Flanging Machine Application: Here to Know

In the realm of modern manufacturing, CNC (Computer Numerical Control) technology has revolutionized many processes, including metal forming. One such advanced tool is the CNC flanging machine, designed to manipulate sheet metal with unparalleled precision and efficiency. This blog explores what CNC flanging machines are, how they are used, and when this technology becomes indispensable.

What is a CNC Flanging Machine?

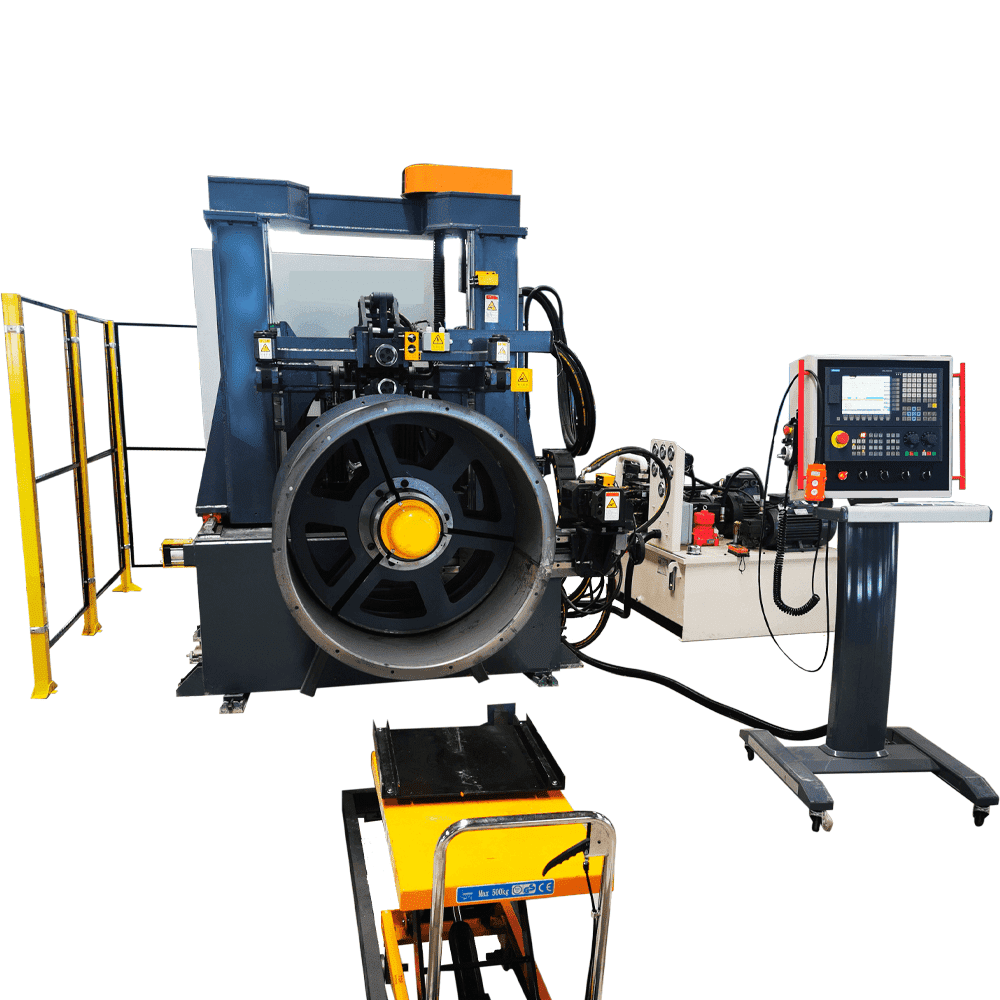

A CNC flanging machine is a specialized tool used in metalworking to create flanges on sheet metal components. Flanging involves bending a edge of the metal sheet to create a stiffened lip or rim, typically for joining with another sheet or component. The CNC aspect refers to its computer-controlled operation, which allows for highly accurate and repeatable manufacturing processes. ALTRON, a prominent manufacturer in the field, produces cutting-edge CNC flanging machines that cater to various industrial applications.

CNC flanging machines from ALTRON are equipped with sophisticated controls that enable precise adjustment of parameters such as flange height, diameter, and edge quality. These machines often feature automated tool changers and programmable settings, making them versatile tools in high-volume production environments.

Introduce CNC Metal Spinning Machine For Industry Fans: ALTRON’s CNC flanging machines are designed to handle a variety of materials with precision and efficiency. Whether it’s stainless steel, aluminum, copper, brass, bronze, or mild steel, these machines deliver consistent results across different material thicknesses. This versatility ensures that manufacturers can meet diverse production needs without compromising on quality.

The integration of cutting-edge spinning software eliminates the need for manual programming, enhancing operational efficiency. This software supports the machines seamlessly, enabling smooth production processes and reducing setup time. Manufacturers benefit from a streamlined workflow that maximizes productivity and minimizes downtime.

How to Use a CNC Flanging Machine

Using a CNC flanging machine involves several key steps to ensure accurate and efficient operation. Firstly, the operator must load the sheet metal onto the machine’s worktable, ensuring it is securely positioned. The next step involves programming the machine via its control panel or computer interface. ALTRON’s machines typically offer user-friendly interfaces where operators can input dimensions, angles, and other specifications directly.

Once programmed, the CNC flanging machine initiates the flanging process. This usually begins with clamping the sheet metal in place and then moving the flanging tool along the predetermined path. ALTRON machines utilize servo motors and advanced guiding systems to ensure smooth and precise movements during the flanging operation. After completion, the finished components are unloaded from the machine for further processing or assembly.

Regular maintenance and calibration are crucial for optimal performance of CNC flanging machines. ALTRON provides comprehensive support and service packages to ensure their machines operate at peak efficiency, minimizing downtime and maximizing productivity for manufacturers.

When Do You Need to Use Flanging Machine Technology?

Flanging machine technology becomes indispensable in various manufacturing scenarios where precise metal forming is required. Here are some common situations where the use of a CNC flanging machine is beneficial:

Mass Production of Automotive Components: In the automotive industry, where consistency and quality are paramount, CNC flanging machines excel in producing flanged parts such as fenders, panels, and brackets. ALTRON’s machines can handle a wide range of sheet metal thicknesses and materials, meeting the stringent requirements of automotive manufacturers.

Aerospace and Defense Applications: For aerospace and defense contractors, CNC flanging machines play a critical role in fabricating components that require high strength and durability. Flanged parts in aircraft fuselages, engine compartments, and structural assemblies benefit from the precision and reliability offered by ALTRON’s CNC machines.

HVAC Systems and Ductwork: Heating, ventilation, and air conditioning (HVAC) systems rely on ductwork that often requires custom fittings and connections. CNC flanging machines are used to produce flanged edges on duct sections, ensuring airtight seals and efficient airflow. ALTRON’s machines are capable of handling the diverse shapes and sizes required in HVAC applications.

Industrial Equipment and Machinery: From agricultural machinery to industrial equipment, many sectors rely on CNC flanging machines to create sturdy and functional components. The ability to precisely control flange dimensions and geometry ensures compatibility and reliability in various mechanical systems.

Which industry needs to use Flanging machine applications?

Flanging machines have become indispensable tools across various industries, each benefiting from their unique capabilities in metal forming and fabrication. Two notable sectors that extensively utilize flanging machine applications are the industrial fan industry and vibrating screen machinery.

Industrial Fan Industry

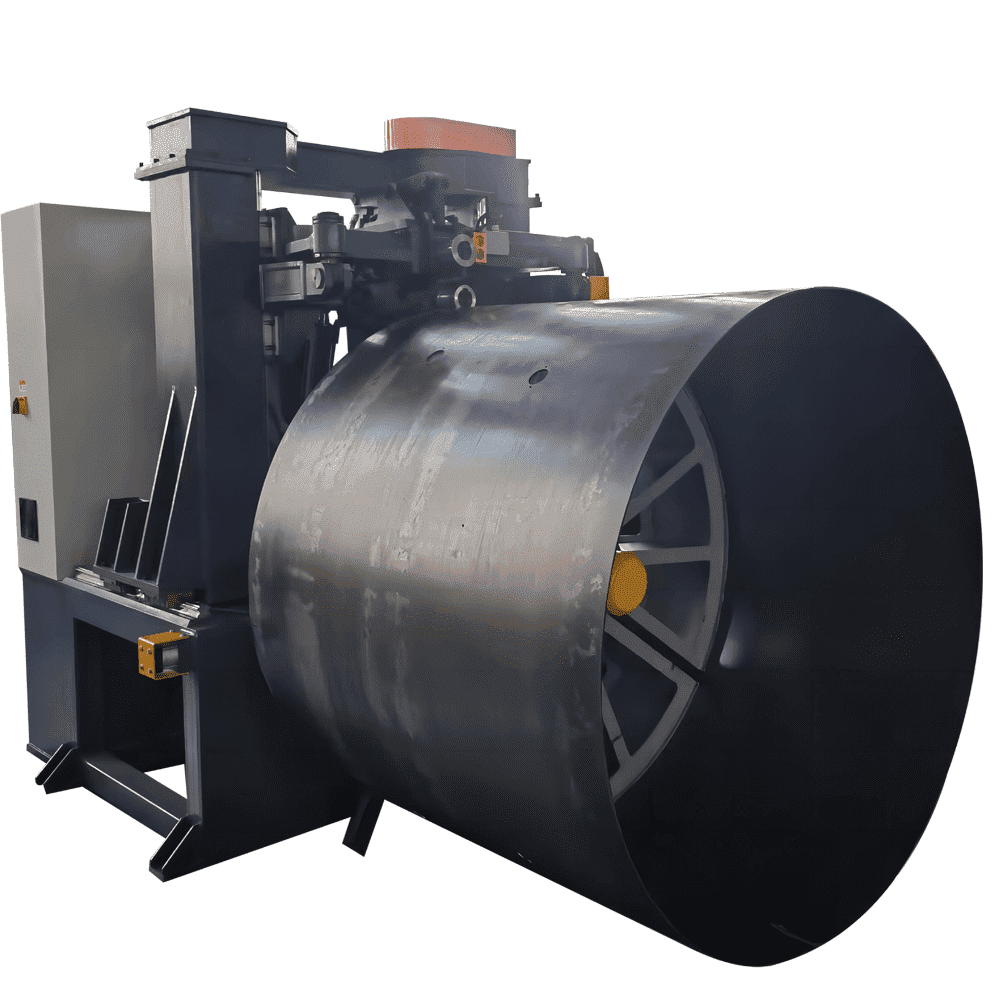

In the industrial fan industry, where efficiency and durability are critical, flanging machines play a crucial role in manufacturing fan components. Fans require robust housings and precise fittings to ensure optimal performance and minimal noise levels. Flanging machines are used to create the flanged edges necessary for assembling fan blades, housings, and ductwork. ALTRON’s CNC flanging machines provide precise control over flange dimensions, ensuring tight seals and efficient airflow management within industrial environments.

Vibrating Screen Machinery

Vibrating screens are essential equipment in industries such as mining, aggregate processing, and recycling, where sorting and separating materials of varying sizes are paramount. These screens consist of multiple layers of mesh or perforated plates with frames that require precise assembly. Flanging machines are utilized to create the necessary flanges on screen frames and components, facilitating the secure attachment of mesh or plates. ALTRON’s CNC flanging solutions offer the accuracy and repeatability needed to ensure smooth operation and extended equipment lifespan in demanding applications.

Who provides CNC Flanging machine solutions?

When it comes to CNC flanging machine solutions, ALTRON stands out as a leading provider in the industry. Specializing in advanced manufacturing technologies, ALTRON offers a range of CNC flanging machines designed to meet the specific needs of diverse industrial sectors. These machines incorporate cutting-edge features such as automated tool changers, precise servo control systems, and intuitive user interfaces, enhancing productivity and operational efficiency for manufacturers worldwide.

ALTRON’s commitment to innovation and quality is reflected in its comprehensive lineup of CNC flanging machines. Whether for small-scale operations or large-scale production facilities, ALTRON provides scalable solutions that cater to varying production volumes and requirements. Their machines are engineered to deliver consistent performance and reliability, backed by extensive technical support and service capabilities.

Why choose Altron’s CNC Flanging machine?

For manufacturers looking to invest in advanced metal forming technologies, ALTRON’s CNC flanging machines represent a strategic choice. By combining innovative engineering with practical usability, ALTRON enables businesses to achieve superior manufacturing outcomes while meeting the rigorous demands of modern production environments.

For more information on ALTRON’s CNC flanging machine solutions or to explore how their technologies can benefit your manufacturing operations, please visit https://www.auto-altron.com/contact.

Altron distinguishes itself in the market with its robust research and development initiatives focused on CNC spinning technology. The company has fostered collaborations with international partners, enriching its knowledge base and staying at the forefront of innovation in metal forming technologies. This dedication translates into superior product design, technical expertise, and customer-centric solutions.

One of the compelling reasons to opt for Altron’s CNC flanging machines lies in their extensive experience and deep industry understanding. Having served over 120 industrial fan manufacturers, Altron maintains continuous technical dialogue and provides comprehensive support ranging from equipment supply to process optimization. This customer-centric approach underscores Altron’s commitment to enhancing production efficiency and product quality in the industries it serves.

Moreover, Altron emphasizes sustainable development and technological innovation in its operations. By investing in automated production lines and advancing welding and metal forming technologies, the company not only meets current market demands but also anticipates future industry needs. This forward-thinking strategy positions Altron as a strategic partner for manufacturers looking to streamline operations and achieve sustainable growth.

Altron’s journey in the industrial fan industry underscores its leadership in engineering and manufacturing automation solutions. The company’s headquarters in Jiangsu/Wuxi and sales office in Guangzhou house state-of-the-art facilities spread over 12,000 square meters, equipped to support comprehensive R&D, production, and customer service operations. This infrastructure enables Altron to deliver turnkey projects and customized solutions that cater to diverse metalworking requirements.

At the core of Altron’s operations is its dedicated team of technical experts and engineers specializing in metal spinning, stamping, stretching, and automatic welding technologies. This multidisciplinary approach ensures that each client receives tailored solutions that align with their specific production goals and quality standards. Altron’s innovative culture, characterized by a relentless pursuit of technological excellence, fuels its ability to deliver cutting-edge solutions that drive industry advancement.

Future Needs and Trends in Flanging Machines

As technology continues to evolve, so too does the landscape of manufacturing processes. Flanging machines, essential tools in metal forming and fabrication, are poised to undergo significant advancements to meet future industry needs and trends. ALTRON, a leading manufacturer of CNC flanging machines, is at the forefront of innovation, anticipating and addressing these evolving requirements.

Integration of Industry 4.0 Technologies

One of the most significant trends shaping the future of flanging machines is the integration of Industry 4.0 technologies. These include IoT (Internet of Things) connectivity, advanced data analytics, and machine learning capabilities. ALTRON is actively developing CNC flanging machines that can communicate real-time production data, monitor performance metrics, and optimize production schedules autonomously. By leveraging predictive maintenance algorithms, these machines can anticipate maintenance needs, minimizing downtime and maximizing operational efficiency.

Enhanced Automation and Robotics

Automation is set to play a pivotal role in the future of manufacturing, and flanging machines are no exception. ALTRON’s future CNC flanging machines may feature a higher level of automation. This includes robotic integration for material handling, tool changing, and quality inspection. This level of automation will not only increase productivity. It will also ensure consistency and precision in flange production across a variety of applications.

Advancements in Material Compatibility and Handling

With the increasing demand for lightweight materials and complex geometries in manufacturing, future flanging machines from ALTRON are expected to support a broader range of materials and thicknesses. This includes advanced alloys, composites, and even materials used in emerging industries such as aerospace and renewable energy. Improved handling systems will facilitate the manipulation of delicate materials with minimal risk of damage, further expanding the machine’s capabilities.

Sustainability and Environmental Considerations

Environmental sustainability is becoming a critical consideration across industries. Future CNC flanging machines may incorporate eco-friendly features. Such as energy-efficient components, reduced material waste, and optimized processes to minimize environmental impact. ALTRON is committed to developing sustainable manufacturing solutions that meet global environmental standards. Ensuring that its machines make a positive contribution to the industry’s sustainable development.

Conclusion

In conclusion, CNC flanging machines represent a pinnacle of precision and efficiency in modern metalworking. Manufacturers in a wide range of industries benefit from ALTRON’s advanced technology. Utilizing CNC flanging machines streamlines production processes, improves product quality, and meets the demands of a competitive market. As the manufacturing industry continues to evolve. These machines will undoubtedly play a key role in shaping the future of metal forming technology.