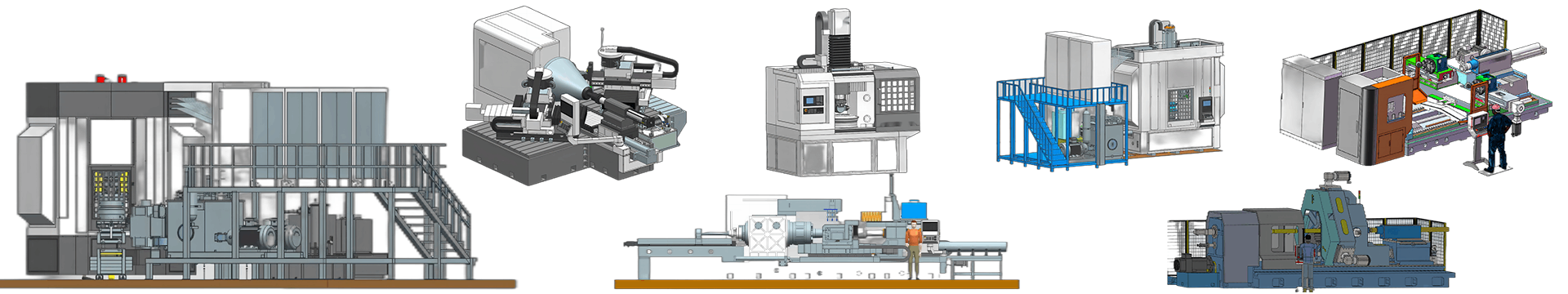

Aluminum Alloy Wheel Hub Powerful Spinning Machine

Customized Spinning Machine for Aluminum Alloy hub

|

Machine Name |

Aluminum Alloy Wheel Hub Spinning Machine |

|

Model |

AC-700/6 |

|

Application Industry |

Casting Wheel Hub, forging Wheel Hub, Car Wheel Hub,Aluminum Alloy Hub,Belt Pulleys |

|

Technical Service |

Complete the test in the early stage; provide online and offline training in the later stage, and complete the turnkey project. |

|

Technical Guidance |

Online 24 hours/7*24 Pre-sales technical service |

|

Project Progress |

30-120 days |

|

Relevant Files |

ALTRON_AUTO Catalog-Industrial Blower Machinery Turnkey Project |

- ADAVANTAGES

- PARAMETERS

- CUSTOMER TESTIMONIALS

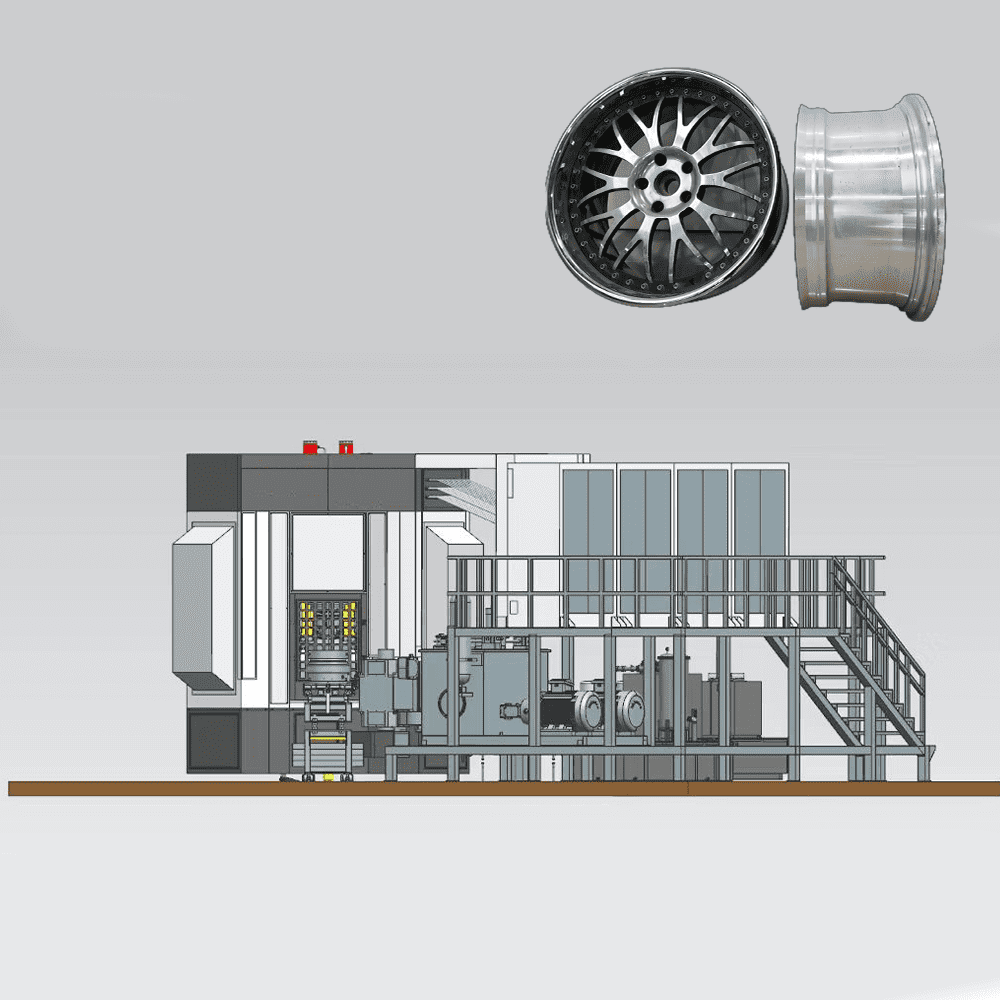

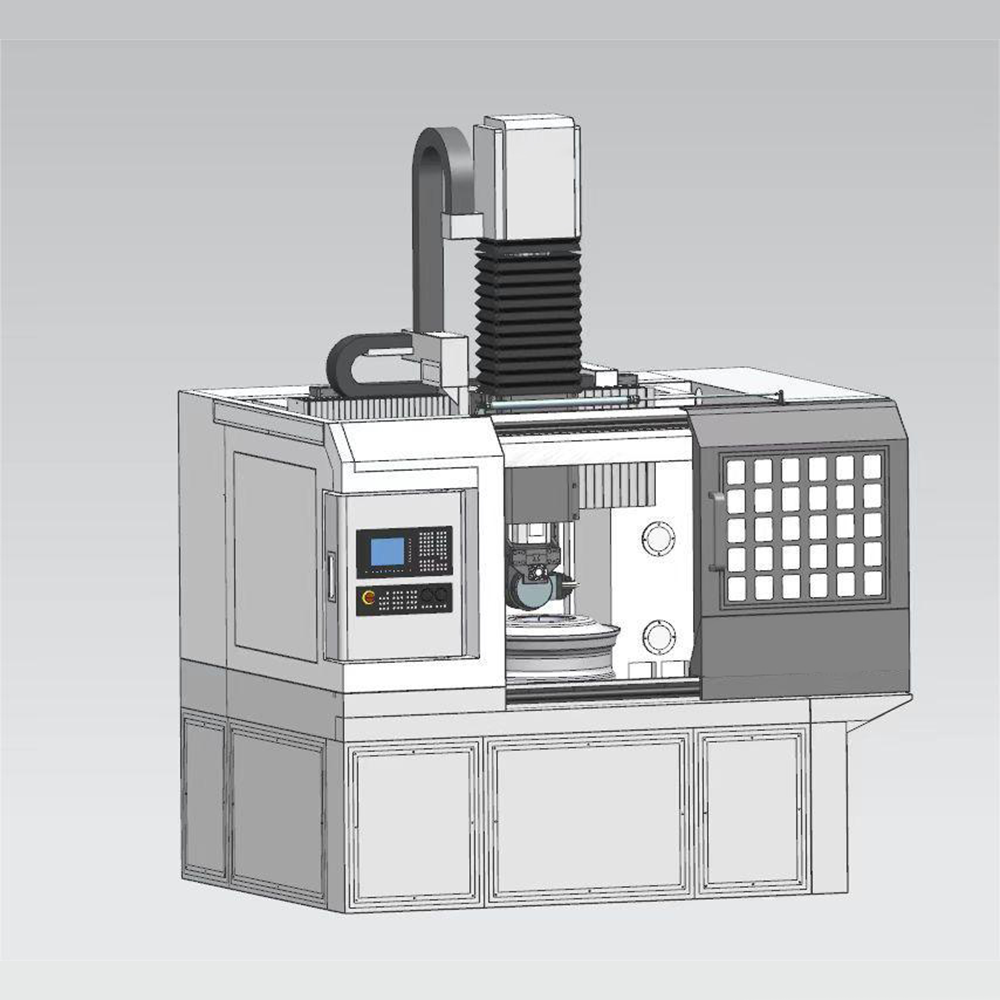

Introducing the AC-700/6 aluminum alloy wheel high-power spinning machine, a metal spinning forming solution designed for aluminum alloy wheel production processes.

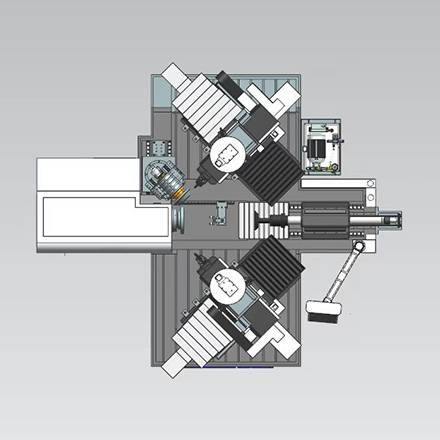

The machine is designed with a 3-axis symmetrical 120-degree layout of spinning rollers! It effectively improves the hub’s flow forming process to be more stable and more accurate.

Customized high precision CNC spinning machine video

Equipment Introduction:

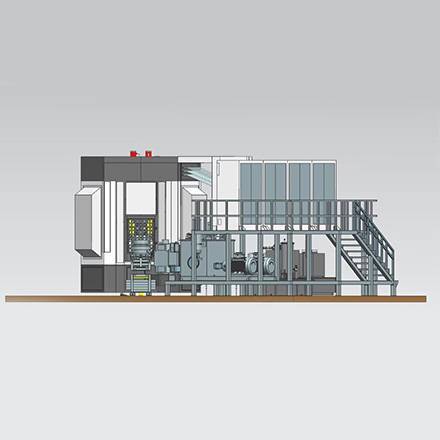

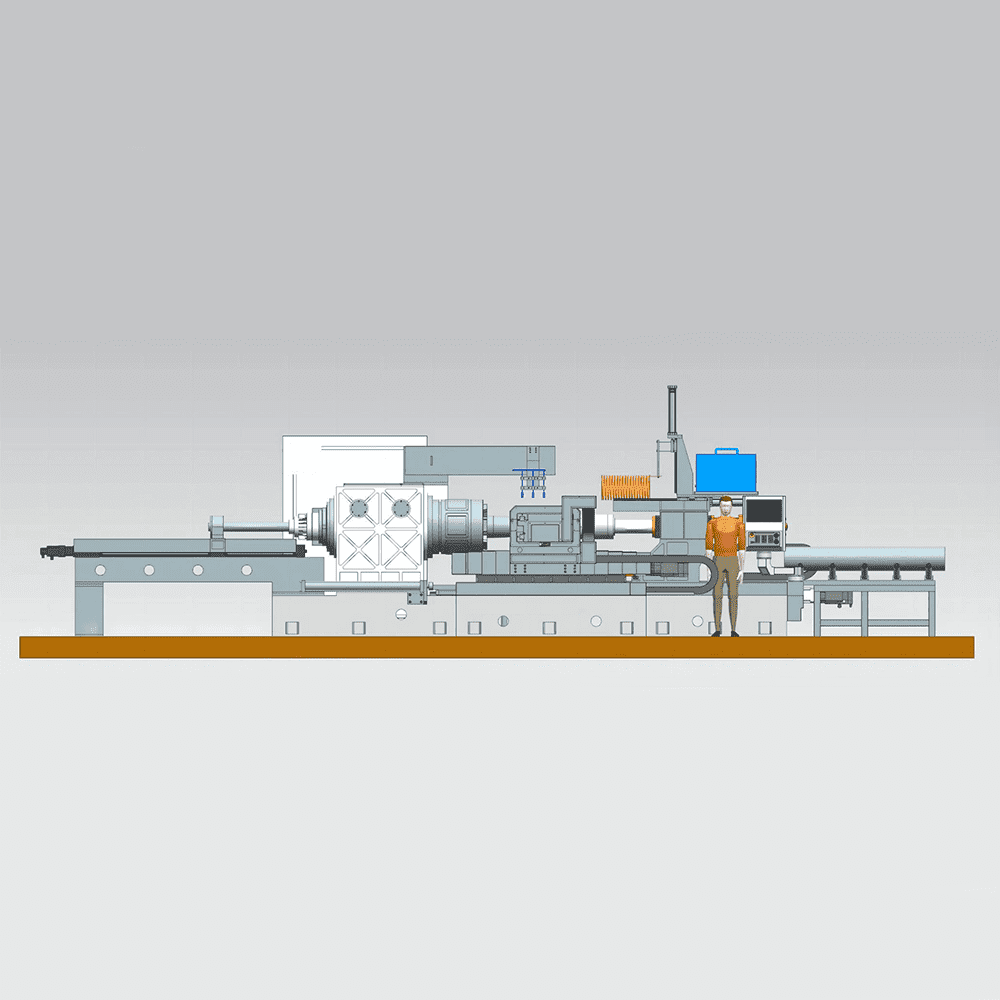

Equipment Name: Aluminum Alloy Wheel Hub Powerful Spinning Machine Equipment Model: AC-700/6 Application: Spinning forming of aluminum alloy wheel hub and rim Equipment Structure: Vertical combined structure of high-strength castings Transmission Mode:

- Cross slide: Servo hydraulic control for high precision, large and stable thrust, replacing the previous servo motor screw drive structure

- Main Shaft: Equipped with a large thrust roller bearing for stable and powerful operation, with an oil-cooled structure for optimal performance Equipment Control System: Siemens 840D SL system, providing high precision and convenient programming Operation Mode: Program control, allowing manual adjustment, semi-automatic, and fully automatic operation modes

Function Description:

- Spindle: Steplessly adjustable and programmable

- Rotary Wheel (Radial Feed): Steplessly adjustable and programmable

- Rotary Wheel (Axial Feed): Steplessly adjustable and programmable

- Tail Top Speed Control: Hydraulic pressure control for quick approach, slow compression, and rapid return

- Fault Alarm Function: Alerts operators in case of any issues

- Spindle Unloaders: Upper and lower spindles equipped with unloaders

- Aluminum Alloy Spinning Rim Forming: Capable of satisfying the spinning rim forming of aluminum alloy forging billet

Basic Composition of Equipment:

The main components of the machine tool include:

- Bed Frame

- Spindle

- Main and Tailstock Shaft Drives

- Tailstock

- Three Precision Spinning Carriages

- Hydraulic Station

- CNC Numerical Control System and PLC Programmable Controller

| Project | Name | Unit | Parameter range |

| Machining capability | Machined hub diameter range | Inch | Fourteen to twenty-six |

| Spindle | Servo spindle total power | KW | 125 + 125 |

| Spindle Revolution | R/MIN | 50-600 | |

| Spindle interface | Din | DIN 55027SIZE15 | |

| Tailstock spindle interface | Din | DIN 55027SIZE15 | |

| Roller | Number of rotors | Of the project | 3 |

| Diameter of roller | MM | 380-400 | |

| Maximum throat depth | MM | 80 | |

| Roller mounting interface | Din | Din Size-6 | |

| Spin thrust | Maximum lateral thrust of roller | Kn | 250 * 3 |

| Maximum longitudinal thrust of the rotating wheel | Kn | 250 * 3 | |

| The wheel moves | Rotary wheel transverse machining speed | MM/MIN | Maximum 2000 * 3 |

| Rotary wheel longitudinal machining moving speed | MM/MIN | Maximum 2000 * 3 | |

| Rotary wheel lateral fast forward speed | MM/MIN | Maximum 5000 x 3 | |

| Rotary Wheel Longitudinal Fast Forward movement speed | MM/MIN | Maximum 5000 x 3 | |

| Roller power | Lateral power of the roller | Hydraulic | Max. 20MPA * 3 |

| Longitudinal power of the roller | Hydraulic | Max. 20MPA * 3 | |

| Roller stroke | Wheel travel (x) | MM | 250 * 3 |

| The longitudinal stroke of the roller (Y) | MM | 500 times 3 | |

| Wheel alignment | Rotary wheel lateral positioning accuracy | MM | 0.015 |

| Rotary wheel longitudinal positioning accuracy | MM | 0.015 | |

| Tailstock | Seat travel | MM | 700 |

| Tailstock thrust | Kn | 100-400 | |

| Hydraulic station | Maximum work pressure | MPa | Twenty |

| Hydraulic power | KW | 120 | |

| Center distance | Center distance between top and bottom spindles | MM | 1300 |

| Return | Spindle unload thrust | Kn | 50-200 |

| Spindle discharge stroke | MM | One hundred | |

| Equipment | Weight | Tons | 36 |

| Size of the device | M | 10 x 10 x 5 | |

-

Marcley

★★★★★Post a review on Aug 21, 2022 From Bolivia

The AC-CNCVW700/6 spinning machine has revolutionized our wheel hub production. Its precision and efficiency have significantly improved our manufacturing process.

-

Arthur Zonneveld

★★★★★Post a review on Fec 21, 2022 From Mauritius

The machine’s advanced features and user-friendly interface have made it easy for our operators to achieve exceptional quality results. We highly recommend it to anyone in the wheel manufacturing industry

-

Nicolas Vazquez

★★★★★Post a review on jul 21, 2022 From Uruguay

The AC-CNCVW700/6 spinning machine has been a game-changer for our production line. Its Siemens control system and fault alarm function ensure reliable and error-free operation. The oil-cooled structure keeps the machine running smoothly, reducing downtime.

-

OSCAR URBANEJA

★★★★★Post a review on Oct 10, 2022 From Venezuela

We are impressed by its versatility and its ability to handle various wheel hub designs. It has significantly improved our efficiency and overall output