Edited by: Engineer Joby

Edited by: Engineer Joby

CNC Flanging Machine Processing Large Arc.

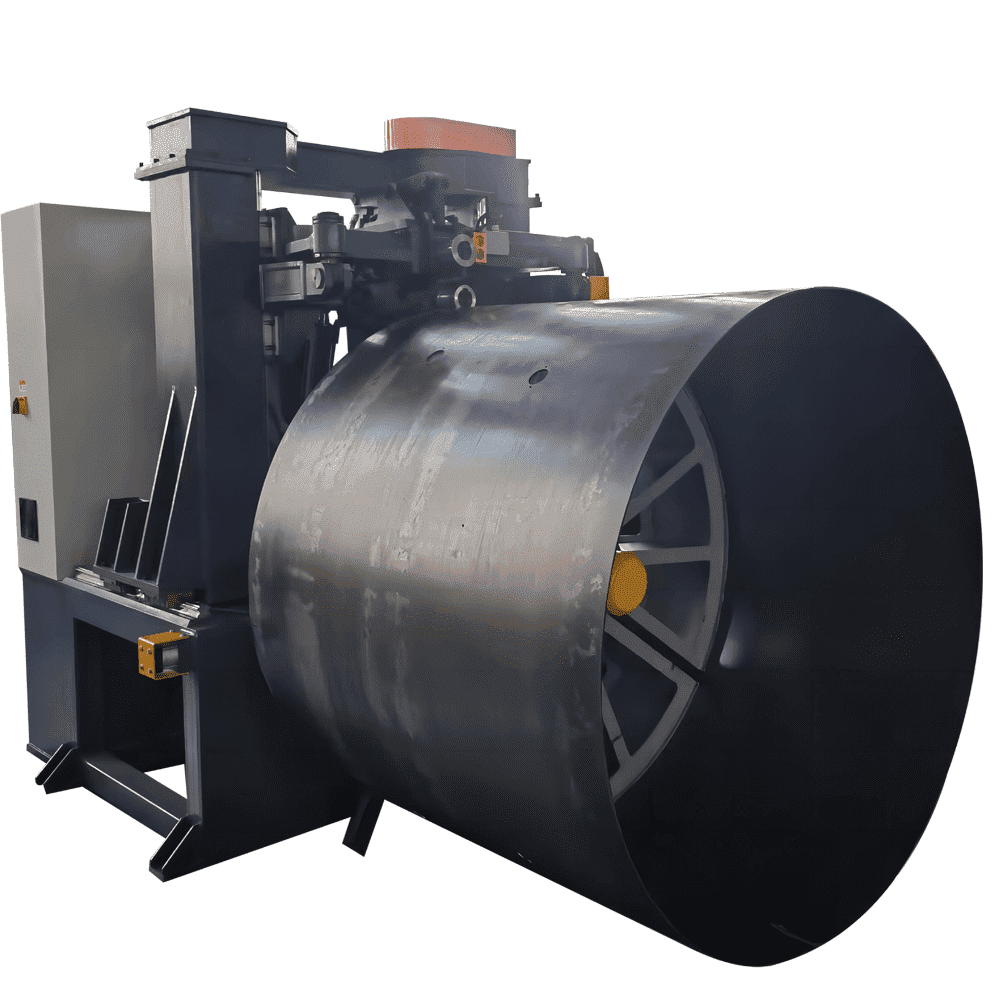

The requirements for performance and energy efficiency of industrial axial flow fans are constantly increasing. Altron uses a CNC flanging machine in the manufacturing of the bellmouth inlet duct of the axial flow fan casing to solve the high-precision metal air duct forming requirements.

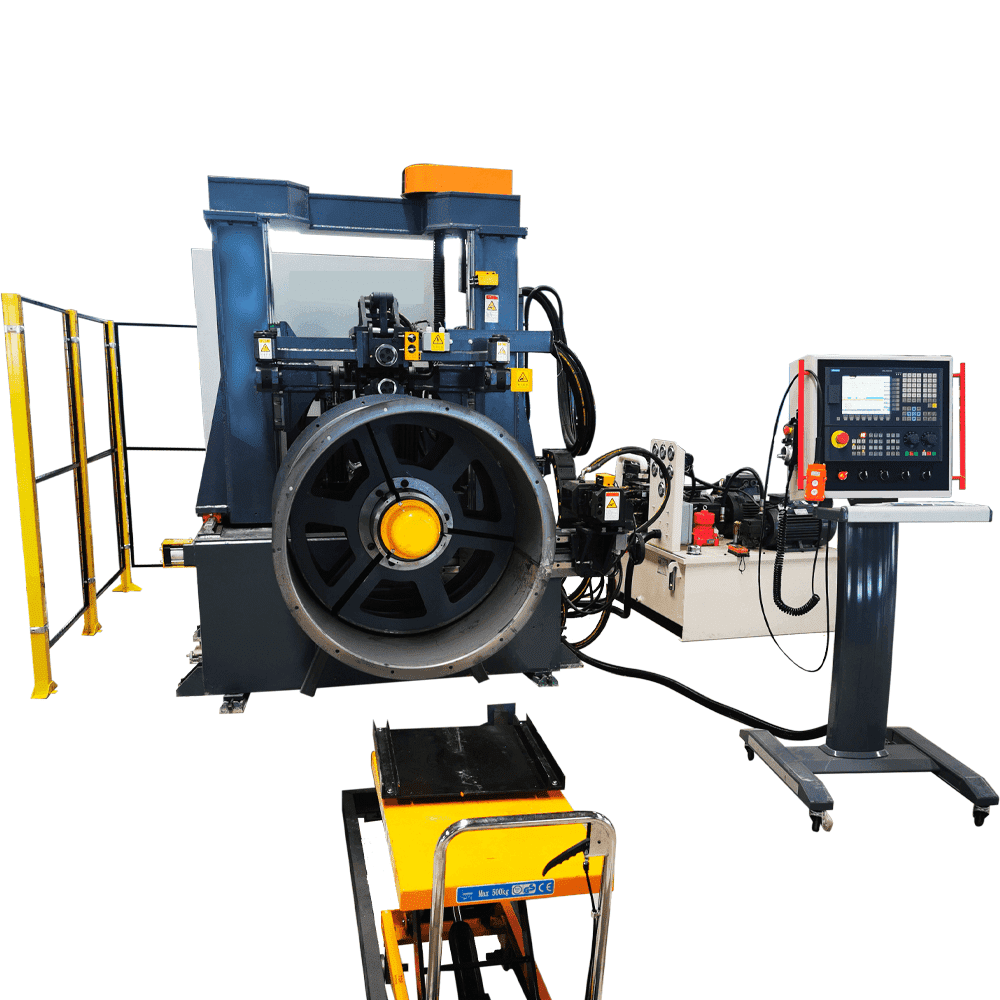

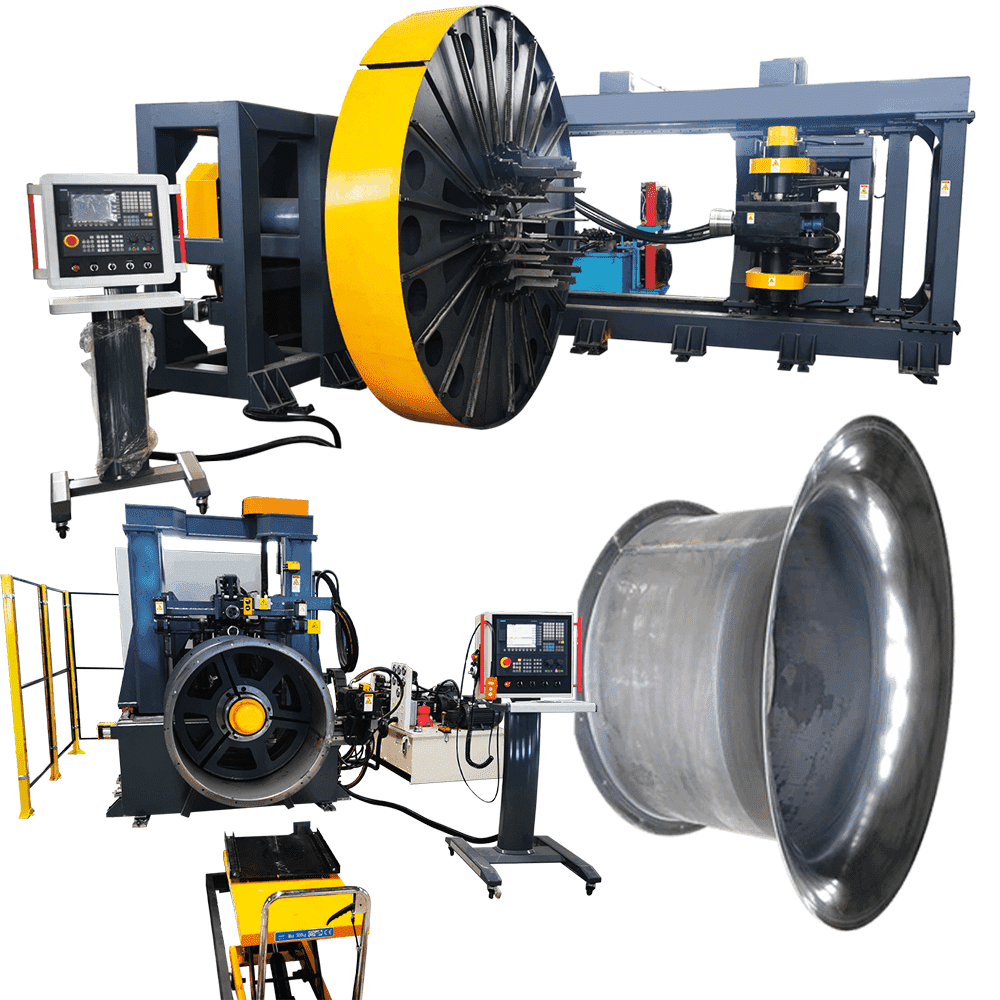

Brief Introduction Of CNC Flanging Machine

The CNC flanging machine is mainly designed and developed for the production of axial-flow industrial fans. Its main function is to perform flange flanging and indexing punching on the welded drum!

The CNC metal flanging machine is easier to operate, each axis has a corresponding value, and the machine can achieve fully automatic production!

Especially for the bell-shaped subway tunnel axial fan housing flanging production, two spinning rollers cold-form the material according to the program contour or different angles of the shape!

Detailed Introduction To The Steps Of Using CNC Flanging Machine

Preparation before flanging! Rolling & Welding

The conventional manufacturing process of the wind tube is:

- Complete the rectangular plate by laser cutting,

- Be rolled into shape by CNC rolling machine,

- And then welded and spliced on the seam welding machine.

Altron provides a full set of metal forming solutions and production line planning and layout for axial flow fans! Let industrial fan manufacturers achieve automated production management!

Automatic Production Steps Of CNC Flanging Machine

- Fix the welded barrel to the mold of the flanging machine.

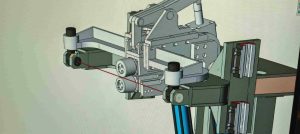

- The machine automatically extends the positioning device and moves the flanging roller to the corresponding position.

- Manually tighten the mold and fix it in the mold.

- Start the running program, and the machine will move according to the set parameters!

- When the forming is completed, the machine will automatically start punching. If the flange holes at both ends need to be aligned, it will be necessary to manually rotate until the weld and the punching mechanism of the machine are at the same angle, and start again!

- The axial flow fan’s air cylinder is formed!

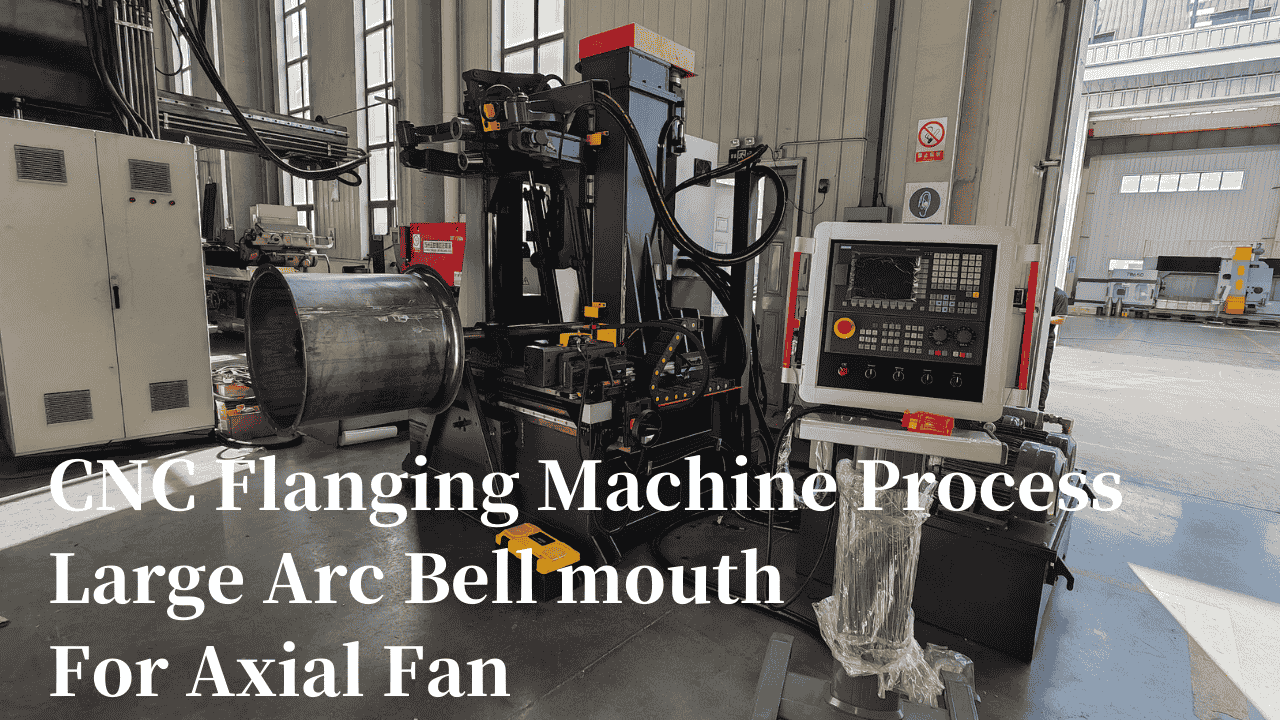

How To Process bellmouth inlet duct Shape

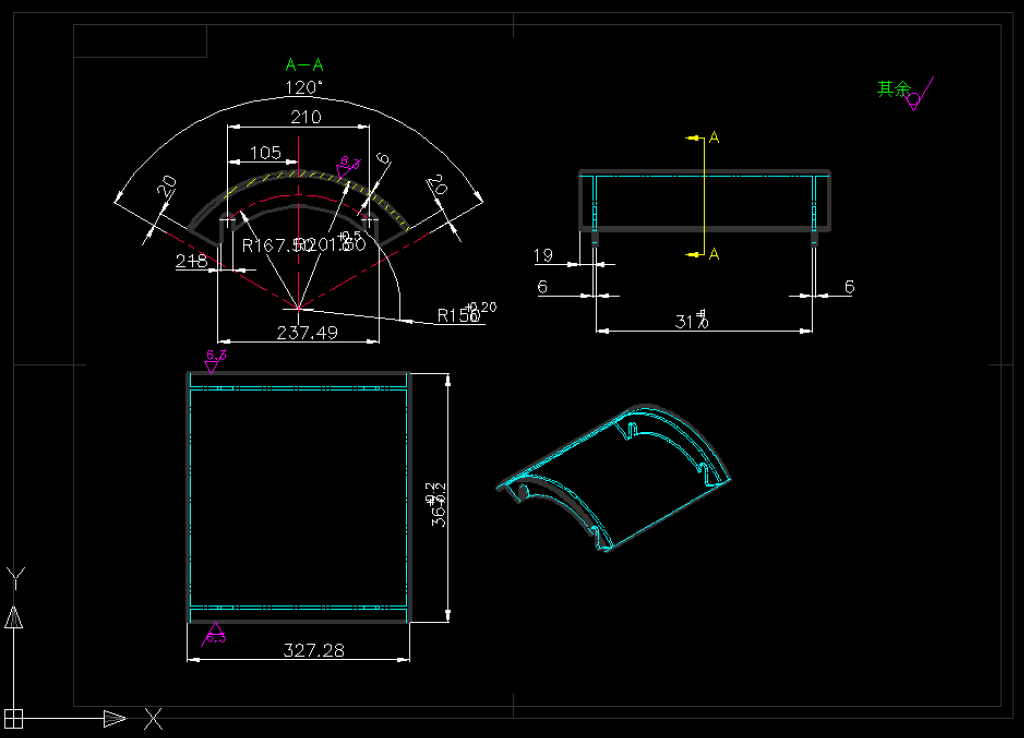

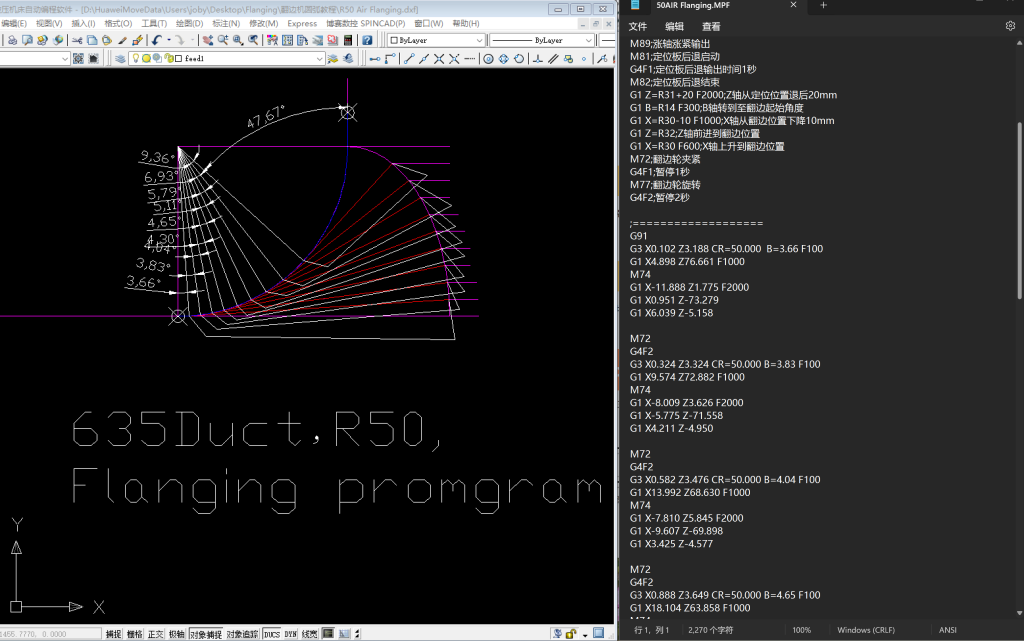

Draw The Forming Trajectory Diagram

- Draw the angle and arc contour of each turn in the CAD software, and use different colors to mark the formed segments!

- You can change the feed speed of different segments, and set a reasonable speed!

- And connect all the trajectory segments!

- Save the CAD file format in XDF format, check the drawings, and avoid segment interruptions or redundant points or segments!

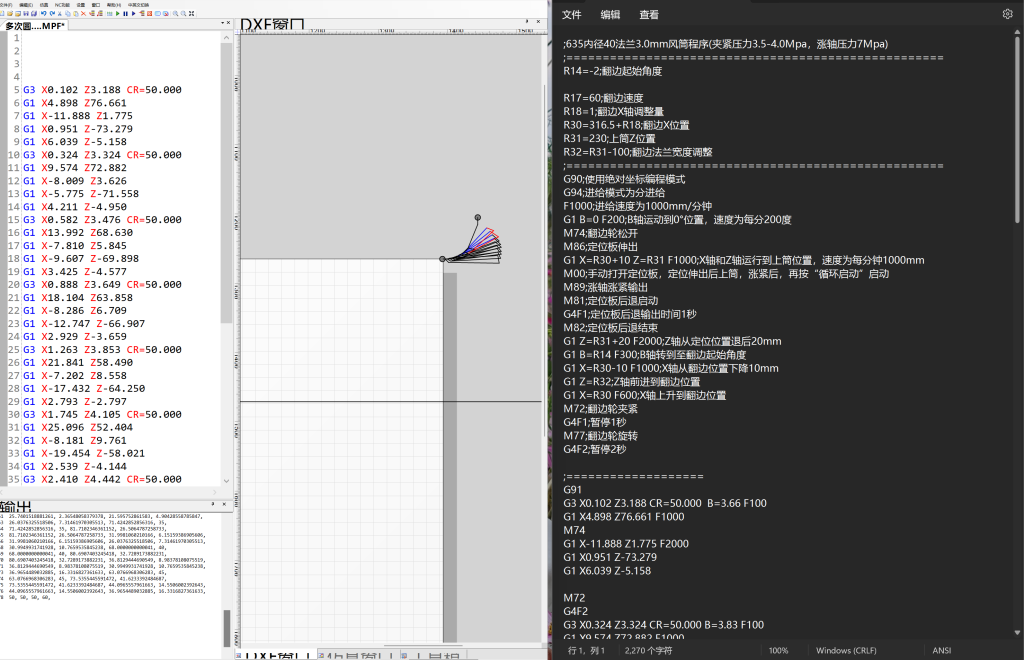

Use Altron Spinning Programming Software To Produce The Correct Program

- Open the software and import the XDF file just drawn;

- The software will automatically generate CNC code and coordinate values!

- Set the speed of different colored segments in the software and save the program in MPF (Siemens format);

- Manually add action instructions in different program segments for tightening and loosening the flanging wheel! M72 and M73 control the opening and clamping of the flanging roller respectively;

- After completing the program, you need to check it carefully once;

- The system transmitted to the machine is run dry! During the dry run, reduce the tightening hydraulic pressure of the flanging wheel! Otherwise, it will cause the flanging wheel to wear too quickly;

- After the dry run, make sure all data is correct, put in the roll, and start the first flanging test!

Metal Flanged Bell-Mouth Axial Fan Duct Test Video

What Adjustments Do The Bell Mouth Flanging Machines Need To Make?

It is actually very simple to process a large arc trumpet air outlet using a CNC flanging machine. I hope it can be helpful to you!

Our machine is more cost-effective than Nodi flanging machine. Its functions are almost the same and can achieve different shapes. Altron always discusses with the manufacturers of industrial fans! Continuously improve the performance of the machine!

Altron makes the metal forming and welding part of industrial axial flow fans simpler, more efficient and high-quality!