Fully Automatic Fan Production Line: Revolutionizing Altron Manufacturing

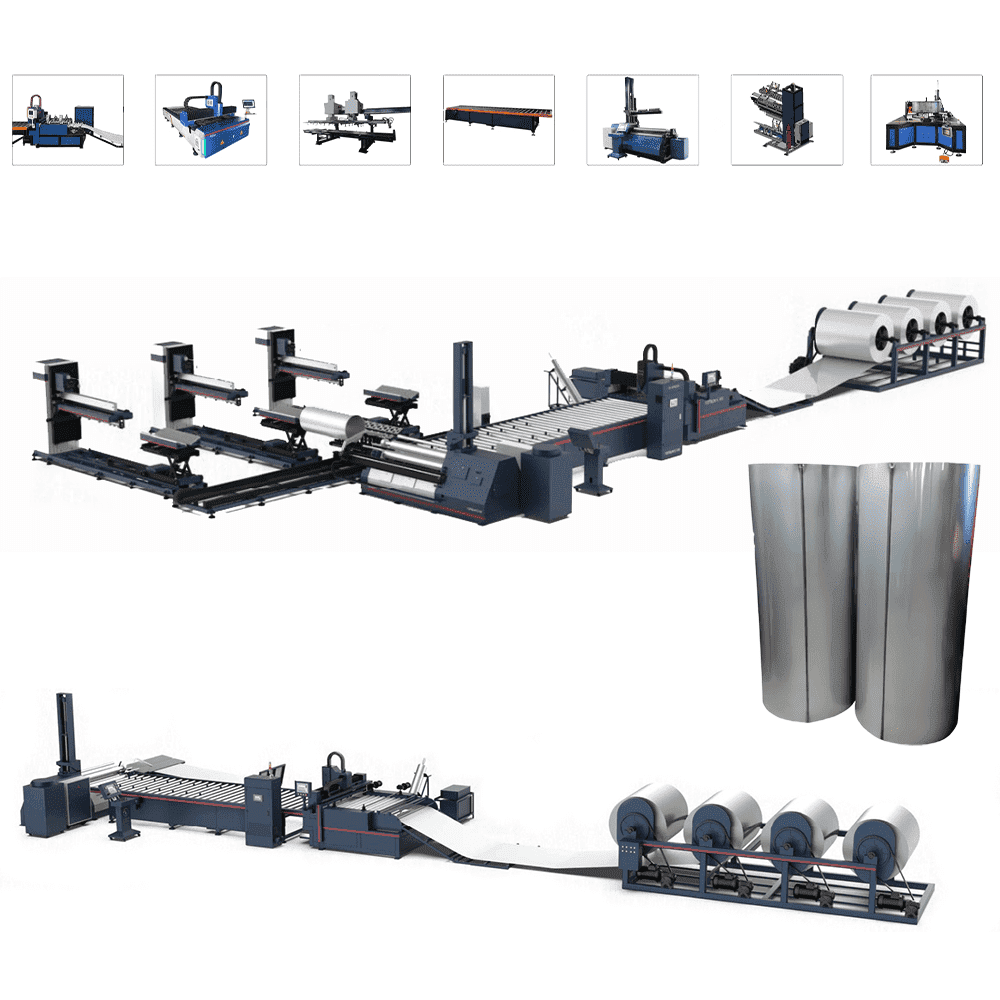

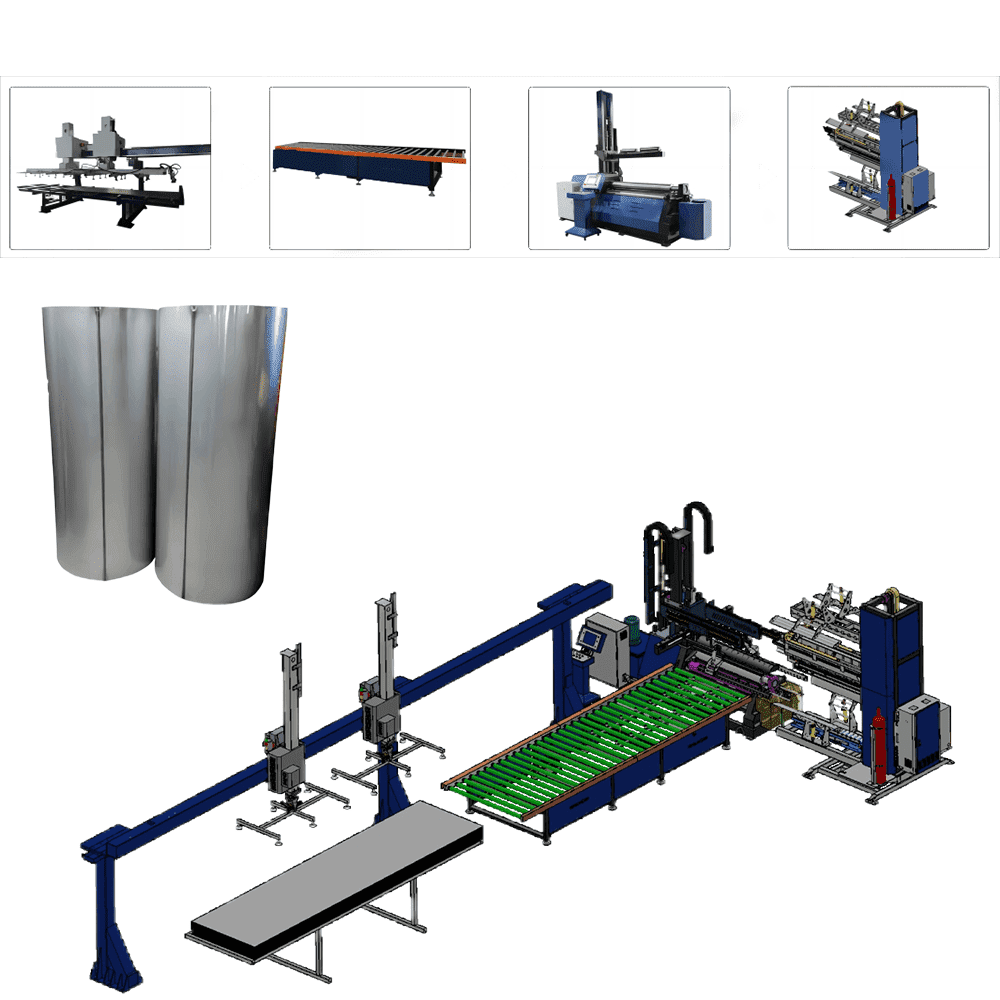

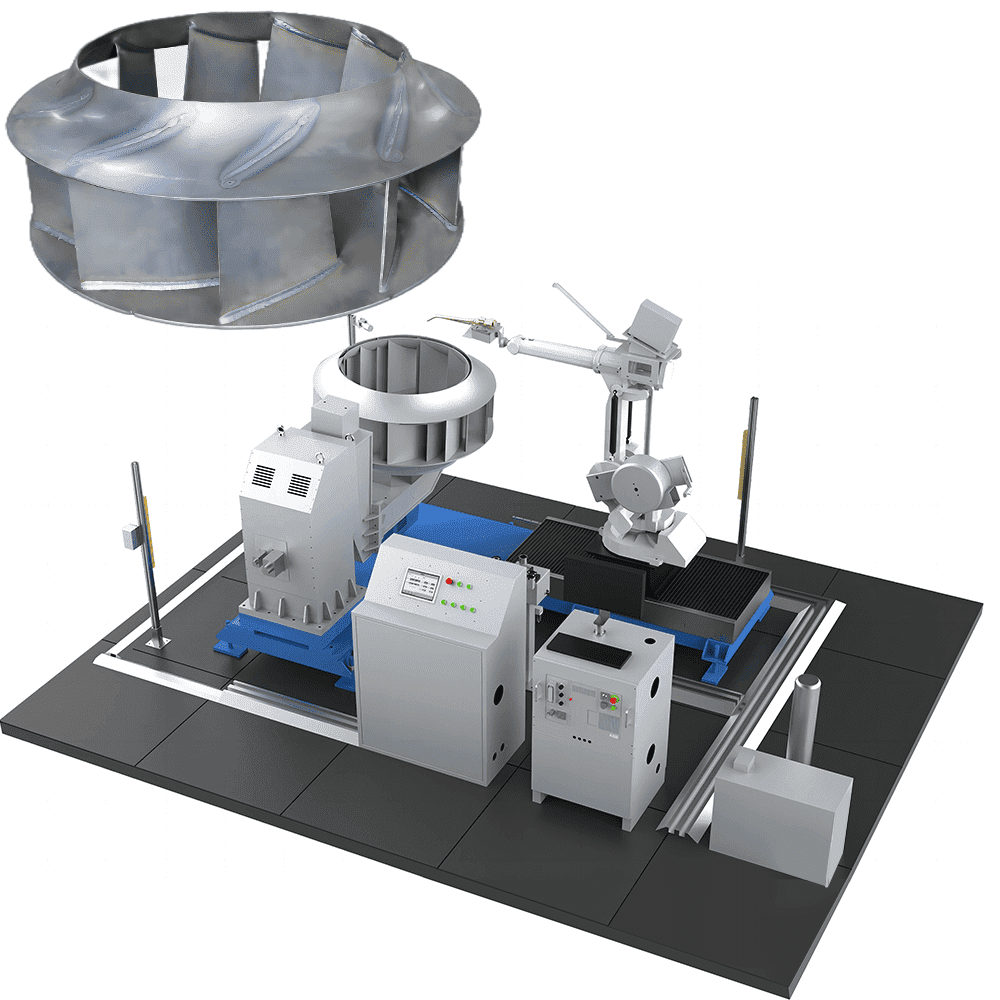

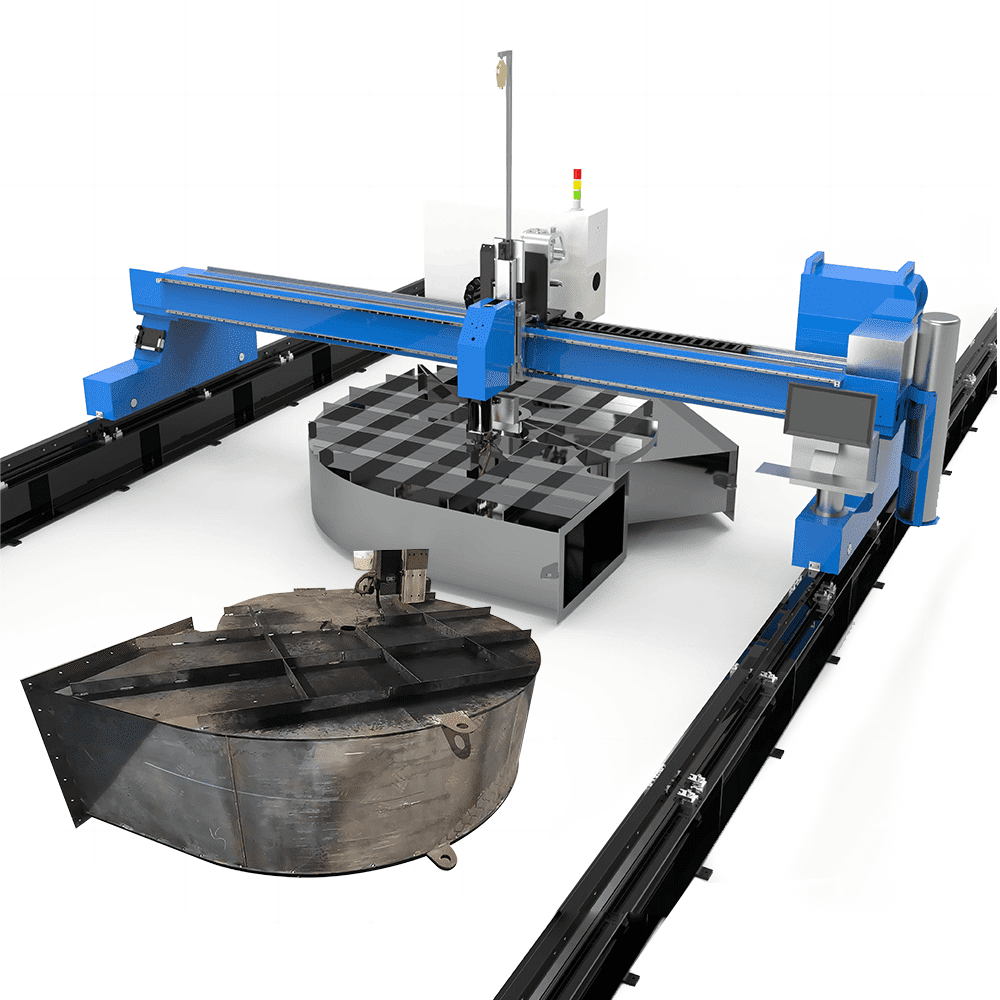

Altron has developed a fully automatic fan production line for the industrial fan industry, which has been delivered to different countries.

In the ever-evolving landscape of industrial automation, the creation of fully automatic production lines has brought about groundbreaking changes. Among these innovations, the development of a fully automated fan production line stands out as a testament to precision engineering and advanced manufacturing.

Evolution of Automation in Manufacturing

The genesis of automation in manufacturing traces back to the early 20th century when Henry Ford’s assembly line transformed automobile production. Over the decades, this concept evolved, integrating robotics, computerized systems, and advanced machinery to streamline processes across industries.

Introduction to Fan Production

Industal Fans, ubiquitous in daily life, serve varied purposes from cooling systems in electronics to industrial ventilation. The conventional production of fans involved numerous manual interventions, leading to inherent inefficiencies in terms of time, precision, and cost.

Components of a Fully Automated Fan Production Line

1. Raw Material Handling:

Raw materials, such as aluminum, steel, and plastics, undergo meticulous handling and preparation. Automated systems precisely measure and cut these materials to the required specifications, optimizing material usage and reducing waste.

2. Component Fabrication:

The production line comprises specialized machinery for forming blades, motor casings, and other components. Advanced techniques like CNC machining and molding ensure precise and consistent part production.

3. Assembly Process:

Robotic arms equipped with sophisticated grippers and sensors handle the assembly of fan components. These robots follow pre-programmed instructions, assembling parts with unparalleled accuracy and efficiency.

4. Quality Control Stations:

At various checkpoints along the production line, automated quality control systems inspect components for defects. Utilizing computer vision and machine learning algorithms, these systems detect imperfections with unparalleled accuracy.

5. Testing and Packaging:

Fully assembled fans undergo rigorous performance testing to ensure functionality and compliance with predefined standards. Automated packaging systems then package the fans efficiently for distribution.

Technological Innovations Driving Automation

1. Robotics and Machine Vision:

The integration of robotics equipped with machine vision technology enables the precise handling and inspection of components. These systems can identify minute defects and ensure uniformity in production.

2. Artificial Intelligence (AI) and Machine Learning:

AI algorithms analyze production data in real time, optimizing processes and predicting maintenance requirements. Machine learning algorithms improve over time, enhancing production efficiency and minimizing errors.

3. Internet of Things (IoT) Integration:

By connecting various components and machinery through IoT devices, manufacturers can monitor and control the production line remotely. This integration facilitates data-driven decision-making and predictive maintenance.

Advantages of Fully Automated Production Lines

1. Enhanced Efficiency:

Automated systems operate continuously, minimizing downtime and significantly increasing production output. The precision and consistency of automated processes lead to higher-quality end products.

2. Cost Savings:

While the initial investment in automated systems is substantial, the long-term cost savings are substantial. Reduced labor costs, minimized material wastage, and optimized production contribute to significant savings.

3. Improved Safety Standards:

Automation reduces the need for manual labor in hazardous tasks, thereby enhancing workplace safety. Employees can focus on supervisory roles, ensuring smooth operations and troubleshooting when needed.

Challenges and Considerations

1. Initial Investment and Training:

Implementing a fully automated production line requires substantial capital investment and skilled personnel to operate and maintain the sophisticated machinery.

2. Flexibility and Adaptability:

Fully automated systems might lack the flexibility to swiftly adapt to design changes or production variations, requiring reprogramming and recalibration.

3. Maintenance and Technical Support:

Regular maintenance is crucial to ensuring optimal performance. Additionally, access to technical support and expertise is essential to address any unforeseen issues promptly.

Future Prospects and Industry Impact

The evolution of fully automated fan production lines signifies a paradigm shift in manufacturing. As technology continues to advance, these systems will become more versatile, adaptable, and interconnected.

Fully Automatic Fan Production Line Conclusion

The advent of fully automated fan production lines marks a significant leap in manufacturing prowess. The amalgamation of robotics, AI, and advanced machinery has not only revolutionized fan production but also serves as a beacon of innovation for diverse industries. While challenges persist, the advantages in terms of efficiency, quality, and cost-effectiveness propel the manufacturing landscape into an era defined by unparalleled automation and precision.