Setting Up & Operating: Comprehensive Guide to Flow Forming Machine

In the realm of advanced manufacturing technologies, the flow forming process has emerged as a game-changer, revolutionizing the production of cylindrical components with unparalleled precision and efficiency. One of the leading manufacturers in this field is ALTRON, renowned for their cutting-edge flow forming machines. In this guide, we’ll delve into the world of flow forming and provide a step-by-step walkthrough of setting up and operating an ALTRON flow forming machine. Whether you’re a seasoned professional or a newcomer to the industry, this guide will equip you with the knowledge to achieve remarkable results.

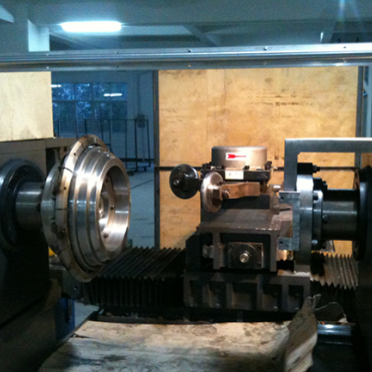

Unveiling ALTRON: Your Trusted Flow Forming Machine Manufacturer

Before we dive into the intricacies of setting up a flow forming machine, let’s familiarize ourselves with the manufacturer behind the innovation – ALTRON. With a legacy of excellence, ALTRON has earned its reputation as a pioneer in precision manufacturing technology. Their flow forming machines are engineered to meet the demands of modern industry, boasting advanced features that ensure impeccable results.

Setting Up Your ALTRON Flow Forming Machine: A Step-by-Step Guide

1. Pre-Installation Preparation

1.1 Creating the Foundation for Success: Workspace Optimization

Efficiency and organization are key when it comes to setting up your flow forming machine. Before diving into the installation process, take the time to optimize your workspace. Adequate lighting, ventilation, and safety measures should be prioritized to create a conducive environment for your machine’s operation. By ensuring a well-prepared workspace, you set the stage for a seamless installation process.

1.2 Unveiling the Potential: Machine Unpacking and Inspection

With your workspace primed for action, it’s time to unpack the components of your ALTRON flow forming machine. During this step, attention to detail is crucial. Carefully inspect each component for any signs of shipping damage. To guarantee a successful setup, verify that all parts are present and in pristine condition. By meticulously inspecting the machine components, you eliminate the risk of encountering unexpected issues during installation.

2. Installation and Calibration

2.1 A Solid Foundation: Machine Positioning

Now that you’ve ensured the integrity of your machine’s components, it’s time to position the flow forming machine in its designated area. Proper positioning sets the stage for stable operation and accurate results. Make sure the machine is level and securely anchored to prevent vibrations that could compromise precision. The careful placement of your machine is the first step towards achieving the desired flow forming outcomes.

2.2 Powering Up: Connection and Power Supply

To fully harness the capabilities of your ALTRON flow forming machine, it’s imperative to follow the manufacturer’s guidelines for connecting it to the power supply. Double-check all connections to mitigate the risk of electrical issues. A flawless connection not only ensures the smooth functioning of the machine but also safeguards against potential safety hazards.

2.3 The Key to Precision: Calibration and Alignment

With the machine securely positioned and connected, the final steps involve calibrating its settings and ensuring proper alignment. ALTRON’s provided instructions will guide you through this crucial process. Calibration fine-tunes the machine’s settings to match your specific requirements, while alignment ensures that the machine’s movements are precisely in line with the intended outcomes. These steps are pivotal in achieving the high level of precision and quality that flow forming is known for.

Operating Your ALTRON Flow Forming Machine: Tips for Success

1. Comprehensive Machine Familiarization

Before embarking on your first flow forming project, it’s paramount to acquaint yourself thoroughly with the functions and controls of your ALTRON Flow Forming Machine. As a novice or experienced operator, understanding the intricacies of the machine will set the stage for successful outcomes.

2. Control Panel Walkthrough

Navigating the control panel is your gateway to unlocking the potential of the ALTRON Flow Forming Machine. Take the time to delve into each parameter displayed and grasp its significance in the flow forming process. One of ALTRON’s remarkable features is its user-friendly interface, designed to simplify this process for operators of all levels.

3. Material Selection and Preparation

The foundation of an impeccable flow forming process lies in selecting the right material and preparing it according to ALTRON’s guidelines. Remember, the integrity of the final product hinges on the quality of the material you choose. Refer to ALTRON’s recommendations to ensure you’re working with the ideal material for your project.

4. Tooling Installation

Achieving precision in tooling installation is a pivotal step. ALTRON’s machines often boast tooling quick-change systems that streamline the process, enhancing efficiency. Follow ALTRON’s instructions meticulously to ensure your tooling is in place accurately before commencing the flow forming process.

5. The Flow Forming Process

Now that the stage is set, it’s time to delve into the heart of the matter – the flow forming process itself.

6. Loading the Workpiece

Placing your workpiece onto the machine’s spindle might seem routine, but it requires careful attention. Secure positioning is paramount to ensure the process unfolds smoothly. Take your time and make certain the workpiece is in place correctly.

7. Initiating the Process

As you initiate the flow forming process, follow the step-by-step instructions provided by ALTRON. The initial phases are crucial, and it’s recommended to monitor the machine closely during this stage. This vigilance ensures that any unexpected issues can be promptly addressed.

8. Quality Control Measures

Quality is non-negotiable when it comes to flow forming. Throughout the process and upon completion, implement stringent quality control measures. Regular checks will guarantee that the dimensions and surface finish align seamlessly with the required specifications, ultimately yielding a superior end product.

Maximizing Efficiency and Product Quality: Expert Tips

1. Workflow Optimization

Streamline your workflow to minimize downtime between projects. ALTRON machines often have preset profiles for common tasks.

2. Routine Maintenance

Adhere to ALTRON’s maintenance schedule to keep your machine in top condition. Regular maintenance prevents unexpected breakdowns.

3. Skill Enhancement

Invest in training programs offered by ALTRON or other reputable sources to continually improve your skills and stay updated with industry trends.

Conclusion

Mastering the art of flow forming with ALTRON’s cutting-edge machines is a journey that promises remarkable results in precision manufacturing. By following this comprehensive guide, professionals can confidently set up, operate, and optimize ALTRON flow forming machines to create superior cylindrical components with efficiency and precision. As technology evolves, ALTRON remains at the forefront, empowering manufacturers to achieve excellence in their craft.