Flanging Machine Insights: What Powers the Precision in Metal Forming?

Flanging machines are an essential part of metalworking and fabrication. They can shape and form metal with accuracy to create components that meet stringent specifications. Let’s delve into the world of flanging machines, exploring their functions, applications, technological prowess behind their precision, where to buy, and how to choose a flanging machine.

What is a Flanging Machine?

A Flanging Machine is a specialized piece of equipment designed for metal forming processes. The term “flanging” refers to the process of creating a flange – a protruding ridge, edge, or rim – on a metal workpiece. This can serve various purposes, from enhancing the structural integrity of the component to facilitating connections between parts. Flanging Machines are versatile and capable of working with different types of metals, including steel, aluminum, and copper.

The Technological Marvel: ALTRON Flanging Machine

Among the leading manufacturers in the realm of Flanging Machines is ALTRON, a company synonymous with precision engineering. ALTRON’s Flanging Machines are renowned for their cutting-edge technology, reliability, and ability to deliver consistent results in metal forming applications.

The ALTRON Flanging Machine is equipped with advanced features that set it apart in the market. High-speed precision machining, intuitive controls, and customizable settings ensure that it meets the demands of various industries. The machine’s robust construction and durability make it a trusted companion for metal fabricators seeking excellence in their craft.

Applications of Flanging Machines

1. Automotive Industry

One of the primary sectors that benefit from Flanging Machines is the automotive industry. These machines are instrumental in forming components like exhaust pipes, fenders, and various structural elements of vehicles. The precise flanging achieved by these machines ensures that the parts seamlessly fit together, contributing to the overall safety and performance of the automobile.

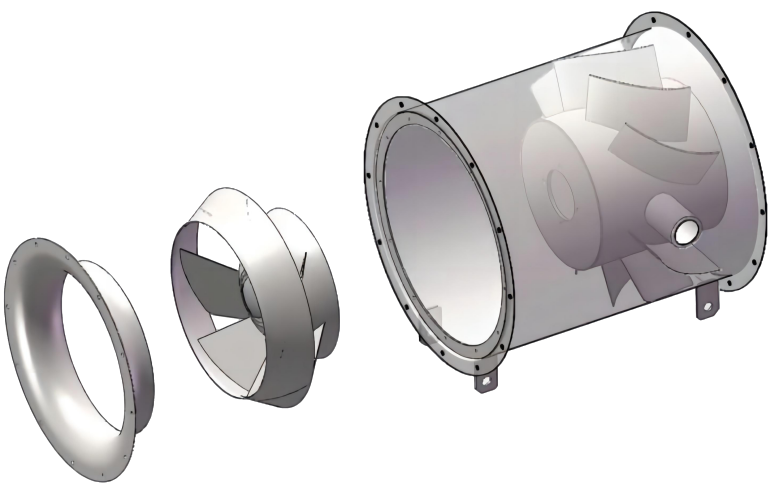

2. Industrial Fan Manufacturing — Blade Formation

One of the critical components of an industrial fan is its blades. Flanging Machines are employed to precisely shape and form the edges of fan blades, ensuring uniformity and optimal aerodynamic performance. This level of precision is crucial for fans to operate efficiently, moving air effectively in industrial settings.

3. HVAC and Sheet Metal Fabrication

Heating, ventilation, and air conditioning (HVAC) systems rely on precision components for efficient operation. Flanging Machines are extensively used in the fabrication of ductwork, ensuring that the ducts are not only airtight but also structurally sound. Additionally, these machines find applications in general sheet metal fabrication, contributing to the creation of a wide range of products, from household appliances to industrial machinery.

4. Energy and Power Generation

Flangers are an integral part of the energy and power generation industry. Helps manufacture components used in the construction of power plants, pipelines and other infrastructure. The ability to accurately form metals is critical to ensuring the longevity and efficiency of power generation facility components.

Flanging Machine: How Does It Elevate Metal Fabrication Standards?

Precision in metal forming, a critical aspect of the manufacturing process, is achieved through the innovative design and features of Flanging Machines. ALTRON, a renowned manufacturer in this field, has been a trailblazer in developing machines that redefine industry standards. These machines are equipped with high-speed precision machining capabilities, ensuring that every bend, flange, and edge meets exacting specifications. The combination of robust construction and cutting-edge technology sets ALTRON’s Flanging Machines apart, making them indispensable tools for achieving precision in metal forming.

At the forefront of precision metal forming is the Flanging Machine, a versatile tool employed in shaping and creating flanges on metal workpieces. These machines play a pivotal role in elevating metal fabrication standards, ensuring that components meet stringent specifications. ALTRON, a distinguished manufacturer in this field, stands out with its commitment to precision engineering, offering Flanging Machines that redefine the benchmarks of quality in metal fabrication.

The Flanging Machine’s ability to elevate metal fabrication standards lies in its precision and versatility. Whether crafting components for the automotive, aerospace, or energy sectors, these machines ensure that every bend, edge, and flange meets exacting specifications. ALTRON’s Flanging Machines, in particular, incorporate advanced technology and customizable features that empower metal fabricators to achieve consistent, high-quality results across various applications.

Metalworking Marvels: A Closer Look at the Flanging Machine Evolution!

The evolution of the Flanging Machine is a fascinating journey through the annals of metalworking history. From humble beginnings to the sophisticated machines of today, this evolution has been marked by advancements in materials, engineering, and automation. ALTRON, as a pioneer in the field, has been at the forefront of this evolution, continuously pushing the boundaries of what Flanging Machines can achieve.

In the early days of metalworking, manual flanging processes required skilled craftsmanship, often resulting in time-consuming and less precise outcomes. However, with technological advancements, Flanging Machines evolved to include automated features, precision controls, and increased speed. ALTRON’s commitment to innovation is evident in their Flanging Machines, which represent the pinnacle of this evolutionary journey, offering state-of-the-art solutions for modern metal fabrication challenges.

Flanging Machine Mysteries: Can You Crack the Code of Precision Metal Forming?

Precision in metal forming has long been a challenge for metal fabricators. The mystery lies in achieving consistent results, especially when working with diverse materials and intricate designs. Flanging Machines, equipped with advanced features and engineering precision, hold the key to unraveling this mystery. ALTRON’s Flanging Machines, in particular, provide a solution to the code of precision metal forming, offering a blend of technology and craftsmanship that sets new standards in the industry.

The mystique of precision metal forming is further unraveled by the customizable nature of ALTRON’s Flanging Machines. Fabricators can fine-tune settings to accommodate specific materials, thicknesses, and design intricacies. This adaptability ensures that the Flanging Machine becomes a versatile ally in the quest for precision, allowing manufacturers to crack the code of metal forming challenges with confidence.

Where to Find the Best Flanging Machine for Your Manufacturing Process

Selecting the right Flanging Machine for your manufacturing process is a decision that can significantly impact the quality and efficiency of your operations. When it comes to finding the best Flanging Machine, ALTRON emerges as a reliable and trusted source. ALTRON’s reputation for precision engineering and commitment to innovation makes it a go-to manufacturer for businesses seeking top-notch Flanging Machines.

Manufacturers can explore ALTRON’s offerings through their official website or connect with their authorized distributors. The website provides comprehensive information about the specifications, features, and capabilities of different machines offered by ALTRON. Additionally, reaching out to their sales and support teams can provide valuable insights tailored to the specific requirements of your manufacturing process.

In the ever-evolving landscape of metal fabrication, the precision achieved through Flanging Machines is the cornerstone of quality manufacturing. ALTRON’s commitment to excellence, innovation and precision engineering has made its flangers the first choice for manufacturers looking to advance their metal forming processes. As the industry continues to demand higher standards, ALTRON remains at the forefront. Providing manufacturers with the tools they need to achieve the precision required for every metal formed part.

How to Buy a Flanging Machine: A Comprehensive Guide

Buying a Flanging Machine involves careful consideration of various factors to ensure that it aligns with your manufacturing needs and budget. Here’s a comprehensive guide to help streamline the purchasing process:

- Assess Your Requirements:Begin by evaluating your manufacturing requirements, including the types of materials you work with, desired precision levels, and production volume.

- Research Manufacturers: Explore reputable manufacturers in the industry, with a focus on their reputation for quality, reliability, and technological innovation. ALTRON, with its track record, is likely to be a top contender.

- Machine Specifications:Examine the specifications of the Flanging Machines offered by different manufacturers. Consider factors such as speed, precision controls, and customization options.

- Budget Considerations:Establish a budget based on your financial constraints. While it’s essential to invest in quality, finding a balance between features and cost is key.

- Customer Reviews:Look for customer reviews and testimonials about the Flanging Machines you are considering. Feedback from other manufacturers can provide valuable insights into the performance and reliability of the machines.

- Support and Service:Assess the manufacturer’s commitment to customer support and service. A responsive and reliable support system is crucial for minimizing downtime and addressing any issues promptly.

- Warranty and Maintenance:Inquire about warranty terms and maintenance requirements. A comprehensive warranty and a manufacturer’s commitment to ongoing maintenance can contribute to the longevity and performance of your flashing machine.

By following these steps, manufacturers can make informed decisions when purchasing a Flanging Machine, ensuring that it aligns with their production goals and quality standards.

Conclusion: Precision Redefined with ALTRON Flanging Machines

In the dynamic world of metal forming, where precision is the key to success, Flanging Machines stand out as indispensable tools. The ALTRON Flanging Machine, with its state-of-the-art technology and engineering excellence, exemplifies the commitment to precision in metal fabrication. Whether shaping components for the automotive, aerospace, HVAC or energy industries. The influence of flanging machines reaches across various industries, helping to create strong and high-quality metal products. As technology continues to advance, flanging machines. Especially flanging machines made by innovators like ALTRON. will continue to play a key role in shaping the future of metal processing.