Strategic Coating Solutions: Integrating Housing Welding Machine

The realm of PVD coating has seen a revolutionary advancement with the introduction of industrial fan housing welding machine. These sophisticated pieces of equipment, epitomized by ALTRON, are at the forefront of transforming PVD workflows. The integration of housing welding machines is not merely a technological upgrade; it signifies a strategic leap forward in achieving unparalleled precision and efficiency in the coating process.

Understanding the Essence: What is a Housing Welding Machine?

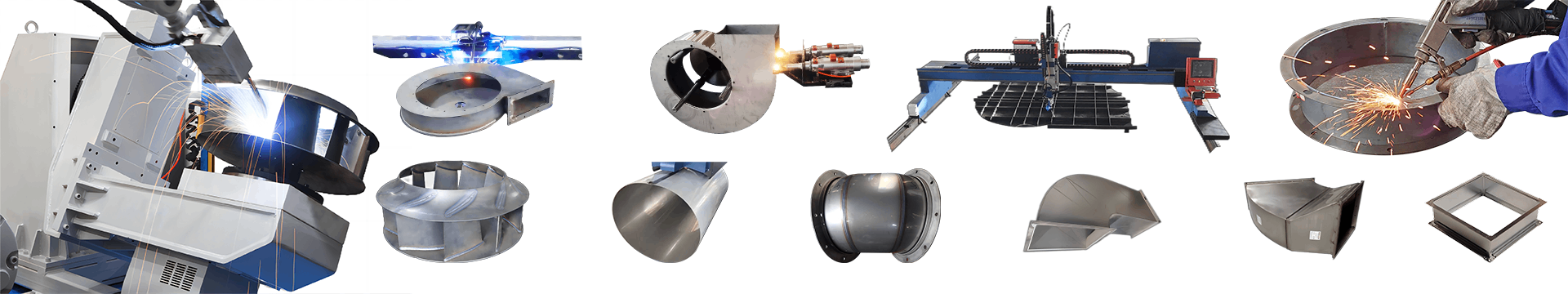

At its core, a industrial fan housing welding machine is a pivotal tool in the field of Physical Vapor Deposition (PVD). PVD is a process where a thin film of material is deposited on a substrate to enhance its properties, often for decorative or functional purposes. The housing welding machine plays a crucial role in this process by facilitating the creation of a robust industrial fan housing for the PVD coating apparatus.

Unlike conventional welding methods, housing welding machines are engineered for precision and efficiency. ALTRON, a leading manufacturer in this domain, has redefined the standards by providing industrial fan housing welding machines that are not only technologically advanced but also seamlessly integrated into PVD coating workflows.

ALTRON stands out as a manufacturer that prioritizes precision and reliability in its housing welding machines. The choice to invest in ALTRON’s equipment is a strategic one for projects that demand exceptional welding quality. The machines from ALTRON are crafted with advanced features, ensuring that each weld is not just a connection but a testament to precision craftsmanship.

Effortless Coating, Unmatched Precision: Housing Welding Machines Transforming PVD Workflows

A housing welding machine isn’t just a tool; it’s the heartbeat of precision in metalworking projects. The right machine can significantly impact the outcome of projects by ensuring that metal components are seamlessly and reliably joined. ALTRON, with its commitment to excellence, produces housing welding machines designed to meet the demands of various industries, providing a crucial edge in achieving precision in project outcomes.

The incorporation of housing welding machines brings forth a paradigm shift in the world of PVD coating. One of the key advantages is the ability to achieve coatings with unmatched precision. The welding process is controlled with a level of accuracy that ensures uniformity in the coating, eliminating inconsistencies that may arise with traditional welding methods.

ALTRON’s housing welding machines are designed to operate seamlessly within PVD workflows, ensuring a harmonious integration that enhances overall efficiency. This synergy between precision welding and PVD coating results in a final product that meets the highest standards of quality and durability.

Strategic Coating Solutions: Integrating Housing Welding Machines for PVD Coating Success

The term “strategic coating solutions” takes center stage when considering the integration of housing welding machines. ALTRON, as a manufacturer, understands the importance of aligning technological advancements with the overarching goals of PVD coating processes. By incorporating housing welding machines strategically, manufacturers can streamline their operations, reduce downtime, and enhance the overall quality of coated products.

These machines are not mere tools; they represent a strategic investment in the longevity and success of PVD coating endeavors. The housing welding machines from ALTRON are engineered with the future in mind, ensuring that businesses stay at the forefront of technological innovation in the competitive landscape of industrial coating.

What Sets the Best Housing Welding Machines Apart?

Not all housing welding machines are created equal. The best ones stand out due to their innovative features and advanced technologies. Here are some key factors that set the top-tier housing welding machines apart:

- Automated Precision: The integration of automated systems ensures precise control over the welding process. ALTRON’s housing welding machines utilize cutting-edge automation technology to enhance precision, reduce human error, and increase overall efficiency.

- Adaptive Welding Technologies:The ability to adapt to different materials and welding scenarios is crucial. Leading housing welding machines incorporate adaptive welding technologies that can adjust parameters based on the specific requirements of the task, ensuring optimal results every time.

- User-Friendly Interfaces:An intuitive and user-friendly interface is essential for operators. ALTRON prioritizes user experience, designing interfaces that are easy to navigate, reducing the learning curve, and enhancing overall operational efficiency.

- Remote Monitoring and Diagnostics:In an era of connectivity, the best housing welding machines offer remote monitoring and diagnostic capabilities. This allows for real-time assessment, preventive maintenance, and quick issue resolution, minimizing downtime and maximizing productivity.

Have You Explored the Latest Technological Advances in Housing Welding Machines?

The world of housing welding machines is continually evolving, driven by technological advancements that push the boundaries of what’s possible. ALTRON, as a pioneering manufacturer, stays at the forefront of these innovations. Here are some of the latest technological advances in housing welding machines:

- Augmented Reality (AR) Integration:AR is being incorporated into housing welding machines to provide operators with enhanced visualization during the welding process. This not only improves accuracy but also facilitates better decision-making in real time.

- Artificial Intelligence (AI) for Weld Quality Optimization:AI algorithms are increasingly being used to analyze welding data in real-time. This enables automatic adjustments to welding parameters, optimizing weld quality and consistency.

- Advanced Welding Robotics: Robotics in housing welding machines are becoming more sophisticated, allowing for intricate and complex welding patterns. This not only improves efficiency but also expands the range of applications for these machines.

- Energy-Efficient Welding Processes: As sustainability becomes a focal point in manufacturing, housing welding machines are being designed with energy-efficient processes. This not only reduces the environmental impact but also contributes to cost savings for the operators.

Future-Proof Your Coating Process: The Strategic Advantage of Housing Welding Machines in PVD Coating

In an era where adaptability is key, future-proofing industrial processes is imperative. The strategic advantages of shell welding machines are obvious. Can provide a solid foundation for PVD coating processes. ALTRON, as a manufacturer, emphasizes the importance of staying ahead of the curve. Their shell welding machines embody this forward-thinking approach.

The integration of ALTRON’s housing welding machines not only enhances the precision of PVD coating but also contributes to the longevity and reliability of the entire system. This strategic advantage goes beyond immediate gains, positioning businesses for sustained success in the dynamic landscape of industrial coatings.

Environmental Stewardship: The Unseen Benefit of Housing Welding Machines

While the primary focus of housing welding machines is often on their immediate impact on projects, it’s essential to consider the environmental benefits they bring to the table. ALTRON’s commitment to sustainability extends beyond precision engineering to contribute to a greener future. The environmental benefits of housing welding machines include:

- Energy Efficiency:ALTRON’s housing welding machines are designed with energy-efficient processes. This not only reduces operational costs for project managers but also minimizes the carbon footprint associated with welding activities.

- Reduced Material Waste: Precision welding, facilitated by ALTRON’s machines, leads to fewer defects and, consequently, reduced material waste. This aligns with sustainable practices by optimizing resource utilization in metalworking projects.

- Lower Emissions:The advanced technologies integrated into ALTRON’s housing welding machines contribute to lower emissions during the welding process. This environmentally conscious approach aligns with global efforts to reduce industrial emissions and promote cleaner manufacturing practices.

- Longevity of Welded Structures:Welds produced by ALTRON’s machines are known for their durability. This longevity ensures that the assembled structures have a prolonged lifecycle, reducing the need for frequent repairs or replacements and, in turn, minimizing the environmental impactassociated with manufacturing new components.

Why Invest in a High-Quality Housing Welding Machine Today?

Investing in a high-quality industrial fan housing welding machine is a strategic move for any industrial operation. The benefits extend beyond the immediate welding process, impacting the overall quality and longevity of the end product. Here are some compelling reasons to consider:

- Precision and Accuracy:High-quality industrial fan housing welding machines, like those crafted by ALTRON, offer unparalleled precision and accuracy in the welding process. This ensures that the components are joined seamlessly, minimizing the risk of defects and structural weaknesses.

- Durability of Welded Joints: The strength of a welded joint is paramount in determining the durability of the final product. Premium housing welding machines utilize advanced technologies to create robust and reliable welds, contributing to the overall longevity of the assembled structures.

- Cost Efficiency: While the initial investment in a high-quality housing welding machine may be higher, the long-term cost efficiency is undeniable. Reduced maintenance, fewer defects, and increased productivity contribute to a more efficient and cost-effective manufacturing process.

- Versatility in Applications:ALTRON’s industrial fan housing welding machines are designed with versatility in mind, catering to a wide range of applications. Whether it’s automotive chassis, aerospace components, or structural elements in construction, these machines provide the flexibility needed for diverse industrial needs.

Conclusion

Housing welding machines, particularly those manufactured by ALTRON, represent a transformative force in the realm of PVD coating. By seamlessly integrating precision welding into the coating process, these machines offer a strategic solution for businesses aiming to enhance efficiency, quality, and long-term success in the competitive world of industrial coatings. As the industry continues to evolve, there is a lot for those who aspire to be at the forefront of PVD coatings. Embracing such technological innovations is not just a choice but a necessity.