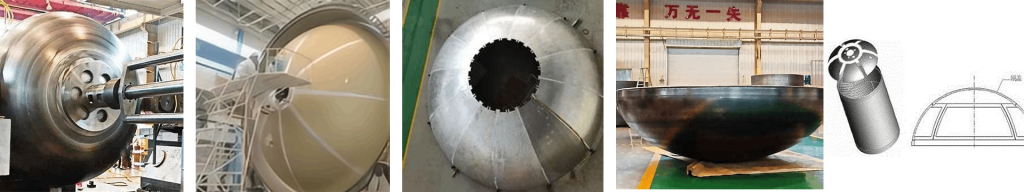

CNC Spinning Machine For Bottom Head Of Large Rocket Fuel Tank

The overall bottom of a carrier rocket with a diameter of 3.35 meters is manufactured by CNC spinning machine. The bottom of the fuel tank is the most complex in structure, the most difficult to manufacture, and the longest production cycle among the fuel tank components of the carrier rocket.

In the past, the bottom of the rocket fuel tank was welded by multiple melon seed pieces, top cover, and transition ring. Each tank bottom had more than ten main welds. The manufacturing process was very complicated. The weld was the weakest link in the entire tank bottom. The weld destroyed the continuity of the material. It was easy to produce defects such as pores, deformation, and cracks during welding, which affected the reliability of the tank bottom.

The bottom of the tank manufactured by the CNC spinning machine is formed by a CNC program mold. After one clamping, it can be formed as a whole at one time. There are few manufacturing processes and high reliability. The entire tank body has no welds, which reduces the weight by 60 kilograms, reduces the manufacturing cost, and greatly improves the rocket’s payload and safety.

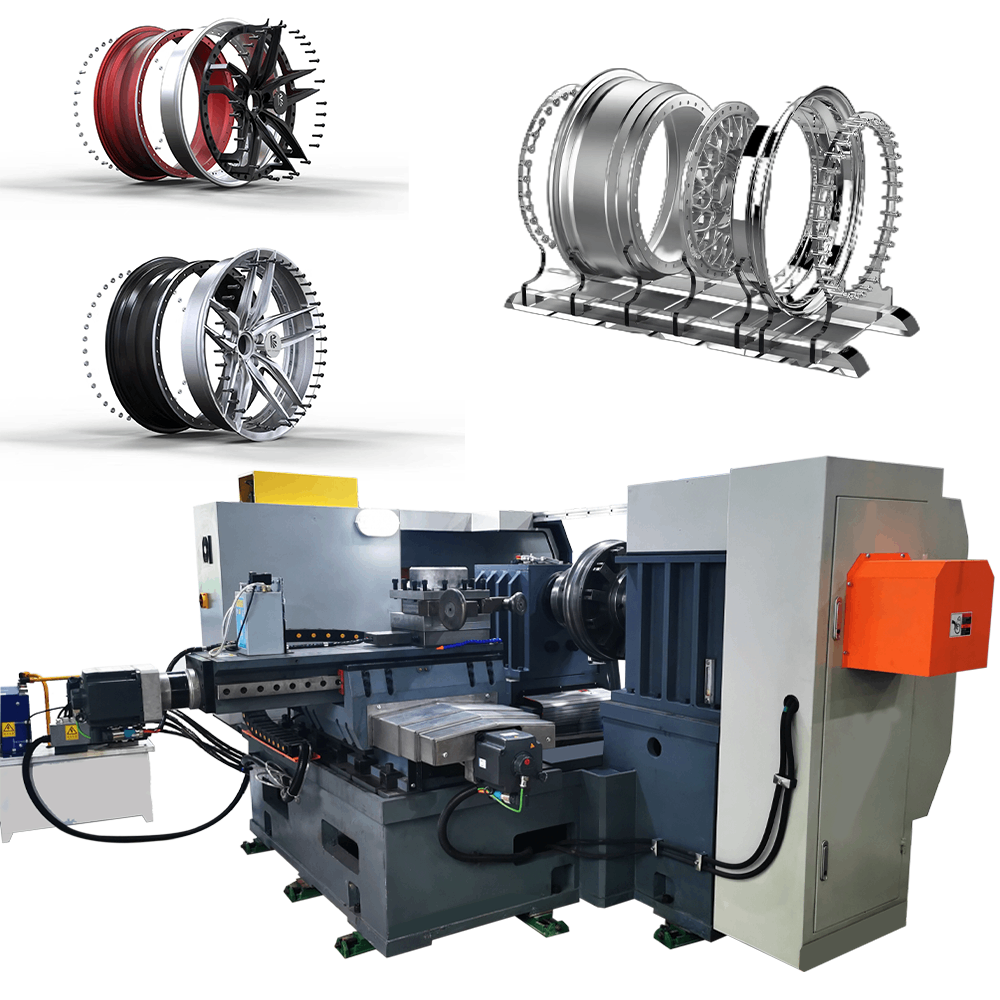

Altron’s CNC Spinning Machine Customization Solutions:

- CNC Metal Spinning Diameter And Length, Metal Spinning Stroke Range;

- Thrust Of CNC Metal Spinning Machine, Kn;

- Spindle Load Capacity Of CNC Metal Spinning;

- Function And Thrust Of Tailstock;

- Hot Spinning Kit

- Clamp Kit;

- Lubrication And Cooling Kit;

- Automation Solution;

Altron’s Factory Video

Altron provides customized CNC Metal Spinning Machine. All spin machines with diameters less 3800mm have successful cases & customer factories for visits .

please contact me and Joby engineers will give you a detailed plan.

Configuration

Standard Configuration

- SIEMENS CNC 808D 828D 840D

- SIEMENS Servo Motor & Drive

- Asynchronous Servo Spindle Motor

- Two Turrets Tool Setting Simultaneously

- APEX Servo Reducer

- High Strength Ductile Iron Sliding Table

- Blanks Center Assembly

- Back Roller Assembly

- CNC Tool Turret

- Hydraulic Station & Air Cooling System

- Air Unload Assembly

- Self-developed Spinning System

- Control System Remote Maintenance

Select Configuration

- Spindle Spinning Cylinder

- Trimming Tool Assembly

- Air Conditioner for Hydraulic Station

- Hot Spinning Parts Under 700℃

- Teach In & Play Back System

| Model No. |

Max. Material Dia. (mm) |

Radial Stroke (mm) |

Axial Stroke (mm) |

Roller Thrust (KN) |

Tailstock Force (KN) |

Spindle Power (KN) |

Spindle Speed (RPM) |

Material Thickness AL./carbon steel/SUS (mm) |

| ACD-600 | 600 | 260 | 1100 | 40 | 20 | 18.5 | 50-1000 | 6 / 4 / 3 |

| ACD-800 | 1300 | 400 | 1600 | 60 | 50 | 30 | 50-800 | 8 / 5 / 4 |

| ACD-1200 | 1650 | 500 | 800 | 80 | 50 | 37 | 30-500 | 10 / 6 / 4.5 |

| ACD-1600 | 1800 | 600 | 1000 | 120 | 70 | 45 | 30-450 | 14 / 8 / 5.5 |

| ACD-2000 | 2000 | 750 | 1250 | 140 | 100 | 75 | 30-400 | 14 / 10 / 7 |

| ACD-2500 | 2500 | 850 | 2050 | 200 | 140 | 132 | 10-300 | 30 / 20 / 15 |

| ACD-3500 | 3500 | 950 | 2550 | 300 | 140 / 200 | 200 | 10-300 | 40 / 25 / 20 |

-

Marcley

★★★★★Post a review on Aug 21, 2022 From Bolivia

Its symmetrical spinning force and pressure distribution provide excellent shock protection, ensuring the spindle’s longevity. We find it ideal for manufacturing long and thin goods, as well as cone-shaped products.

-

Arthur Zonneveld

★★★★★Post a review on Fec 21, 2022 From Mauritius

The integration of the SIEMENS control system and programming software has made the machine highly intuitive and easy to use. We highly recommend the ALTRON series for anyone in need of precision and reliability in their spinning operations.

-

Nicolas Vazquez

★★★★★Post a review on jul 21, 2022 From Uruguay

The ALTRON series double wheel spinning machine has been a game-changer for our production line. Its ability to handle blanks up to 3500mm in diameter with great accuracy has allowed us to take on larger and more complex projects with ease. The machine’s shock protection system ensures smooth and stable operation, increasing the lifespan of the spindle.

-

OSCAR URBANEJA

★★★★★Post a review on Oct 10, 2022 From Venezuela

I have been using the ALTRON series double wheel spinning machine for several months now, and I am extremely impressed with its performance. The machine effortlessly handles blanks up to 3500mm in diameter with incredible accuracy, giving me consistently excellent surface quality.