Top-Rated Flanging Machine for Sale: Look in ALTRON

As the manufacturing industry continues to evolve, the demand for precision and efficiency in metalworking processes has never been higher. Flanging machine plays a crucial role in meeting these demands, offering a range of advantages that contribute to increased productivity and cost-effectiveness.

Introduction — Top-Rated Flanging Machine for Sale

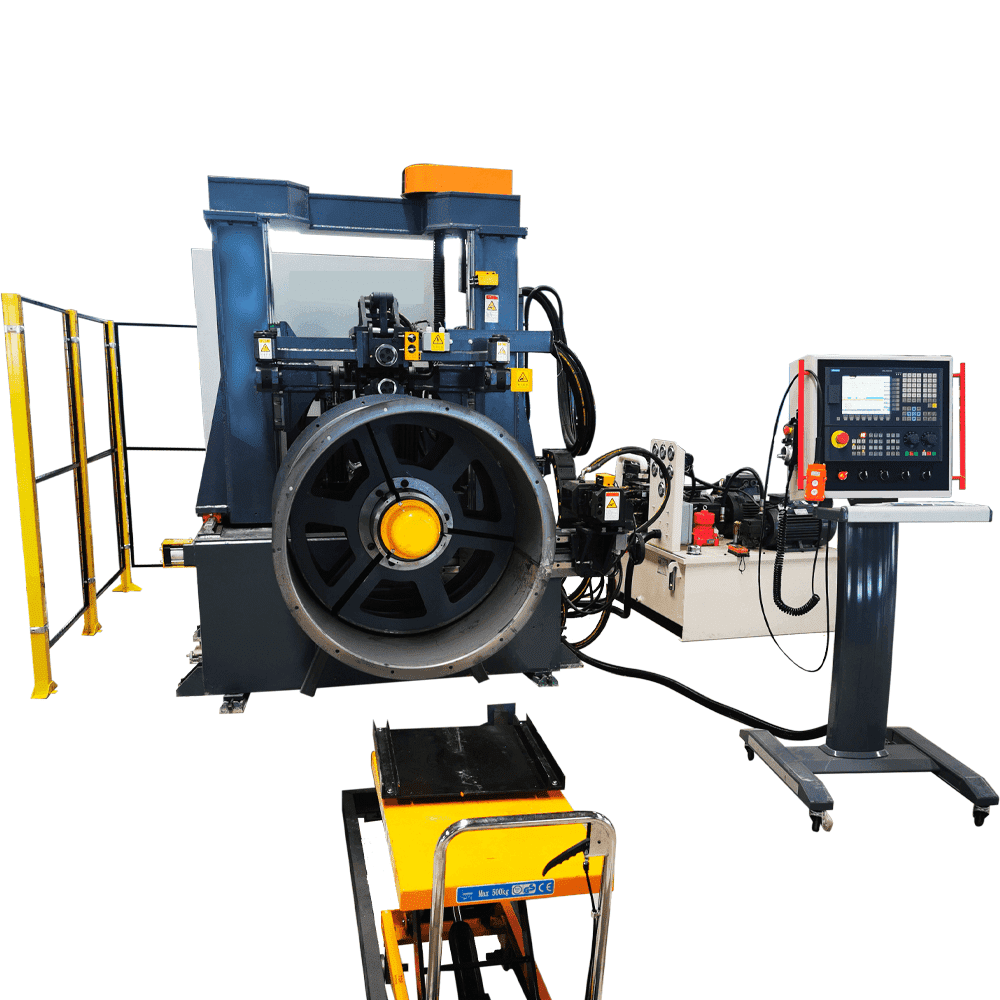

In the dynamic landscape of industrial machinery, the flanging machine stands out as a crucial player, enabling precision and efficiency in various applications. One notable player in this arena is ALTRON, whose FB series has been making waves. This blog will delve into the significance of flanging, the evolution of flanging machines, and a detailed exploration of ALTRON’s FB series.

ALTRON FB series two-wheel flanging machine has proven itself as a reliable and efficient solution for manufacturers seeking precision, versatility, and cost-effectiveness. As we celebrate its capabilities on its first anniversary, it’s evident that this machine has not only addressed current industry needs but also set the stage for future advancements in flanging technology.

With a commitment to safety, innovation, and customer satisfaction, ALTRON continues to play a pivotal role in shaping the future of metalworking processes. Cheers to precision and progress with the ALTRON FB series!

Understanding Flanging — Top-Rated Flanging Machine for Sale

2.1 Definition of Flanging:

Flanging is a metalworking process that involves bending or forming a workpiece’s edge to create a desired shape. This technique finds applications across industries due to its ability to enhance structural integrity and functionality.

2.2 Historical Context and Evolution:

The roots of flanging can be traced back through the annals of industrial history. Initially a manual process, flanging has evolved with technological advancements. Today, flanging machines streamline and enhance this age-old technique.

2.3 Types of Flanging Processes:

Roll Flanging: Utilizes rollers and dies to shape the material.

Hydraulic Flanging: Employs hydraulic systems to achieve precise and controlled bends.

Applications of ALTRON FB Series — Top-Rated Flanging Machine for Sale

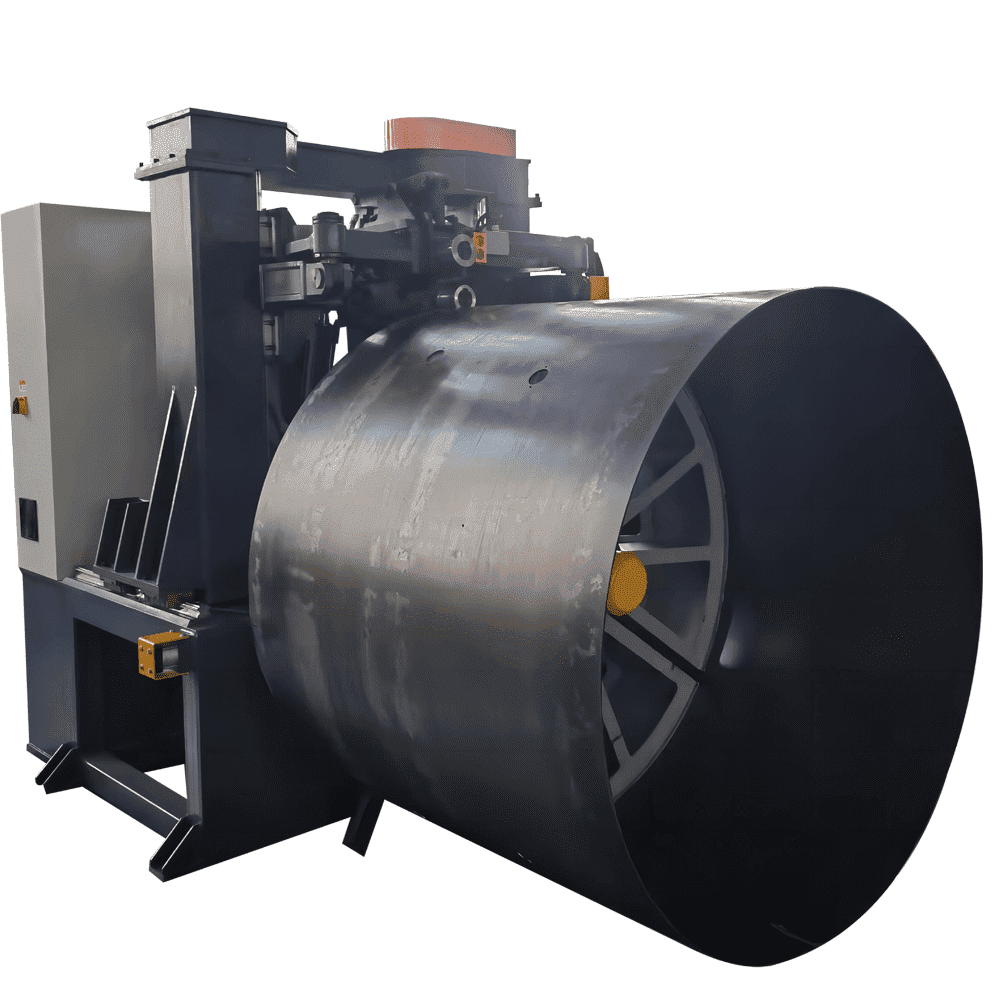

ALTRON’s FB series flanging machine, exemplified by the FB series, is a versatile powerhouse in the realm of metalworking. Tailored for windpipes, tubes, cones, and more, this machine excels in flanging and spinning tasks for curved surfaces with multiple tracking requirements. Its applications extend to constructing windpipes, fan wind collectors, pipe flange hub wheels, and similar components.

Key Components of Flanging Machine — Top-Rated Flanging Machine for Sale

4.1 Rollers and Dies:

These components play a pivotal role in shaping the material. The precision and quality of the rollers and dies directly impact the final product’s integrity.

4.2 Hydraulic Systems:

The hydraulic system is the heartbeat of a flanging machine, providing the force required for controlled and accurate bending. ALTRON’s integration of the ATOS Hydraulic Servo Valve ensures optimal performance.

4.3 Control Panels:

Modern flanging machines come equipped with advanced control panels, such as the SIEMENS CNC 808D/828D, allowing manufacturers to program and monitor the machine with precision.

4.4 Safety Features:

Safety is paramount in industrial settings. Flanging machines, including the ALTRON FB series, incorporate safety features to protect both operators and the machinery itself.

Advantages of Flanging Machine — Top-Rated Flanging Machine for Sale

5.1 Precision and Accuracy

The ALTRON FB series two-wheel flanging machine stands out for its remarkable ability to perform flanging and piercing operations at various angles. This precision and accuracy are essential for applications involving windpipes, tubes, cones, and more. The CNC division punching capability ensures a high level of homogeneity in the resulting goods, making them compatible with other products and seamlessly integrating into broader manufacturing processes.

5.2 Increased Production Efficiency

One of the primary advantages of the ALTRON FB series is its highly integrated and modular form. This design ensures stable and reliable operation, providing manufacturers with a dependable solution for their flanging needs. The machine’s efficiency is further enhanced by its ability to handle flanging and spinning tasks on curved surfaces with multiple tracking, contributing to faster and more efficient production.

5.3 Cost-Effectiveness

With its precise punching capabilities and integrated design, the ALTRON FB series offers a cost-effective solution for manufacturers. The compatibility of the resulting goods with other products allows for seamless integration into assembly lines, reducing overall production costs. The machine’s versatility in handling various materials adds to its cost-effectiveness, making it a valuable asset for diverse manufacturing applications.

5.4 Versatility in Handling Various Materials

The ALTRON FB series is designed to handle a wide range of materials, making it suitable for diverse manufacturing needs. Whether it’s windpipes, cones, or tubes, this flanging machine excels in providing versatility without compromising on precision. This adaptability is crucial for manufacturers working with different materials and varying production requirements.

Common Challenges and Solutions — Top-Rated Flanging Machine for Sale

6.1 Material Distortion

One common challenge in metalworking processes is material distortion during flanging operations. The ALTRON FB series addresses this issue with its precise punching system, minimizing material distortion and ensuring the quality of the final products.

6.2 Maintenance Issues

To maintain peak performance, flanging machine requires regular maintenance. ALTRON provides solutions by offering a reliable design that minimizes maintenance issues. Additionally, the availability of a remote maintenance feature streamlines the upkeep process, reducing downtime and optimizing operational efficiency.

6.3 Operator Training

The complexity of flanging machines necessitates proper operator training. ALTRON recognizes this challenge and emphasizes the importance of comprehensive training programs to ensure operators can maximize the machine’s capabilities while adhering to safety standards.

Choosing the Right Flanging Machine — Top-Rated Flanging Machine for Sale

7.1 Factors to Consider

When selecting a flanging machine, manufacturers must consider factors such as material type, thickness, and production volume. The ALTRON FB series caters to a broad spectrum of needs, making it suitable for applications across various industries.

7.2 Popular Brands and Models

ALTRON emerges as a leading manufacturer of flanging machines, with the FB series gaining recognition for its precision and versatility. As manufacturers explore options, the ALTRON FB series stands out for its innovative design and reliable performance.

Safety Considerations — Top-Rated Flanging Machine for Sale

8.1 Proper Training for Operators

Safety is paramount in manufacturing, and flanging machines require operators with specialized training. ALTRON prioritizes operator safety by emphasizing rigorous training programs, ensuring that those operating the machine are well-equipped to handle its complexities.

8.2 Safety Features of Flanging Machines

ALTRON integrates advanced safety features into the FB series, contributing to a secure working environment. From hydraulic safety mechanisms to protective enclosures, the machine is designed with the operator’s well-being in mind.

8.3 Compliance with Industry Standards

To maintain safety standards, flanging machines must comply with industry regulations. ALTRON ensures that the FB series aligns with these standards, providing manufacturers with confidence in the safety and reliability of their operations.

Case Studies — Top-Rated Flanging Machine for Sale

9.1 Real-World Examples of Successful Implementation

The ALTRON FB series has been successfully implemented in various real-world applications. Whether in the construction of windpipes, wind collectors, or pipe flange hub wheels, the machine has consistently demonstrated its capabilities, resulting in high-quality, homogeneous products.

9.2 Notable Projects and Their Outcomes

Manufacturers across industries have undertaken notable projects with the ALTRON FB series, achieving positive outcomes in terms of production efficiency, cost-effectiveness, and product quality. These projects serve as testimonials of the machine’s reliability and versatility.

Future Trends in Flanging Technology — Top-Rated Flanging Machine for Sale

10.1 Emerging Technologies in Flanging

As technology continues to advance, flanging machine is likely to incorporate more sophisticated features. The integration of artificial intelligence, automation, and enhanced connectivity may shape the future landscape of flanging technology.

10.2 Potential Advancements and Innovations

Manufacturers can anticipate advancements in flanging technology, with a focus on further enhancing precision, efficiency, and adaptability. Innovations in material handling, software integration, and process optimization may redefine the capabilities of flanging machines in the coming years.

Looking Ahead: ALTRON’s Innovative Flanging Machine

11.1 ALTRON’s Technological Innovation and Sustainable Development

From its inception, ALTRON has been at the forefront of technological innovation and sustainable development. The company, headquartered in Jiangsu, Wuxi, and Guangdong Province, covers an expansive area of more than 12,000 square meters. ALTRON AUTO is one of China’s rare high-tech firms that seamlessly integrates research and development, manufacturing, sales, and services.

11.2 Comprehensive Solutions for Metal Products

ALTRON’s dedicated technical team, comprised of core technicians, is committed to serving the field of metal forming. The company’s goal is to provide turnkey projects for customers, focusing on comprehensive customized solutions for various metal products, including metal spinning, stamping and stretching, metal cold forming, metal polishing, and automatic welding.

11.3 The Strength of ALTRON’s Team

A key component of ALTRON’s success lies in its robust team of engineers. The company boasts a strong research and development, production, and sales elite team. ALTRON stands out as an innovative technology-based enterprise, with innovation at the core of its competitiveness. The company’s commitment to innovation has fueled leapfrog development and fostered a unique innovation culture.

11.4 Leading CNC Spinning Technology

ALTRON takes pride in its leading CNC spinning technology, both domestically and internationally. The company has engaged in academic exchanges and cooperation with numerous foreign countries, especially in the field of metal spinning. Unwaveringly rooted in scientific and technological innovation, ALTRON focuses on product technology research and development, emphasizing product quality and honest service.

Conclusion

In conclusion, as we celebrate the first anniversary of ALTRON’s FB series, it’s evident that flanging machine continues to be instrumental in shaping the future of metalworking. The integration of cutting-edge technology, modular design, and a commitment to precision places ALTRON at the forefront of this industry. Here’s to another year of innovation and excellence in flanging!