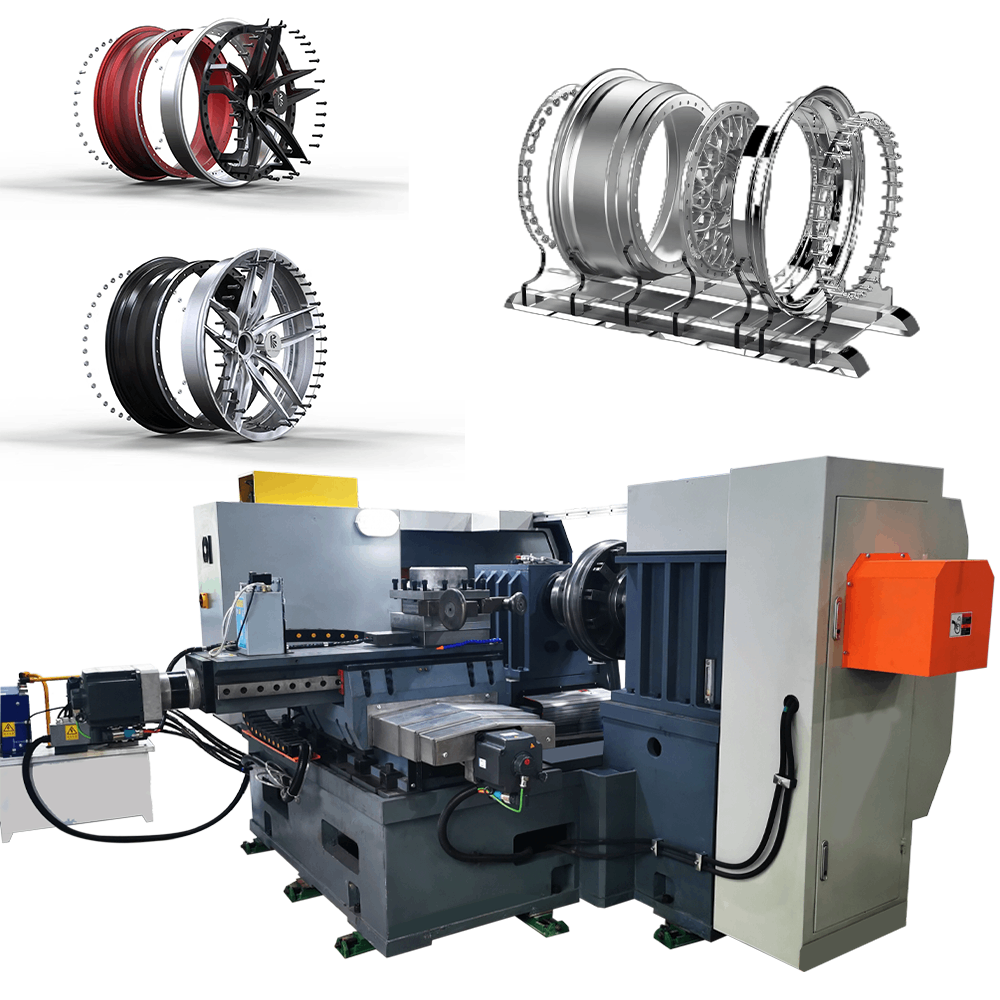

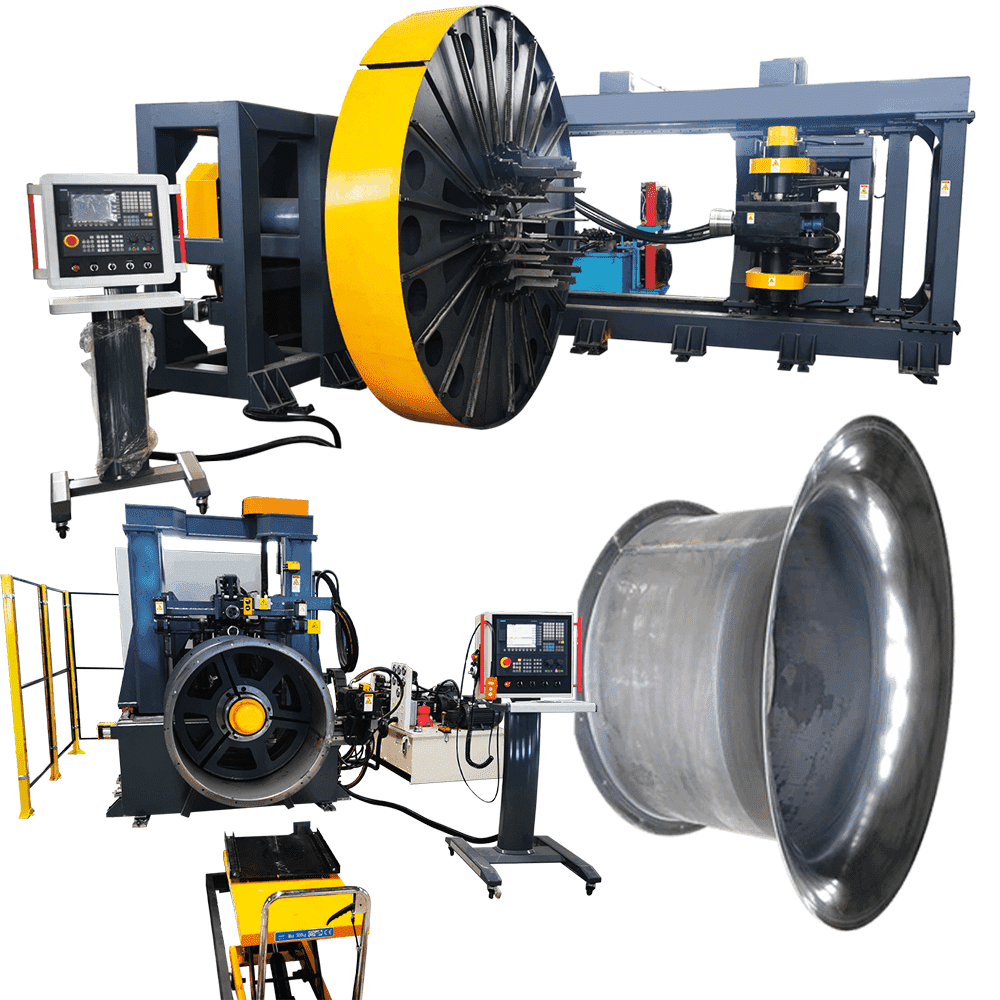

Horizontal Hub Wheel CNC Spinning Machine

Hub Wheel Spinning Machine for 3/2-piece Hub-CNC Metal Forming

|

Machine Name |

CNC Metal Spinning Machine |

|

Model |

AC 1400-H |

|

Application Industry |

Three-piece wheel hub, two-piece wheel hub, racing modified car wheel hub |

|

Technical Service |

Complete the test in the early stage; provide online and offline training in the later stage, and complete the turnkey project. |

|

Technical Guidance |

Online 24 hours a day/7*24 Pre-sales technical service |

|

Project Progress |

30-120 days |

|

Relevant Files |

ALTRON_AUTO Catalog-Industrial Blower Machinery Turnkey Project |

- ADAVANTAGES

- CUSTOMER TESTIMONIALS

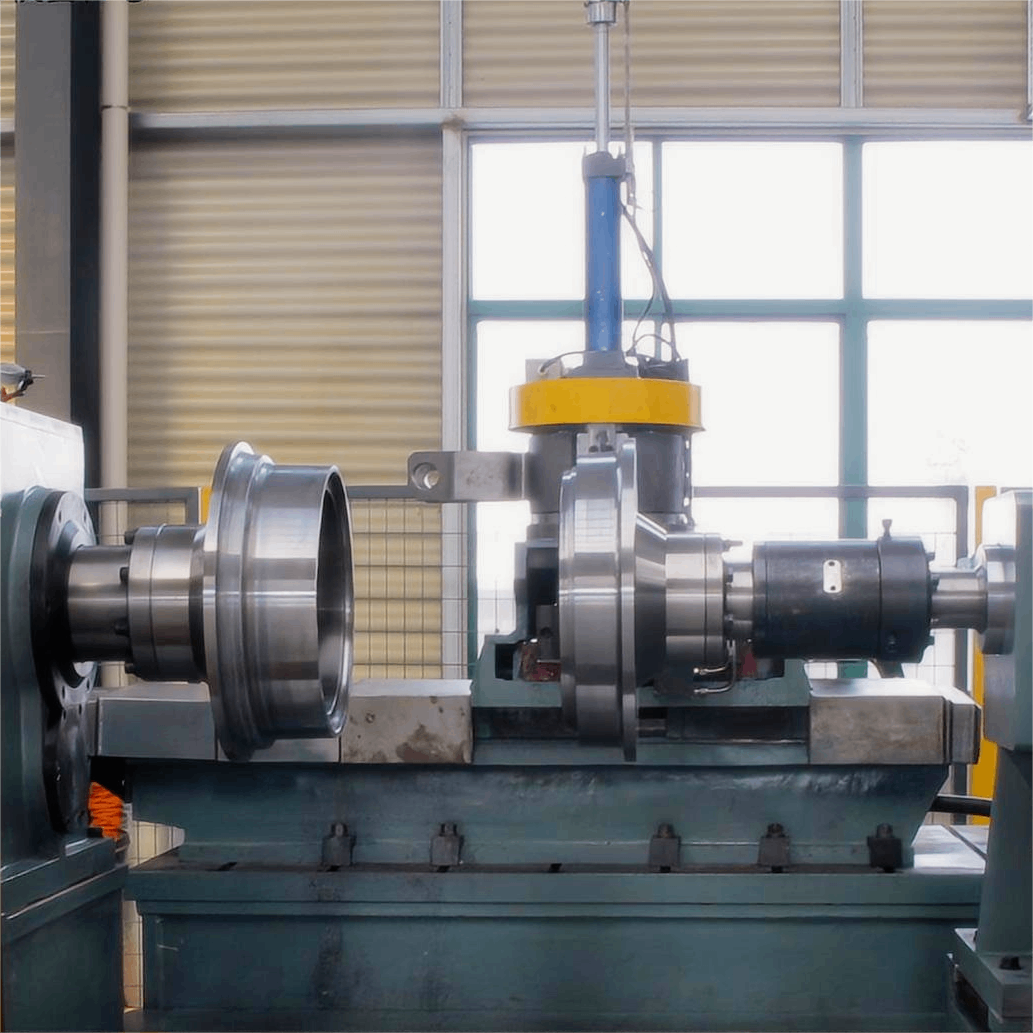

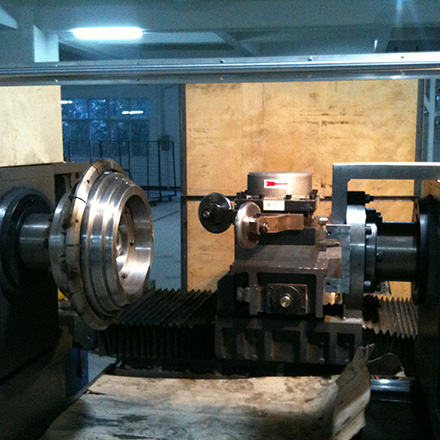

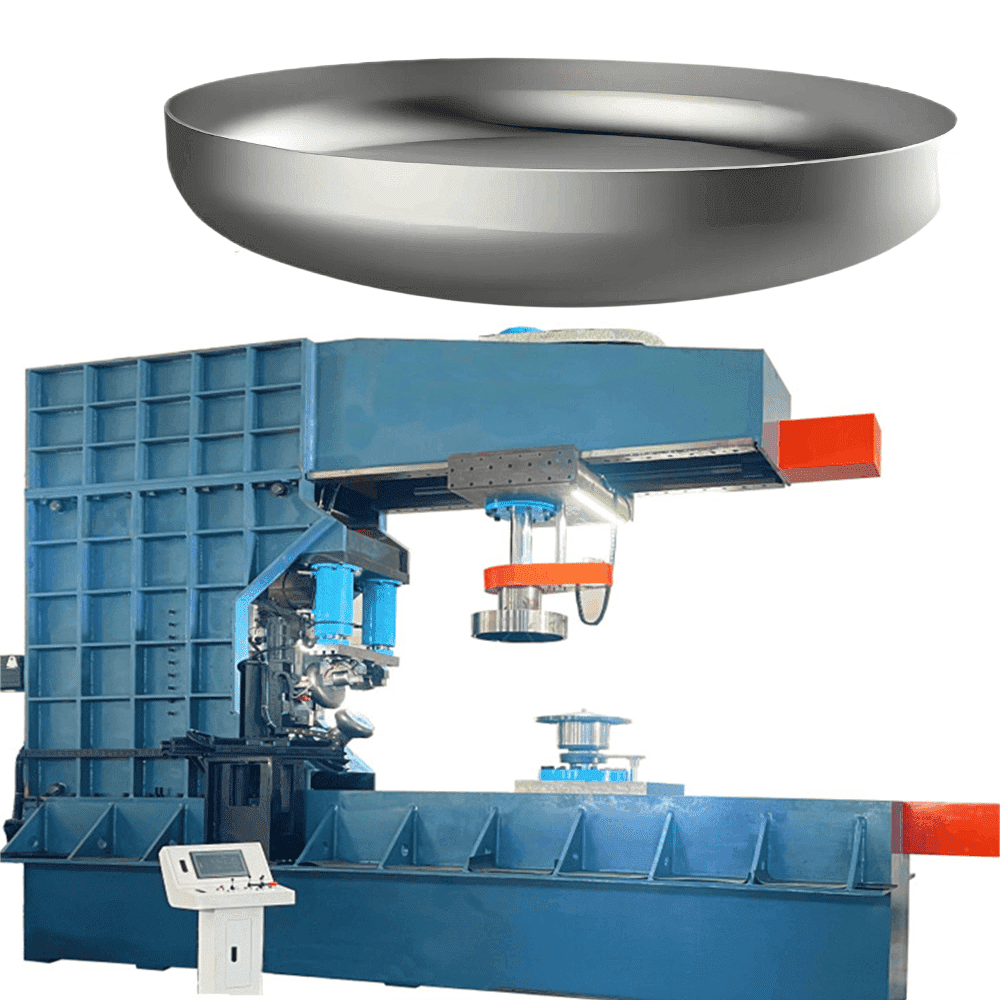

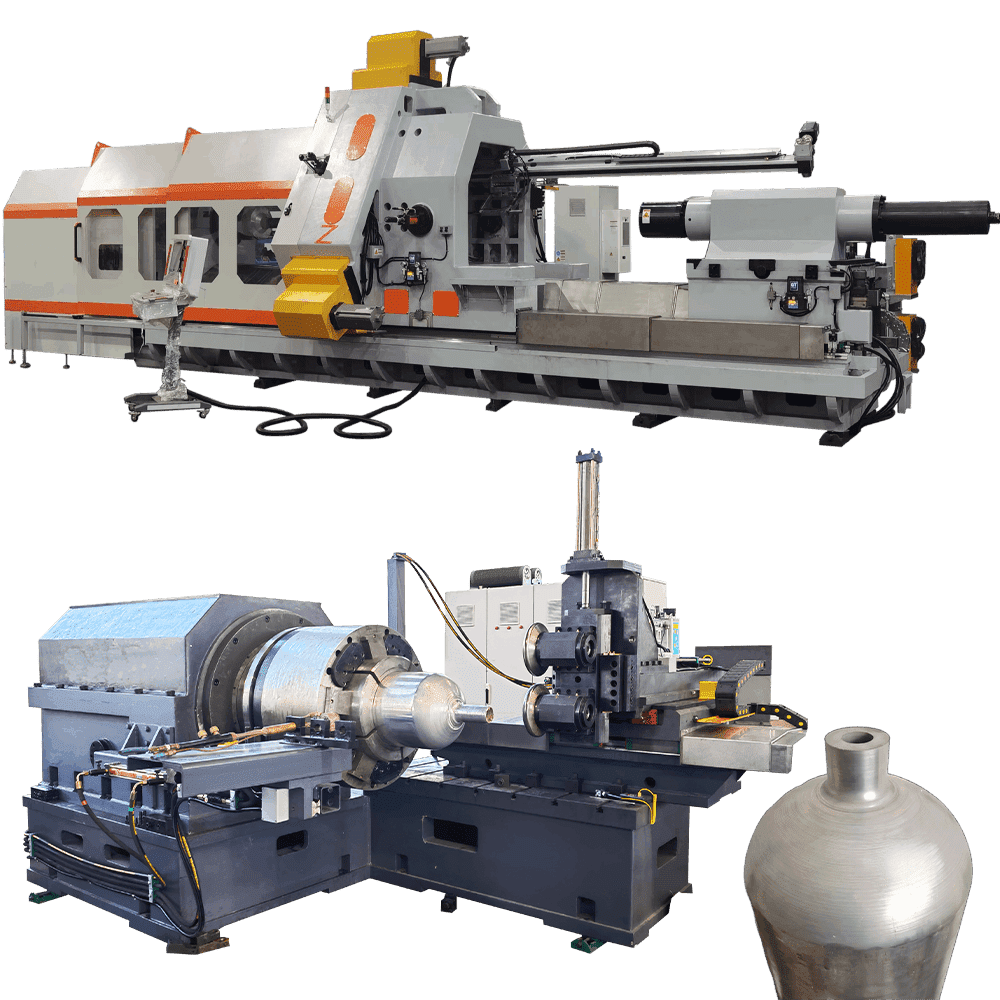

AC1400 H single roller CNC spinning machine is a horizontal wheel hub spinning machine, mainly used for metal blanks with high rotation strength. It applies cold spinning forming process and can spin carbon steel, aluminum alloy, stainless steel and other materials. It is widely used in automobile, military and other production fields. It is particularly suitable for the spinning production of two-piece, three-piece and integral automobile and motorcycle wheels, and also suitable for spinning shaping of motorcycle wheels after heat treatment.

The AC1400 wheel hub spinning machine refers to the mature technology of companies in Germany, Spain and other countries, adopts machine tool standards and combines China’s actual situation to design and produce. All functional indicators have reached or exceeded the international advanced level. At the same time, the spinning machine is driven by Siemens high-torque servo motor!

Video Of CNC Metal Spinning Machine for 3-piece Hub

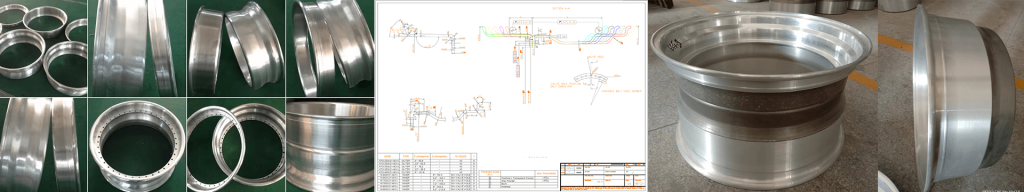

Production of 2-piece and 3-piece hubs for racing

The 2-3 Leaves Hub Wheel Spinning Machine is an advanced industrial equipment specifically designed for spinning hub wheels with 2 or 3 leaves. It is widely utilized in wheel manufacturing companies, automotive industries, and other sectors requiring high-quality hub wheels. This machine efficiently and precisely transforms blank materials, which can be in the form of sheets or tubes, into perfectly spun hub wheels.

Wheel Hub CNC Metal Spinning Machine Parameters

Processing method: Horizontal CNC spinning

Raw material diameter: maxФ 1400

Material: Aluminum, copper, carbon steel and other materials

Thickness range: max 6mm ( Tensile strength is about 380MPa ordinary carbon steel)/max 15mm (Tensile strength is about 230Mpa aluminum)

Technical indicators

X-axis displacement 700mm

Z-axis displacement 850mm

Double center distance 1200mm

X, Z moving speed max 6m/min

X, Z axis rated thrust 150KN

Axial positioning accuracy 0.02mm

Repeat accuracy 0.02mm

Spindle speed: 50-600rpm

Hardware configuration

Control method: Siemens 802C CNC numerical control system

Feed power: Siemens servo motor

Drive control: Siemens

Spindle power: **KW motor

Spindle control: **kw Siemens 440 inverter

Tailstock: Hydraulic cylinder telescopic drive, hydraulic locking

Slide: Heavy-duty linear slide, ball screw

Tool rest 4-station electric CNC tool rest

Hydraulic station power 5.5KW

Power supply Voltage 3Φ 380V ±5%

Power About 60 KW

Wheel Hub CNC Metal Spinning Machine Parameters

Processing method: Horizontal CNC spinning

Raw material diameter: maxФ 1400

Material: Aluminum, copper, carbon steel and other materials

Thickness range: max 6mm ( Tensile strength is about 380MPa ordinary carbon steel)/max 15mm (Tensile strength is about 230Mpa aluminum)

Technical indicators

X-axis displacement 700mm

Z-axis displacement 850mm

Double center distance 1200mm

X, Z moving speed max 6m/min

X, Z axis rated thrust 150KN

Axial positioning accuracy 0.02mm

Repeat accuracy 0.02mm

Spindle speed: 50-600rpm

Hardware configuration

Control method: Siemens 802C CNC numerical control system

Feed power: Siemens servo motor

Drive control: Siemens

Spindle power: **KW motor

Spindle control: **kw Siemens 440 inverter

Tailstock: Hydraulic cylinder telescopic drive, hydraulic locking

Slide: Heavy-duty linear slide, ball screw

Tool rest 4-station electric CNC tool rest

Hydraulic station power 5.5KW

Power supply Voltage 3Φ 380V ±5%

Power About 60 KW

-

Marcley

★★★★★Post a review on Aug 21, 2022 From Bolivia

The 2-3 Leaves Hub Wheel Spinning Machine has significantly transformed our manufacturing process. Its precision and versatility have allowed us to produce hub wheels of exceptional quality. The machine’s automated operation and high-speed performance have increased our productivity and reduced production time. It’s a game-changer for our business.

-

Arthur Zonneveld

★★★★★Post a review on Fec 21, 2022 From Mauritius

We recently integrated the 2-3 Leaves Hub Wheel Spinning Machine into our production line, and the results have been outstanding. The machine’s ability to handle both sheet and tube blanks has provided us with flexibility in our manufacturing process. The quality assurance features have ensured consistent wheel dimensions, and the customizable options have allowed us to meet specific customer requirements. It’s a reliable and efficient solution.

-

Nicolas Vazquez

★★★★★Post a review on jul 21, 2022 From Uruguay

I have been using the 2-3 Leaves Hub Wheel Spinning Machine for several months now, and I am extremely satisfied with its performance. The machine’s precision spinning capabilities have allowed me to achieve superior wheel finishes and tight tolerances. Its user-friendly interface and safety features have made operation seamless and secure.

-

OSCAR URBANEJA

★★★★★Post a review on Oct 10, 2022 From Venezuela

I highly recommend this machine to any wheel manufacturer looking to enhance their production capabilities.