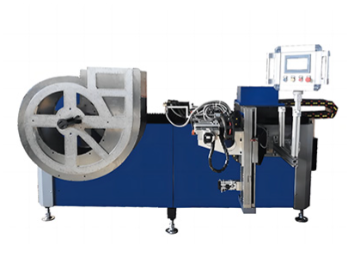

ALTRON Fan Robotic Welding Machine: Benefits & Tips to Maintain

In recent years, technological advancements have transformed industries across the board, and welding is no exception. One notable innovation in the welding field is the ALTRON Fan Robotic Welding Machine. Developed by ALTRON, a leading manufacturer in the robotics industry, this state-of-the-art machine has revolutionized welding processes, offering unmatched precision, efficiency, and reliability. In this blog, we will delve into the remarkable features and benefits of the ALTRON Fan Robotic Welding Machine, exploring how it is shaping the future of welding.

1. Unparalleled Precision:

The ALTRON Fan Robotic Welding Machine is engineered with meticulous attention to detail, delivering unrivaled precision in every weld. Equipped with advanced sensors and intelligent software, the machine ensures consistent and accurate welds, eliminating human errors and resulting in superior weld quality. By leveraging its robotic capabilities, the ALTRON Fan Robotic Welding Machine achieves precise movements and weld angles, even in complex welding scenarios. This level of precision guarantees weld integrity and enhances overall product quality.

2. Enhanced Efficiency:

Efficiency is a crucial factor in any manufacturing process, and the ALTRON Fan Robotic Welding Machine excels in this aspect. By automating the welding process, this machine significantly reduces the time and effort required to complete each weld. Its high-speed operation, coupled with rapid response times, allows for continuous and uninterrupted welding, minimizing production downtime. Additionally, the machine’s ability to perform repetitive tasks with consistent quality enhances productivity, enabling manufacturers to meet demanding deadlines while maintaining the highest standards.

3. Seamless Integration and Adaptability:

ALTRON understands the importance of seamless integration within existing manufacturing workflows. The Fan Robotic Welding Machine seamlessly integrates with various production lines, providing versatility and adaptability. Whether used as a standalone unit or integrated into an existing robotic assembly line, the machine effortlessly adjusts to the specific welding requirements of each application. This flexibility empowers manufacturers to optimize their welding processes, easily adapting to evolving production demands and ensuring a streamlined and efficient operation.

4. Enhanced Safety Measures:

Safety is paramount in any industrial environment, and the ALTRON Fan Robotic Welding Machine is designed with safety at its core. Equipped with advanced safety features, such as integrated collision detection and emergency stop systems, the machine ensures the protection of both the operators and the surrounding equipment. By minimizing the risk of accidents and injury, manufacturers can maintain a secure work environment while maximizing operational efficiency.

5. Advanced User Interface:

The ALTRON Fan Robotic Welding Machine boasts an intuitive user interface that simplifies the welding process. The machine’s user-friendly control panel allows operators to easily program, monitor, and adjust welding parameters. This intuitive interface eliminates the need for extensive training, enabling operators to quickly familiarize themselves with the machine and leverage its full potential. Moreover, the machine’s connectivity options facilitate data exchange and remote monitoring, enhancing overall control and management of the welding process.

Tips to Maintain Fan Robotic Welding Machine

Purchasing a high-quality robotic welding machine like the ALTRON Fan Robotic Welding Machine is a significant investment for any manufacturing facility. These advanced machines provide unparalleled efficiency and precision in welding tasks. To ensure that your ALTRON Fan Robotic Welding Machine continues to deliver optimal performance and extends its lifespan, proper maintenance is crucial.

1. Regular Cleaning and Inspection:

Keeping the ALTRON Fan Robotic Welding Machine clean is vital for its smooth operation. Dust, debris, and welding spatter can accumulate on the machine’s surfaces, potentially hindering its performance. Regularly clean the external components, such as the torch, worktable, and cables, using appropriate cleaning agents and tools recommended by ALTRON. Additionally, inspect the welding machine’s components for signs of wear and tear, and promptly replace any damaged parts to prevent further issues.

2. Lubrication of Moving Parts:

Proper lubrication is essential to maintain the ALTRON Fan Robotic Welding Machine’s mechanical components. Regularly apply lubricants to the moving parts, such as robot joints and rails, to reduce friction and wear. Refer to the manufacturer’s guidelines for the correct lubrication schedule and use the recommended lubricants for optimal results.

3. Calibration and Alignment:

Accurate calibration and alignment are crucial for the precise functioning of the robotic welding machine. Periodically check the machine’s alignment and recalibrate it as needed. Misalignment can lead to faulty welds and decrease the overall productivity of the machine. If you are unsure about the calibration process, consult ALTRON’s technical support or schedule professional service.

4. Monitor Weld Quality:

Keep a close eye on the quality of welds produced by the ALTRON Fan Robotic Welding Machine. Irregular welds could be an indication of various issues, such as incorrect settings, worn-out components, or programming errors. Regularly inspect welds and adjust parameters if necessary to maintain the desired weld quality.

5. Software Updates and Maintenance:

The robotic welding machine’s software plays a crucial role in its performance and efficiency. Stay updated with the latest software releases and patches provided by ALTRON. Regularly update the machine’s software to access new features and improvements. Additionally, ensure that the machine’s internal systems, such as the controller and operating software, are free from viruses and malware by using appropriate cybersecurity measures.

6. Operator Training and Safety:

Proper training of the machine operators is essential to ensure the ALTRON Fan Robotic Welding Machine’s longevity. Well-trained operators are less likely to cause unnecessary wear and tear on the machine due to mishandling. Emphasize safety protocols and best practices during welding operations to prevent accidents and reduce the risk of damage to the equipment.

7. Timely Professional Maintenance:

While regular cleaning and inspections are essential, professional maintenance is equally crucial. Schedule periodic maintenance visits by ALTRON’s authorized technicians. They have the expertise to identify potential issues that may not be apparent during routine inspections and can perform necessary repairs and adjustments to keep the machine in top-notch condition.

Conclusion:

ALTRON’s Fan Robotic Welding Machine has emerged as a game-changer in the welding industry. With its unparalleled precision, enhanced efficiency, seamless integration, and advanced safety measures, this machine is transforming welding processes and setting new standards of excellence. As manufacturing continues to evolve, embracing technological advancements such as the ALTRON Fan Robotic Welding Machine is crucial for staying ahead of the competition and meeting the ever-increasing demands of the industry. By combining automation, precision, and user-friendly interfaces, ALTRON has created a welding solution that paves the way for a more efficient and productive future.