Innovations in Welding Technology: Industrial Centrifugal Fan Impeller Welding Machine

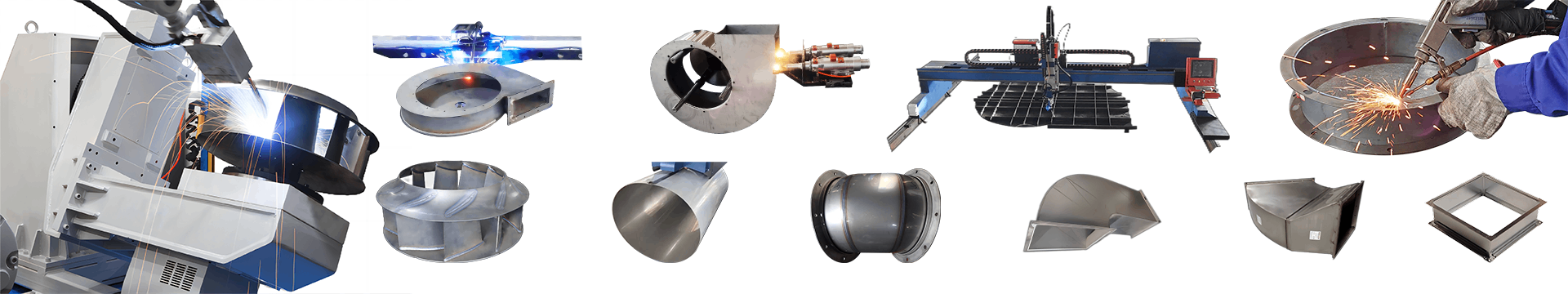

Industrial centrifugal fan impellers play a crucial role in various industrial settings, including ventilation systems, HVAC systems, and manufacturing processes. These fan impellers are responsible for moving air or gas through the system, ensuring proper ventilation, and maintaining optimal conditions within the facility. To manufacture these critical components efficiently, the use of specialized welding machines is essential.

Introduction to Industrial Centrifugal Fan Impeller Welding Machine

1.1 Overview of Centrifugal Fan Impellers and Their Importance in Industrial Settings

Centrifugal fan impellers are designed to generate airflow by converting the rotational energy of the motor into kinetic energy. They consist of blades or vanes mounted on a central hub, which accelerates the air outward and creates the desired airflow. In industrial settings, these impellers are utilized in various applications such as cooling systems, material handling, and exhaust systems.

1.2 Introduction to Welding Machines Used for Manufacturing These Impellers

Welding machines used for manufacturing centrifugal fan impellers are specialized equipment designed to join the components of the impeller securely. These machines employ various welding techniques such as MIG (Metal Inert Gas), TIG (Tungsten Inert Gas), or resistance welding, depending on the material and specific requirements of the impeller design.

Key Components and Features of Industrial Centrifugal Fan Impeller Welding Machines

- Impeller Fixture: Industrial centrifugal fan impeller welding machines feature a specialized fixture to hold the impeller components in place during the welding process, ensuring precise alignment and accuracy.

- Welding Power Source:These machines are equipped with a high-quality welding power source capable of delivering the required current and voltage for the selected welding process.

- Control System: Advanced control systems allow operators to adjust welding parameters such as voltage, current, and welding speed to achieve optimal weld quality.

- Automation Features: Some industrial centrifugal fan impeller welding machines offer automation features such as robotic arm integration, which enhances productivity and reduces labor requirements.

Benefits of Using Industrial Centrifugal Fan Impeller Welding Machines

The utilization of industrial centrifugal fan impeller welding machines offers several significant benefits for manufacturers.

3.1 Increased Efficiency and Productivity

Automated welding machines enhance production efficiency by reducing cycle times and minimizing downtime associated with manual welding processes.

3.2 Consistency and Quality

Industrial centrifugal fan impeller welding machines ensure consistent weld quality, resulting in reliable performance and longevity of the manufactured components.

3.3 Cost Savings

By reducing labor requirements and minimizing material wastage, these machines contribute to cost savings over time, making them a cost-effective investment for manufacturers.

Factors to Consider When Choosing an Industrial Centrifugal Fan Impeller Welding Machine

When selecting an industrial centrifugal fan impeller welding machine, several factors should be taken into account to ensure optimal performance and compatibility with specific manufacturing requirements.

4.1 Capacity and Size Requirements

The machine’s capacity should align with the production volume and the size specifications of the impellers to ensure seamless integration into the manufacturing process.

4.2 Welding Process Compatibility

Consideration should be given to the welding processes supported by the machine, such as MIG, TIG, or resistance welding, to meet the material and design requirements of the impellers.

4.3 Integration and Automation

The machine’s compatibility with existing manufacturing systems and automation capabilities should be evaluated to streamline production processes and maximize efficiency.

Maintenance and Troubleshooting of Industrial Centrifugal Fan Impeller Welding Machines

Industrial centrifugal fan impeller welding machines are essential equipment in various manufacturing processes, but like any machinery, they require regular maintenance to ensure optimal performance and longevity. Routine maintenance tasks such as cleaning, lubrication, and inspection of components such as welding torches, power sources, and control systems are crucial for preventing breakdowns and extending the lifespan of the equipment. Additionally, calibration of welding parameters and replacement of consumable parts like welding tips and electrodes should be performed according to the manufacturer’s recommendations.

5.1 Common Issues and Troubleshooting Techniques

Despite regular maintenance, industrial welding machines may encounter issues during operation. Common problems include irregular welds, arc instability, and power supply fluctuations. Troubleshooting techniques involve systematic diagnosis of the problem, checking connections and settings, and adjusting parameters as needed. For example, irregular welds may be caused by improper material preparation or incorrect welding parameters, while arc instability can be mitigated by adjusting the arc length and ensuring proper gas flow in gas shielded welding processes.

5.2 Importance of Proper Training

Proper training for machine operators and maintenance personnel is essential to minimize downtime and prevent costly repairs. Operators should be trained in machine operation, safety protocols, and troubleshooting techniques to identify and address issues promptly. Maintenance personnel should receive specialized training in equipment maintenance, including preventive maintenance tasks and troubleshooting procedures. By investing in training programs, manufacturers can ensure the efficient and safe operation of their industrial centrifugal fan impeller welding machines.

Case Studies: Applications of Industrial Centrifugal Fan Impeller Welding Machines

6.1 Real-World Examples

Numerous industries and companies rely on industrial centrifugal fan impeller welding machines for the manufacturing of critical components. For example, in the automotive industry, welding machines are used to fabricate impellers for engine cooling systems and HVAC systems. In the aerospace sector, these machines are utilized in the production of aircraft ventilation systems and cabin air circulation components. Additionally, manufacturers in the energy sector employ welding machines to fabricate impellers for gas turbines and power generation equipment.

6.2 Challenges and Solutions

Integrating welding machines into production processes can present challenges such as equipment compatibility issues, workflow disruptions, and training requirements. However, companies have implemented various solutions to overcome these challenges. For example, some manufacturers have invested in modular welding systems. Can be easily integrated into existing production lines, minimizing downtime and disruption. Others implement comprehensive training programs. To ensure that operators and maintenance personnel are proficient in operating and maintaining equipment.

6.3 Performance Improvements and Cost Savings

The use of automated welding machines has enabled manufacturers to achieve significant performance improvements and cost savings. By automating repetitive welding tasks, companies can increase productivity, reduce labor costs, and improve weld quality consistency. Additionally, automated welding machines offer greater flexibility and adaptability to changing production demands, allowing manufacturers to respond quickly to market trends and customer requirements. Overall, the adoption of industrial centrifugal fan impeller welding machines has resulted in enhanced efficiency and competitiveness for businesses across various industries.

Future Trends in Industrial Centrifugal Fan Impeller Welding Machines

7.1 Emerging Technologies

Emerging technologies such as artificial intelligence (AI) and machine learning are poised to revolutionize the welding automation industry. AI-driven welding systems can analyze large amounts of data in real time. To optimize welding parameters, improve welding quality and automatically detect defects. Additionally, advances in sensor technology and connectivity have enabled the development of smart welding machines that enable remote monitoring. Predictive maintenance and integration with other manufacturing systems.

7.2 Industry 4.0 and Smart Manufacturing

The integration of welding machines into Industry 4.0 initiatives is expected to further enhance efficiency and productivity in manufacturing processes. Smart welding machines equipped with sensors and IoT connectivity can communicate with other equipment and systems within the manufacturing environment, enabling seamless coordination and synchronization of operations. This connectivity facilitates real-time data sharing, predictive maintenance, and adaptive control, ultimately leading to more agile and responsive production systems.

7.3 Predictions for Future Developments

Looking ahead, the future of industrial centrifugal fan impeller welding machines is characterized by increased efficiency, flexibility, and sustainability. Advancements in robotics, additive manufacturing, and materials science will enable the development of more versatile and cost-effective welding solutions. Additionally, an emphasis on sustainability and environmental responsibility will drive the adoption of environmentally friendly welding processes and materials. Thereby reducing energy consumption and carbon emissions. Overall. The development of welding automation technology has great potential for transforming the manufacturing industry and promoting innovation in impeller manufacturing processes.

Why Choose ALTRON for Industrial Centrifugal Fan Impeller Welding Machines?

ALTRON stands out as a leading manufacturer of industrial centrifugal fan impeller welding machines, offering comprehensive solutions backed by over 18 years of experience in the industry.

8.1 Experience and Expertise

- 18+ Years of Experience: With over 18 years of experience in industrial blower production line turnkey projects, ALTRON brings a wealth of knowledge and expertise to the table.

- Technical Innovation:ALTRON is committed to technological innovation and sustainable development, continuously striving to improve its products and processes.

8.2 Integrated Solutions

- Complete Turnkey Projects:ALTRON specializes in providing end-to-end solutions for industrial fan automation production lines, from R&D and manufacturing to sales and services.

- Comprehensive Customization: The company’s technical team offers comprehensive customized solutions for metal products, including metal spinning, stamping, stretching, and automatic welding.

8.3 Strong R&D and Elite Team

- Strong R&D Capability:ALTRON boasts a strong R&D team dedicated to innovation and continuous improvement, ensuring that its products remain at the forefront of technological advancements.

- Innovative Culture:Innovation is at the core of ALTRON’s competitiveness, driving the company’s leapfrog development and fostering a unique innovation culture.

Industrial Centrifugal Fan Impeller Welding Machine

Conclusion

In conclusion, industrial centrifugal fan impeller welding machines play a crucial role in the efficient manufacturing of these critical components for various industrial applications. By selecting the right welder type and considering key factors such as throughput, welding process compatibility and automation capabilities. Manufacturers can improve productivity, quality and cost-effectiveness in their production processes.