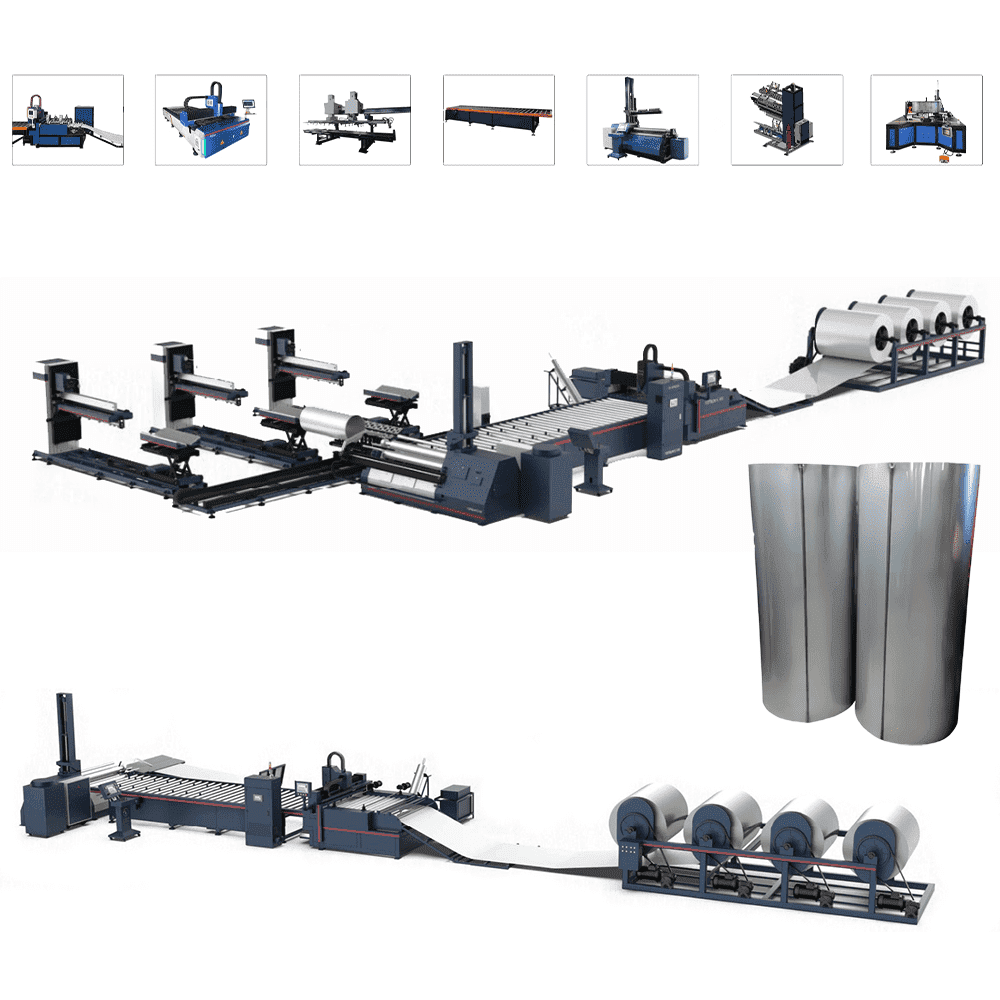

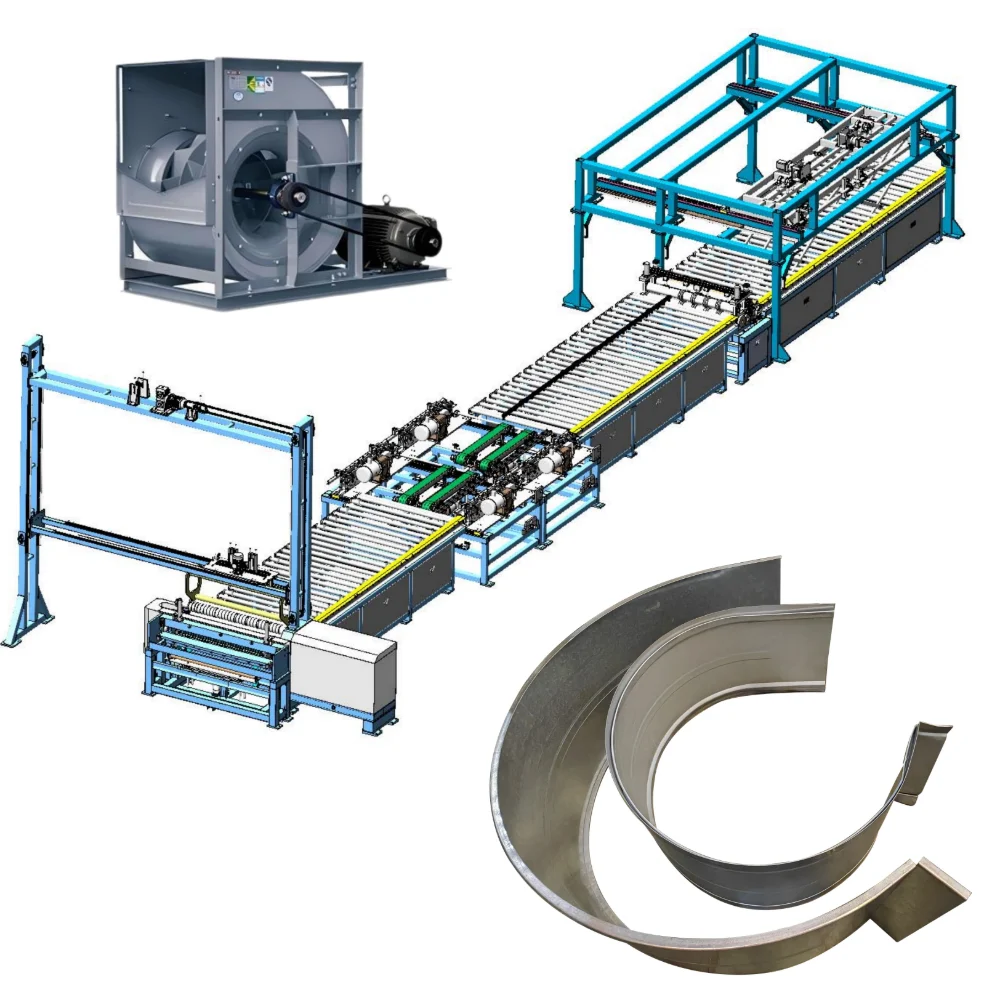

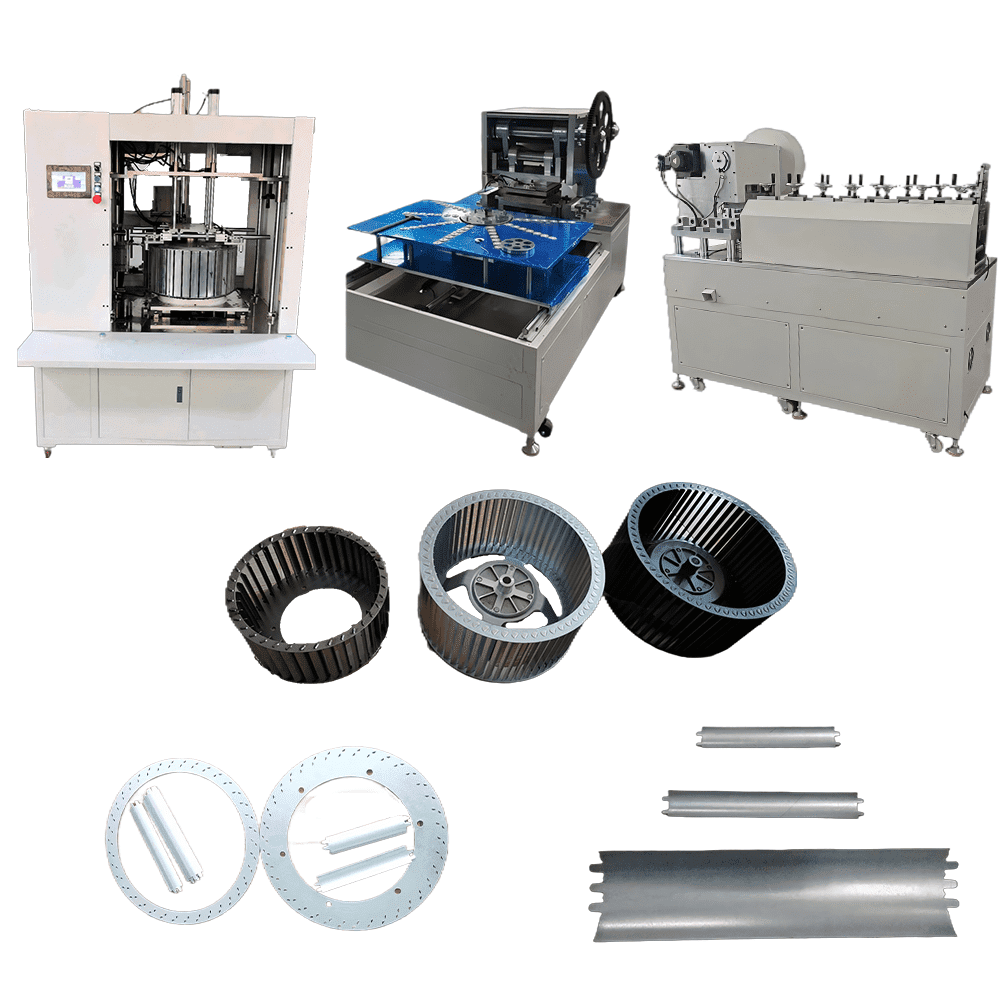

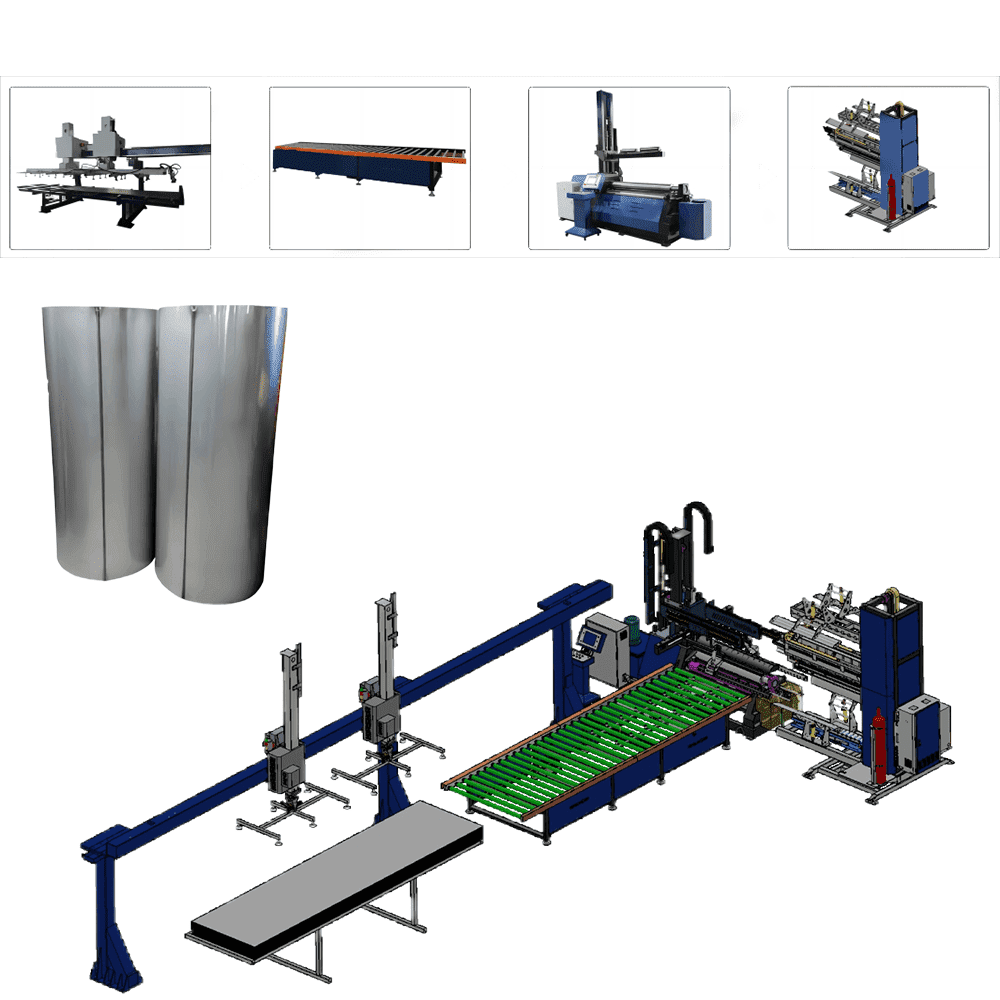

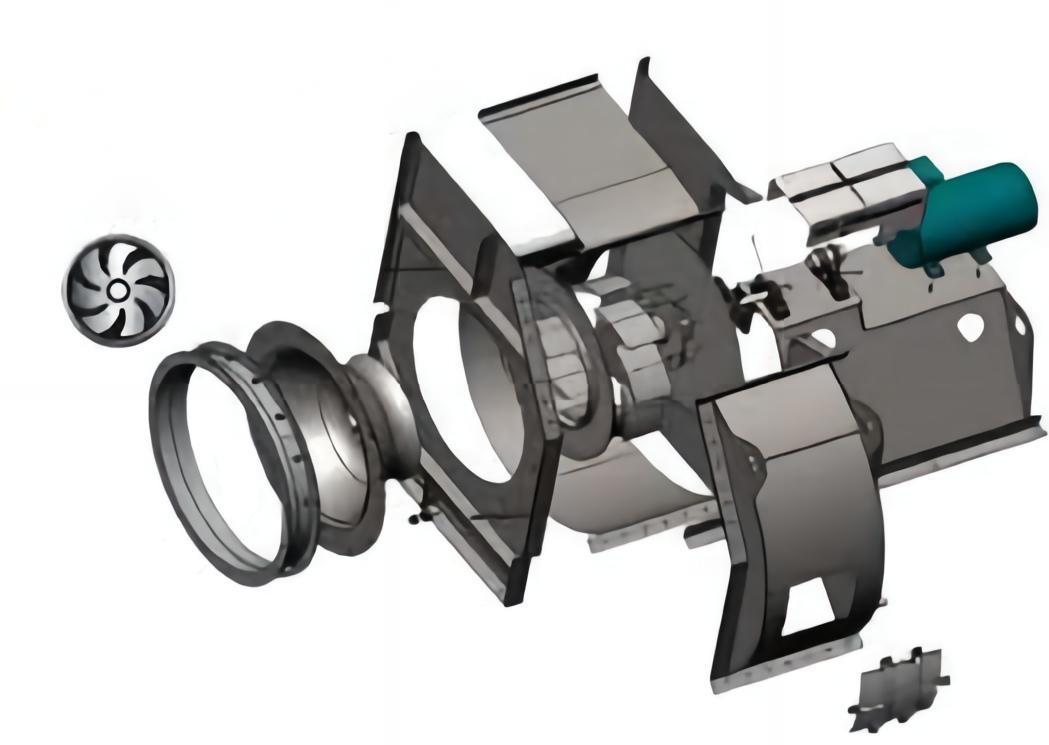

Industrial centrifugal fans manufactured using Altron automated production line machines

Altron Joby

Altron Joby

When it comes to industrial ventilation and air movement, there are many factors that can affect the efficiency of your equipment. One key player in this arena is ALTRON, a leading manufacturer of industrial centrifugal fan lines. Their products adapt to diverse applications and can help you achieve optimal performance through their efficient design.

Key Components of an Efficient Industrial Centrifugal Fan Line

An industrial centrifugal fan line is a complex system with several key components that determine its efficiency. ALTRON’s fan line incorporates mechanical conveyor belt loading, hydraulic rolling, a 90° swing angle for convenient material return, and straight seam welding. These components work together seamlessly to ensure a reliable and high-performance system.

- Mechanical Conveyor Belt Loading: ALTRON’s industrial centrifugal fan line features a mechanical conveyor belt loading system, providing a reliable and efficient way to feed materials into the system. This ensures a consistent and controlled input, optimizing the overall performance of the fan line.

- Hydraulic Rolling: The inclusion of hydraulic rolling in ALTRON’s fan line enhances the system’s flexibility and ease of use. This feature allows for a 90° swing angle, making material return more convenient. The hydraulic rolling mechanism adds a layer of adaptability crucial for various industrial applications.

- Straight Seam Welding:Straight seam welding is a fundamental component of ALTRON’s fan line. This welding technique ensures the structural integrity and durability of the components. The automatic alignment of welds and automatic straight seam welding contribute to the precision and consistency of the manufacturing process.

Considering an Upgrade? Explore Industrial Centrifugal Fan Line Benefits.

Industrial processes often generate heat, pollutants, and contaminants that can compromise both the working environment and the machinery involved. Upgrading to an industrial centrifugal fan line can significantly enhance ventilation and address these challenges effectively.

- Energy Efficiency:One of the primary advantages of an industrial centrifugal fan line is its energy efficiency. These fans are designed to move large volumes of air with minimal power consumption, resulting in lower energy costs for your facility. This not only aligns with sustainability goals but also contributes to overall operational cost savings.

- Versatility in Applications:ALTRON, a leading industrial centrifugal fan line manufacturer, offers a range of fan models suitable for diverse applications. Whether it’s cooling, exhaust, or material handling, their centrifugal fan line can be customized to meet specific industrial needs. This versatility ensures that the fan system is tailored to the unique requirements of your facility.

- Improved Air Quality:Efficient ventilation is directly linked to improved indoor air quality. The industrial centrifugal fan line helps in expelling stale air, pollutants, and fumes, creating a healthier and safer working environment. This is particularly crucial in industries where the release of harmful substances is common.

- Consistent Performance: ALTRON’s industrial centrifugal fan line is known for its consistent and reliable performance. These fans are engineered to operate seamlessly even in demanding conditions, providing a stable airflow that meets the stringent requirements of various industrial processes. This reliability translates to enhanced productivity and reduced downtime.

How ALTRON’s Industrial Centrifugal Fan Line Adapts to Diverse Applications

ALTRON’s commitment to versatility is evident in the design and features of its industrial centrifugal fan line. The 90° swing angle facilitated by hydraulic rolling is just one example of how this fan line can be adapted to different material handling scenarios. Whether it’s loading, unloading, or material return, the fan line’s adaptability ensures seamless integration into a variety of industrial processes.

The straight seam welding technology employed by ALTRON further enhances the adaptability of the fan line. The automatic alignment and welding processes contribute to the precision and consistency required for diverse applications, from heavy-duty industrial environments to more delicate manufacturing processes.

Industrial Centrifugal Fan Line: A Game-Changer for Your Ventilation Needs?

As industries evolve and expand, the demand for efficient ventilation solutions becomes more critical. The industrial centrifugal fan line emerges as a game-changer, offering a range of features that address the challenges faced by modern industrial facilities.

- Space Optimization: Traditional ventilation systems may require extensive space for installation. In contrast, ALTRON’s industrial centrifugal fan line is designed with compactness in mind. This allows for more efficient space utilization within your facility, ensuring that the ventilation system seamlessly integrates into the existing infrastructure.

- Noise Reduction:Industrial environments can be inherently noisy, and traditional fans may contribute to the overall noise level. ALTRON’s industrial centrifugal fan line incorporates advanced noise reduction technologies, providing a quieter operation without compromising on performance. This is crucial for creating a conducive and comfortable workspace for employees.

- Customization Options:Every industry has unique ventilation requirements, and a one-size-fits-all approach may not suffice. ALTRON understands this diversity and offers customization optionsfor their industrial centrifugal fan line. From fan size and speed to material selection, these fans can be tailored to align with the specific needs of your industry.

- Ease of Maintenance:Downtime due to maintenance can be a significant concern for industries relying on ventilation systems. ALTRON’s industrial centrifugal fan line is designed for easy maintenance, with features that simplify cleaning and inspection processes. This ensures that your ventilation system remains operational with minimal disruptions.

Maximizing Energy Savings with Our Industrial Centrifugal Fan Line

Efficiency and energy savings are at the forefront of ALTRON’s Industrial Centrifugal Fan Line design. By incorporating state-of-the-art technologies and advanced engineering, ALTRON aims to provide a solution that not only meets but exceeds energy efficiency standards. The fan line is meticulously crafted to minimize energy consumption without compromising on performance.

- Innovative Motor Technology: ALTRON’s fan line boasts innovative motor technology that maximizes energy efficiency. These motors are designed to deliver optimal performance while consuming minimal energy, contributing to significant cost savings for industrial facilities.

- Variable Speed Control: Another key feature that sets ALTRON’s fan line apart is its variable speed control capabilities. This technology allows for precise adjustment of fan speeds based on the specific needs of the facility. By dynamically responding to varying airflow requirements, the fan line ensures energy is used efficiently, further enhancing the overall sustainability of operations.

Is Your Facility Ready for the Innovation of Industrial Centrifugal Fan Line?

ALTRON’s commitment to innovation shines through in every aspect of its Industrial Centrifugal Fan Line. If your facility is looking to stay ahead in the rapidly evolving industrial landscape, embracing the innovation brought by ALTRON’s fan line is a step in the right direction.

- Smart Control Systems: ALTRON integrates smart control systems into its fan line, allowing for remote monitoring and control. Facility managers can optimize fan performance and energy consumption from a centralized location, streamlining operations and enhancing overall efficiency.

- Predictive Maintenance: The fan line is equipped with predictive maintenance features, leveraging advanced analytics to anticipate potential issues before they arise. This proactive approach not only reduces downtime but also ensures that the fan line operates at peak efficiency over its lifespan.

What Makes ALTRON Industrial Centrifugal Fan Line Ideal for Your Industry?

Choosing the right it is crucial for the success of your ventilation system, and ALTRON stands out as a preferred manufacturer for several reasons.

- Expertise and Experience:ALTRON brings a wealth of expertise and experience to the table. As a trusted name in the industry, they have a proven track record of delivering high-quality industrial centrifugal fan solutions. Their experience spans various sectors, including manufacturing, petrochemical, and pharmaceutical industries.

- Cutting-Edge Technology:ALTRON invests in cutting-edge technology to stay at the forefront of innovation. Their industrial centrifugal fan line incorporates the latest advancements in fan design and materials, ensuring optimal performance and longevity. This commitment to technology positions ALTRON as a reliable partner for industries seeking state-of-the-art ventilation solutions.

- Comprehensive Support: Beyond the product itself, ALTRON provides comprehensive support to its customers. This includes technical assistance, installation guidance, and responsive customer service. This commitment to customer satisfaction reinforces the reliability of ALTRON’s industrial centrifugal fan line.

- Adherence to Standards:ALTRON’s industrial centrifugal fan line complies with industry standards and regulations. This commitment to quality and safety ensures that their fans meet the required specifications for various applications. Choosing ALTRON is not just a purchase; it’s an investment in a ventilation solution that aligns with industry standards.

Industrial Centrifugal Fan Line Explained: FAQs and Insights for Buyers

Q1: What sets ALTRON’s fan line apart from competitors?

ALTRON’s line stands out due to its combination of mechanical conveyor belt loading, hydraulic rolling with a 90° swing angle, and advanced straight seam welding technology. This comprehensive approach ensures not only efficiency but also adaptability to various industrial settings.

Q2: How does the automatic alignment of welds contribute to performance?

The automatic alignment of welds in ALTRON’s fan line ensures precision and consistency in the manufacturing process. This, in turn, leads to a more durable and reliable fan system, reducing the likelihood of maintenance issues and downtime.

Q3: Can ALTRON’s fan line handle heavy-duty industrial applications?

Yes, the design and components of ALTRON’s industrial centrifugal fan line make it well-suited for heavy-duty industrial applications. The robust straight seam welding and hydraulic rolling features enhance the fan line’s durability, making it suitable for demanding environments.

Conclusion

ALTRON’s Industrial Centrifugal Fan Line stands as a beacon of innovation and efficiency in the industrial fan industry. By prioritizing energy savings, embracing cutting-edge technologies, and offering features that optimize facility operations, ALTRON continues to be a trusted partner for industries seeking sustainable and high-performance solutions. If you’re looking to elevate your facility’s efficiency while minimizing energy costs, ALTRON’s Industrial Centrifugal Fan Line is the answer to your ventilation needs.