Mastering Metal Fabrication: ALTRON’s Forming Machine Unveiled

Metal forming machines have been at the heart of industrial progress for centuries. From shaping raw materials into intricate components to streamlining mass production processes, these machines have continuously evolved to meet the demands of modern manufacturing. Among the pioneers in this field stands ALTRON, a leading manufacturer of cutting-edge forming machinery. Let’s delve into the world of metal forming machines and explore their diverse applications.

The Versatility of Metal Forming Machines

Metal forming machines encompass a wide range of technologies tailored to different industrial needs. Whether it’s bending, cutting, stamping, or shaping, these machines play a crucial role in transforming metal sheets or blocks into desired configurations. Here are some key types of metal forming machines:

- Hydraulic Presses:These machines utilize hydraulic power to exert immense force on metal workpieces, enabling precise shaping and forming. With adjustable pressure and versatile tooling options, hydraulic presses are ideal for a variety of applications, from simple bending to deep drawing.

- Roll Forming Machines:Roll forming is a continuous bending operation where metal strips pass through a series of rollers to gradually shape them into desired profiles. This method is widely used in industries such as construction, automotive, and appliance manufacturing for producing components like roof panels, window frames, and structural supports.

- CNC Machining Centers:Computer Numerical Control (CNC) machining centers offer unparalleled precision and flexibility in metal fabrication. By automating the machining process based on digital designs, these machines ensure consistent quality and high productivity. They are commonly used for milling, drilling, and turning operations on metal workpieces.

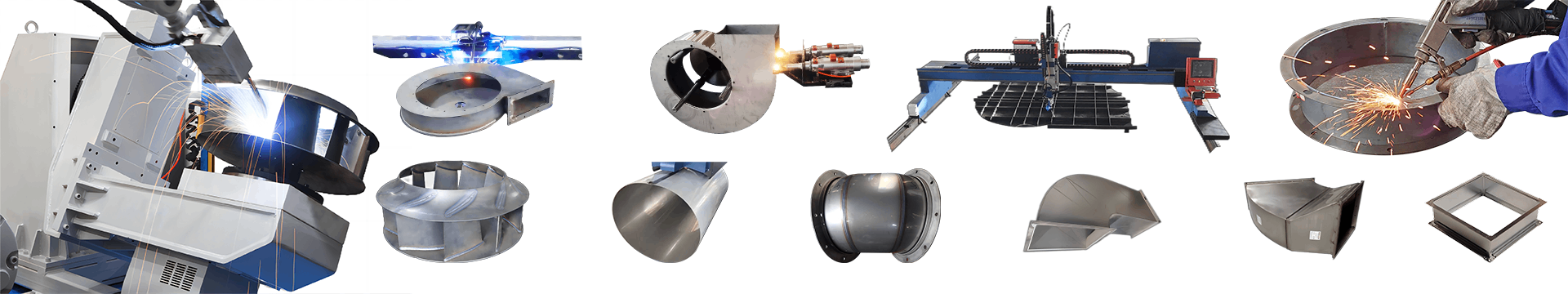

Enhancing Industrial Fan Production with ALTRON’s Industrial Fan Forming Machine

Industrial fans are integral components in various sectors, including HVAC systems, manufacturing plants, and power generation facilities. The efficiency and reliability of these fans depend largely on the quality of their components, particularly the fan blades. ALTRON’s industrial fan forming machine revolutionizes the production of fan blades by offering:

- Advanced Blade Design Capabilities:ALTRON’s forming machine is equipped with cutting-edge software and tooling systems that enable the creation of intricate blade designs with optimal aerodynamic performance. From traditional axial fans to high-efficiency centrifugal fans, the machine can accommodate a wide range of configurations to meet diverse industrial requirements.

- High-Speed Production:With rapid forming cycles and automated material handling features, ALTRON’s machine significantly reduces production lead times for industrial fan manufacturers. This allows for faster response to market demands and increased competitiveness in the industry.

- Quality Assurance:ALTRON prioritizes quality control throughout the manufacturing process, integrating inspection systems and feedback mechanisms into its forming machine. This ensures that each fan blade meets stringent quality standards for performance, durability, and safety.

Revolutionizing Automobile Hub Production with Automobile Hub Spin Forming Machine

Automobile hubs are critical components that connect the wheels to the vehicle’s axle, providing support and enabling smooth rotation. The manufacturing process for these hubs requires precision and reliability to ensure optimal performance on the road. ALTRON’s automobile hub spin forming machine offers:

- Seamless Integration with Automotive Production Lines:ALTRON’s spin forming machine is designed to seamlessly integrate into automotive manufacturing facilities, enabling efficient production of hub components with minimal downtime. Its compact footprint and modular design allow for easy installation and scalability to meet evolving production needs.

- High-Speed Spin Forming Technology:By utilizing advanced spin forming techniques, ALTRON’s machine achieves precise dimensional accuracy and surface finish on automobile hubs. This results in superior product quality and consistency, enhancing the overall performance and safety of vehicles.

- Customization and Flexibility: ALTRON understands the diverse requirements of automotive manufacturers and offers customizable solutions to suit specific hub designs and production volumes. Whether it’s alloy composition, geometry, or surface treatment, the machine can adapt to various specifications to meet customer needs.

Unleashing the Potential of Deep Drawing Forming Machines

Deep drawing is a metal forming process used to create hollow, three-dimensional shapes from flat sheet metal. This technique is commonly employed in the production of various components, including automotive parts, kitchen utensils, and household appliances. ALTRON’s deep drawing forming machines boast several key features:

- Precision Engineering:ALTRON’s deep drawing machines are engineered to deliver precise results, ensuring uniform wall thickness and consistent geometries across complex shapes. This precision is essential for meeting strict quality standards and achieving optimal performance in end-use applications.

- Versatility in Material Handling:Whether it’s steel, aluminum, copper, or other metals, ALTRON’s deep drawing machines can accommodate a wide range of materials with varying thicknesses. This versatility enables manufacturers to produce diverse components while maintaining high efficiency and cost-effectiveness.

- Advanced Control Systems:ALTRON integrates state-of-the-art control systems into its deep drawing machines, offering operators intuitive interfaces and real-time monitoring capabilities. This allows for greater control over the forming process, minimizing errors and maximizing productivity.

Empowering Manufacturers with Custom Forming Machines

In today’s rapidly evolving market landscape, customization is key to meeting the unique needs of customers across industries. ALTRON’s custom forming machines are designed to provide manufacturers with the flexibility and agility required to adapt to changing demands. Here are some noteworthy features:

- Tailored Solutions:ALTRON works closely with customers to develop custom molding machines suited to their specific requirements. Whether it’s unique product design, volume or material specifications. ALTRON’s engineering teams work tirelessly to provide individual solutions that optimize efficiency and quality.

- Modular Design: ALTRON’s custom molding machines feature a modular design. Customization and scalability are easily achieved. Manufacturers can easily integrate additional modules or upgrade existing modules. to meet changing production demands without significant downtime or disruption.

- Enhanced Productivity:By streamlining the manufacturing process and eliminating unnecessary steps. ALTRON’s custom molding machines help manufacturers increase productivity and reduce lead times. This enables them to meet tight deadlines and maintain a competitive edge in the market.

Unlocking Potential with Metal Spin Forming Machines

Metal spin forming is a specialized process. Used to make symmetrical hollow parts by rotating a metal disk or tube on a rotating mandrel. The technology is widely used in industries such as aerospace, automotive and energy to produce components such as cones, cylinders and hemispheres. ALTRON’s metal spin forming machines offer many advantages:

- High Precision Machining:ALTRON’s metal spin forming machines are equipped with advanced processing capabilities. Ensures precise dimensional accuracy and surface finish. This level of accuracy is critical to meeting tight tolerances and achieving optimal performance in demanding applications.

- Versatility in Material Selection: From aluminum and stainless steel to titanium and Inconel. ALTRON’s metal spin forming machines can process a wide range of materials with different properties and thicknesses. This versatility enables manufacturers to explore new opportunities and expand their product range.

- Efficiency and Cost-Effectiveness: By combining spinning, forming and machining processes into a single operation. ALTRON’s metal spin forming machines help manufacturers reduce production costs and lead times. This integrated approach minimizes material waste and eliminates the need for secondary operations. This saves a lot of time and cost.

The Precision of Stainless Steel Forming Machines

Stainless steel is known for its corrosion resistance, durability, and aesthetics. Making it the material of choice in industries such as automotive, aerospace and construction. ALTRON’s stainless steel forming machines are designed to take advantage of the unique properties of this material. while delivering superior results:

- High-Temperature Resistance: ALTRON’s stainless steel forming machines are capable of handling the high temperatures often required when forming this elastic material. Whether deep drawing, bending or stamping. These machines ensure precise control of the molding process. The result is uniform, perfect parts.

- Surface Finish Excellence:Achieving a smooth and polished surface finish is critical for stainless steel parts. Especially in applications where hygiene and aesthetics are crucial. ALTRON’s molding machines use advanced tooling and processing technology to provide superior surface quality. Meets the most stringent cleanliness and appearance standards.

- Corrosion Mitigation:ALTRON understands the importance of maintaining the corrosion resistance of stainless steel during the forming process. Through careful design and material handling strategies. Their machines minimize the risk of contamination and oxidation. This maintains the integrity and longevity of the final product.

Empowering Efficiency with Carbon Steel Forming Machines

Carbon steel is prized for its strength, versatility and cost-effectiveness. Making it a popular choice for a variety of industrial applications. ALTRON’s carbon steel forming machines are carefully engineered. Harness the full potential of this strong material while maximizing efficiency and productivity:

- Rapid Forming Cycles:ALTRON’s carbon steel forming machines utilize advanced hydraulic and mechanical systems to achieve rapid forming cycles. without affecting accuracy or quality. This enables manufacturers to meet tight production schedules and respond quickly to market demand.

- Flexibility in Forming: Whether it’s mild steel, high-strength low-alloy (HSLA) steel, or tool steel, ALTRON’s forming machines offer unparalleled flexibility in shaping various grades of carbon steel. From simple bends to complex geometries. These machines cater to a variety of molding requirements, allowing manufacturers to diversify their products.

- Cost-Effective Solutions:By optimizing material use and minimizing waste. ALTRON’s carbon steel forming machines help manufacturers reduce production costs and increase profitability. Additionally, its rugged construction and reliable performance ensure long-term operational efficiency and minimal downtime.

Precision Crafting with Copper Forming Machines

Copper is valued for its conductivity, ductility, and corrosion resistance. Making it indispensable in electrical, plumbing and telecommunications applications. ALTRON’s copper forming machines are carefully designed. Able to handle this unique material with precision and finesse:

- Non-Sparking Operations:ALTRON’s copper forming machines are designed to minimize the risk of sparks during the forming process. Ensures safety in environments where flammable gases or liquids may be present. This feature makes them ideal for use in hazardous industrial environments and critical infrastructure projects.

- Dimensional Accuracy:Maintaining precise dimensional accuracy is critical for copper components. Especially in electrical and electronic applications where tight tolerances are required. ALTRON’s molding machines utilize advanced control systems and mold technology to achieve micron-level precision. Ensure optimal performance and reliability.

- Customized Solutions: ALTRON understands that every copper forming application is unique. There are specific requirements in terms of geometry, electrical conductivity and mechanical properties. Their engineering team works closely with customers. Develop custom solutions to address these unique challenges. Deliver custom machines that meet or exceed expectations.

Aluminum Forming Machines: Efficiency and Precision

Aluminum is prized for its lightweight, corrosion resistance and electrical conductivity. Making it the material of choice for industries such as aerospace, automotive and consumer electronics. ALTRON’s aluminum forming machines are designed to take full advantage of this versatile material. Delivers efficiency and precision simultaneously:

- Lightweight Construction:ALTRON’s aluminum forming machines utilize lightweight structural materials and advanced design technology. Ensure optimal performance while minimizing energy consumption and environmental impact. This lightweight design also facilitates transportation, installation and maintenance, improving overall operational efficiency.

- High-Speed Machining:ALTRON’s aluminum forming machines are equipped with high-speed processing capabilities. Fast production cycles are achieved without sacrificing accuracy or surface finish quality. This enables manufacturers to meet tight deadlines and remain competitive in a fast-paced industry.

- Enhanced Surface Treatment:Aluminum parts often require surface treatment. Such as anodizing or powder coating to enhance corrosion resistance and aesthetics. ALTRON’s molding machines are compatible with a wide range of surface treatment processes. Enables manufacturers to achieve the desired finish and performance characteristics for their products.

Conclusion

In conclusion, metal forming machines continue to drive innovation and efficiency across a wide range of industries, from manufacturing and construction to automotive and aerospace. ALTRON’s commitment to excellence and technological leadership ensures that its molding machines enable manufacturers to stay ahead of the curve in today’s competitive market landscape. As the industry evolves, ALTRON remains at the forefront. Shaping the future of metal manufacturing with cutting-edge solutions.